Keithbrad80

-

Posts

416 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Keithbrad80

-

-

Do you know the reason behind diagonal planking? Was it stronger somehow? Horizontal planks give the ship strength and rigidity, I’ll assume diagonal planks do the same, but what was the specific reasoning behind diagonal planks?

-

The Cutty Sark has been high on my build list for a while but I’m running into an issue. There are too many kits to choose from! I have read through plenty of logs trying to find the one I want to build but I’m hoping for some input from people who may have built this model or know more about it.

Im hoping to find a kit in 1:48 or 1:72, wood, POB or POF, and most importantly realism. I have seen and read that certain companies are more realistic than others, so I’m really trying to find something that isn’t speculation or guess work. If any one has built this model with these specifications I would love to know. I’m thinking this will be my last kit build before I attempt a scratch build, thanks again everyone!

Bradley

-

-

This is really cool model, personally i have never seen this method of planking so ill follow with interest!

Bradley

- Rik Thistle and BobG

-

2

2

-

This is so cool! The leaf blower was a really good idea, I wouldn’t recommend it on smaller models though lol!

Bradley

-

I can’t believe I just found this log... your work is incredible, maybe the best I have ever seen, and your work station is one the most professional work places I have seen for model ships. your work is truly an inspiration for someone like me who hopes to scratch build a clipper one day.

I don’t have words for some of the things you have created like the windlass and pump. I want to say your work is unreal but that’s the exact opposite!

It’s also crazy to think things like your two incredible boats will be secondary details compared to the final product!

Bravo!

Bradley

-

3 hours ago, druxey said:

While the above information and personal experience is interesting as well as eliciting my sympathy, we seem to have wandered a long way from chisels and edge tools in general, which is what the original enquiry was all about!

Sorry everyone for wandering off topic!

Back to chisels, my buddy recently picked up a few new chisels from a company called Narex. I had never heard of them before that but he swears by them, has any one ever used their chisels?

-

I built two of these kits as Christmas presents a few months ago and had a lot of fun putting them together, its an excellent little kit that produces a very nice model.

Bradley

- thibaultron and Ryland Craze

-

2

2

-

46 minutes ago, Bill Morrison said:

I'm looking for the old solid hull version.

Bill

So I’m pretty sure the solid hull version of this kit has been out of production for awhile. The original kit was a solid hull but was discontinued in 1993 when the plans for the kit were rewritten to include a POB frame and all the necessary material for planking. I’m guessing this was done to attract different types of ship modelers. You may be able to find a vintage kit on eBay but i think you would have a hard time finding one. If you do let me know! I would love to see some one build this kit with a solid hull. Hope that helps!

Bradley

-

The Cutty Sark has been high on my list for awhile now. It will probably be my next build so I’ll pay close attention to your build. Judging from your other work I’m sure it will be a beautiful model ship!

Tracking your time sounds like an interesting project, I kind of wish I did it with my Flying Fish.

Bradley

-

38 minutes ago, EKE said:

I hope your hand is healing well.

My cast should be coming off right after Christmas so it will be nice to start the year with two working hands!

Clipper ships are my personal favorite, especially to model. Once the hull is painted and copper the lines of the ship should really stand out. Thanks for checking in.

Bradley

-

13 minutes ago, Roger Pellett said:

I am fortunate to have space for a dedicated shop equipped with full sized woodworking tools

Ahh how I miss my shop, my house burned down in a wild fire a few years ago and my shop went with it. I don’t have space or time any more for a full size shop but your advise holds true, buy the tools that will do the most work for you now.

Bradley

-

-

I almost forgot to mention that you will spend far more money over time on tooling for a metal lathe than you will the lathe. Say you buy a 750 USD metal lathe, expect to spend at least 100 on a very basic set of tooling unless it comes with your set up like @Bob Cleek mentioned. The grizzly model is not a bad option if you want all the basics included. If you do get a metal lathe I recommend learning to make your own tools very quickly because you will spend way more on tooling than any thing else.

at least you have the holy trinity as I call it lol. (Byrnes table saw, thickness sander, and disk sander) honestly I would invest in a better scroll saw or a band saw if you plan to only use the lathe for modeling. I love my lathe and use it all the time but that’s because I make all sorts of stuff, not just for modeling.

