-

Posts

1,734 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by flying_dutchman2

-

-

One word.

IMPRESSIVE

It is amazing what you accomplish with card.

Marcus

- popeye the sailor, Piet, FrankWouts and 2 others

-

5

5

-

41 minutes ago, Landlubber Mike said:

Coming along very nicely Marcus. I like the colors you are using. Can I ask what brand of paints?

Thank you.

Most of the paints are from Hobby Lobby. There signature brand is called Master's Touch acrylics.

Master's Touch - Chrome oxide green

Liquitex Basics - Cadmium red deep hue

Golden - Mars black (had some left over).

The scratch built yacht Utrecht is painted with both Master's Touch and Liquitex basics paints. These are thick enough to get thick layers, can be diluted with a bit of water and affordable.

Master's Touch 4 oz. = $3.99 and 8 oz $6.99

Liquitex Basics are a dollar more for the 4 oz and the 8 oz. Both available at Hobby Lobby.

Marcus

- Landlubber Mike, Piet, Jack12477 and 1 other

-

4

4

-

-

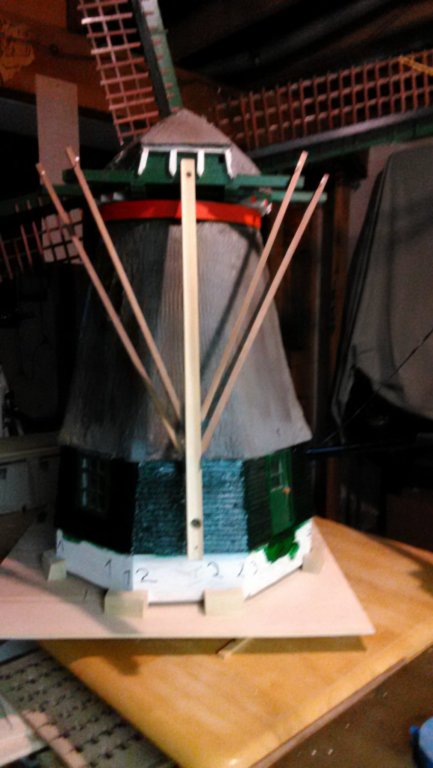

Made another batch of bricks and installed the two bottom layers. Let it dry for a couple of days. Then I will sand the bricks somewhat even.

The red blocks on the corners are called pananten. They are usually made of concrete and are there to keep the foundation walls in place.

Finished painting the triangular piece (kruiwerk). At the end of the long slender sticks there are light red caps (klapmutsen). Jan or Cog might know what they are for.

Once bricks are sanded and painted I will also add a coat of Dullcoat to all the shiny paint.

Still need to make the hooks that will be placed in the window frames which are for the shutters.

Also need to add a flag, a vangstok (long stick painted in red, white and blue stripes, when the stick is down the mill is operational and up, it is not or the other way around) and a few other things.

Than put it all together and balance the vanes.

Marcus

- cog, mtaylor, thibaultron and 2 others

-

5

5

-

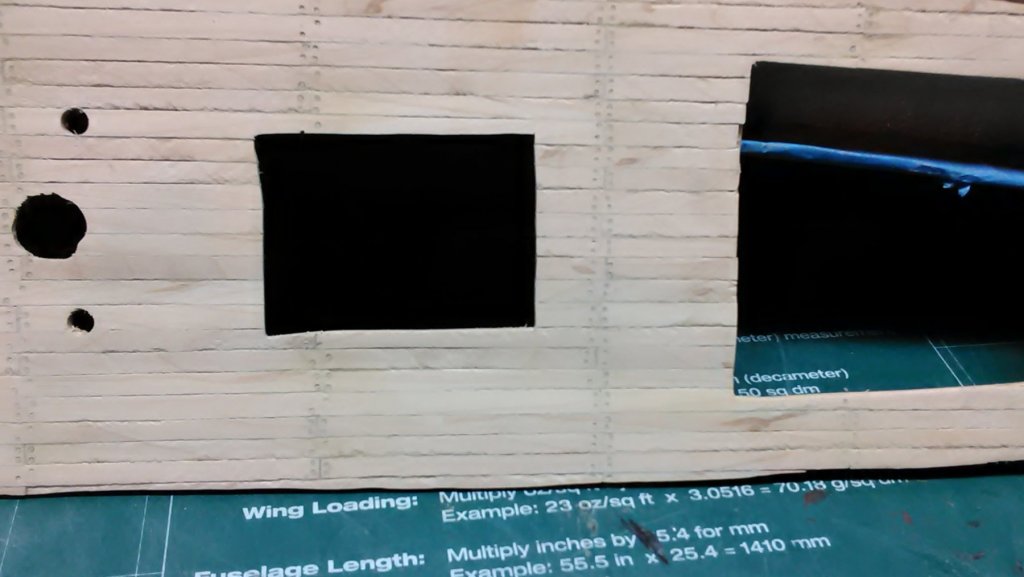

Caulking the deck was done with marking the edges of the planks with a number H pencil. Installed all the planks and did a bit of sanding. Drilled the holes for the imitation dowels. The used a soft lead pencil in each hole, twirled it around a bit, vacuumed the lead dust off and pressed wood filler in the holes. Let it dry and sanded the deck.

