-

Posts

2,739 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Gregory

-

-

-

-

26 minutes ago, RockinBudgie said:

then fills out to square with the second planking

The false keel will be full thickness at the blue line where the 1st planking will end. The ends of the first planking ( blue ) will be tapered ( faired ) into the false keel so the maximum thickness there is still 5mm. ( my measurements )

The false keel will be tapered to 2mm from the blue line to the stern post. At the stern the false keel (viewed end on ) will be 2mm from top to bottom.

The fitting of the planks will be a little more involved for the counter and the transom..

If you want to hold out for more illustrations, I can see what I can do later.. No trouble, it's what we are here for.

-

Here is the bender I use for long planks.

The soaking is not to soften the wood, it's to better transfer the heat when applied.

In my method, after the plank is completely dried after heating, letting it sit in the jig till it cools, it will stay bent when you remove it.

In your example you can bend both ends... The jig doesn't have to match your bend perfectly. In fact, a little over bending will cause it to grip the bulkheads when you glue it up.

You can see how one could adapt the principle to different jigs with pegs and such. The key is to heat the wood while it is bent, and keep it bent while it cools.

-

3 hours ago, RockinBudgie said:

the taper is a constant width? I was worried that it would taper on both axis and feared that would be a nightmare for a novice to get even widths

It's not clear to me what your concern is. I can think of one more thing that might help with clarification, but it will be later today before I can illustrate.

- CaptnBirdseye and mtaylor

-

2

2

-

Keith is right on.. I don't think that gap has a chance to be noticed after all the bow detail is in place..

