-

Posts

8,149 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by allanyed

-

Poochie, A couple pieces of 1 inch PVC pipe in different lengths and an end cap on each works well to soak wood and saves water and abuse from the admiral if using the bath tub or anything else in the bathroom or kitchen. Allan

-

Royal Louis by fmartins - multi-media

allanyed replied to fmartins's topic in - Build logs for subjects built 1751 - 1800

Fmartins According to Goodwin, for British ships, the lining planks were the same width as the planking in that area, and the thickness was equal to the difference between the normal planking and the thickness of the wales which make it flush with the wales, just as you suggest. Allan -

Royal Louis by fmartins - multi-media

allanyed replied to fmartins's topic in - Build logs for subjects built 1751 - 1800

Fmartins I agree with Mark, the second layer is the anchor lining. Allan -

Many thanks Wayne. These are all very interesting and I see a lot of reading ahead of me. Of particular note in Kenchington's piece is the comment regarding the sketch on page 10 about the lack of contact between most futtocks. There is an obvious gap between at each end of each floor and each futtock on the sketch. Goodwin shows scarphs, not gaps. Ensor's drawing in the Restoration Warship of the Lenox 70, (1678) shows chocks. (Thanks Druxey, I did have this book and forgot all about it - getting old I guess) Is this a pick your poison or would there be variations between shipyards? I have no idea which is right or if all three methods were used. The first futtocks end before reaching the keel in both this sketch and the drawing in Goodwin so I am of the opinion that the frames with floors were first raised and ribbands and or planking put in place, then the frames between floor frames were installed and did not reach the keel. A big difference for Lenox before her first rebuild in 1704 and other ships before 1706 is that the ornamentation was drastically reduced starting about 1706. The galleries by 1706 for example are much closer in appearance to the galleries for the entire 18th century than those of the late 17th century. I took a photo of the cross section of the Lenox (1678) as shown in Restoration Warship and inserted it into my initial drawing that has as the body plan of the Elizabeth from the NMM Collections. The Lenox is 27.75" less in breadth than Elizabeth (1706) but scaling it up it is a near perfect match in shape to the Elizabeth. Next is checking deck framing and planking details between the sources to see if they are at least similar. Progress is being made thanks to all your help. Allan

-

In studying a ship built in 1706 I read the framing description and looked at the sketch for ships built between 1650 and 1710 in Goodwin's Construction and Fitting British Man of Way. He states, and shows in the sketch, the floors rested on the hog, but the first futtocks were fayed and bolted to the adjacent side of a floor and terminated at a position about 18 inches to 24 inches away form the keel. This is the first time I have really looked at pre-1715 Establishment construction so is a new area for me. So far I cannot find another source that describes the first futtocks not resting on the keel. If anyone has more details they can share, I would appreciate it very much. Allan

-

OMG Brasso!!! I remember polishing my belt buckles with that stuff before every inspection. The first few hours was the hardest on a new one to get the darned lacquer finish off the buckle and get to the brass. I also remember worn out brass drain pipes that had been polished with Brasso from the late 1930's to the early 60's when the academy finally realized the cost to replace the piping was not worth the shine. Allan

-

Good point Druxey. Even Longridge's model of the Victory developed a lot of open seams on the planking, but could that also be that was not fully framed? Allan

- 19 replies

-

- separation

- wood movement

-

(and 1 more)

Tagged with:

-

Sorry to hear what happened to you. One should never glue down the planks while they are wet. The results are what happened for the reason you gave. You can wet the wood and then pin the plank in place and let it dry. After it completely dry it is removed and then reset and glued in place. There is no fix for this except maybe filling, sanding and repainting. Allan

- 19 replies

-

- separation

- wood movement

-

(and 1 more)

Tagged with:

-

Books for historic rigging reference

allanyed replied to pshrynk's topic in Masting, rigging and sails

Thanks Brian, I appreciate your response very much. Allan -

Hi Alexander I sent an email to your wizard using Google Translator and he responded VERY quickly with how to find more information on his tools. Now I have to go look and do more translating, but he is definitely willing to add anyone to his client list. It may take some time to figure what I need and to get the details on pricing and how to do a transaction, but for those interested, he seems happy to have new clients. Thanks for sharing the information on contacting him. Allan

-

Chuck, Your photos have once again given me the one reason I miss living n NJ, that is attending a meeting and seeing Cheerful in person. Love the traveler rings. Looks like a rod in a tube then shaped, soldered and blackened. Close? Your Cheerful shows big vessels are not the end-all to having an impressive model. Allan

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Books for historic rigging reference

allanyed replied to pshrynk's topic in Masting, rigging and sails

Pyshrynk (Try sharing your name, real or made up, it may get you more responses) Blue Ensign is right. Even if you find a good book on rigging, and there are many, being a lazy person will not be conducive to making the most of them. Being incompetent is not forever, it goes away with trying and practicing. Being lazy, that will not get fixed by the membership enabling your problem Spend a little time on the search feature on this site, that's why it is here. Allan -