First coat of paint in the plank that is above the first wale (Cadmium dark red) and Chromium oxide green above the second wale.

Started on inserting black steenless steel pins in the holes that are in the wales and where 2 planks are fitted together. The above methods are from the book and I like it.

Marcus

- GrantGoodale, Piet, Omega1234 and 2 others

-

5

5

-

-

Welcome to the forum. Your models that you put in the gallery are beautifully built.

I have been a fan of yours for a long time. I have many books and publications that you have authored in both Dutch and English and have learned many things from that.

I built the Utrecht and now I am working on the Boyer. The plan is to built many of the 17th century Dutch merchant ships.

Your latest book from N. Witsen on shipbuilding has been an education for me. It is an excellent source that I use on my buulds.

When I visit my mother in Heerhugowaard, I always spend a day in Amsterdam and visit the Rijksmuseum and het Scheepvaart museum. Next year when I go I plan to visit both the Maritime museum in Rotterdam and the Zuiderzee museum in Enkhuizen. I take notes and pictures of ships that I plan to built

I do have a question. What are the sizes (height) of the figures you use in your models? I know it depends on the scale of the ship.

Or do you create them yourself?

Regards,

Marcus

-

-

I completed the deck and created it a very 'unconventional' way. I made a false deck from 2-ply maple and sanded it into shape.

Took maple stock and used my table saw to cut long planks of 1mm thick by 360mm long by 5mm wide. The planks for the deck are 120mm (4-3/4") long strips.

Took the false deck out of the hull, laid it on the table and planked it taking into account where the frames were.

Still need to sand the deck and with it being 1mm thick I can sand away. The sides are to be sanded to slightly past the false deck so when it is placed in the boat it will bulge a bit giving it a slight curve

I can do the above method as the deck is in 2 parts. The larger part can slide in.

I also cut the top railing to size.

Marcus

-

Beautifully done. At the scale you build the ice yacht the details are especially great. You can add so much more.

You thought "outside the box" when building this yacht. MSW is not ships anymore.

