-

Posts

641 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by schooner

-

-

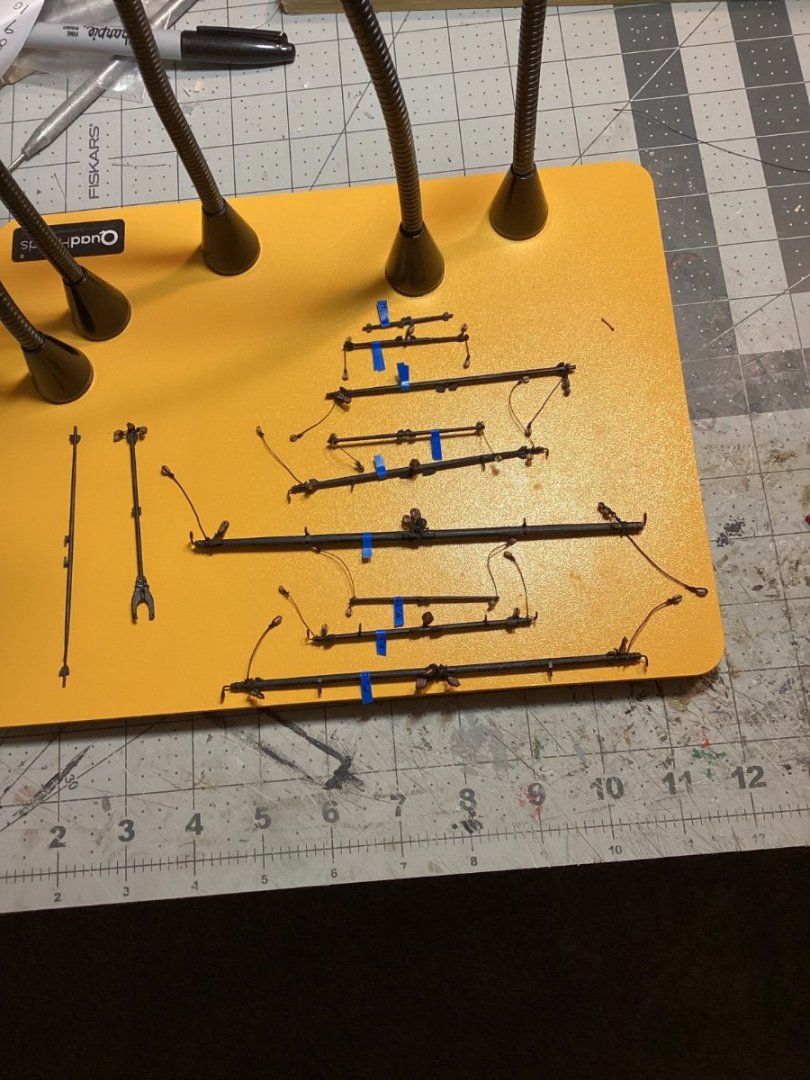

Upper Ratlines

I prepared for adding the upper ratlines by adding the Futtock Staves below the crosstrees and then the carpathans:

The process of adding the ratlines was slow, mainly due to a case of “two steps forward, one step back” as I figured out how to tie them and then had to remove them to try something else.

Although I use clove hitches on my “real” boat all the time they are made using rope (obviously) and usually tied around a horizontal bar. Trying to tie them with thread around another vertical thread kept confusing me. I finally found a great little video on Bruma’s build of the Revell plastic kit of the CUTTY SARK. His video is helpful because the thread is large, he works slowly and best of all, he uses tweezers for everything so his fingers are not blocking the view. It is on post # 366 of the attached:

After watching it several times I finally got it in my head how to do it.

