-

Posts

5,946 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

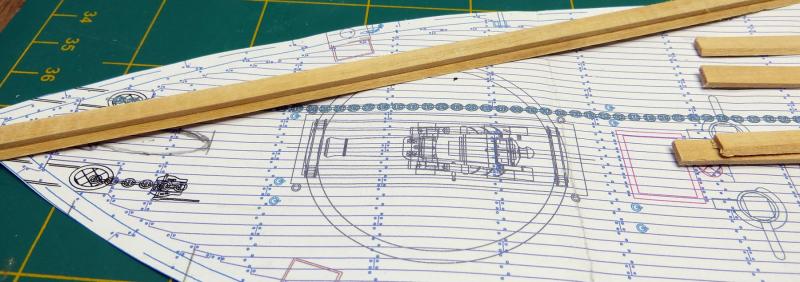

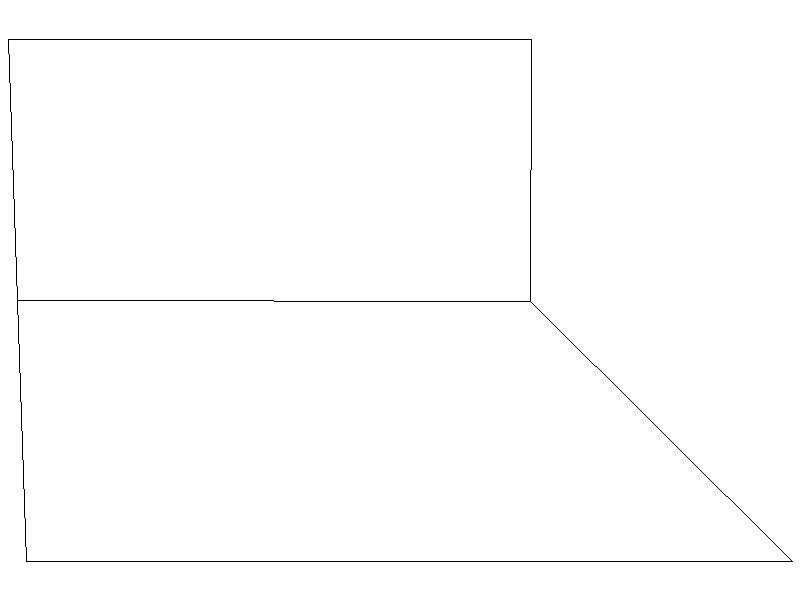

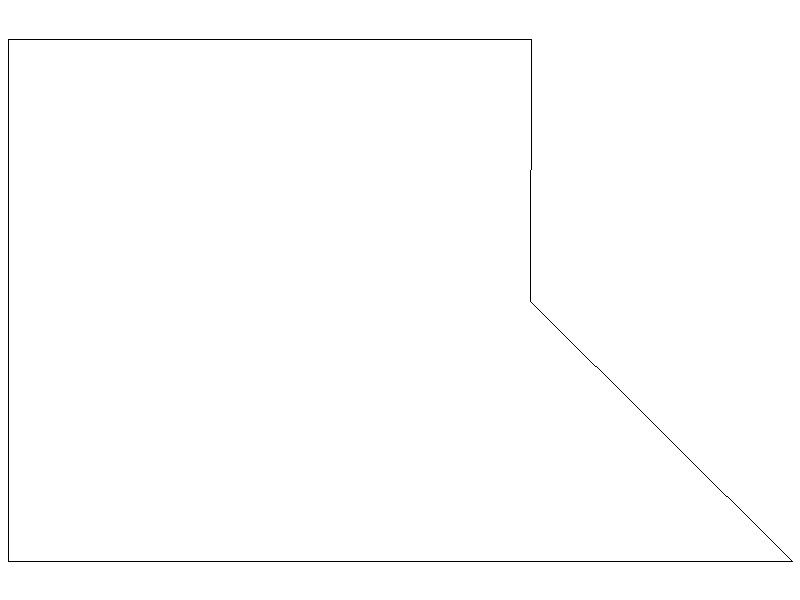

Well folks, apart from continuing to research I have been making some small progress on the model also. The research is important as the results will determine the location of the fittings that I need to add to the bulwarks before doing any doing deck furniture etc, as it will be too difficult to do so later. It is vital that I can determine the location and orientation of as many of the rigging fittings, pinrails, backstay straps, eyebolts etc before progressing too much further; otherwise, it will be a matter of redoing the work yet again. Some rework has already proven to be the case (unavoidable) as we have no plans, and information on ships of this type is very scarce - so we were forced to make some assumptions which have since proven wrong As you can see from the following photographs, I have started opening the ports; and, unfortunately I have also had to remove and redo about 95% of the roughtree timbers (risers). I have completed that and I am now in the process of fitting the waterways. Again there was not much information, and while the Contract had specifications for many of the ship's timbers/scantlings; all it said for the waterway was "to be shaped and fitted as shown on the plan" - not very helpful Looking at the profile of contemporary vessels of this type, shows a very substantial waterway with a profile as shown in the first drawing. To obtain this shape I found it easiest to make it in two pieces which were then laminated, and then shaped at the rear with a slight profile to butt up against the bulwark planks which tumble out from the ship's side - see diagram 2. The following photo (not very good) of the HMS Warrior forecastle shows this profile fairly clearly - I found this on the internet unsourced but I believe it is from the book "HMS Warrior, Frigate by Wynford Davies and Geoff Dennison. Sorry about the in-your-face sizes of the drawings - I will need to to resize these first in the future. The following photos show the waterway strips in their various stages of assembly and in being dry fitted. I soaked the individual planks and used a bending jig to get the curved profile of each layer by stacking them in the jig, before gluing and profiling the outboard side. The 45 degree profile was obtained by passing the plank though my mill fitted with a 45 degree cutter (in the upside down router style ). I then glued the upper plank to the lower plank following