Marcus

- CaptainSteve, Jack12477, Canute and 1 other

-

4

4

-

-

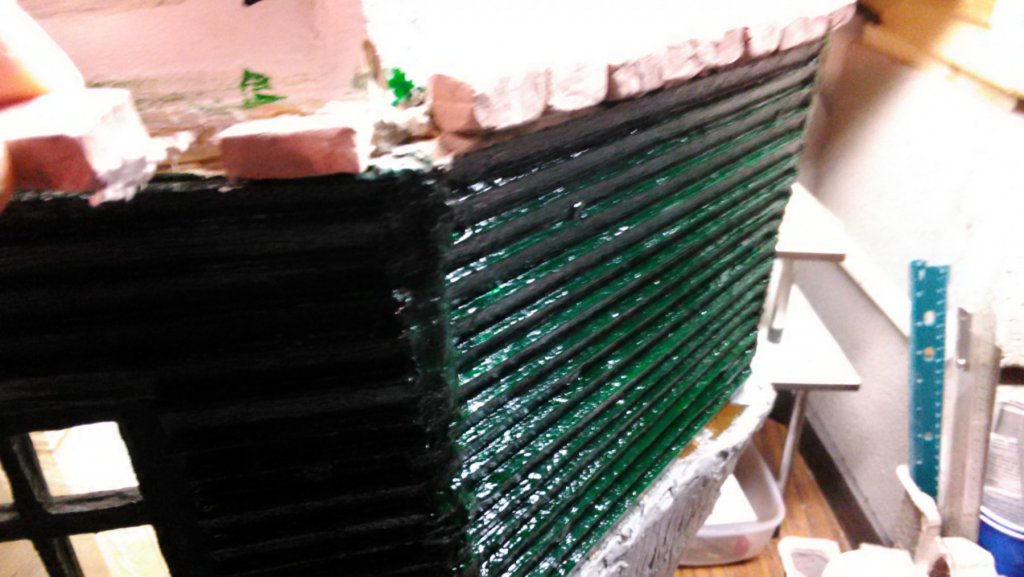

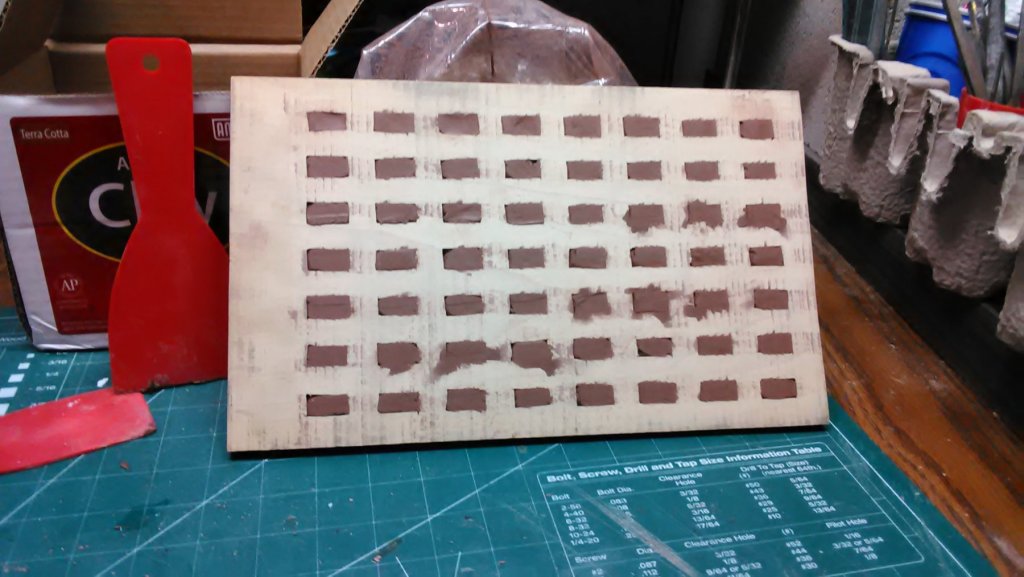

Working on the brick wall. Ran out of the little bit of tile glue I had left over so now I am using flooring adhesive. Works well. More liquidity so it goes in all the empty spaces. I apply it with a syringe.

Layers of bricks.

I know I am going to run out of bricks so I'll have to make more.

Once the foundation wall is finished I will let it dry for a week.

Then I will add a combo of tight bond glue and clay dust to fill in the large crevices, then lightly sand some of the edges to give it a more even look.

Because the clay is a bit brittle, I will use a primer and paint it crimson red which looks like brick red and finalizing with several coats of lacquer.

Hopefully with all these layers of material it will hold out in the weather.

Marcus

-

# Jan and Cog, thank you both for the information and Jan for the video.

So once you have moved the kruibalk with the kruiwiel you leave the rope that is attached to the kruiwiel tied to the kruipaal so the cap and the vanes do not move

Must be a heavy rope or chain to keep it steady.

Took the vanes and the cap of the mill and turned it upside down. Installed the first layer of bricks. As glue I am using the same material that I used to make the thatch. I think it will look good. Bit uneven but that gives it character. 😀

