-

Posts

3,077 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Gregory

-

-

It's been a while since my last update and I am close to start rigging, but I have been spending a lot of time 'playing' with my laser and learning some new software.

Over a year ago when I started this build I was talking about the guns early on. They turned out to be a mini project on their own, and a real exercise in using my laser.

Here is a flashback to my early gun experiment. The walnut is definitely not a good choice.

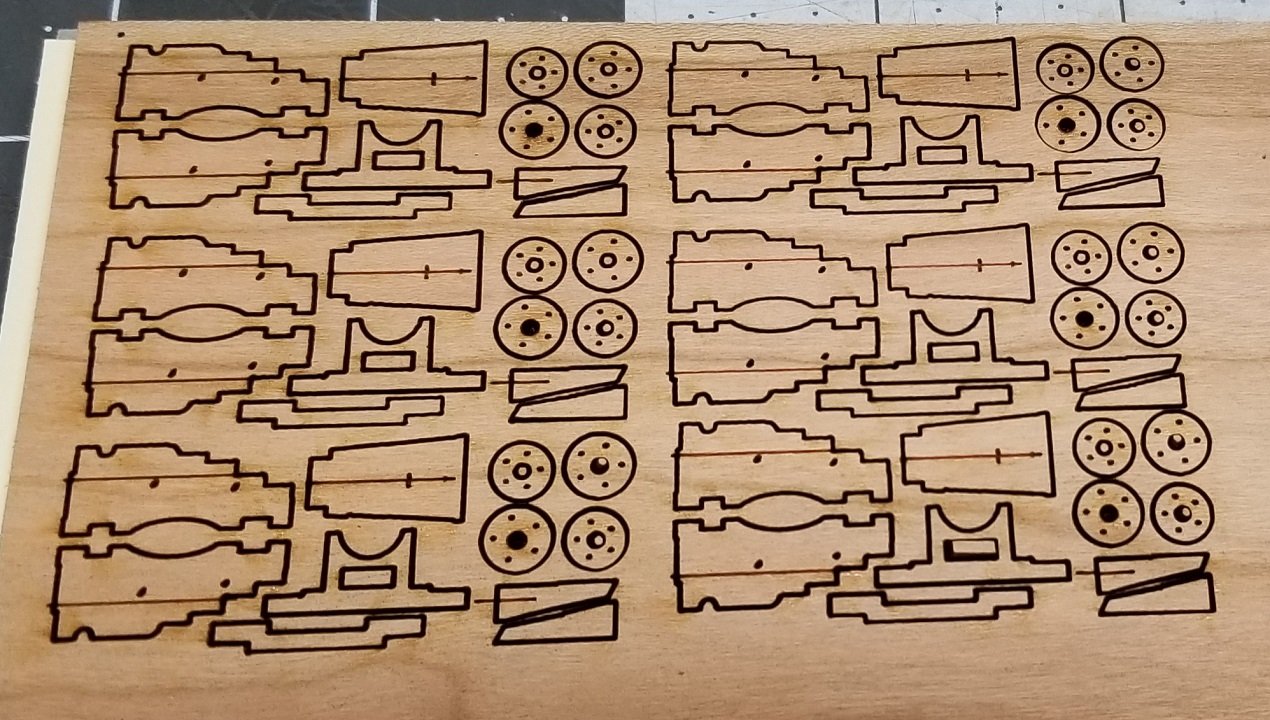

I decided to go with cherry. Here is a sheet with the carriage parts fresh out of the laser.