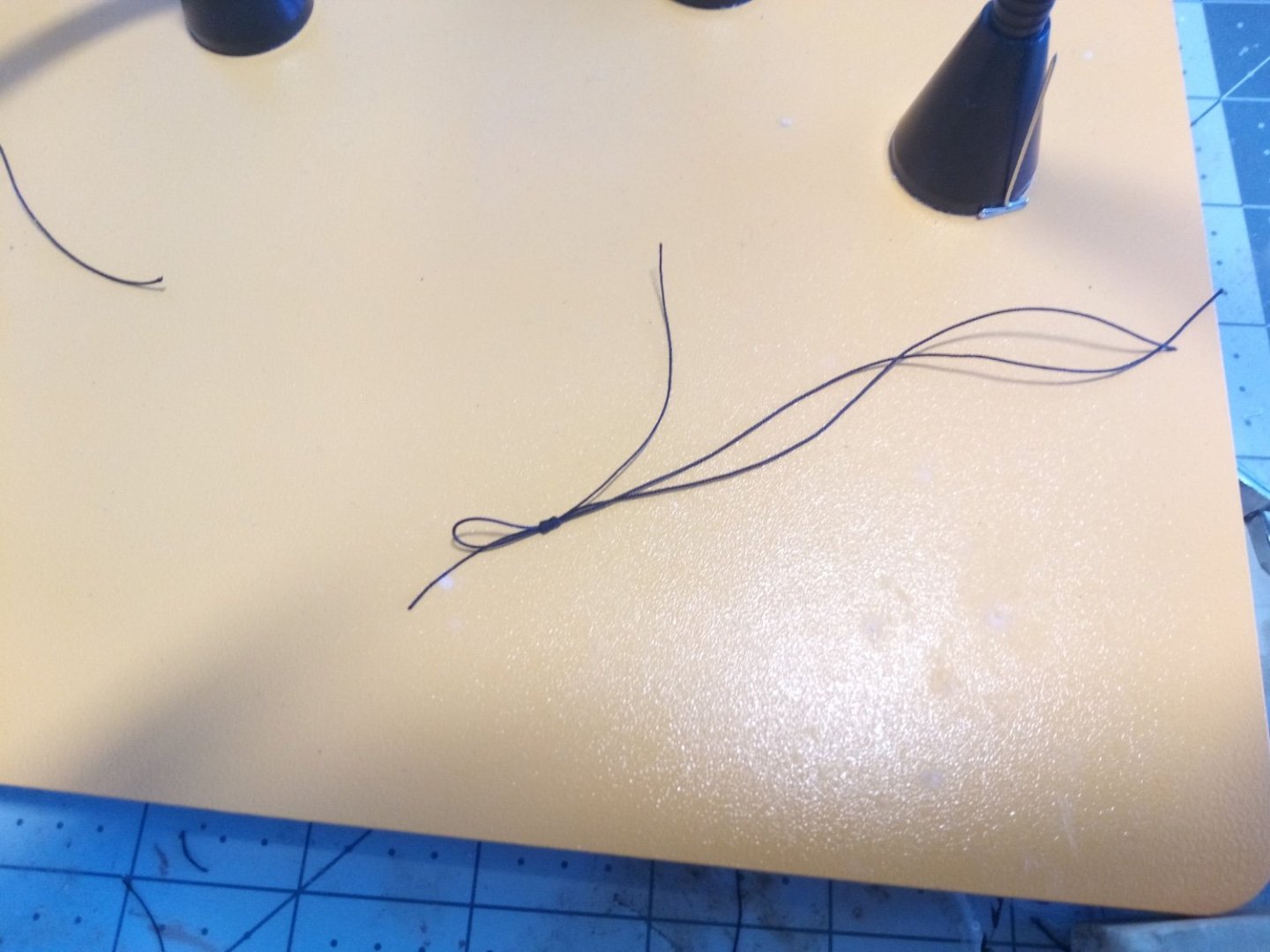

My first attempt at tying clove hitches did not go well - I managed to get them crooked and many of the knots loosened up to the point that loops were clearly visible. Fortunately I had secured them with diluted white glue so they were easy to remove after brushing the knots with water.

My second attempt went much better after I figured out how to cinch them tightly. Then the problem was that the knots were simply oversize at this scale. I tried some super fine thread I have but it was to too hard to see it and to manipulate it with tweezers so I decided to remove all the ratlines I had added to that point and to try gluing them to the shrouds.

I’m satisfied with this result:

Next up will be adding the backstays and the fore stays to the masts.

-

Very nice job with your detail painting! Few paint jobs can hold up to the photo magnification here on MSW but your's looks good no matter how close you look. Cannons look great too.

-

Thanks Keith,

Actually I did try that based on what I saw on your log. The threads I have to use for the upper shrouds at 1:96 are just too narrow (thin) to swing it, even with my wife's thinnest needle. I will try it again when I get to the lower (& thicker) shrouds.

Keep up the great work on the Tennessee, she's a beauty.

