-

Posts

3,176 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

Question regarding the base of the mast

Gregory replied to DaveBaxt's topic in Masting, rigging and sails

You might consider dropping the metal ring, which is just a kit convention, and using wedges, once you are ready to step the mast. ( you can make the wedges look a lot neater than this ) Or fashion a wooden fabrication that you will find on a lot of models.. ( Chuck's Cheerful ) On the actual boat, this area would have a canvas cover, which isn't seen often on models.. -

Gratings

Gregory replied to DaveBaxt's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

I have used clear plastic wrap and zip-lock bags. -

It became popular because of the very fine, almost invisible grain and it's carving properties. It holds a very fine edge. Personally, I like the look of wood grain on large areas like the hull, as I prefer not to paint. Purists however, will decry open grain wood as being way out of scale for model ships. Too me, boxwood looks like something besides wood, like marble or ceramic, so in that regard, I like it for decorations and things like figureheads. The price has probably at least quadrupled in the last few years, and it does not show up in models here as much as it used to. Chuck's Cheerful and many of the early kits he sold were based on Boxwood.. So, you will find several Cheerful logs that utilize boxwood. I have really grown fond of cherry as of late, but it's darker color is not appealing to a lot of folks.

-

CA residue problem

Gregory replied to Doc James's topic in Painting, finishing and weathering products and techniques

Just a note, it may take several swipes with the acetone. The cured CA is essentially plastic, and the acetone dissolves it. -

If they are twisting, it is because the shroud or lanyard is trying to find a rest position that it was forced out of when it was laid up.. You have to make sure both are hanging untwisted naturally before seizing them..

- 21 replies

-

- model shipways

- Finished

-

(and 1 more)

Tagged with:

-

CA residue problem

Gregory replied to Doc James's topic in Painting, finishing and weathering products and techniques

Have you tried wiping with acetone? You might need to put some cloth on a thin blade of some sort, saturate it with acetone and wipe between the planks. -

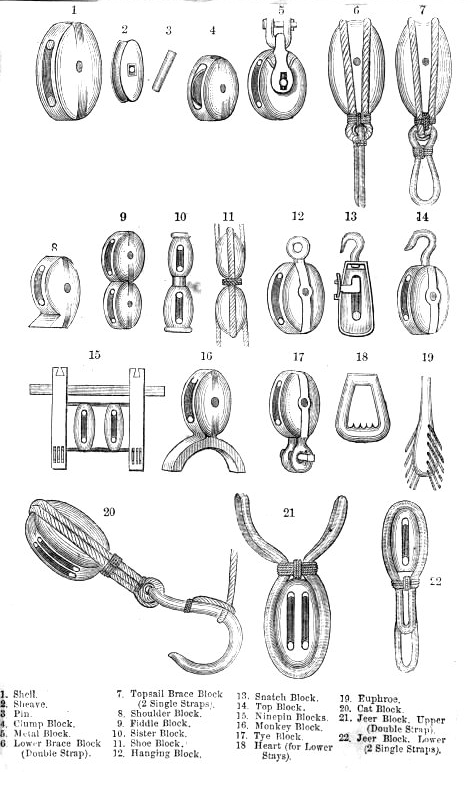

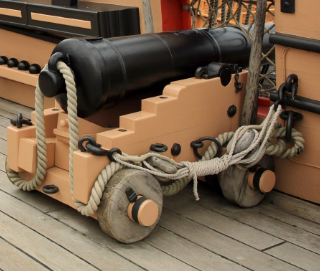

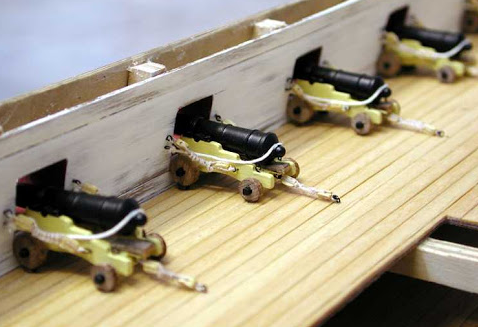

You would be hard pressed to find an example of where this is done well by anyone at this scale.. Even at 1:48, most efforts leave a lot to be desired. More often than not, any strops and hooks look way out of scale.. You will find many fine models where the tackle is not rigged at all, or maybe just the breaching rope is present. You might consider a method called " frapping " Shown here on tkayy11's Triton cross section. However, I think this is a 1:48 build.. Getting the hooks to look good at 1:64 is more of a challenge.

-

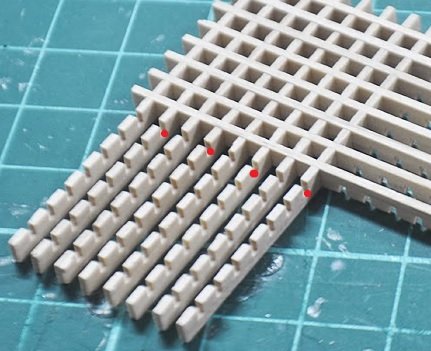

Gratings

Gregory replied to DaveBaxt's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

I guess this part is a little late if you have already put them together.. When I have put these together, I just put a little white glue in random slots of one layer. Doesn't take much to keep these assemblies together. As far as where to put yours while they dry, just set them on some plastic wrap or a plastic bag.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.