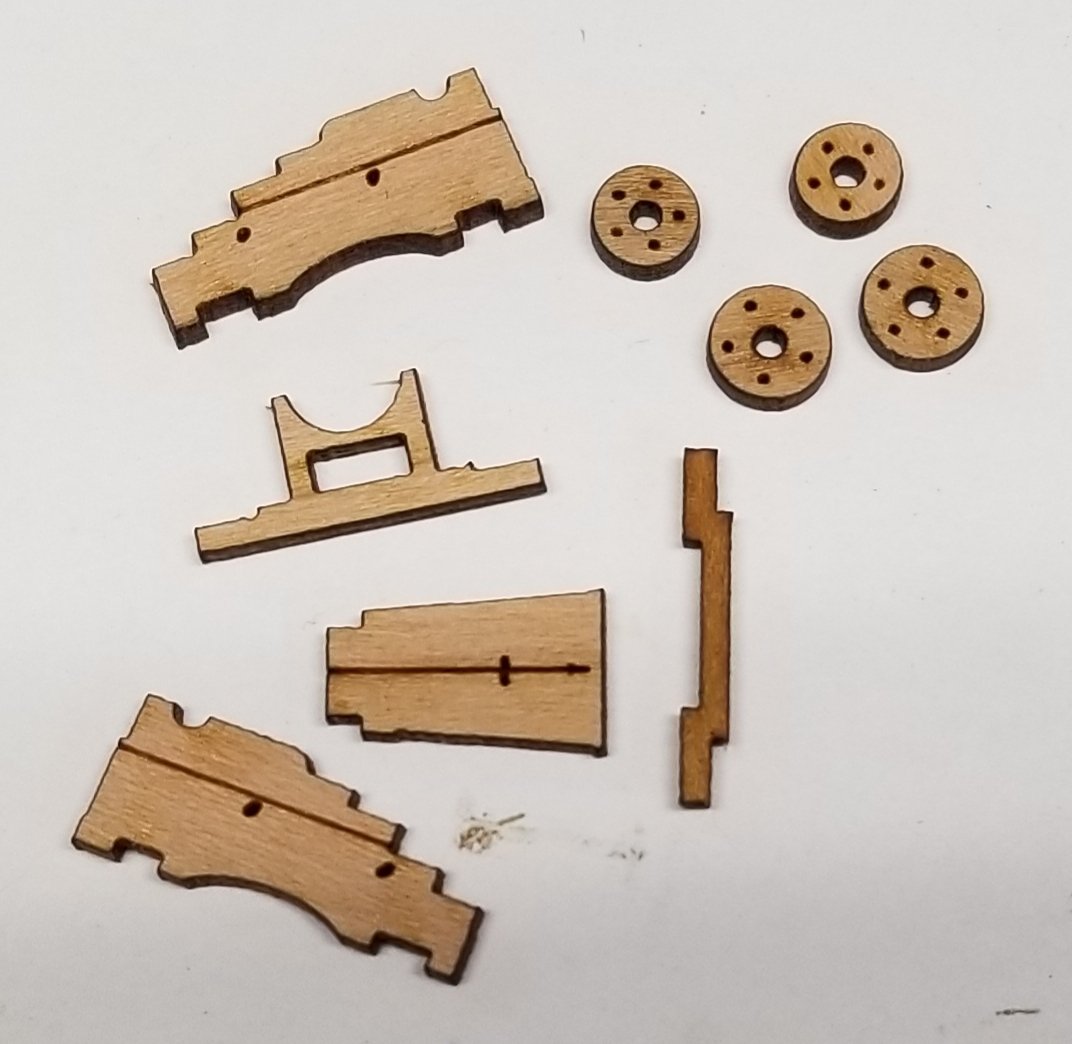

My mini kit is a hybrid of different kits I have seen.

It goes together tightly without a jig. ( Glue not dry. It practically disappears when fully cured. )

I use a brass collet in a small rotary tool to round off the axles.

.. another rotary tool to clean the char off the trucks..

The camera picks up more grain detail, than is apparent in person. The color tends toward a pinkish, not unlike pear, that really doesn't show well here.

There is some WOP in my future.. I'll be getting back with a finished gun soon..

Maybe even later today.

- gieb8688, GrandpaPhil, Edwardkenway and 5 others

-

8

8

-

The video at the top of your link is " How to faux burl wood-Artisan Rooms "

Is that the one.

If not, do you think you could click on the video , then paste the link here?

- thibaultron, mtaylor and Canute

-

3

3

-

On 6/14/2021 at 7:51 AM, allanyed said:

but I found the following website video that gives step by step instructions on creating a burl finish on a plain piece of wood.

Do you have a specific video in mind?

Your link takes me to a page with several.

- mtaylor, thibaultron and Canute

-

3

3

-

Is that the Occre kit?

Someone having just the hull parts to spare is unlikely.

Your best shot would be finding a kit someone wants to sell.

- mtaylor and thibaultron

-

2

2

-

1 hour ago, Suzdal said:

No it doesn't make you strange but I believe a way should be made to make it visible.

Richard

The builder can make as much visible as they want to.