Marcus

- thibaultron, mtaylor, Jack12477 and 3 others

-

6

6

-

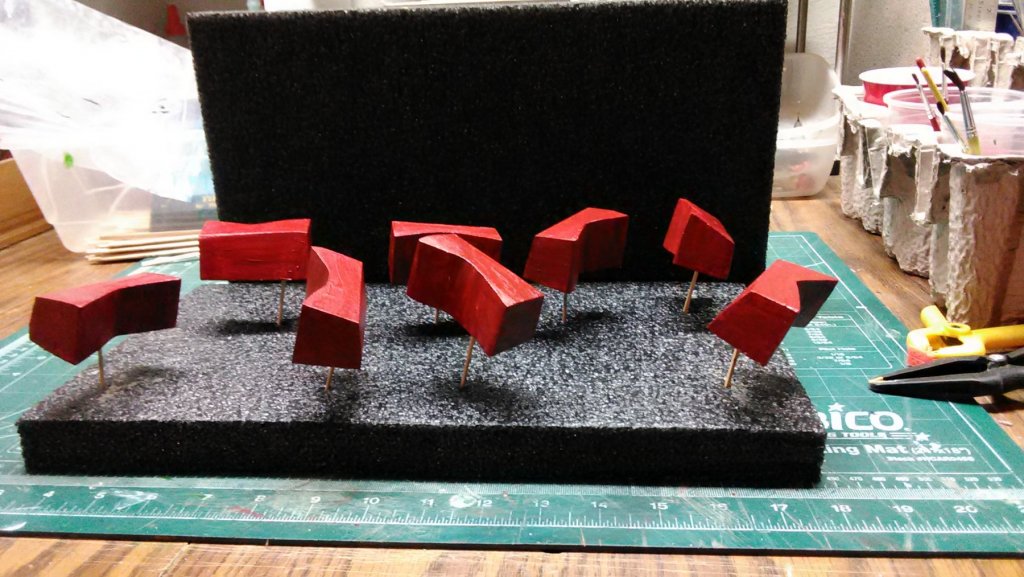

Finished painting the vanes. All I need to do is balance them and once that is completed, drill a hole through the red part and the copper tubing and put a nail through it so the vanes stay in place.

Close up of the axle head. The piece of paper with numbers is that when I take the vanes off I put them back where they were initially.

These are penanten. The are located on the corners at the bottom of the mill.

These are called the kruipalen. These stakes are located in the garden. That big triangular piece (kruibalk), the bottom of it corresponds with the stakes that are on the ground.

Questions for Jan.

What are the kruipalen for?

Is it to let people know that this is a danger zone?

What are the penanten for ?

Is this made of concrete and holds the mill in place?

Still need to do the bricks, put and place the triangular piece permanently put the cap and mill together with a bolt and nut and some more painting.

Marcus

-

Started working on the triangular piece (kruiwerk) opposite of the vanes which is the back. Measured the strips that were needed and put a coat of primer on them.

The second coat of paint has been applied and the mill is starting to look good.

While the gray paint was still wet, added a bit of yellow ochre and brown to it and with a brush, brushed downward strokes. Need to do some areas again. Then I will add a picture here.

At the woodclub yesterday someone mentioned a site that sells high quality silicone molds for bricks, pavers, blocks, etc. Should have known, I would have purchased the brick mold. Some of my bricks are a bit uneven. The molds eliminate that. My bricks will have that 'old look'.

Site is called hirstarts.com

They send international as well.

Marcus

- Elijah, cog, thibaultron and 3 others

-

6

6

-

-

3 hours ago, amateur said:

Are those 200 enough, or will there be a second batch?

jan

There will be many more. My guess is 200-250 for one side. I have 8 sides. Under 2000 should be enough. The clay cost $11.00 for 10 lbs which is 4.5 kilo. Pretty cheap.

When the mill is completed it will be heavy so a strong wind should not be a problem.

Marcus

- thibaultron, mtaylor, cog and 2 others

-

5

5

-

Bricks were completely dry and several had there edges sanded off. Most of them are similar in shape. I stacked them to make a wall and a few are off, so those I won't use.

Took about 2-1/2 hours to make around 200 bricks, this is excluding drying.

After looking at many mill pictures on the Net and in a mill booklet I have decided how to paint the vanes. I am using the colors from the instructions and may improvise a bit.

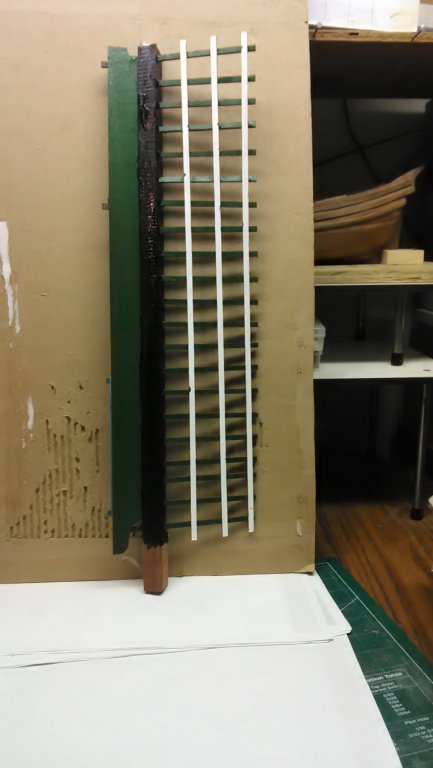

Started on the first coat vanes. The roede is black on all sides, the windbord is chromium oxide green on both sides, the vertical slats (zoomlatten) are Titanium white on the front and the horizontal slats (heklatten) are chromium oxide green on the front.

Lots of mills don't have paint on the back and sides of the horizontal and vertical slats.

I think I mentioned the reason already. The Miller doesn't paint the slats so he can climb on the vanes to check for broken areas.

Marcus

-

1 hour ago, cog said:

you might want to use a satin or matt water resistant varnish. glossy lacquer ... not so mill like ...