- Keith Black and Scottish Guy

-

1

1

-

1

1

-

Great build and build log, nice clear photos!

I really appreciate your posting of the video of how to do ratlines back in September. Although I use clove hitches all the time on my real boat somehow when using thread around another vertical thread I keep screwing it up. Your video is great because you tie the knots slowly and your use of tweezers keeps your fingers from blocking the view of what you are doing. I'm no in the process of tying stress-free clove hitches!

- Bruma, Scottish Guy and Keith Black

-

2

2

-

1

1

-

-

Topmast Shrouds

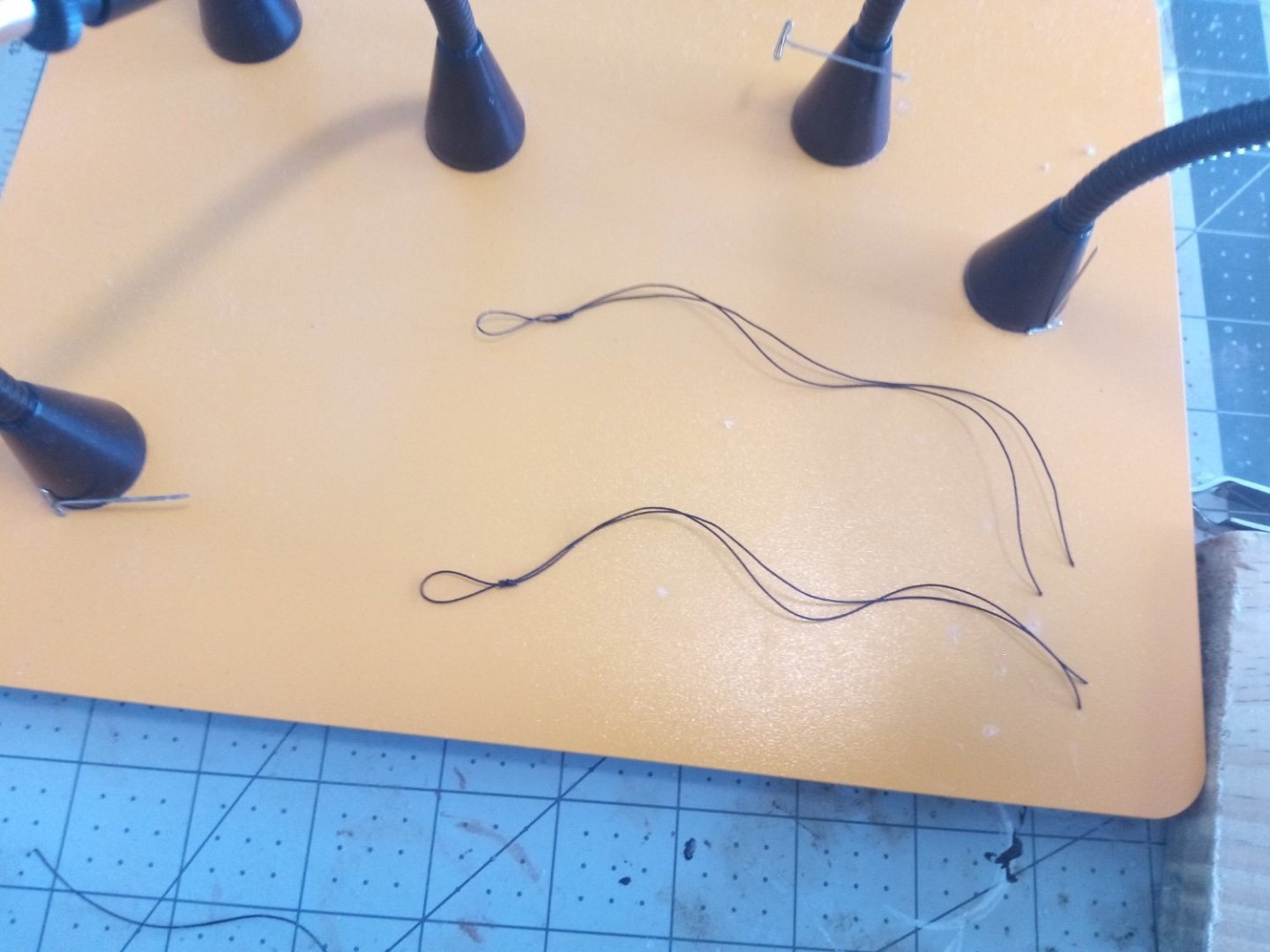

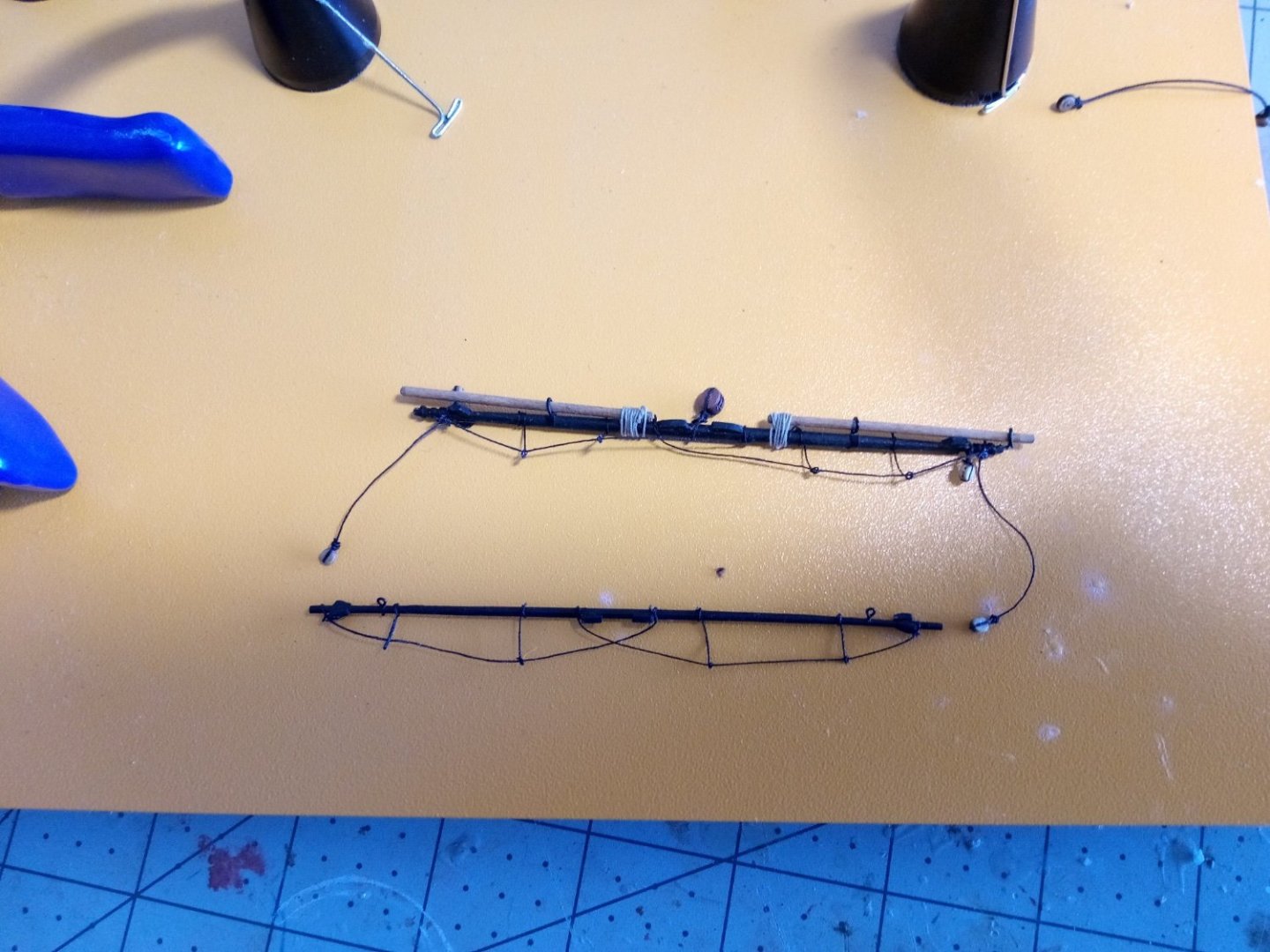

The shroud pairs and individual ones (odd number) were made up same as the lower ones:

A simple jig like that found on countless other build logs was made up with 2 pieces of wire to fit into the upper and lower deadeyes to keep their spacing per the plans and the same to each of their neighbor’s:

Once the shrouds were in place it was just a matter of reeving the lanyards thru the deadeyes and securing them:

Next on the to -do list is rigging the Futtock Shrouds, the Catharpans (hopefully) and the ratlines.