- KentM, chris watton, mtaylor and 1 other

-

4

4

-

-

In this topic, Chuck said:

QuoteI was hired by a major well known museum in Europe (I wont mention their name) to make several thousand feet of rope for them. They were going to use it to restore a contemporary model....and also to rig a newer model. But they told me they have now decided that polyester scale ropes are being used from this point forward because of its longevity and its crispness and beauty.

Hard to argue with that..

- mtaylor, Mark P and Chuck Seiler

-

3

3

-

-

9 minutes ago, BenD said:

Another problem with polyester is the shiny texture.

I feel like the baking tones that down somewhat..

- mtaylor and Chuck Seiler

-

2

2

-

How much time?

Isn't just bout any material going to change with humidity if it is not sealed in some way?

- mtaylor and Chuck Seiler

-

2

2

-

-

Here is an image I found.

- thibaultron, mtaylor and Canute

-

3

3

-

-

-

-

On 6/12/2021 at 4:11 PM, Chuck said:

One is made entirely of Boxwood while the other is made almost entirely of Yellow cedar.

While I am well aware of the qualitiies of boxwood, the cedar has more of a glow.

I look forward to seeing how it ages..

I wouldn't want to wait 200 years for the boxwood to take on the amber look that looks so well.😁

- scrubbyj427, Chuck, KentM and 2 others

-

5

5

-

-

I get the cutting blades from Malco. On my last orders a few months ago, they have required $100 minimum order.

I don't see any thing in the 200 tooth range. I know I have made super fine cuts with teeth in the ~100 range.

Byrnes also sells blades Not sure about the arbors, but they also sell arbor adaptors..

For the gratings look for a thickness that suits your job.

-

-

Have you tried changing the file extension to .STP and see if Tinker can see it?

You might consider installing the free version of Fusion 360, import the STEP files, then export them in a format TinkerCAD can use..

Meanwhile you might want to up your game by playing around with Fusion360..

-

While you are here..

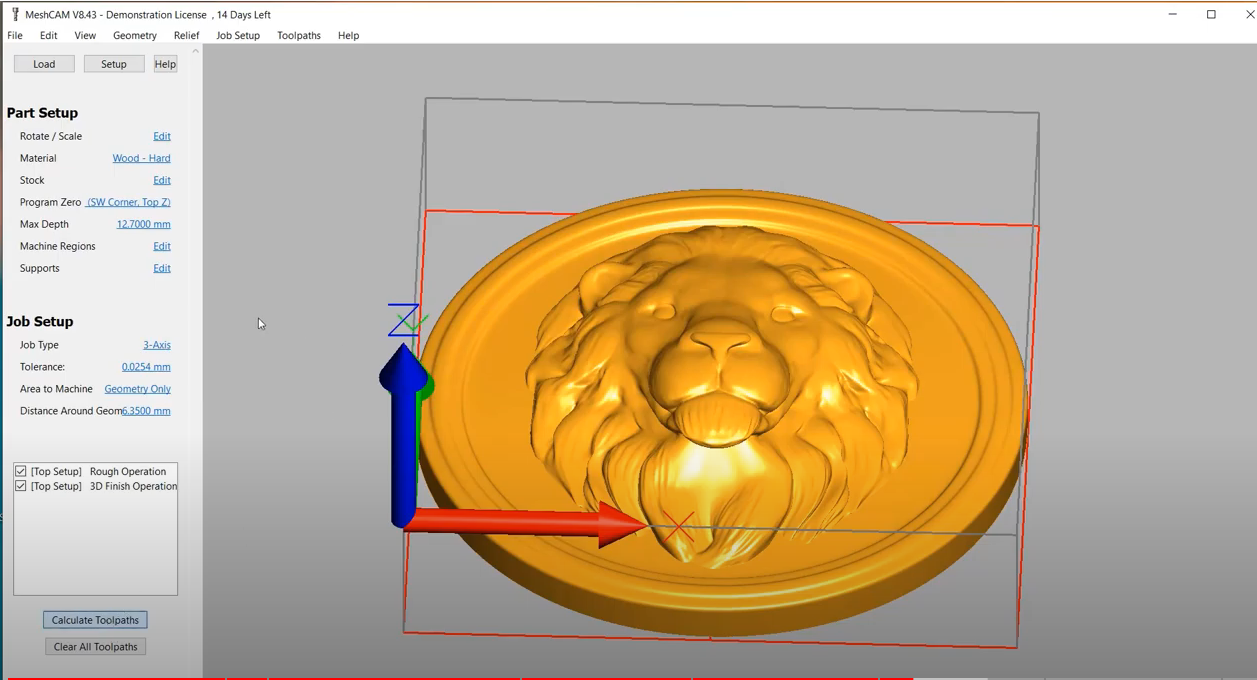

Have you heard of Meshcam ?