Bradley

-

2 hours ago, Anthony Hearne said:

is the proxxon one the same as the micro mark one?

Proxxon produces their own tools I’m pretty sure so the Micro mark and the Proxxon lathes and mills are all different. IMO Proxxon sells much higher quality tools than micro mark.

Bradley

-

As for the Lathe you have two options, metal lathes and wood lathes. Wood lathes shouldn’t be used for cutting metal but wood can be cut on a metal lathe.

there are several good options available on Amazon for wood lathes, the two most important things IMO with wood lathes is weight and speed control. With a single speed you have to change the gears when you want to increase or decrease RPM, variable speed is like most other tools, turn a knob and the speed goes up and down. Weight is really important with wood turning lathes because they create a stable base for the project, with a lot of weight and a good work table it will be a breeze to learn. My friend has a Jet variable speed lathe that I like a lot.

When it comes to tooling and wood turning lathes, you need to buy wood turning chisels which are very different than regular carving chisels (wood turning are typically much longer than wood carving chisels). You hold the tool to the material and move your body or hands to apply pressure the material. You will probably need more room if you consider a wood turning lathe.

Metal turning lathes are very different. Metal turning lathes generally require very tight measurement to achieve a good result. There are lots of ways to cut metal or wood on a metal lathe but basically you have tools on a tower that get slowly introduced to the metal to remove very thin layers of metal. At least in my experience metal turning lathes are harder to set up and use initially, once you figure out your machine and tooling it becomes much easier. I would recommend a variable speed lathe if you consider this type of lathe. there are a lot of different types of metal lathes and I guess it depends on what you want to do with a lathe. If the only thing you plan to use it for is models then I highly recommend the Proxxon lathe. I don’t personally have one (yet lol) but I have heard very good things about them.

Metal turning lathes require much different types of tooling as well. You have a tool post with a your tool that can be moved to meet the material and a single point of that tool does all the cutting so it has to be in line horizontally to the center of the material you are working with. I have no idea how to make chisels but I can make lots of tools for my metal lathe using a grinder mostly, which is really nice. If you need an 85 degree tool it’s much easier to make one then wait for one to be sent to you.

Last thing about metal turning lathes. If you decide on something other than the Proxxon model you will notice most metal lathes on amazon look very similar. That’s because they are, most of them in the 600-900 USD market are the same lathe from China that has been repainted some companies include tooling and other don’t. Good luck and have fun machining if you get one!

Bradley

-

Welcome to MSW Bill!

Make sure to start a build log when you start your model, that way we can help and watch your progress as you go.

Bradley

- mtaylor and Keith Black

-

2

2

-

1 hour ago, Bill Morrison said:

Hello! I just found this build. OUTSTANDING WORK, and GREAT SAVE on the false keel!

Thanks bill! Overall I would say the quality of kit is worth the 399 price tag. I got the kit pretty cheap because I bought it during one of model expos big sales, but it’s a really nice kit. I wouldn’t have had any problems what so ever if I didn’t have the issue with the false keel! Thanks!

Bradley

-

Hello again everyone,

This will probably be my last update for the year, and thankfully this year is almost over!

