-

Posts

3,079 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Gregory

-

-

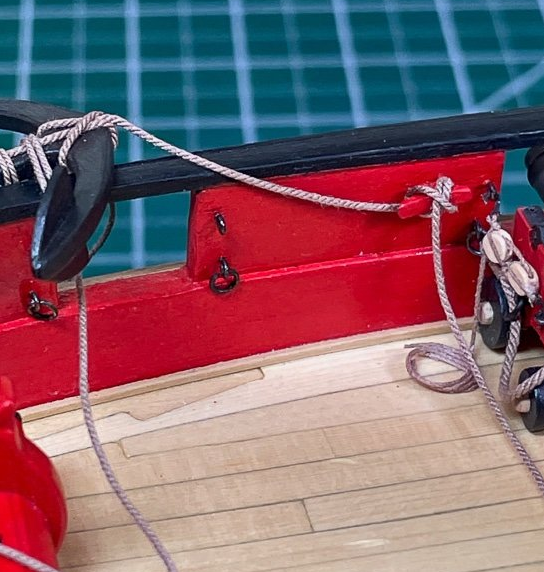

An eye or a hook?

Here is a block stropped with rope and a hook added.

If you also meant an eye bolt, just picture the above arrangement with the hook missing and the shaft of the eyebolt being a bit longer..

- thibaultron, nehemiah and Ed Gibbons

-

3

3

-

Small update.. Fiddly stuff..

Some pumps I can live with.. Pretty simple.. Basic design from the Cheerful plans.

Broke a few of these before I got two I could use..

Ladder going up to the quarterdeck. Plan on a few more details there, like a railing of some sort..

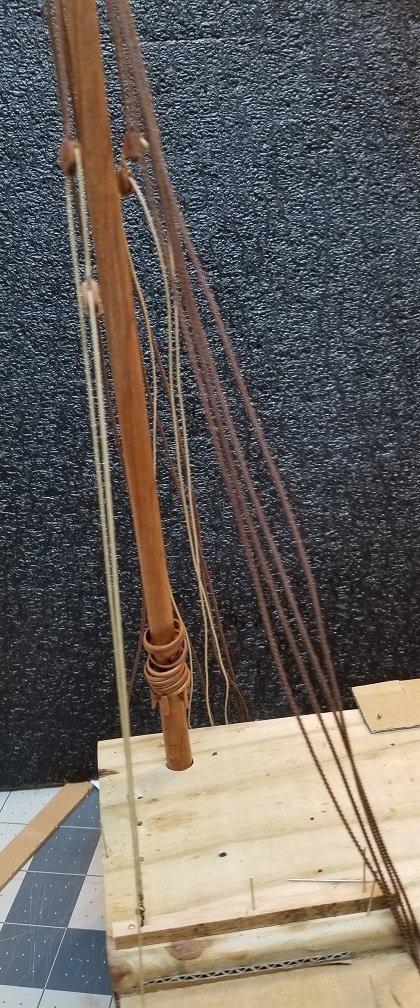

Working on some rigging off the ship.. Shrouds and Burton pendants with tackle..

Another view of my little off-the-ship rigging jig.

- egkb, GrandpaPhil, gieb8688 and 2 others

-

5

5

-

Dave, if you hover over the users icon, you have the option to send a message..

- Ryland Craze and mtaylor

-

2

2

-

18 hours ago, PRS said:

....would like input from people that have one and how it works out for them.

This is what PRS asked, and it looks like a couple of owners have responded with relevant information..

I can only echo what tkay11 says.

The tilting blade and micro adjustable fence are great to have without having to assemble or disassemble anything.

Of course, the heart of a good saw is the blade, and I don't care for the options offered by Proxxon. I have been using blades from Malco Saw.

I'm sure there are superior machines but I have no reason to purchase one if the FET is doing what I need to do..

If you have any specific questions Pail, I will try to answer based on my experience.

-

-

On 9/7/2021 at 9:27 PM, yvesvidal said:

What is the best way to protect that cherry stem, for now?

The oil looks very nice and you might apply more coats as time goes on..

To protect it as you go forward, you will see a lot of builds where the stem and keel are covered with painters tape until the major hull finishing is done.

-

-

On 9/11/2021 at 9:39 AM, nehemiah said:

I am a bit stuck though. How do I go about permanently attaching the shroud plates? It says to nail them but I'm not certain how to go about doing that.

If someone doesn't beat me to it. I will offer a suggestion soon.

Your build looks great so far..

-

Something else about those cast transoms..

They are often a lot thicker than they need to be. You may be able to sand them down from the back and make them easier to bend..

