-

Posts

5,368 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by BETAQDAVE

-

-

On 4/3/2018 at 2:19 AM, DORIS said:

I love this room in our house; we call it a "harbor", cause you can see more than 40 ship models there.

As intricate as your models are, and the fact that you have so many of them, how do you manage to keep them all from collecting dust?

Is this room off limits from your feathered friends? (We only have one bird and he can put out a lot of dander, especially when he is molting

Is this room off limits from your feathered friends? (We only have one bird and he can put out a lot of dander, especially when he is molting  .)

.)

- mtaylor, popeye the sailor, Piet and 2 others

-

5

5

-

While searching for info on the masts for my 1:96 MS Phantom build, specifically the mast trucks, I came across this mast truck in an antique shop shown below that gave me some idea of its construction.

While searching further I found this picture in Doris's Royal Caroline build.

I made this comment in her current build of the Royal Katherine:

"You really pay attention to the smallest details, as can be seen by the flag at the stern of the Royal Caroline where you even detailed the truck on the flag pole. Now, that is one detail that I have very seldom seen realistically addressed in such a small scale!"

After seeing this photo, I thought that I should be able to make something similar for the upper masts on my build. I haven't made anything in clay yet, but after seeing her version I'll give it a try. (I'm assuming that hers was made from clay)

- mtaylor, Canute and John Allen

-

3

3

-

My father came across one of these on the side of a road, while in France in WWII. He told me that there didn't seem to be any visible damage to it other than the track being blown off. While he was with a mobile anti-aircraft artillery company and never saw one in action, he said he couldn't imagine being one of our tank crews trying to face one of these monsters while inside our own under armed and thinner armored Sherman tanks.

He talked to some some guys who did just that, telling him that their 75 mm shells just seemed to bounce off of them, while the Panzers' 88's just ripped right thru ours. They would try to disable them by going for the tracks, but even having done that, they were still facing an armored artillery piece that was still capable of taking out just about anything we could throw at them!

Until we started getting more of our newer Patton tanks into the war to level the playing field somewhat, we were really taking a beating. Lucky for us the number of these tanks in the field at that time was limited.

While it may be true that they were some of the most formidable weapons of their time, lets never forget all of our servicemen who were killed and wounded facing monsters like this just to make the life we lead now even possible!

- mtaylor, Roger Pellett, Omega1234 and 1 other

-

4

4

-

Was looking back at your Royal Caroline build log and can see that your current build is just more of the same exquisite workmanship! You really pay attention to the smallest details, as can be seen by the flag at the stern of the Royal Caroline where you even detailed the truck of the flag pole. Now, that is one detail that I have very seldom seen addressed in such a small scale!

I showed the video at the end of that build to my wife (who seems to think I'm kind of nuts

to put in all the small details that I try to incorporate into my ships) and she was astonished to see the level of detail that you included. She was particularly impressed by all of the interior details down to the paintings on the walls and the watermelon slices on the table!

to put in all the small details that I try to incorporate into my ships) and she was astonished to see the level of detail that you included. She was particularly impressed by all of the interior details down to the paintings on the walls and the watermelon slices on the table!

I still have a hard time believing that these are built with card stock! Anyone should be able to see now that this build of the Katherine is just a continuation of your skills that frankly tell me that your ships deserve to be in a museum!

-

On 3/15/2013 at 7:48 AM, john46 said:

The decoration is great. Your parrot is very particular, normally speaking a bird is not doing so well when lying on its back. . .