My plan was matt lacquer. The varnish idea sounds like a good idea as well.

Any of the shiny paints that are on the mill get a coat of Dull coat.

Marcus

- thibaultron, Canute and Elijah

-

3

3

-

17 minutes ago, cog said:

You are right, there. Take into account that for the inside to dry completely it takes a bit longer (at your size certainly an hour

). However, since, I presume, you won't bake your bricks.

). However, since, I presume, you won't bake your bricks.

I am letting them dry overnight. Baking? At what temp. and how long, is it better than air drying?

I went to the website of this product and can't find anything on baking this type of clay

I will paint it a darker red and use lacquer on it to protect it from the weather

Marcus

- Canute, thibaultron, cog and 2 others

-

5

5

-

Bought some more supplies to finish the mill.

Menards: 1 quart of Cliff gray Max Bond exterior paint. This is to imitate the thatch.

Hobby Lobby: More acrylic paints. Orange, Grass green, Black, Titanium white and Crimson

For the bricks that will be glued to the foundation wall.

AMACO 10 lbs Air Dry clay ($11.00), terra cotta color.

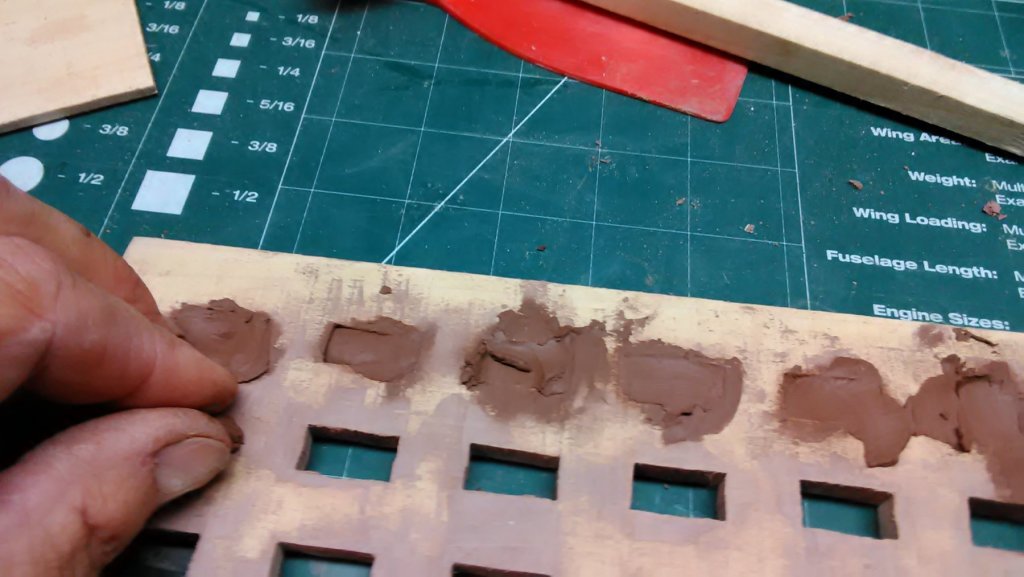

Made a template of poplar with 56 rectangular holes 3/4" by 1/4" by 1/4".

Took pieces of clay and press in the molds, making sure that the corners are filled in.

Once all clay is in the molds, scrape off excess clay on both sides.

The mold is filled with clay.

Use a scrap piece of wood that is the same size as the mold and gently push out the clay bricks (looks like little loafs of bread) .

SO far it seems to work. Once dry I can always sand the edges. Not all of them are the same size.

This process can be applied to any size bricks. I opted out of the method that uses tile grout and fortified as I had previously mentioned in this build. This method is cheaper, no mixing of material and works just the same.

I don't know how long it takes to air dry but I assume it has to do with the temp. and humidity of the location.

Marcus

-

- thibaultron, mtaylor, yvesvidal and 7 others

-

10

10

-

Wood used on the vanes.

Long piece that holds it together (Roede) is poplar.

Piece on top of the roede and the windbord is cherry.

Horizontal (heklatten) and vertical (zoomlatten) slats are purpleheart.

Someone at the woodclub gave me a big tube full of it. So I thought that it would be a perfect fit as it is strong and dark in color.

Marcus

- cog, mtaylor, thibaultron and 2 others

-

5

5

-

Boyer by flying_dutchman2 - FINISHED - Scale 1:48 - 17th Century Dutch Coastal water freighter by Marc Meijer

in - Build logs for subjects built 1501 - 1750

Posted

Noel, I pm'd you about this

Marcus