-

Posts

3,079 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Gregory

-

-

Knowing you were in the doldrums for a while, I'm looking forward to seeing your progress on this kit..

I know you will do it justice..

- Jack12477, Canute, Old Collingwood and 1 other

-

4

4

-

-

Here is what I received.. It looks like other castelo I have, and have seen in the past.

It is very dense and fine grained. The finish is marble smooth.

May be a while before I see how it saws and carves..

The big pieces are 15cm long and 5cm square.

I have yet to see anything compared to this price in this type of size..

Here are a couple of eBays:

South American Castelo Boxwood turning blank 1-7/16" x 1-7/16 x 6 $13.25 shipped.

Boxwood Logs for Knife Handle Scales Blanks Wood carving, 15cm Length, 1 piece $37 shipped

Those prices seem pretty outrageous, but I guess someone is buying it..

-

To take the discussion a bit further, archjofo makes rope from silk.

It looks good, but I wouldn't know about overall performance..

There has also been discussion about linen but it seems to be relatively expensive and hard to source..

It was Chuck's preferred thread at one time, and I believe the go-to standard for museums..

-

-

-

-

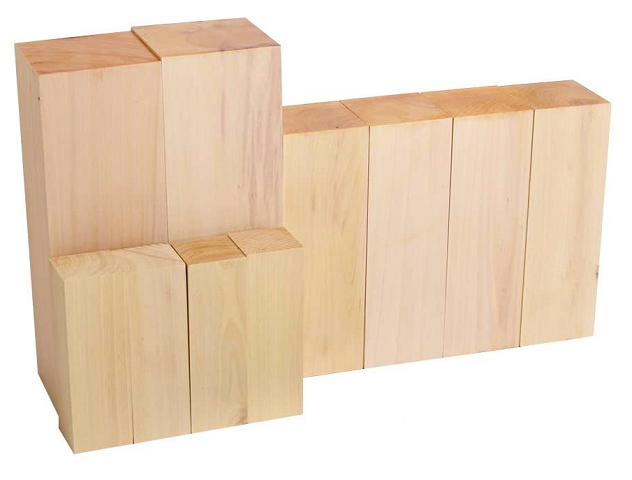

If this really is boxwood. is it a good price?

The total is 12 pcs.The size of 2 large boxwood carving blocks is 2x2x6 in.The size of 4 medium blocks is 1.5x1.5x4.5 in.The size of 4 small wood blocks is 1x1x3 in.

At Amazon $30

-

It's a matter of personal preference once you realize that model rope is what you want and not the stuff that usually comes in kits and looks pretty much like string, or thread.

Here is some of BenD's rope..

The different types will behave differently as far as flexibility and their ability to retain moisture..

Nylon is probably not a good idea IMO as it is generally more rigid and glossy..

I have come to prefer polyester and make my own rigging line.

Lot's of rope discussion here:

https://modelshipworld.com/forum/82-discussions-about-rope-making/

-

-

5 hours ago, Laggard said:

2. Anyone willing to accept Venmo to send me a few blocks? I can’t spend 10 bucks just to get blocks to replace the broken ones.

Thanks

What is a few? What size? ( 3mm? )

Are you concerned about the blocks matching the ones you already have?

I have a stash of typical kit blocks and I could possibly send you a few..

As far as cost, my time and trouble would be worth more than 10 bucks, but I have been known to help fellow modelers without expecting

any more compensation than the knowledge they will pass it on should the opportunity present itself.

With regard to Allan's suggestion, here is a simplified process for making your own blocks..

The quality would be superior to most kit provided blocks, and you would have a process to take forward in your modeling endeavors.

-

-

-

Are you going to leave the hull un-painted?

I think it will finish well with WOP..

-

That new molding looks exceptional!

-

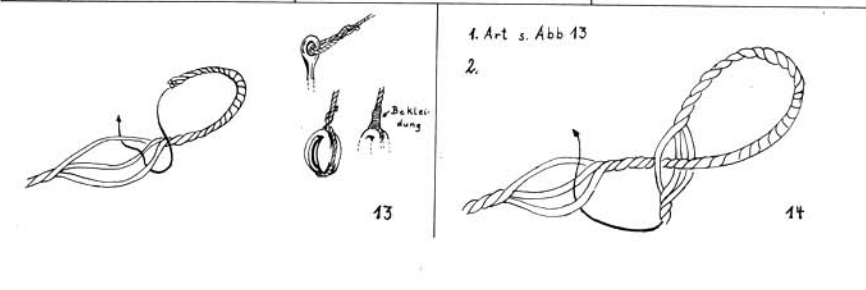

13 hours ago, wefalck said:

If you download this article I wrote in 1980, on the second page there is a sketch (no. 13 and 14) for how to make fake splices and how to tie in blocks: https://www.maritima-et-mechanika.org/maritime/tips/FALCK-SM-5-80.pdf

This was written at a time, when there was no Internet to ask questions, but one had some books on full-size practice and then deducted some useful practice for modelling.

Really nice technique..

I grabbed a snip for my reference and will post here..

Let me know if you would rather I not share, and i will delete the picture..

-

I'll Post an example in a little while..

- mtaylor and Ryland Craze

-

2

2

-

-

1 hour ago, glbarlow said:

others just offer an opinion forgetting it is just their opinion and not gospel

Not to mention, " a picture is worth a thousand words "..

When people suggest something should be done a certain way, it doesn't mean much if they can't provide an adequate illustration of how it is accomplished, or at least a nice picture of the end product.

Several such pictures are posted in page one of this topic.

Those pictures can be saved and printed for future reference..

Search for " strop " or "stropping " in the forum, and you will get more information than you can deal with in a lifetime..

-

Quote

Well thats easier said then done.

Isn't it always?😁

I am experimenting with making small moldings with a tabletop CNC, but still learning the software.

I'll share when I have something..

Another option is to make your initial grooves with a (small ) table saw then round off the profile with files, sandpaper etc.

You would not be starting with the final molding dimensions.. It would be strip or sheet wood, that you would cut from the stock once the rough shaping is done.

I will try to put together a visual if you could share the profile and dimensions of your molding..

-

8 hours ago, Mldixon said:

I am going to have to learn how to make scraped moldings better,

You have CNC skills..

Have you considered doing moldings with CNG?

-

3 hours ago, Jasseji said:

I hate Cast Carriages

They really look pretty good.

We know the difference, but how close is your target audience going to be, and will they know the difference?

I struggle over details that I know are important to me, but at some point I have to let it go..

-

-

This will be great practice for your Sphinx..

Occre Corsair Rigging

in Masting, rigging and sails

Posted

Your question would take a lot of answering that would probably lead to many more questions, and I'm sure you will get some help..

For something so essential to model ship building you need a good reference like Historic Ship Models where you will find drawings like:

Or Rigging Period Ship Models.. where you will find a diagram for every line on the ship..