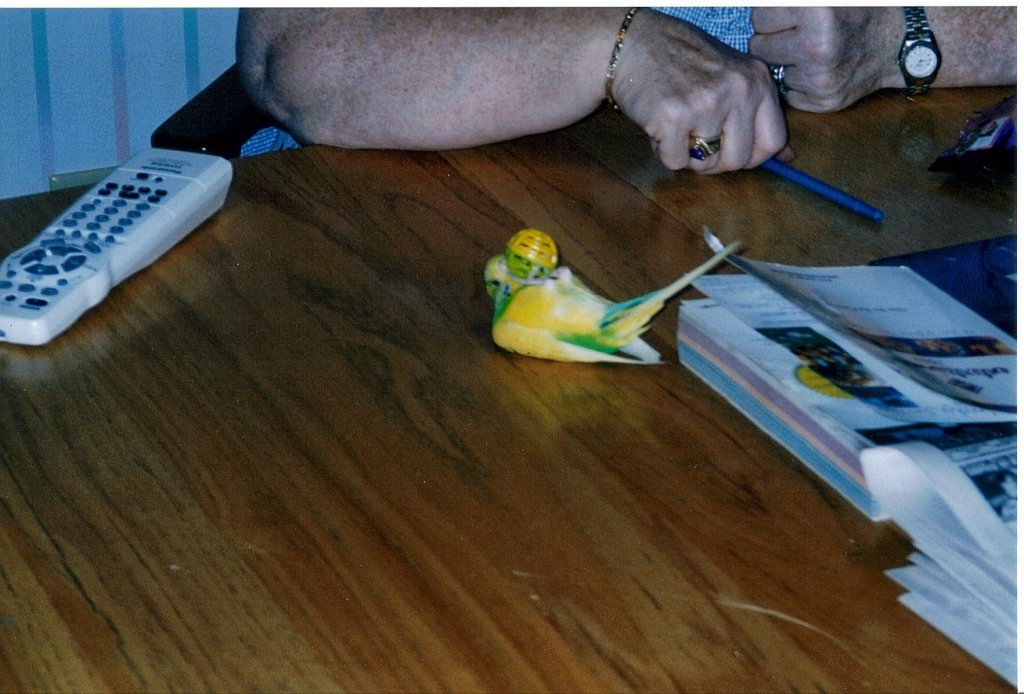

I was just reviewing the Royal Caroline build log and came across the picture of the parrot on its back and the ensuing comment and thought I could maybe add some insight as to the birds' peculiar behavior. We had a parakeet awhile ago who would do the same thing but was generally just looking for some attention or wanted to play.

Here he is with his favorite toy. He could spin it around, throw it away, chase it down and repeat several times. (Maybe he was in a circus in a previous life?)

- druxey, popeye the sailor, Piet and 2 others

-

5

5

-

I think your first order of business would be to look up the Endeavor in the build logs for Ship Model Kits and open the quick-find indexes. There you will even find a couple listings for the kit by Constructo. Good luck with your first wood build, as this will be a totally different experience than plastic kits.

-

On 4/18/2018 at 3:13 PM, Jim Rogers said:

I use Chuck’s hooks and the ones from Age of Sails. I wind up drilling both.

How were you able to drill the holes without twisting or tearing up the hook or having it rotate out of the sheet? Did you back up the sheet with anything in particular?

-

-

On 5/29/2017 at 3:51 AM, DORIS said:

During the weekend I made wooden finish of the hull using foil stripes

Hi Doris

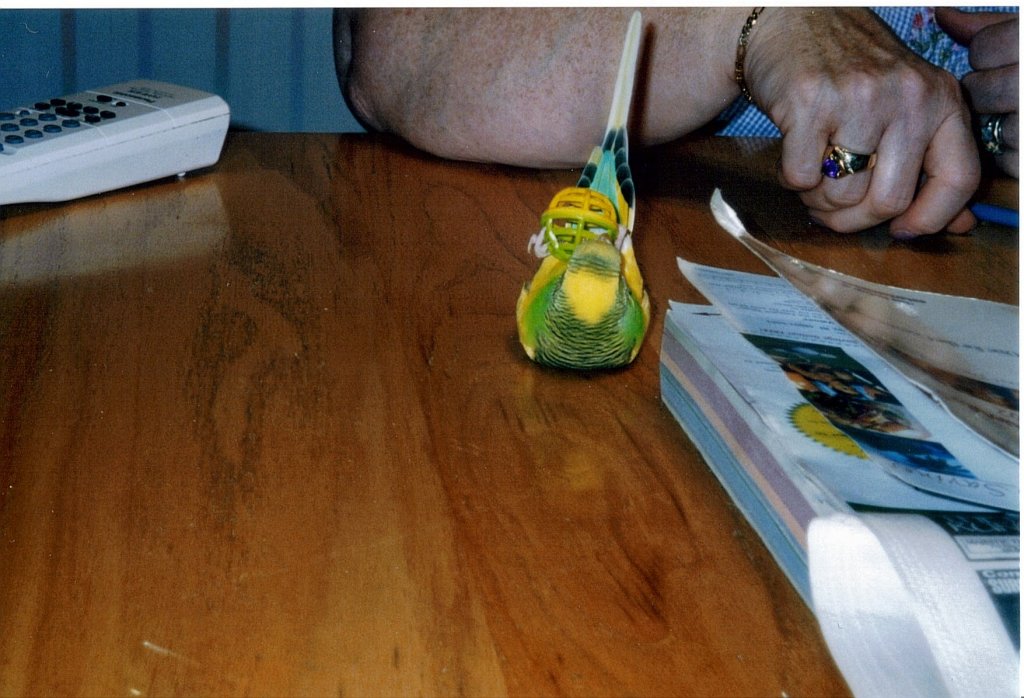

What is your source for these foil strips? Are these part of your card ship kit or can they be ordered separately? The reason I ask is, on my current build log for my hybrid (as Jesse calls it) whaling bark Wanderer, the inside of the bulwarks as you can see here are just smooth plastic.

I was thinking of lining them with a wood veneer to give it the impression of wood but am unable to get anything nearly thin enough to not bring the facing beyond the inside edge of the main rail. These strips that you are using could maybe do the job.

Thanks

- popeye the sailor, DORIS, Piet and 2 others

-

5

5

-

-

Another method would be to plane or sand the wood into much thinner planks which will bend much more readily. Then soak or steam the planks to make them more pliable and bend enough layers of these thin planks to total the required final thickness around a form matching the shape required and clamp to dry. When dry, laminate the layers with a thin layer of glue between and clamp the layers back on to the form and let dry. This may be a bit involved but with this method you can bend planks into very tight bends and there will be very little if any spring-back. Once trimmed and sanded they should be very easy to apply.

- Jim Rogers and mtaylor

-

2

2

-

Another method would be to plane or sand the wood into much thinner planks which will bend much more readily. Then soak or steam the planks to make them more pliable and bend enough layers of these thin planks to total the required final thickness around a form matching the shape required and clamp to dry. When dry, laminate the layers with a thin layer of glue between and clamp the layers back on to the form and let dry. With this method you can bend planks into very tight bends and there will be very little if any spring-back. Once trimmed and sanded they should be very easy to apply.

- mtaylor, John Allen and bluenose2

-

3

3

-

To shape the deck beams with the camber for the ships deck, I first found an appropriate ships curve. I traced around the curve with a .5 mechanical pencil with a soft lead installed from the center mark on the top of the beam to the marks that I had previously put on both ends of the beams.

Taking this beam to my belt sander, (being careful not to sand off the marked center-line) I sanded down to the curve. (just taking off the line)

Now, taking my micrometer to each end I measured them again and sanded the wider of the two of them till both ends matched.

This beam was now marked template #1 and was used to make two other templates marked #2 and #3. Using #1 to make 5 more beams, I switched to #2 to make 8 more beams and finally to #3 to make the rest. Using the templates tends to wear them down if used too often as it was just made of basswood.

With the beams shaped with the camber, I now took the two plastic hull halves to a sink filled with warm soapy water and scrubbed them down with an old toothbrush. This needed to be done to remove the mold release agent from the plastic to allow paint to adhere properly.

- gieb8688, John Allen, JesseLee and 6 others

-

9

9

-

Great! I still think that your tall ship illustrations are some of your best stuff.

- John Allen, mtaylor and Canute

-

3

3

-

Thanks a lot for all the comments guys. This is one of the great things about this forum, many different views on just about any facet of ships, be it models or full size ships! I figured that someone here would be able to come up some answers, or at least where to look for them.