- KurtH, David Lester, whitejamest and 2 others

-

5

5

-

-

Rigging intentions and starting the lower shrouds

As I get ready to start the rigging I thought it might be a good time to explain my plan for going about it, always subject to change since my plans/intentions/assumptions are blissfully free of relevant experience, this being my first real rigging job.

Resources

- The kit’s instructions contain a general discussion of how to go about the rigging but they assume a level of experience/knowledge that I don’t have. The rigging diagram is one sheet of plans that shows all the standing and some of the running rigging - it is a real spaghetti pile that I find hard to pick out individual lines from but it is useful for figuring out shroud lengths and deadeye spacing. The instructions do contain good info with regard to line sizes and the belaying diagram is fine.

- I will be using a mix of kit-supplied Brittania metal blocks and wood ones from SYREN Ship Model Co. For rigging line I will be using a lot from SYREN with the sizes being the closest match available to the kit’s.

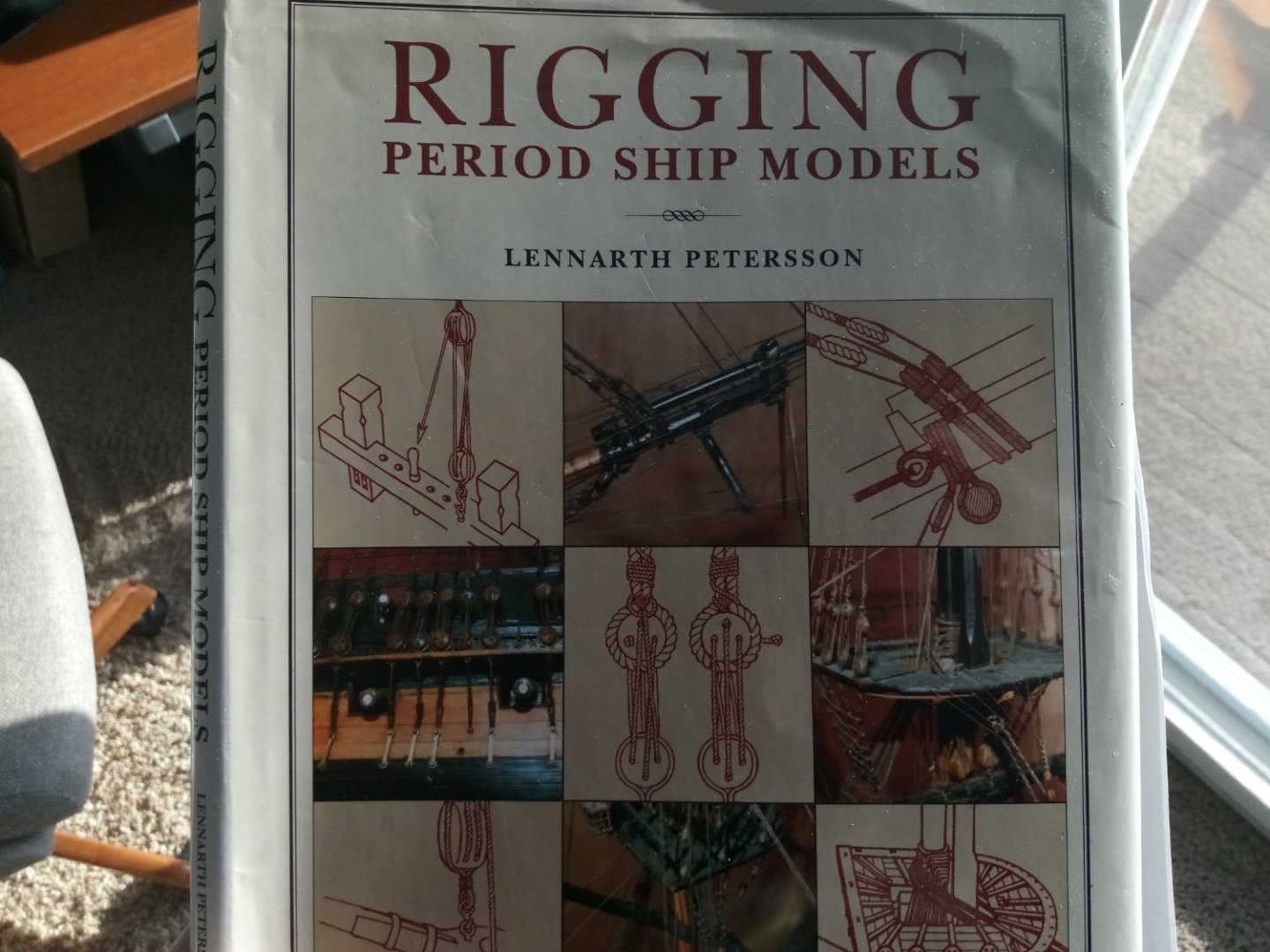

- I’ll be using Lennarth Peterson’s Rigging Period Ship Models as my primary reference for what to rig. The book is based on the late 18th century Royal Navy Frigate HMS Melampus. It has almost NO text but is made up of a clear diagram for each rigging line. It has the advantage that they are arranged in a sequence that makes sense for rigging a model with minimal interference between new and previously-rigged lines. The book does not contain any information about line or block sizes nor are the diagrams to any consistent scale so dimensions are not useful. It does have diagrams of all sails and their rigging for those who want to go that far and it does have belaying diagrams