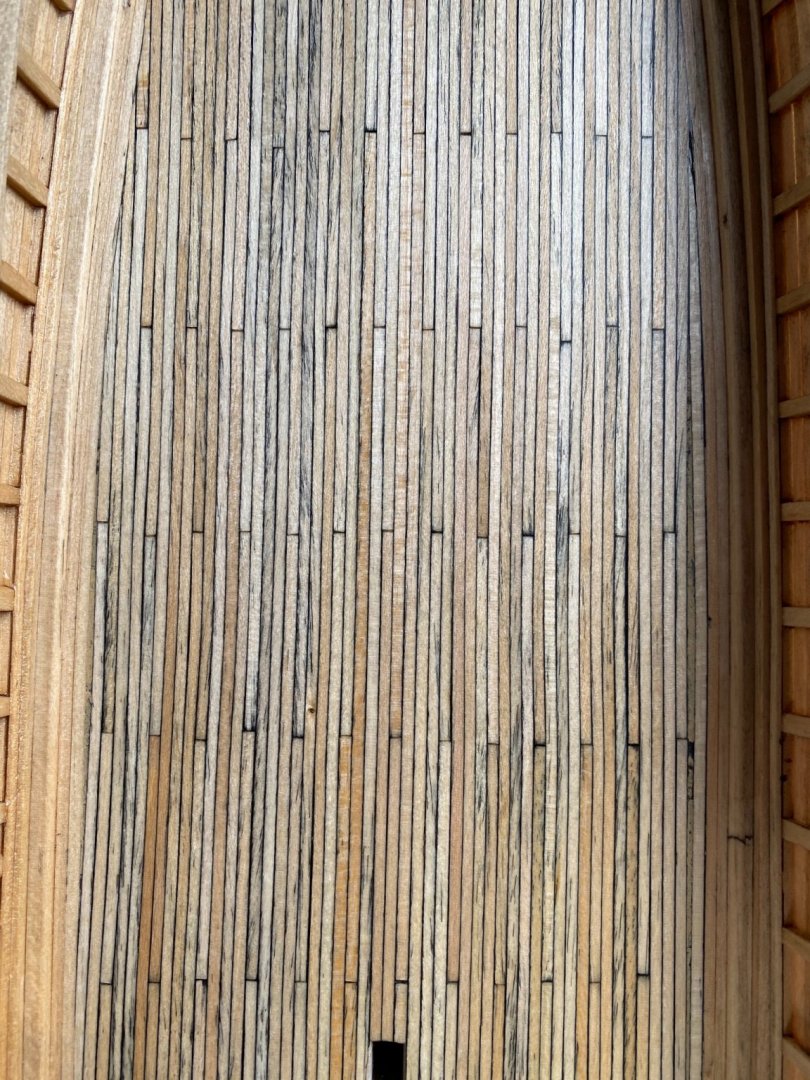

I finished putting the timber heads for the top gallant rail in, and got about 40 percent of the rail on. Maybe I can sneak in a little time today to finish this step before putting everything away for the year. Here is a pic of all the timber heads in place:

After, I planks the space below the top gallant rail and above the main rail. For anyone who builds this model later or is curious, the timber heads are supposed to be cut to .12” I found it a lot easier to cut the timber heads to something like .14” and file it down by dragging a heavy file over both sides. This also ensures that both sides of your rail are level with the deck, cutting them and filing took a while but it was worth it to get a nice flat rail on both sides. Here is a pic of my rail and the planked areas:

I also included the gangways in this update. At bulkhead 10 I added another timber head directly next to the existing ones which gave me the correct dimensions of the gangways. Here is a close up of the gangways:

the vertical wood at the gangways might be too thick so I may have to remove it and use a thinner piece. Thanks everyone, happy holidays!

Bradley

-

Good point, if the navy is spending money restoring it then it must have been built well. I could see it being a project for a shipyard apprentice, i could even see this as a commission for some well respected ship modeler at the time it was built.

I’m thinking about it now as if i were to build it and i would build frames of some kind, maybe like you said a beam that holds it all together, or even vertical beams supporting the decks. They picked it up with a crane and nothing moved so it looks well build. Very interesting!

Bradley

- Rik Thistle, mtaylor and Canute

-

3

3

-

That thing is huge!

being a parade float I would imagine they would need to keep the weight down in order to be pulled by a truck. I couldn’t find any thing on the construction but if I were building it I would think a sheet metal hull would do the trick and then maybe a spray in foam or something to fill the inside and then probably wood for the decks? I have no idea how it was made but it is pretty cool!

Bradley

- Rik Thistle, Canute and mtaylor

-

3

3

-

1 hour ago, Nirvana said:

the adhesive starts to set hard after 4 hours

This was enough for me to run back out to my shed in the rain to pull that tape off lol. I didn’t even think of this, thankfully it came off clean!