the edge of the profile on the lower plank. This has worked out a lot better than I hoped but did take quite a few trials to get the right wood and mill speed combinations. I have fitted a high-speed pulley upgrade to my Sherline mill to start approaching router like speeds - just have to remember this before attacking some metals (that need the slower speeds ). cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Ditto Rick's recommendation - should look good! cheers Pat

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

Hi, just a small consideration to ponder Vossie. The preciseness of your first planking might also be the cause of some issues down line. If you plank exactly the same for first and second layers, the seams/plank joints will all be coincident. By not having them coincident (having overlapping of planks between layers), you can reduce the chance of seams opening if there is any movement in the wood from humidity/heat etc; whereas, if coincident they may open up. That said, the argument can be made that a single layer of planking would have the same issues and that doing this is virtually the same as having a single layer of planking. However, with two layers, especially the uneven thicknesses, will make one layer might expand more than the other? Just raised as something to consider. cheers Pat

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

Nice detailing there Carl' will look really good when all is brought together. cheers Pat

-

There is really a lot of nice detail in this build Greg; will look good when all together. The guns look great. Makes you wonder how some of these things floated with all that metal cheers Pat

-

Michael, was that typical of the sort of material used in ship models of that period? Was brass wire available back then? I think you are well on your way to achieving your stated aim of no noticeable repairs and looking like as he should for an older model. i know the camera can show or hide a multitude of thing, but looking closely the is not much to show of where you repaired her (and I mean that as a compliment) cheers Pat

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

Beautiful decoration Gaetan; very good quality control as the pair look nigh identical. cheers Pat

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Looks good Ben, will the new timbers gain some colour with age and even out a bit? cheers Pat

- 889 replies

-

Look forward to seeing you back in the shipyard Denis; sorry to hear of yor ails but happy you are on the road to recovery - a few of the finest of brews may assist further cheers Pat