Hello From David - A new member

allanyed replied to David of Berwick's topic in New member Introductions

Hi David, Great intro, you brought a smile to my face. Know that we are all here to help in anyway we can. Allan -

Thanks Dave. I do look forward to using a wooden jig such as you have shown, but cut down as you mention you did recently. Allan

-

Dave, I really like your locator board to hold the deadeyes in place while the shrouds and stays can be turned around them. I see you have not yet done so, but would it be easier to make the shroud and stay cross overs and apply the cross seizing if the top of the jig was even with the top of the upper dead eyes. That way the crossovers and seizing would be above the jig thus easier to make. Page 42 in Lees' shows this area in a drawing better than I am sure I am explaining it. Allan

-

When to varnish

allanyed replied to medic's topic in Painting, finishing and weathering products and techniques

I pin anything possible, even if no finish is applied. Stanchions, gun carriages, pedestals, &tc are all pinned. I use bamboo pins made with a draw plate and cut them as needed. If I have already applied a finish, be it paint or anything else, then have to glue a part, I use a small chisel to scrap the surface to get back to the wood before gluing. Allan -

Great to see you back in the fold Remco. MANY of us are looking forward to seeing new photos of your work! Allan

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

"Gunnery notes" from William Rivers (*1755, †1817)

allanyed replied to dafi's topic in Nautical/Naval History

Dafi, Your post got me looking into it as it would be a great find. I saw the 12 page article by Gareth Cole that was very interesting and he uses Rivers' information as part of his article. One of the most interesting charts Cole gives are the age ranges for gunners on a number of specific ships. I hope you find the source for River's writing and share. If I find it, I will be sure to post it. I sent an email to the National Archives in the UK asking if was possible to get a copy. To get to the Cole paper, Google gunnery notes from William Rivers cole.pdf Allan -

Planking Constitution

allanyed replied to Barbara's topic in Building, Framing, Planking and plating a ships hull and deck

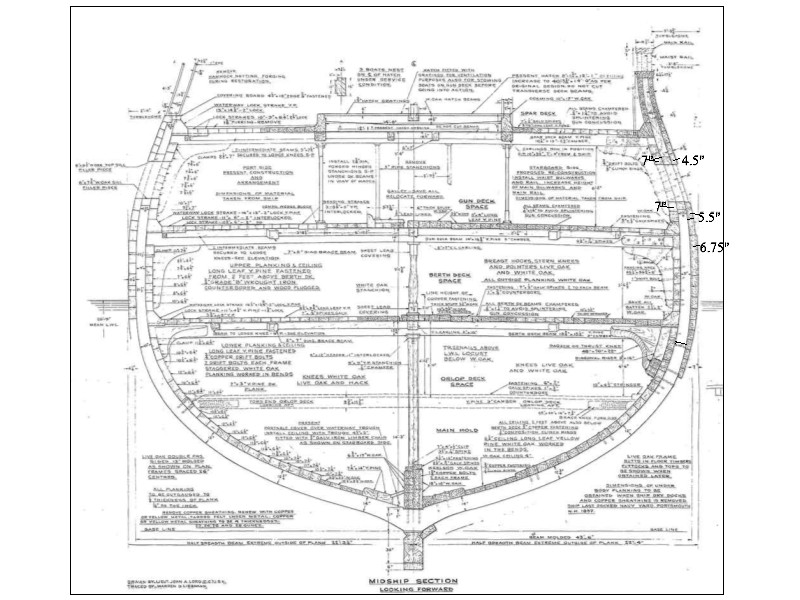

Barbara Hopefully the following will help. I inserted the drawing I found on the net into Turbo Cad and scaled as close as I can then came up with the dimensions I show. The drawing was too small to be able to see the dimensions they already show for some of the planking, but the numbers I show should be very close. Not knowing the scale you are building to I put real world dimensions but you can easily figure out what they are in your scale and see if the kit supplied properly thicknessed planking material. Allan -

Advice for planking

allanyed replied to Slowhand's topic in Building, Framing, Planking and plating a ships hull and deck

Maurice, VERY clever intro to your name (assuming you are referencing the music) As it is 43 years later I am sure Steve, Ahmet and Eddie would be happy. Based on the planking expansion drawings I have seen, for a two to one at the point of the drop, the top plank would normally run short, but the underlying one would continue to the stem. For a three to two drop, the "arrow" the butts form would point forward, not aft. Check out David Antscherl's tutorial on this forum. Overall, looks like a nice job on the 2nd planking. Can't say that I like the open grain of the wood they provide but sometimes one must work with one has been handed in the kit, same as in life. Happy New Year Allan -

Advice for planking

allanyed replied to Slowhand's topic in Building, Framing, Planking and plating a ships hull and deck

Glenn, All tutorials are still here, including planking. Allan -

I usually grasp the wood with a folded piece of sandpaper between my thumb and finger but resort to pliers now and then. The sand paper gives better control. Everything else Russ said as well...... Allan

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.