although I will be using the kit instructions since ALFRED had a lot fewer belaying pins than MELAMPUS. The differences between ALFRED and MELAMPUS are mainly ones of subtraction; ALFRED did not have a spanker boom, martingales, boomkins, flying jib, spirit sail topsail yard or royal yards.

General plan of attack

This is going to be a challenging rigging job because of space constraints. To start with ALFRED was a small ship and at 1:96 (1/8”) scale there is little room to work on belaying rigging, for example there is less than one inch separating the aftermost deadeye on the main chains from the forward most on the mizzen chains. Because of this I plan on including all of the standing rigging but only those running rigging lines that are associated with controlling and securing the yards (i.e halyards/slings/jeers, lifts, and braces). I will also attempt to rig each mast as much as possible, including the upper shrouds and the yards, before stepping them so that I can secure the running rigging lines that are tied off around the mast bases and many of the stays before securing the shrouds.

Starting the lower shrouds

After dry fitting each mast in place I used a piece of line to determine the shroud length for each mast, leaving what I hope is enough extra to allow for seizing around the deadeyes. I held off attaching the topmasts so that I could make up the shrouds off the mast and then slip them over the masthead before the mast caps are installed. The shroud loops are secured with an unglued seizing that can be cinched up to the mast head and then brushed with diluted white glue.

All 16 shrouds were easy to make up in this manner and were added to the masts, alternating each pair, starboard to port and forward to aft. They are all labeled with a small piece of tape holding the pairs together.

