-

Posts

3,108 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

Byrnes Table Saw making a 1mm by 1mm strip

Gregory replied to CharlieZardoz's topic in Modeling tools and Workshop Equipment

Has anyone mentioned blade height? I wouldn't have the blade height much higher than the final thickness, and also at low RPM.. -

If you decide to glue them, just some white glue in the hole should keep them in place, but allow for easy removal if you need to later.. Meanwhile your cutter is really looking great!

- 436 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

Just found this in another discussion:

-

Someone mentioned AOTS, which is 32-Gun Frigate Essex (Anatomy of the Ship, which would be the best source, depending on your budget. Not cheap, but Googling shows copies for less than $50.. While there are those who would argue the details, the general arrangement of the Constitution might be an option. There are lots of resources for Constitution rigging plans.

-

Have you checked out the pricing at Cornwall Model Boats ? Even after shipping costs, the price can be very competitive..

-

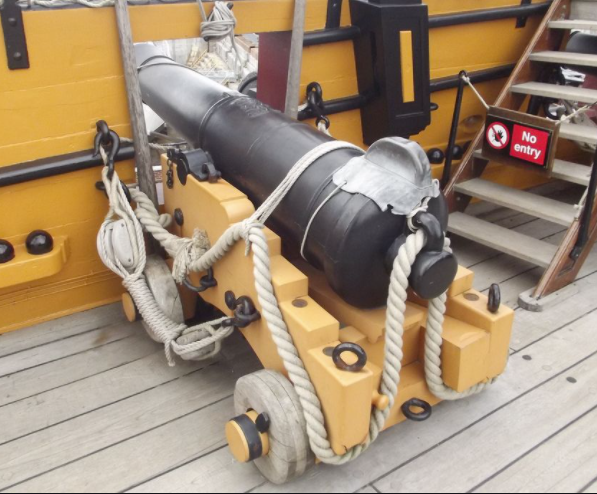

I've been told the flat coils might have been used for inspection, but not on a working ship. I have never seen a contemporary model or illustration with the coils. Here is what you see on brig Niagra Another method is called frapping, as seen here on Victory. I think the coils are a modeling convention from who knows where. In the end, it is how you choose to present your work.

-

Can someone have pity on a landlubber and tell me what the " hair bracket " is? You can imagine what Google came up with.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

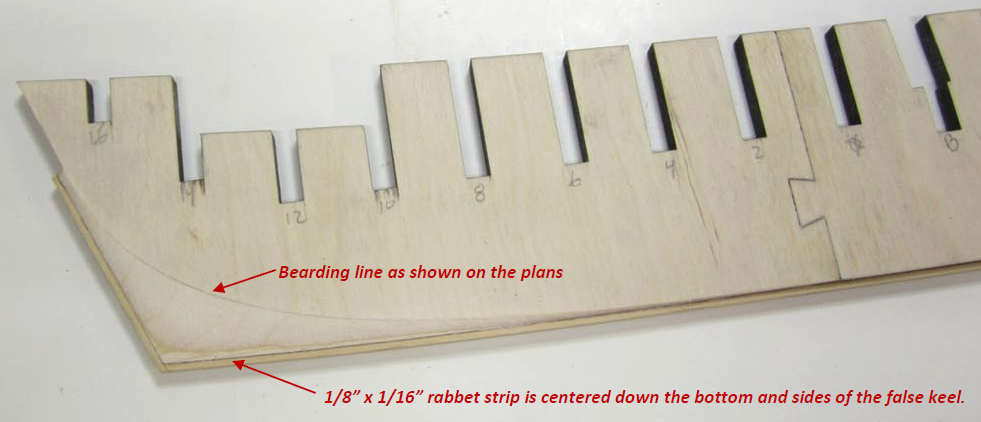

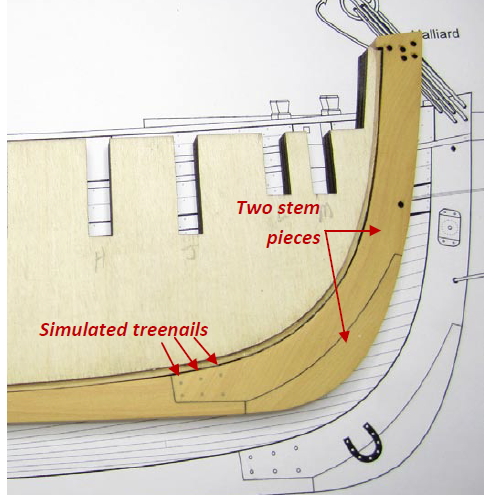

There is also the option when building a POB kit, of using an offset strip a'la Chuck, down the center of the backbone .. Image from Chuck's Cheerful instructions. Notice the groove created by the rabbet strip, that serves as the rabbet at the stem. Of course, kits that haven't provided separate parts for the stem, keel and sternpost, would not lend itself to this method.

-

This is far above anything available in a kit. Beautiful work.. I don't think it would be unreasonable to try to recover some of your development cost in your pricing structure before the cheap knock-offs show up. I know there is already a lot on your plate, but perhaps sometime in the future you could offer headrail upgrade kits for kits like Syren and Confederacy.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

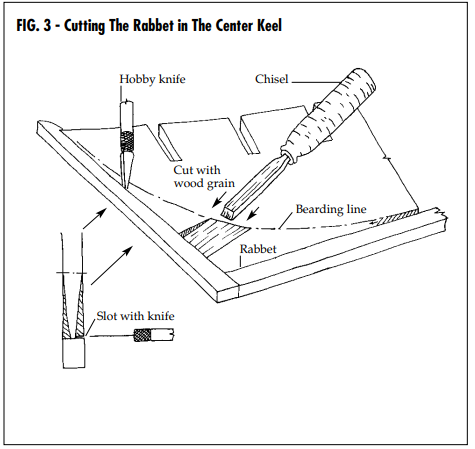

Here is a basic drawing from some of the ModelShipways kits. The idea, is that the final planking fits flush with the keel and stern post. So the depth depends on the thickness of your planking material and whether or not you will be doing single or double planking.. For instance, if the keel piece is 3/16 and your total planking material is 1/16, you would want the bearding line and rabbet to be recessed 1/16 on each side of the keel piece. Regardless of the thickness of the keel piece, the depth of the bearding line and rabbet needs to be the thickness of your planking. There is tapering to be done, but you have to refine that as you go along.

-

I helped out in a school cafeteria for a while. Even though we are talking about simple dishes that the staff had prepared hundreds, if not thousands of times, if a supervisor came through, and you did not have the recipe nearby, you would be severely reprimanded.

-

Reading them, is sometimes the only way to determine they are useless..😄

-

Topsail schooner sail plans and rigging

Gregory replied to Dr PR's topic in Masting, rigging and sails

Now, if you would kindly show all the lines and their belaying points...😁- 104 replies

-

- schooner rigging

- Topsail schooner

-

(and 1 more)

Tagged with:

-

I see you answered your question, but keep in mind, you can do as much or little as you see fit. While my decking would not survive a test of realistic accuracy, I got everything as close as I could within a mm or so, then used the waterway to fill any gap. P.S. Let me add one more thing. When I glued my off the deck planking onto the false deck, I used yellow glue. I had to take few minutes of smoothing and pressure with my fingers until the glue started setting up, which it did pretty fast - 5-10 minutes

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.