-

Posts

3,174 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Gregory

-

-

Is there some reason why you feel I am not competent to judge the quality of this tool I am holding in my hand?

I need a good reason to spend $100 for a tool that is not as versatile or any better made than a $20 tool.

I judge a tool by it's ability to do the work I want to do, and a quality that means I don't expect to have to replace it any time soon.

I would have been real disappointed if I had spent $100 on a set of Starretts and subsequently found this tool for $20.

- Roger Pellett, Canute, Capella and 1 other

-

4

4

-

I don't see where the Starretts come with different size collets . Do you have to buy at least four of them to get the .04 to .187 pin range?

I'm sure they are well made, but doesn't ease of use count for something?

I used to have two of the double ended ones so I could have four different bits available without changing bits.

I threw them away after I acquired this:

It will hold anything from a cat hair up to 1/8 ".. The 1/8 is really convenient for holding a lot of different Dremel type accessories & milling tools if the need arises.

Since I haven't had the opportunity to use some of the " higher quality " suggestions, I don't know how this compares in that regard, but it has some kind of baked or anodized finish that appears to be very well done.

-

I really like this one. The 3 jaw chuck is really useful for a wide range of sizes without changing collets

like a lot of traditional pin vise'..

36 Pieces Vise Hand Drill for Jewelry Making Set

If you get something like this, be aware those burrs at the top are brittle and break easily, but it is

easy to get replacements.

- Capella, Ryland Craze, mtaylor and 3 others

-

6

6

-

I have read a lot of different sources regarding Bligh and the aftermath of the mutiny, and I don't recall any mention of the launch after the landing in Kupang..

Considering the times, there would have been nothing special about the boat.

- thibaultron, allanyed and mtaylor

-

3

3

-

-

Lot of rope making info here:

Did you check out Ropes of Scale? Another MSW sponsor.

Another sponsor is Crafty Sailor

Until you start making your own, stuff like Syren rope is still a bargain at $50.

-

For whatever reason, I was able to get a color change on 100% polyester rope with Fiebing's leather dye.

It seemed to be permanent and resisted wiping off after it was dry..

It was just an experiment, as I have no reason to change the color of the rope I make beyond changing the color of thread I use..

-

Have you seen the log by vossiewulf where he used red primer:

QuoteThe gun carriages have had their train tackle holes drilled out, casting plugs filed off, and seams sanded down. I then shot some Tamiya red primer over them, and drilled holes on each side for eyebolts for the breech rope and the gun tackles, but I don't think I will fit the latter.

They look pretty good IMO..

- mtaylor, Keith Black and Dave_E

-

2

2

-

1

1

-

Any dying option you use may be subject to changing over time, and you won't know how long until it happens..

Have you looked at BenD's rope?

-

29 minutes ago, Roger Pellett said:

From the drawings, it is not going to result in anything that resembles a real ship.

That's never stopped anyone before..😄

- Roger Pellett, Dave_E, Ryland Craze and 3 others

-

4

4

-

2

2

-

3 hours ago, paul carruthers said:

I’m not going to paint the hull or copper it.

I really like that decision.. Your planking looks like a fine piece of furniture.. Would be a shame to paint it.

-

Sorry I didn't get back sooner, but didn't find what I thought I might have..

