-

Posts

1,171 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by jud

-

-

-

Sorry you were down, missed my chance to whip your ***, didn't I. Glad you're feeling better. Think about it, two wet rags going at it, wondering why, dripping all over the place and along comes the wringer. Be watching for your progress on this Boat, it has kind of grown on me.

jud

-

Tools are tools, which to use is a mater of preference, confidence, knowledge and the availability of tools to choose from. I may choose to measurement using cubits, 'IE 14.7 cubits, the .7 being an eyeball best guess', and a slide rule for the math or a calculator if I need to measure that result somewhere using a measuring device marked in meters. I prefer to work in decimals, decimal feet unless I need decimal inches, you will find lots of little pencil marks around my fabrication projects. I may measure using a decimal scale with 10, 10 or a thousand divisions regardless of scale, imperial or metric, scales are a simple conversions, divisions are visible things that create refinement in the eyeball reading of a measuring tool and are the single most used method of refinement in any measurement until needing to think about technique to avoid repetitive and cumulative errors. Wife was an inch, foot girl, a defect in her early potty training, had to rid the place of such marked measuring devices, until the lesson was absorbed with comfort, that the end of fractions did not destroy her world, only requirement, was to be aware of the division, inches or decimal feet, I have pocket tapes with both, amazingly the foot marks are common, not double. Why pick on the wife? She wanted, and did help me in my work, Inches were a problem in a decimal world.

-

Hhhmm, just thinking about error addition/multiplication ... using proportional dividers to mark out n equal divisions for planks along e.g. the circumference of a frame requires that you apply the dividers n times, thus likely adding n times an error of similar magnitude, e.g. because the dividers slip a bit on the woodgrain, parallaxes, etc. If you were lucky, you would make as many positive as negative errors, so that you would end up at the desired end-point. You could do the same process from the opposite end again and then middle out the differences. Not sure one gains a lot of time.

Learned long ago when laying out multiple points along an object, not to measure and mark each one individually, error in the measuring device will multiply and accumulate. Determine spacing, use a measuring device that will reach the full length, pick a scale that has the most number of divisions per inch, determine how many of those divisions equals the desired distance. With that lay your measuring device out with the beginning end securely held and mark the first distance, move nothing but your marker and mark the next point by adding the first distance to the next and mark the sum, continue adding and marking the sums and you will have well spaced marks, may be some random isolated errors but they remain where they occurred. Amazing how fast errors can accumulate by repetition. A method taught in basic surveying. not appreciated until you see it at work, matters not if you are laying out stations on a highway or stations on a model, same factors and principles at work.

jud

-

Suspect that the use of proportional dividers becomes a habit, the tool you automatically reach for. I remember sitting in the Student Union doing some homework and a very simple division question came up that was a step in a solution, something like 12/3, I reached for my slide rule, that stopped me and got me to thinking about what I had just done, looking around and such things happen all around us. Dependency or habit? I like to think habit but I know the panic when I find my pocket knife is not in my pocket. Creature of habit, I think we be.

jud

- mtaylor, captainbob and Canute

-

3

3

-

Have you considered Paper Mache? Recipes on line and is is a versatile material that could be used as a form, then sealed for use or the hulls could also be made from it. I have never used it since the first grade when all of us little darlings made some trinket from it for our mothers, do remember the sore thumb from poking cloves into a fresh apple until no apple remained in view, intended to sweeten up the smell of a clothing drawer, after she had passed on we found it in one of her dresser drawers, dried out but still smelling like cloves, sister has the thing, must be close to 68 years old now. Anyway lots of useful and decorative things are made using Paper Mache, might check it out on line. You probably have most, if not all, of the ingredients in the kitchen.

jud

-

The easiest way to resolve the issue is to carefully apply some white-out to the plans over the guns. When dry, accurately redraw the guns to match what is available. Your model will match the plans.

jud

- uss frolick and Canute

-

2

2

-

Hi Jeff

Thanks for the article.

Hi Jud

I was talking to the jeweler about doing some very small silver soldering n the broken stanchions and talked about a small torch for my ox-acetylene set up and he said to use the oxy-propane because it was much cleaner, that there was no soot with the propane. when he lit the propane it was very clean burning and then he turned on the oxygen and gave me a demo of the little torch. I was impressed with the way he handled it. I still have my Acetylene torch and for some work I will still use it.

I hope this answers your question adequately.

Michael

Michael, thanks, suspected it may have had something to do with the soot that can come from acetylene.

Let me add, You are doing an exceptional job on your restoration project. Frankly I expected to see the parts returned or replaced but most of the damage obvious in the finished project, wrong again.

-

Michael: Acquired one of those, ' Smith, The Little Torch ', setups with the hose, torch and tips, 1, 2, 3, 4, 5 and 6. Tip number 1, 2 and 3 are tips with sapphire orifices. This torch being a gift has resided in the box for a few years, have looked it over and read the manual to see what I had. Felt it was worth keeping around for small soldering and brazing jobs, perhaps even some torch welding could be done with it. Have a couple of acetylene torches, each with their own carts, own the bottles and the regulators are two stage regulators so from what I read in this little torch manual was of the opinion I could use one of my torch setups by attaching to my existing regulators and use oxygen and acetylene in the little torch. Manual calls for tip numbers 2 and 3 for that gas combination. You apparently sought out some advice from an experienced user and chose to use propane and oxygen with a number 4 tip, matches my manual instructions. Now I get to my question, why choose propane when you already have an Oxegen - Acetylene setup with regulators, you must have a good reason for that choice, could you enlighten me please?

jud

- mtaylor, Chasseur, FriedClams and 2 others

-

5

5

-

I wonder if used nylon stockings or pantyhose would work.............