- KurtH, etubino and mort stoll

-

3

3

-

-

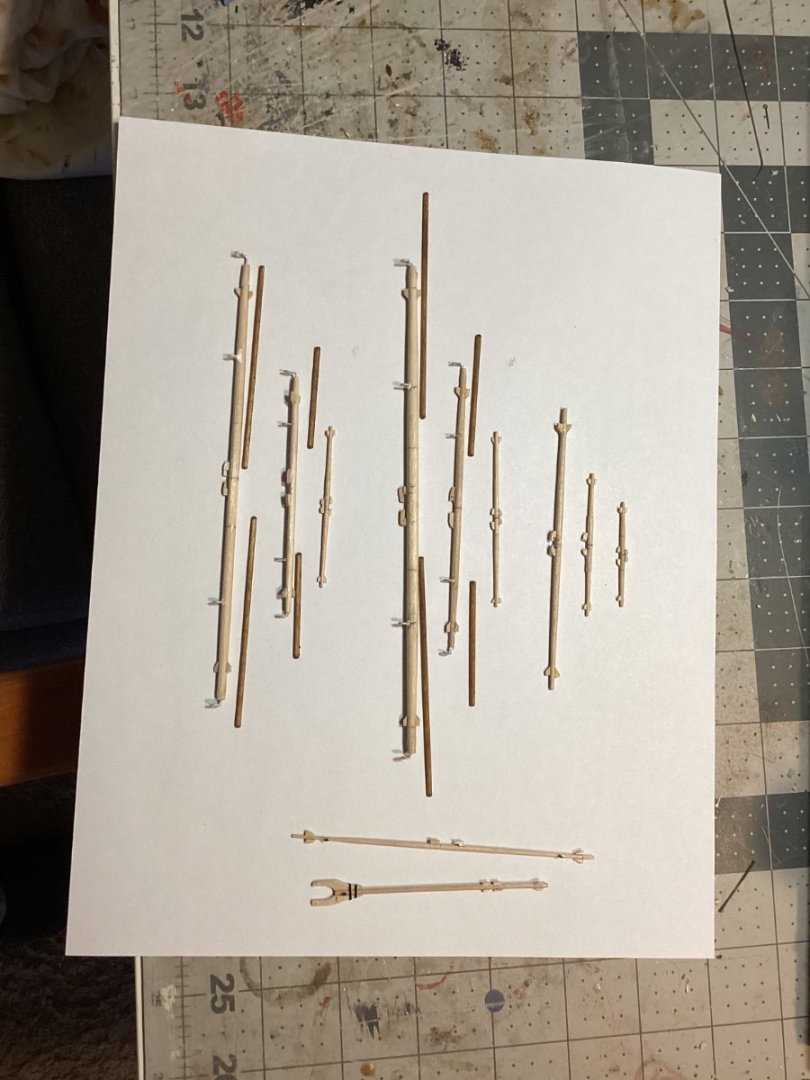

Foot ropes and Burton Pendants

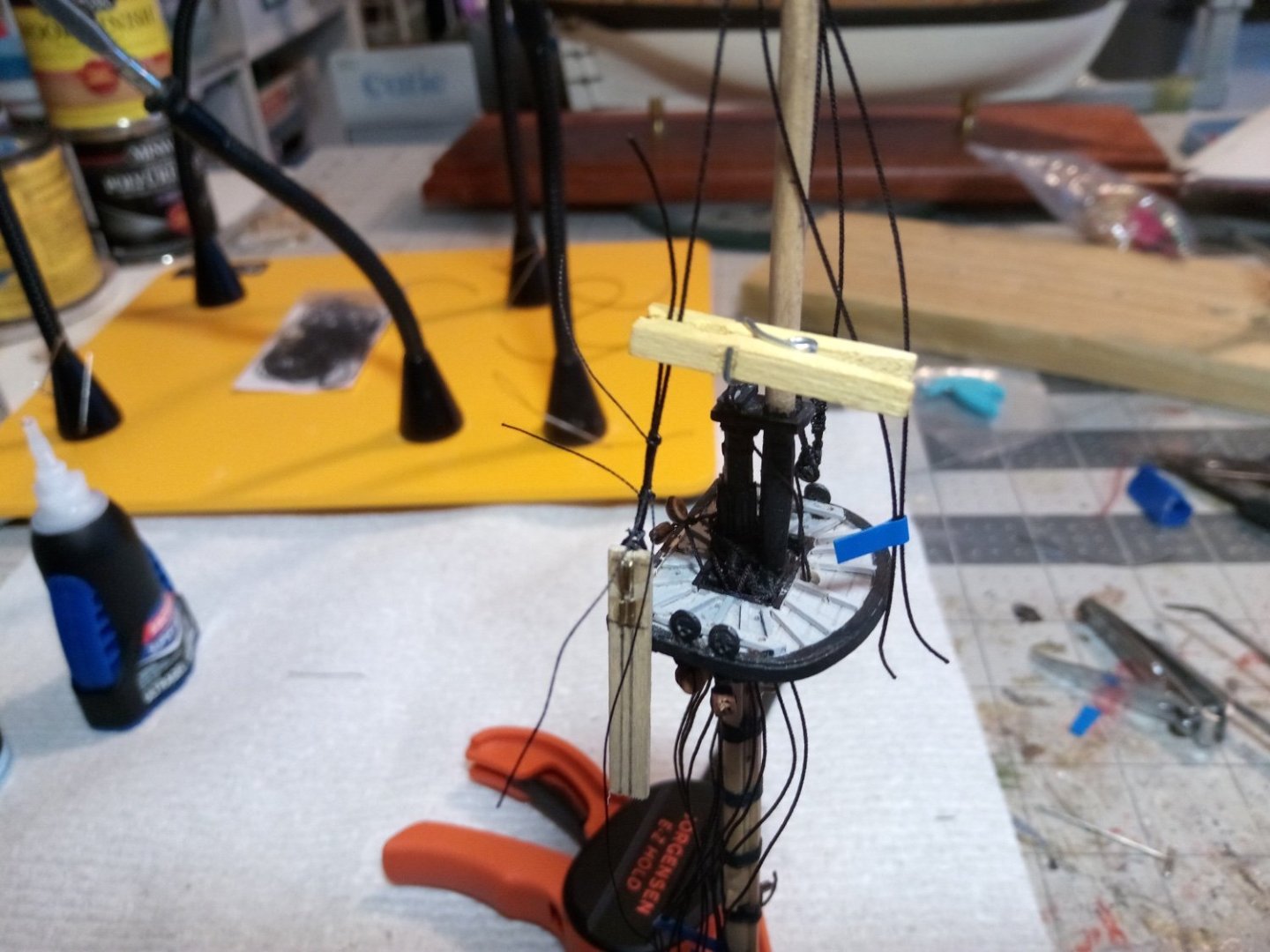

I’d originally planned (hoped) to use some very small eyebolts I have on hand for the foot rope stirrups (the vertical lines that hold up the inner portions of the foot ropes). Unfortunately at this scale the upper yards are too thin to withstand drilling with even a #74 bit so I had to go with thread. After some trial and error I finally settled on making the stirrups by starting with an overhand knot tied around a needle to form an eye and spot glued to hold it. The stirrup was then led down the aft side of the yard and tied off to the eye would be 2-3 scale feet below the bottom of the yard. The foot rope was then tied off and one end, threaded thru the stirrups and secured at the other end. Once fabricated the stirrups were weighted with some small clothespins and everything was brushed with diluted white glue to stiffen them.

Next up was what has got to be the easiest part of the whole rigging process - the Burton Pendants which were anchoring points for blocks when handling heavy loads on deck. Two bullseyes were seized at opposite ends of a piece of line, they are then looped over the crosstrees of the tops and upper shrouds. The Fore and Main masts get 4 lower ones and 2 upper, the Mizzen just gets 2 lower ones. The pendants will all get the white glue treatment to keep them hanging vertical.

Next up will be adding the lower shrouds to the masts.

- mort stoll, KurtH, chuckthedragon and 3 others

-

6

6

-

Agree with the 2 footers being the largest practical size for a model that does not become a piece of furniture when cased, at least for sailing ships.

As far as specific ships I think the cutter Bear or the west coast schooners Wawona or Thayer would be great. As far as USN subjects the armored cruisers of the Tennessee class (4 ships) were stunning in their as built white rig, plus each was first named for a state and later renamed after a city so that might increase their marketability/appeal.