-

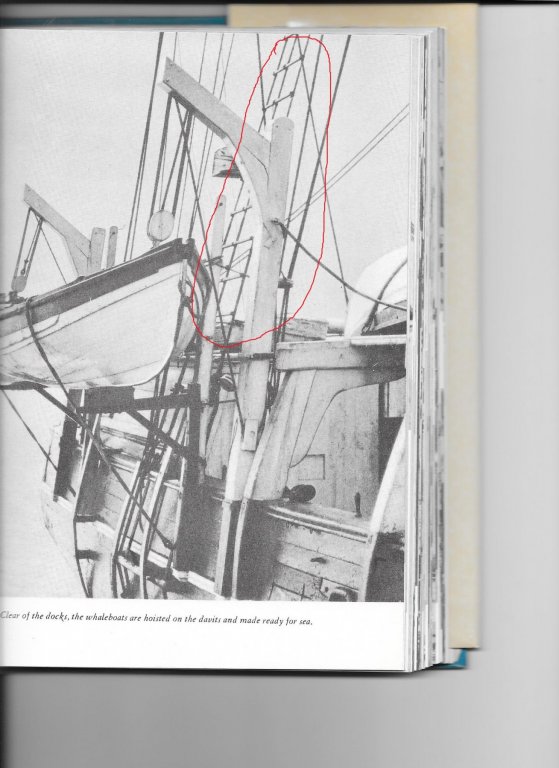

While researching the whaling bark Wanderer, I found that the ratlines were actually bars made from wood or metal. (not sure which but several other whalers were also outfitted with this feature) You can see them in the circled area of the photo below that they were attached to the face of the shrouds, but I was also unable to determine exactly how they were lashed in place. This is another detail that most contemporary models or plans of this ship do not show. (including the Aurora kit and the A.J. Fisher blueprints)

If they were just tied in place, what would keep the ratline bars and the shrouds from shifting sideways? Did they have some kind of notch or pin in the ratline bar to give them better purchase to keep them secured, or would the lashing alone be enough? Does any one else have any suggestions?

By the way this photo was taken from Whale Ships and Whaling by Albert Cook Church, and it is a real good source of info and photos on this ship and several other famous whalers, (including the Charles W. Morgan) if anyone else is interested in modeling this type of ship.

-

This model was just sitting on a shelf patiently waiting for some attention when a friend of mine saw it and wondered if I could build it for his office. While I am currently working on the MS Phantom, I thought I could do both and try my hand at making a build log for this one. I suspect that this method of model building is quite unusual, To tell the truth, I was not certain that this belonged in the kit built category, as the only part of the kit that is being used is the hull with all the rest being scratch built from wood and metal.

My friend was actually interested in a wooden ship, but I told him that I could replace most of the plastic parts with wood. I told him I’ve done that before and he agreed that it would probably look better that way, as the kit had heavy plastic sails moulded right to the spars and the deck had a lot of the details moulded right on which he thought looked pretty bad.

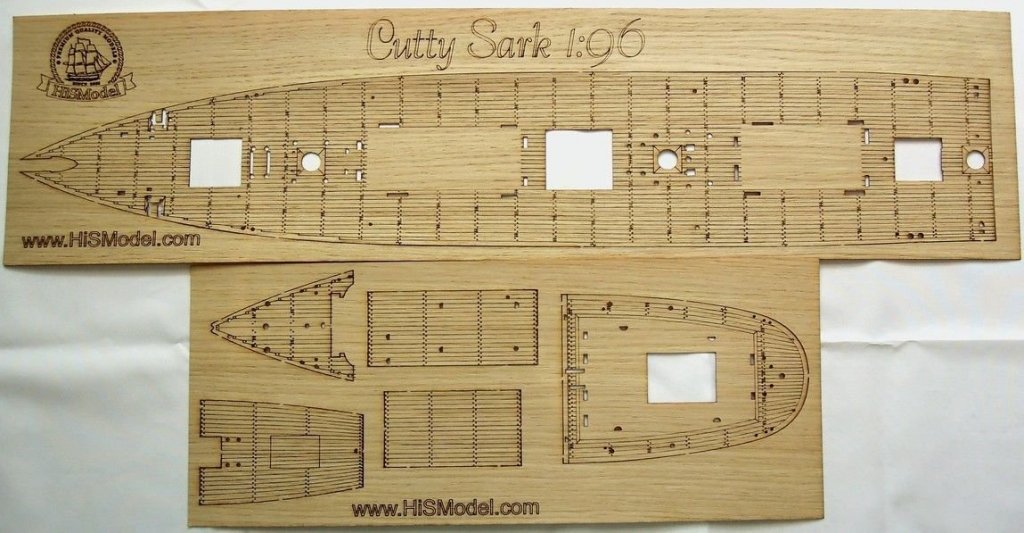

As I reopened the box to examine the kit I found that the instruction manual was missing! Luckily, I had built this ship before in wood and still had the blueprints from A.J. Fisher. The plastic deck was not very impressive with a lot of the details moulded on it, but it was a one piece deck so that would make it easier to use as a template to make a wood replacement.