- Keith Black and mtaylor

-

2

2

-

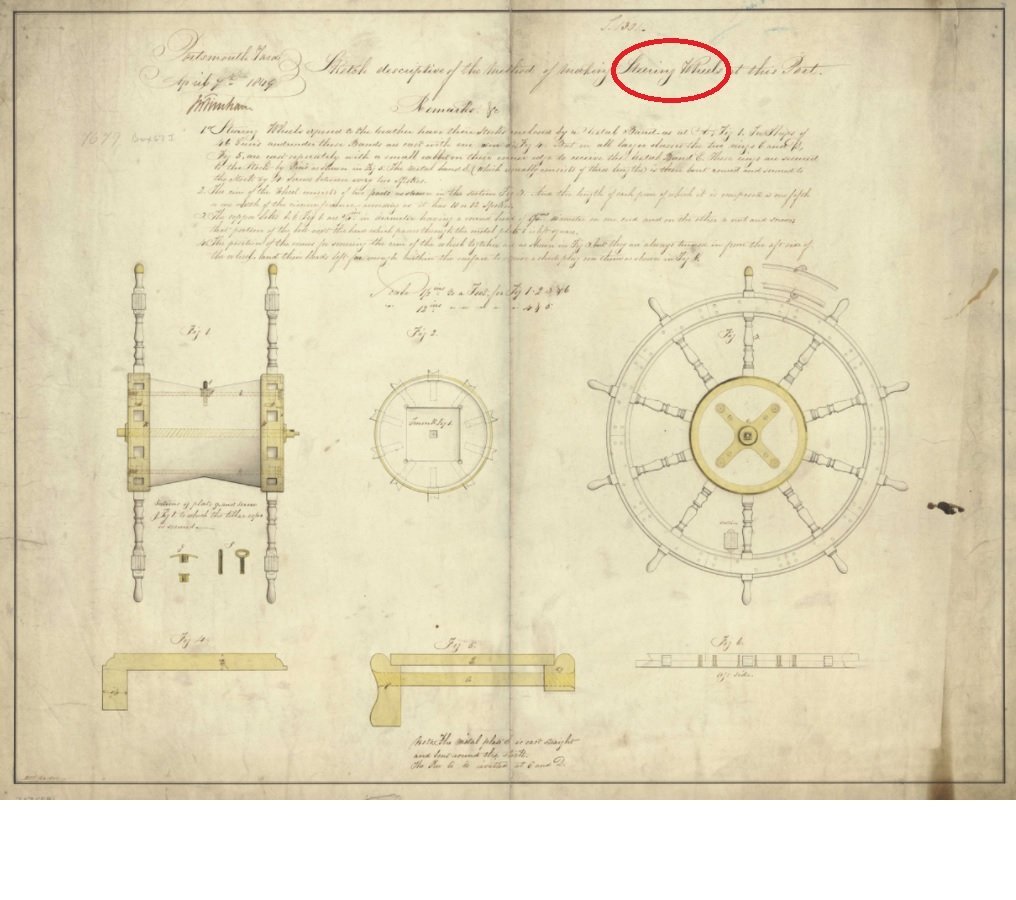

On 1/3/2022 at 7:45 PM, Keith Black said:

Ray, steering wheel is incorrect

Keith, I came across this when browsing through the drawings at Wiki Commons, and thought I remembered someone commenting in this regard.

Whoever drew this didn't get the word..😁

-

The counter looks like an excellent preview of your usual planking prowess..

It's almost a pity the that the fancy stuff will hide your fine work in that area..

- glbarlow, FrankWouts and AlleyCat

-

3

3

-

I will look in my stuff and get back to you later...

- mtaylor and Keith Black

-

2

2

-

The Master Korabel boats are similar to the Falkonet, and you can find them at our sponsor Crafty Sailor.

-

They look great! Those would work well for any 1:64 cutter..

- thibaultron, mtaylor, chris watton and 1 other

-

4

4

-

44 minutes ago, Gahm said:

Beautiful capstan, Patrick!

I 2nd that!

-

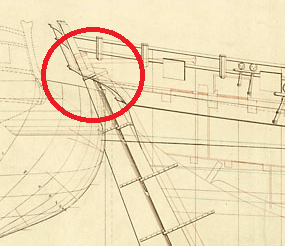

9 hours ago, Jim Lad said:

The waterway actually guides any small amounts of water along the deck and the scuppers run through the waterway at deck level and take the water outboard.

here is a sketch from AOTS Royal Caroline that illustrates it rather well.

- DelF, Beef Wellington, AJohnson and 3 others

-

6

6

-

4 hours ago, Dr Syn said:

I see everywhere that the complete mast with all the tops,tressles and upper masts are assembled before fitting shrouds.

That is probably because many kit plans and instructions often present it that way.

If you dig a little deeper, you will find many build logs where that is not the case.

-

That stern looks a lot like one of the Bounty replicas..

- Ian_Grant, allanyed, Keith Black and 3 others

-

6

6

-

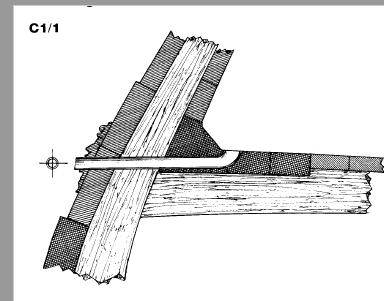

The plan I used was to illustrate how the rudder post enters the transom and determine the position of the tiller.

Not necessarily how you plan to build Sophie.

Your plan doesn't show where the rudder post enters the counter.. That would determine where the tiller would lie.

- Keith Black and mtaylor

-

2

2

-

12 hours ago, TBlack said:

Furthermore, in other ships with a wheel, regardless of where it was situated, had to deal with the same mechanics and space, right?

Well, no.. All ships with a wheel did not have the same amount of space below decks to accommodate tiller mechanics, but it would have been adequate for the tiller as designed.

Where does your rudder enter the transom?

What kind of space do you have at that point for the swing of the tiller?

- Keith Black and mtaylor

-

2

2

-

The cables would do that if space permitted, however you have to consider how far up into the boat the rudder post extends in your ship as she sits.

Is there enough lateral room for the tiller to swing below the cabin?

- Keith Black and mtaylor

-

2

2

Looking for a good "starter" pin vise set

in Modeling tools and Workshop Equipment

Posted · Edited by Gregory

I'm a little challenged when it comes to small diameters, in that I just have to eye ball it after .5 mm or so.

I see that #80 should be .0135.

This little 3 jaw chuck closes essentially to .000, so the #80 shouldn't be a problem..

Here is some copper wire that is about .01, and it's not going anywhere unless it comes out smaller than it went in.

I think you would be surprised at the quality of these. Chances are a lot of different 'Brands' are coming from the same factory, the one I have doesn't seem to be available at Amazon right now, but any similar one should do as well.

PS

Just noticed the specs say this is made of aluminum, so I guess long term durability could be an issue.

I don't see any noticeable wear after over a year, but I mostly use the 1/8 shank micro bits..