While it targets CNC users, it is a very powerful tool for refining STL files..

It is not free, but some might find it a worthwhile investment.

Here is a demo video of what it can do..

-

Do you mean Blender ?

Blender seems to be more about 3D animation rather than creating objects for 3D printing.

Fusion 360 might be more of a go-to for parts creation.

It's free for hobbyists.

-

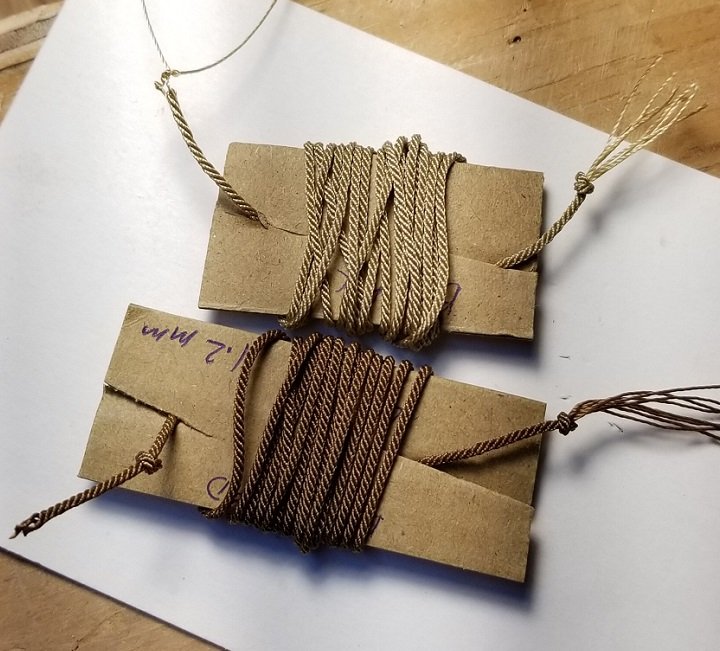

I'm revisiting this in response to the original post.

On 3/2/2021 at 2:26 PM, Tomculb said:What methods and dyes have people successfully used to get the color they want?

There was a discussion about staining/dyeing boxwood where it was agreed boxwood doesn't take some stains very well. One or more people mentioned dyeing with an alcohol based stain.

I proceeded to get some Fiebling's dark brown shoe dye to experiment. It actually worked pretty good to make my boxwood blocks darker.

I had thought, and mentioned above, that I didn't think synthetic/polyester would take dye very well, with the idea that it was like trying to dye plastic and wouldn't stick.

Well, I was wrong.

On a whim, I dyed some of my home made polyester rope with the above mentioned dye and it really worked pretty good.

Top is before, bottom is same rope dyed. ( Please ignore the unravelling.. That happened before I baked my rope.. )

Getting the color you want could take a lot of experimenting, and have a lot to do with the color you start with.

For home rope makers, I see it as a way to avoid getting different colored thread for standing and running rigging..

Find a good light color you like for running rigging, then dye it dark for the standing..

Note: The dye can be very messy, but it cleans up pretty easily with alcohol, depending on how long it sits before you get to it..

-

7 hours ago, DaveBaxt said:

That sounds like a good way to do this but could be a little tricky as I have already fitted sections for strengthening

When I described extra bulkheads, they don't have to extend to the backbone like the original framing.

All you are looking to do is fill out the outer profile to provide a surface for planking. Just add what amounts to shims

to the edges of the existing bulkheads. Create as many layers as you feel necessary. It is a lot like adding blocks, but laminated so

you can reduce the amount of shaping needed.

Errors in zu Mondfel's "Historic Ship Models"?

in Book, Monograph and Magazine reviews and Downloads. Questions and Discussions for Books and Pubs

Posted · Edited by Gregory

I am not aware of a compiled list of errors.

It would probably be better if you asked about a particular entry, and we could discuss possible errors.