-

Hi rexy, Steve has summarised it very well. Exact paint schema could never be known without a Tardis White stuff (white lead) bottoms were a bit after this but starting to emerge as Steve points out. If I recall correctly, this particular item was mentioned in some Contract letters and a Log or Journal reference that mentions the Brown stuff. The brown stuff would not have been readily visible as it was also covered with a sacrificial layer of wood sheathing and this would probably have been painted with some form of varnish of pine also to seal it a little. I have read somewhere, that as the sacrificial layer was lost and the brown stuff began to wear, it became slightly polished and for a while may have had a buffed creamy colour but very patchy? So, I think the bare bottom you see for a lot of models is the most popular solution; as Steve points out, the white is incorrect. I followed the clone path mostly as the Replica people put quite a bit of research into the colour schema; I did differ with the boats though. cheers Pat

-

Nicely done Michael. some awkward shapes to control there. cheers Pat

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

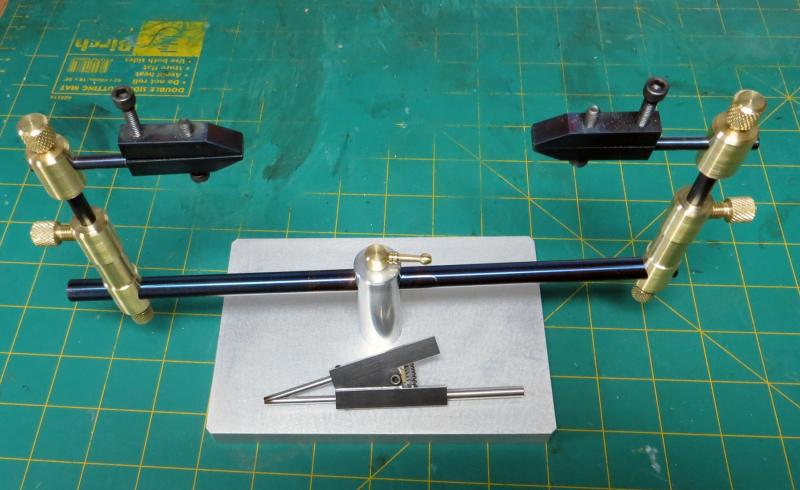

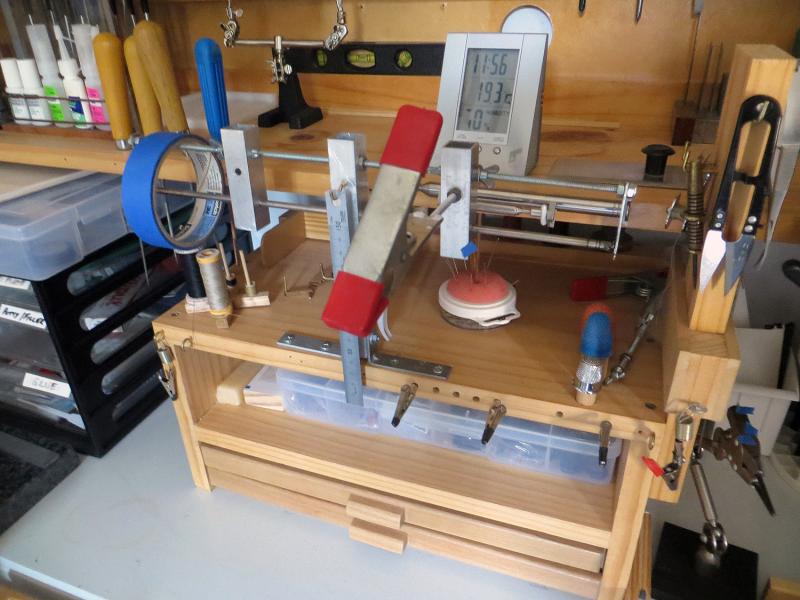

Hi folks, I thought I would do a bit of a tool review on a great new tool I have just received. Michael Mott, in his build log for the restoration of the Basset Lowke Albertic introduced a great new third-hand he had designed for himself - a new take on the usual designs. This looked very promising but as I am no tool maker, I asked him if he might make one for me - which he did See following picture. This was such a great adaption of the common cheap tool that are usually next to impossible to use for finer soldering projects, that I started looking at alternate uses for it. I realised it could also be very useful for rigging and opened another discussion with Michael on alternate clamp designs/arrangements that would not crush rope cordage, but could also be utilised for working wire rope where necessary. Michael has agreed to trial a few alternate clamps and has asked me to feed back to him on how useful they are. I thought the best way to do this is via a tool comparison and review; so here goes. Early in my hobby days, I had purchased two of those cheap version you can find in many tool, hobby and electronics stores. These were okay for basic use, until I found they were difficult to configure exactly for the job at hand, the clamps were very poor quality (fit, purpose, pressure) and marred the parts, or crushed the fibres of rope. I made a quick fix by putting heat shrink on the alligator clamp teeth which helped with grip and stopped some crushing of the fibres, but they still were not flexible enough to configure to hold small parts for a tight fit for soldering. I looked around on the Internet and found what looked like the best solution available; the GRS soldering station used by many jewellers, and some electronics guys - they seemed to have good reviews, and although expensive I invested in one. See the following photo: These have proven much better for soldering but did not resolve my rigging requirements. I then made a jig, based on a jig made by CristiC (I