Before I actually started construction, I decided that I wanted to do a search in the internet for more details of the actual ship. One thing that really caught my attention right off the bat, was the fact that the real ship only had four sails on the main and foremasts and not five as shown both in the kit and my set of blueprints. These two pictures below show both the box art and one of the pictures that I found showing the ship as it was built.

Discovering this, I decided to really do some digging to see if any other discrepancies were evident. There were a few, but nothing as glaring as the sails.

Taking the plastic deck in hand, I traced the outline onto a piece of manila folder including the mast holes, marked the center line of the deck, and transferred the outline of the hatch as shown below.

As the end of the hull was closed in and the tumble home of the hull sides was too severe to allow a one piece deck to be slipped into place, I decided that I would have to split the deck down the middle for it to be installed. I took two 3”x24” sheets of glued up 1/8” wide 1/32” thick decking boards that were glued up with black colored glue to represent the caulking joints and joined them together edge to edge with tape across the backside.

Placing the manila pattern over the pair of decking sheets, I taped them together, being careful to align the center-lines of the pattern and the joint of the two decking sheets. I traced this outline onto the decking sheets and unassembled it to allow easier cutting of the rough outline of the two deck pieces on my scroll saw.

After cutting, the next step was to carefully tape the rough cut decking sheets back together again on their backside and tape these under the original plastic deck. Once again, I was careful to align that center joint of the decking with the center of the plastic deck. This assembly was then taken to my belt sander and sanded close to the edge. I would sand up to the tape and re-position the tape as I went along. (This was necessary because the plastic deck was quite warped and once untapped; it wanted to spring away from the decking sheets.)

At this point the assembly was taken to my drill press. I drilled all of the larger round holes right thru the plastic deck to assure that they would align exactly. (This was especially important for the heel of the masts to align with the mast steps on the inside of the hull.) I then took the whole assembly to my workbench and drilled all of the remaining round holes with matching small bits in a pin vice. Here is a picture below of my progress to this point.

Taking a look here at the inside surface of the hull, you can see that the waterway was already moulded on and would remain. However, the projecting tabs for support of the plastic deck and the injection mold stubs would have to be removed.

Taking my new battery powered Dremel, I ground off all of these unwanted projections and sanded them smooth to allow me to glue some 1/32”x 13/64” basswood strips to serve as a ledger to support some new deck support beams.

I decided that I should make a 1/16” thick basswood sub-deck, as the decking sheet was very thin, so I cut up two sheets of basswood for the sub-deck similar to the decking sheet as shown here. (notice the plastic decking springing away from the tapped wood deck)

Then I made up a spacing jig to help align the top edge of the planking to the underside of the moulded waterway. Taking short pieces of the decking and sub-deck for spacers, I glued them to a thicker piece of wood for a handle as shown.

Here is a picture of the spacer jig in use.

Using this spacer jig as a guide, I used some thin ACC to attach the 1/32”x 13/64” basswood for the beam support ledger and clamped it in place for it to totally set up overnight.

While the hull was drying I decided to work on the upper structure. The first thing I did with the masts and bowsprit was to do a trial assembly without glue of all the components to see how they all fit together.

Disassembling these assemblies, I drew up some dimensioned diagrams of all the components for making their wooden replacements. The lengths were all drawn full size and the widths were written out next to their locations.

Returning to the hull construction, I cut 17 3 ½” long pieces and 4 shorter pieces of 3/8”x 3/16” basswood to use for the deck beams. The kit was designed (as most plastic models are) to have a flat deck, so I worked up a method of adding the camber to it. I marked the center-line of all of the beams on their top edge as shown below.

The camber was scaled off the 1/6” scale A.J. Fisher blueprints and converted to the models 1:87 scale. This worked out to about a 1/16” slope. Flipping over the whole stack of full length beams, I shifted the full size beams up against a piece of 1/32” scrap wood (to account for the approximate 1/32” width of the pen point), and marked all of the pieces on both ends.

I set the beams on top of the plastic deck to get an idea of how to arrange them.

That’s as far as I’ve gotten so far, I will post more later on the shaping and installation of the beams.

- Cathead, Rudolf, Jim Rogers and 12 others

-

15

15

-

I just received my order of Chucks' rigging rope which included the 4 mm hooks. While I am very pleased with the rope, there seems to be a discrepancy with the hooks. The hooks look different than the 3 mm hooks that came my previous order of blocks. Obviously they were a different size,

but they also were not the same pattern.

but they also were not the same pattern. (The rope hole for the 4 mm was actually smaller than the hole on the 3 mm hooks.