- mort stoll, Keith Black and Heinz6672

-

3

3

-

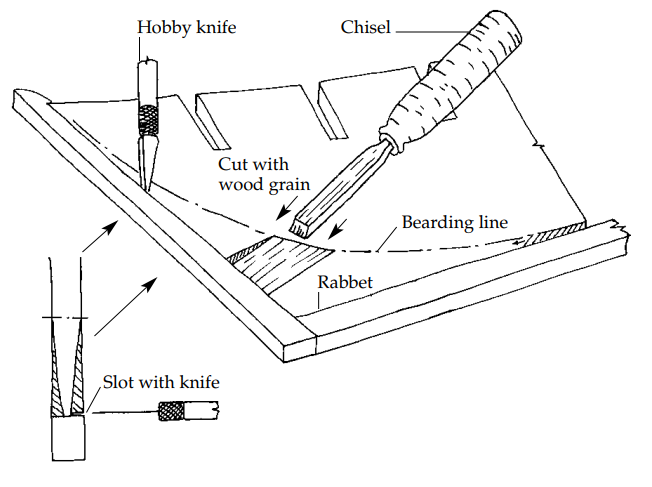

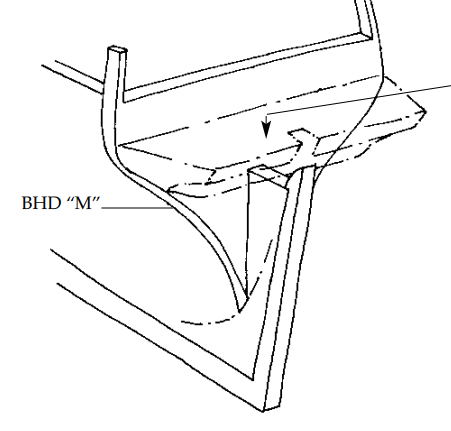

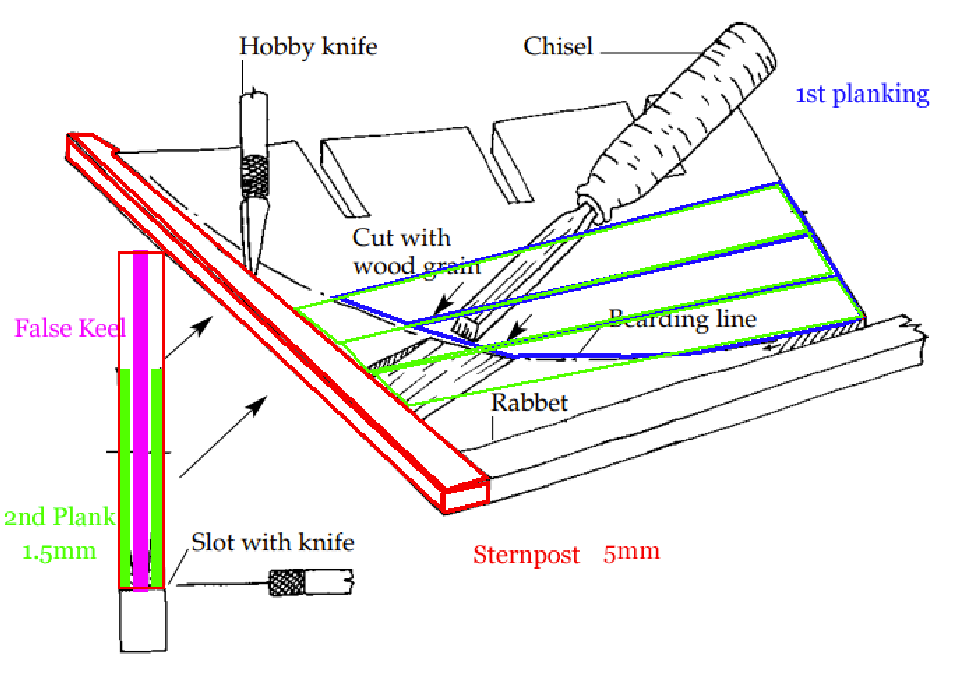

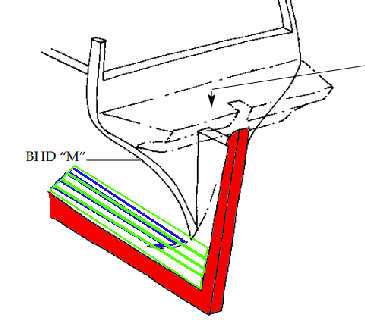

Here are a couple of images from the ModelShipways Rattlesnake that I will proceed to mark-up and hopefully explain things.

They show the keel and sternpost in place, but I prefer to do the bearding area on the backbone piece ( some call it the false keel ) before the keel and sternpost have been added. It's easier for me to do with sanding tools than a chisel.

Here is my attempt at illustrating planking to the bearding line for a double plank POB kit.

Your numbers may be different. If the sternpost is 5mm thick, and the 2nd planks are 1.5mm, taper from the bearding line to make the false keel 2mm at the stern post. This will make the 2nd planking flush with the sternpost.

I also end the 1st planking at the bearding line and sand the ends so they blend into the false keel at the bearding line. The 1st planking does not show in the end-on view.

Of course this is simplified and the finer details of how everything blends together have to be worked out by the builder. But hopefully this will answer the basic question of:

Quotehow thick would the stern be to allow for the double planking?

Let me know if I made it worse or if I can try to clarify something.

Here is a build log where Jobbie does his bearding line. It may help to better visualize things.

Note, he accounted for the thickness of the first planking all the way to the stern post resulting in a very thin false keel. If you just run the 1st planking to the bearding line, this won't be an issue.

P.S.

I noted by reading further into jobbie's log that he got a tip about taking the first planking to the bearding line, and followed through with that..

-

-

I don't know if this will work without pictures, but what you want is for the ends of the planking, both layers, to fit flush with the stern post; with that in mind you want to shave the bearding area to account for that.

To some extent you can blend the 1st planking into the bearding area short of the stern post, so it won't necessarily be necessary to shave the bearding area to the total depth of both layers of planking.

If you need more info just say so and i will try to round up some illustration.

- mtaylor and Ryland Craze

-

2

2

-

-

Looks like a good idea for use with a model..

Thanks for sharing.

- AJohnson, bruce d, thibaultron and 2 others

-

5

5

-

Nice touch..

People rarely add those reliefs to deadeyes, which can be a nice detail.

I couldn't see if you have Chuck's Syren deadeyes, which do include the relief..

-

While not the AL kit, Dave Baxter's log of the Amati Bounty is very informative.

He has asked lot of questions in other topics and his build reflects a lot of research.

If you also look through his forum activity, you will see where he asked questions and got a lot of good answers.

-

Chris, your kits present a challenge to get more detail than already provided ..

You have set a very high standard..

-

For black, monofilament is good also..

- mtaylor and flying_dutchman2

-

1

1

-

1

1

-

Another table top laser with 'CNC' incorrectly part of the description.. There is no CNC function for this machine.

No power rating in the Amazon info, but searching the questions indicates it is a 4w laser.

No useful cutting power except for paper and card and the thinnest of veneers.

Possibly a good starter for getting familiar with using a laser.

- Canute, thibaultron and mtaylor

-

3

3

-

-

-

You get a lot of Medway's Longboat but others also..

The Medway longboat should be a good example of framing for the next 100 years..

Also the Model Shipways 18th CenturyLongboat is a good example.

P.S.

-

29 minutes ago, Don Case said:

Can someone give me a rough idea of the spacing.

The drawing that Allan referenced above should help..

https://collections.rmg.co.uk/collections/objects/86917.html

There are many " longboat " logs and topics here, any number of which should help.

Many of the basics probably didn't change very much for a period of over 100 years..

- thibaultron and mtaylor

-

2

2

-

7 hours ago, allanyed said:

(There are used copies on Amazon for $11.)

- mtaylor and thibaultron

-

2

2

-

Great to see another Cheerful on the blocks..

If you haven't seen it, there are a lot of good tips in the prototype build log.

-

44 minutes ago, Robby The Brobot said:

I was lookin at their endurance model,

There is a revue of the endurance kit.

I don't see any build logs.

- Robby The Brobot and mtaylor

-

2

2

-

The Mamoli/Dusek Flying Cloud might be another option.

- Robby The Brobot and mtaylor

-

1

1

-

1

1

HM Cutter Cheerful 1806 by glbarlow - FINISHED - 1:48

in - Build logs for subjects built 1801 - 1850

Posted

Nice finish on the fiddle blocks.. i wasted some of those before I got it right..