think) to assist in rigging which I used in conjunction with my 'rigging crab' which is an adaption of an idea by the late 'Hubert Sicard' on his Wood Ship Modelling Dummies site. However I still found I needed another arm, so invested in a single arm version of the GRS third arm soldering station. These can all be seen in the following photo: This collection of tools and jigs worked okay for my Endeavour rigging - that was until I saw what Michael had designed . Michael's third-arms are very well made, and with a wider spaced/longer base arm, and rotating components that can be tightened securely without damage to the arms, provide great flexibility in positioning to hold parts or cordage. The flexibility is enhanced with some great clamps, of which a wider range will be available after some further refining (if needed) whenI have used them for a while. I will provide an update to these clamps once I have received them and had an opportunity to try them for awhile: 1. soldering small and larger pieces typically used in our hobby; 2. holding soft cordage in various sizes for various tasks such as whipping, seizing, making tackles etc.; and 3. holding wire rope for the same purposes. With the wider spread of the lower bar, I am also going to trial its use to hold spars while fitting stirrups and blocks etc. As to soldering, at times you just need another hand to hold things, so I am going to trial an adaption to the base to allow me to screw in one of my GRS arms. I opted for a rectangular rather than circular base, and glad I did now as I can drill and tap a hole in one of the corners to allow me to fit that arm out of the way and get max configuration options Happy days! If anyone has any queries, or additional comments to make please feel free to add to this thread. cheers Pat

-

I prefer the bending technique you have used over the use of a heat source/plank bender although, sometimes the shape does resile a little and a further over bending may be required to allow for it. I also find that for thinner pieces I only have to soak for about 20 minutes. Nice progress, the planks should lay along this with very little pressure. cheers Pat

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

Looks good to my eye Jay cheers Pat

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

She's looking great John, not far to the finish line now. Any ideas on your next project? cheers Pat

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Nice little project Michael. Based on what I have seen posted in these forums, there are three workshops that I would love to tour noting the excellent tooling shown - those belonging to Gaetan and Wefalck, and yours - seeing some of these wonderful tools you knock up I'll bet your workshop is is something to behold. cheers Pat

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

117 huns, phftt - you could do that in your sleep Carl - glad it is you and not me. Nice work on all that PE, seems you have quite a bit of dexterity left in them fingers but you probably have worn out the eyes cheers Pat

-

Great to have that old tooling hull to practice on; the actual model will look all the better for the practice. cheers Pat

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.