A .5 mm drill bit would pass thru the smaller hook but could not pass thru the larger one.) If you look at the pictures above closely you can see that the hole in the small hook takes up almost the entire end of the hook while on the larger hook it takes up much less. Then I looked at the number stamped on the brass and found that while the 3 mm hook was labeled 90006.3mmA (as shown on the web site), the 4 mm hook was labeled 90006.4mm without the A. So apparently the A series must be different from the one without it. Hopefully the A series in the 4 mm hook size is still available for exchange. The larger hole size is the reason I need the larger one as I have to get a heavier line thru it. I would hesitate to try and drill the hole larger as that really doesn't sound feasible at all.

A .5 mm drill bit would pass thru the smaller hook but could not pass thru the larger one.) If you look at the pictures above closely you can see that the hole in the small hook takes up almost the entire end of the hook while on the larger hook it takes up much less. Then I looked at the number stamped on the brass and found that while the 3 mm hook was labeled 90006.3mmA (as shown on the web site), the 4 mm hook was labeled 90006.4mm without the A. So apparently the A series must be different from the one without it. Hopefully the A series in the 4 mm hook size is still available for exchange. The larger hole size is the reason I need the larger one as I have to get a heavier line thru it. I would hesitate to try and drill the hole larger as that really doesn't sound feasible at all.

- John Allen, src and Canute

-

3

3

-

-

Those hooks that you're using look very good also. Are they fittings that came with the kit, purchased, or did you have to make them yourself?

- Canute, Piet, popeye the sailor and 2 others

-

5

5

-

Love your tall ship illustrations!

- mtaylor, John Allen and Canute

-

3

3

-

On 3/22/2018 at 3:47 AM, Dan Vadas said:

There is some unfortunate printing on the lower skins. The difference in colours is quite evident here :

Perhaps a little feedback to Halinski is in order? I am sure that as they appreciate favorable reviews on their products, maybe they would also like being informed of the shortcomings of their products. Most of the good companies usually do. As you have mentioned they seem to have otherwise put out a great kit. I would send them your photos indicating the obvious error!

-

On 2/10/2018 at 6:35 AM, John Allen said:

I had some 2 year old couple of bottles half full hard as a rock. I being cheap started with a little water and drill bits small first drilling many holes at a slow speed than more water and graduated the bit size. It did work but took about 30 minutes.

Thanks for the suggestion John. I took one of my Model Expos "hockey pucks" and was able to resurrect it!

I now poured it into one of those plastic bottles with a cap that allows me to dispense the paint by the drop. Now I'm also planing on making it a monthly routine to shake all my paint bottles to try and keep them more usable.

I now poured it into one of those plastic bottles with a cap that allows me to dispense the paint by the drop. Now I'm also planing on making it a monthly routine to shake all my paint bottles to try and keep them more usable.

This saved me quite a headache as I had painted the inside of my Phantoms bulwarks quite some time ago, and now needed to paint the deck furniture to match, but found that particular paint color was now a hockey puck. My only two options seemed to be either try and match the paint with another brand (good luck with that) or to repaint the bulwarks with another paint that would match the new color.

Somehow neither choice appealed to me, so thanks again for the suggestion!

Somehow neither choice appealed to me, so thanks again for the suggestion!

-

Well, let me be the first of many members to welcome you to the club.

Like you, I started with plastic kits as did many of the other members, and was looking for something a little more challenging. We have a wealth of experience in our club, so if you need help with just about anything about modeling be free to ask as we would all be willing to help.

Like you, I started with plastic kits as did many of the other members, and was looking for something a little more challenging. We have a wealth of experience in our club, so if you need help with just about anything about modeling be free to ask as we would all be willing to help.

HMS ROYAL KATHERINE 1664 by Doris - 1/55 - CARD

in - Build logs for subjects built 1501 - 1750

Posted

I am currently researching methods of making sails from paper (since any cloth would be much to heavy for this small scale) for my 1:96 MS Phantom. To date I have experimented with several different methods, but am not entirely satisfied with the results.

As I was looking at your "harbor", I realized that quite a few of your ships have sails. Since I assume that you make your sails with some type of paper and that you are a very skilled at modeler in this medium, I wondered if you have any info available for the method that you use.