GrandpaPhil

-

Posts

4,955 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by GrandpaPhil

-

-

The P-38 would only have an 18” wingspan.

Definitely hangable.

-

-

Personally, I would finish the galleon, it’s almost done.

However, if it is no longer fun, then build the Viking ship.

-

Build whatever makes you happy.

Also, regarding references for the post-Mary Rose era, the Revenge might be a useful example.

Peter Kirsch’s “The Galleon” has been very useful for me, too. -

- Snug Harbor Johnny, Baker, Knocklouder and 1 other

-

3

3

-

1

1

-

-

-

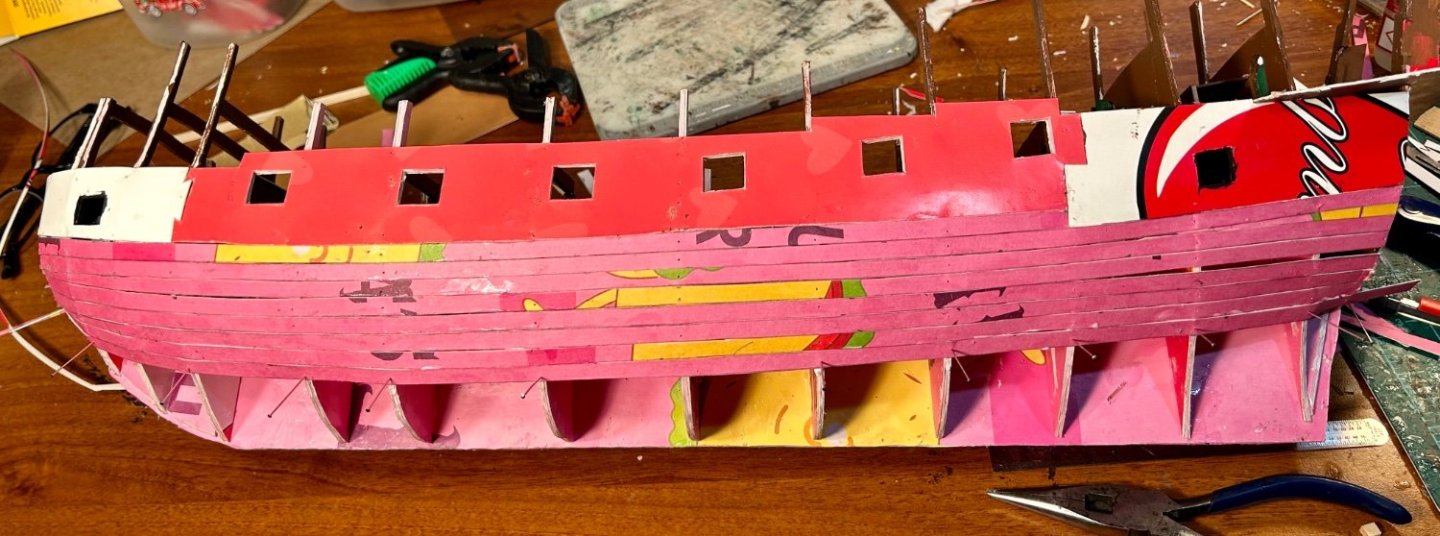

And now it is time to make another round of parts:

I really wanted my keel in place prior to installing the wales.I am going to install the lower wales prior to installing the second planking.

And, I was printing on paper anyway….so I decided to trace more pieces just to get them made and not waste the paper.

This methodology of making parts and assemblies in advance has been working really well for me so far.

- mtaylor, Glen McGuire, John Fox III and 4 others

-

5

5

-

2

2

-

The inner planking and shaping is done now:

I will clean it up a little bit, later on today, with a paint brush.

Then I will seal the model.

But first, I need to repair some of the upper beams, because I accidentally crushed them while sanding.

That is no big deal, I will add CA to the separated pieces of card to reinforce, and then keep rolling.

I have the most difficult part of my model done now.

- Canute, John Fox III, Glen McGuire and 4 others

-

7

7

-

The port side is puttied with spackle:

I used the color changing type and have it sitting under halogen lamps to force dry it.

I use this type from Lowe’s:

Drywall spackle works great for card ships.

Drywall spackle works great for card ships.

It will sand with the card and makes for a smooth surface that you can seal and then adhere the second layer to.

This one will be different than my last two.

Those, I just added the contact paper to the first layer, and then painted.

This one, because of the intent behind the design of the plans, I am utilizing a full second planking.

- Thukydides, Canute, mtaylor and 3 others

-

6

6

-

-

-

-

I got my Soleil Royal plans today.

It will be built much like this model.

I now have 17 ship models in my stash, with 2 more in Ordinary.

I think I should stop adding to my stash now, at least until after I complete a couple more models, lol.

-

-

-

My plastic builds include the Heller La Reale, the Heller Amphitrite, the Encore Olympia, a 1/350 Arleigh Burke, a 1/144 Gato, a 1/350 Independence (the LCS) and a 1/720 Carl Vinson.

When I was a teenager, I made a try at the Revell 1/96 Constitution and later tried it again while in college. I never finished either one.

Maybe I’ll make a Constitution out of card one of these years.

- mtaylor, Canute and Old Collingwood

-

3

3

-

That’s cool!

- BLACK VIKING, thibaultron, mtaylor and 1 other

-

4

4

-

Jan,

Your models are very impressive.

I have learned a lot from them.

I will add a second layer of planking.

Once the first layer is done, the model will be getting a lot of putty and then sanded smooth, before being sealed, to give the second layer a solid base to adhere to.

The second layer will be 1mm card, with contact paper to give them a wood grain texture, cut into individual “planks”.

That will then be painted.

-

Lol, yep. Those cards were a good find for me. I could not have resold them, so them being the right type and size of card for model making worked out really well.

Plus, we got the pallet right before Valentine’s Day (they were the 2022 Valentine’s cards, not the 2023 ones), so the timing worked out for the card giving to the wife, too, lol.

On a serious note, planking with card is much faster than planking with wood.

Card works quicker and no heat or water is required.Vertical planking actually seems to work much better, but I wanted to try conventional planking just to see how it played out.

I’ll give a full opinion after I see how it works out.

I should have made full filler blocks for the bow, but it is too late now.

-

Welcome!

- Keith Black and mtaylor

-

2

2

-

Welcome!

- Keith Black and mtaylor

-

2

2

-

Welcome!

- Keith Black and mtaylor

-

2

2

-

Golden Hind by Rock_From_Korea - 1:48

in - Build logs for subjects built 1501 - 1750

Posted · Edited by GrandpaPhil

Your Golden Hind is incredible!

I made several of the Henry VIII style breech loaders from toothpicks with paper banding.