Bradley -

Hello again everyone,

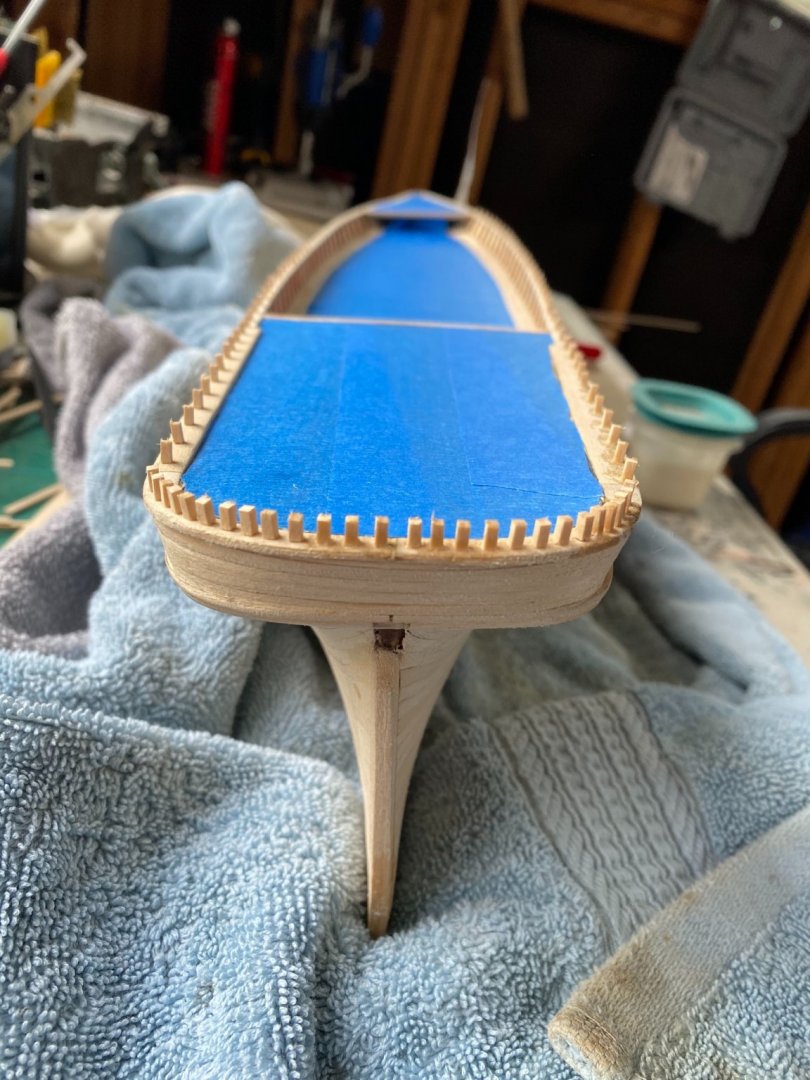

I have finished the decks! For real this time... I tried tree nails in a few spots and couldn’t get them the way I wanted them so I’m going to go back and add them later If I decide to do that.

I finished the deck with a sanding from 60 - 5000 grit paper, leaving a polished look. I do this because it brings out the color of the wood and really makes things look great, but it’s never that easy. Sanding with paper that high leaves the decks shiny which I don’t want so after 5000 grit I use #000 steel wool. The steel wool dulls the surface just a little bit and creates a rough enough surface so things can still be glued on, this way I get a high definition in the wood but it isn’t to shiny or polished looking. After sanding I cleaned everything using mineral oil and let it dry, finally I covered e dry thing in blue painters tape so I don’t scratch the surface or get glue on anything. Here is a few pics of the final product:

Also don’t worry about the planking on the poop deck in the photo above, it should all be covered by deck furniture.

I then started on the timber heads for the top gallant rail which up to this point has been the most difficult part of the build. Each timber head falls in line with the timber head below it so it’s not to bad lining everything up it just takes time and lot of good measurements. I should be totally finished with the top gallant rail tomorrow. Here is where we are right now:

after the top gallant rail is done then it’s time to paint! I’m making some good progress so far and I’m happy with the build up to this point. Thanks for the likes and support as well!

Bradley

- BobG, gieb8688 and Duanelaker

-

3

3

-

HMS Winchelsea 1764 by Wyz - 1:48 scale

in Member Build logs for the HMS Winchelsea

Posted

Wow, your work space is incredible! You’re set up to do pretty much anything! I’m looking forward to following your build.

Bradley