- Canute, mtaylor, GrandpaPhil and 3 others

-

6

6

-

Thanks for the kind words and the likes. I've been plugging away on the foot ropes and will then double check to make sure I have mounted all the blocks on the masts that I can at this point and then it will be time to actually start rigging (finally!).

-

-

-

Glad to be of help Ramsey, it is a great kit. Don't hesitate to PM me if you have questions.

-

Great painting and decal work!!

- patrickmil, Old Collingwood, mtaylor and 1 other

-

4

4

-

-

-

Geoff, although I have not got to the point of adding the futtocks and cartharpins I did find a good explanation of how to to them on Glenn-UK's build log for HMS Sphinx, starting at post # 281 for the lower ones and #367 for the upper ones.

You are doing a great job, keep up the good work.

-

-

Great choice Rod! That is one classy kit. I'll be following along.

- mtaylor, Knocklouder, Canute and 1 other

-

4

4

-

This is a great lesson on small boat kits whose ideas can be applied across many different kits and kit brands since they most of them follow the same basic construction sequence,

even lift-type hulls can still benefit from your ideas on detailing the interior.

Your techniques are very helpful since they do not require elaborate shop machines.

You have shown what planning, patience and attention to detail can accomplish - I just wish I had them.

I'll be saving this build log. Keep up the good work and thank you for taking the time to build it.

-

-

Lightship #112 NANTUCKET 1936 by Jeff Preisler - FINISHED - BlueJacket Shipcrafters - Scale 1/8" = 1'

in - Kit build logs for subjects built from 1901 - Present Day

Posted

Great job!!!

The hull lettering looks very nice, are they decals? stick on letters? painting stencils or something else?