-

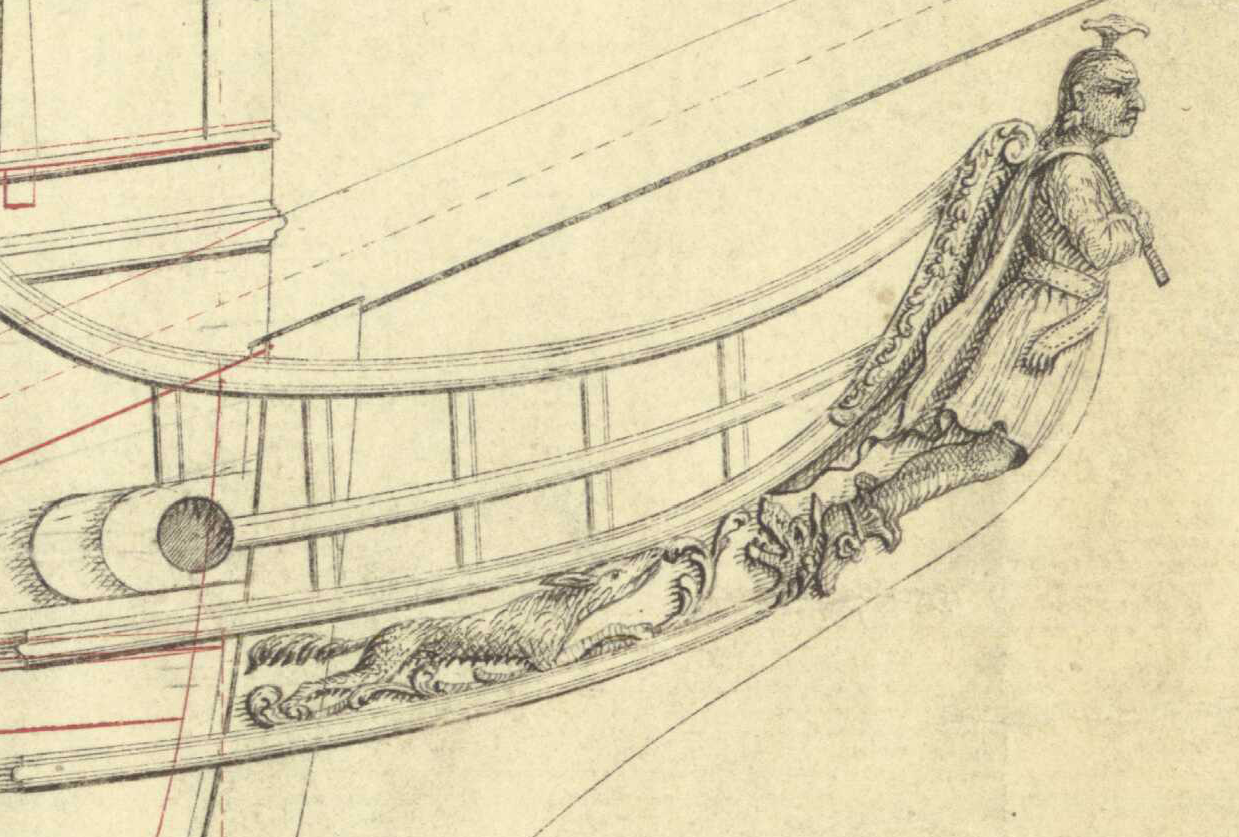

You might find the high resolution plans of Cormorant at Wikimedia commons helpful.. There are several different sheets.. You can click through them at the link provided.

All Rattlesnake kits are based on these plans.

The plans do not show any quarter badges, but they make a nice extra touch..

The carving detail and figurehead are very interesting..

-

I've seen some pretty decent mahogany veneer.. Not cheap but not crazy either..

I like veneer for 2nd planking on double planked kits.. You can do some spilling and really fine tune your plank widths..

At Rockler for instance..

-

I think you should go with what works and looks good to you.

Is there some room to add a cleat to the bulwark?

-

I respect your decision to paint, but that wood looks fantastic..

- Ryland Craze and DelF

-

2

2

-

-

-

Mark,

' Martindale ' would not search at either of those sites..

-

-

14 hours ago, Boatsinc2000 said:

Sorry if my comment came across poorly.

Really it didn't.. I sensed the spirit of your comment..

Actually, I do hate the idea that I missed out on some essentially free stuff, that is hard to get today at any price..

It's like the thought of all the comic books and baseball/football cards I had as a kid in the 50's...

- mtaylor, JohnLea and Boatsinc2000

-

3

3

-

-

28 minutes ago, Mark P said:

although when fired in action the gun's recoil acted as the inhaul force

I seem to remember a long discussion where there was speculation that the recoil forces would not contribute that much to gun movement.

But I might be remembering incorrectly. I'll have to see if I can find the topic..

-

1 hour ago, Mark P said:

My theory, for what it is worth, is that the train tackle, which was not used at all for training the gun, ie aiming it, was originally called the 'restrain tackle', as in restraining, or holding back.

I thought I had seen it called the " in-haul " tackle, and used to pull the gun inboard, and also restrain the gun from rolling when hauled in..

A true train tackle would be attached to either side of a carronade on a swivel mount.

The only way to train a carriage mounted gun would be to pull the rear sideways across the deck, not from a tackle to the rear of the gun.

-

You have to add the paper.. I don't know if they have this in the UK, but it is my go to sanding for all uses..

Dura Gold Adhesive backing that is really good, but not too hard to remove.. Many different grits

The sanders themselves are not real soft. They are a firm foam, but not spongy..

-

No reason to hate.. Times have changed.

I bought this on a whim just to check the quality, knowing I could return it if I had a problem..

Getting a decent board, or combination of similar pieces from Gilmer would probably put me at least $30 before shipping costs..

Our sponsor Modelers Sawmill has some nice sheets for what seems a reasonable price..

- Nunnehi (Don), JohnLea and mtaylor

-

3

3

-

Blocks to eye hooks?

in Masting, rigging and sails

Posted

The hook in my picture is made from scratch with wire. It was made by member Chuck in his Cheerful log..

These hooks from Crafty Sailor are pretty good and come in several sizes.

Falkonet Hooks (20pcs)