Jim

X used to wear pantyhose, seemed to pass gas fine, never noticed any dust.

- mtaylor, CaptainSteve, mrjimmy and 2 others

-

5

5

-

The Colors at anchor were flown from this Flag Pole, probably rigged this way for years using a single pulley, swivel snaps and one line with, in this case opposing securing hooks. This gun was maned 24-7s and the gun crew took care of the flag, hoists and lowering while at anchor, the Colors were flown from the cross arm on the mast while underway. The following are all related to the one pole, starting with location, then retrieving the end after a swivel snap failure and the last a photo of the Colors flying from that pole taken from the gun. I thought it made a nice sequence.

-

Looking good with all the details you are adding, have been waiting for someone with a little experience on small working boats to point out what a hazard those line hooks on the outside of the fish box are to the seamen working the decks. The idea of providing a place for rope and lines to hang off the deck is a good one, just move them up to a bar placed corner to corner on top of the corner posts of your fish box, holes with belaying pins, hooks or rings would get the ropes up and not be a hazard to the crew working the decks. Sorry for sounding like all I do is find fault, but what you are and have been doing on this model is good enough to deserve some fine tuning and My intent is to be constructive in this observation.

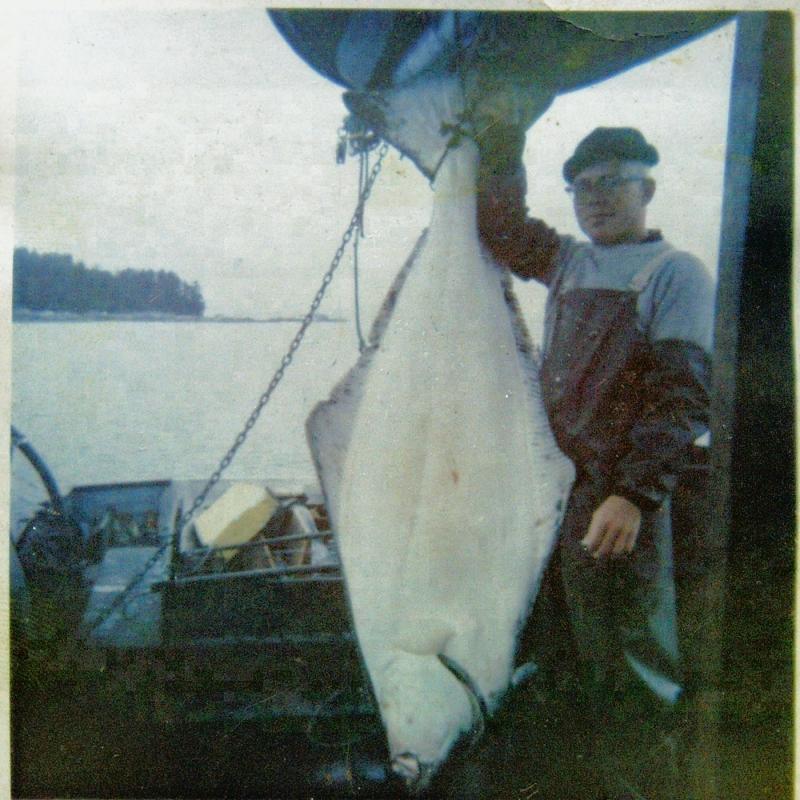

Aboard the Cape Race, 'Troller', SE Alaska 1965. we brought her up from Belingham and returned there in the fall.

- canoe21, popeye the sailor, BANYAN and 5 others

-

8

8

-

From what I am seeing on the first reference Mark has on his list, the stun sails were never bent onto the yard stun sail extensions, they were bent onto their own short yard which was hauled up to the stun sail yard extensions with two lines through blocks and hung a little lower than the yards. I wound expect to see a dedicated block on the end of the yard and another at the end of the extension and used to hoist the surn sails into position, each with their own light free hanging yard. Storage, I would expect that after drying, the stun sails were wrapped around their own yard, secured into the wrapped configuration and struck below as a unit.

jud

-

Hope your bear gets to feeling better, looks very unhappy. Reminds me of the way all those Canadians rushing the docks looked when we tied up while coming back from a summer of fishing in Alaska. In 1965, British Columbia suffered from the great beer strike and were out of suds, every boat traveling through from Alaska was checked for beer, maybe some of your family have talked about that disaster.

Enough BS, like your shop setup and think you have asked a good question that needs some more discussion. A bellows would take care of gas expansion and contraction, the out gassing could be minimized by the passage of time before sealing, UV light can be turned by glass coatings and unless the internal lighting was 24-7s would be insignificant. There are some old models out there that have survived well, don't know if you could improve on that, finding out what materials were used in the model and the environment it was in would allow duplication, perhaps that is the best route.

jud

Merry Christmas

- mtaylor, thibaultron and Canute

-

3

3

-

The photos posted in post number 10 show two tail tackles being used to hold the gun against the breaching ropes for loading, what I would expect, much quicker and handier than placing blocks or other methods of fouling the carriage into submission so the gun could be serviced. Also I studied the Vasa footage and noticed that by the time the gun had traveled to the end of the breach rope limits, it was just coasting, still a large mass to stop suddenly. Those large wheels, clean deck and no rigging to cause drag one would allow for the long movement seen in the video, but it does not represent reality, only the physics of the forces at work on that setup. Going to stick with my opinion about how and what was done to control and disperse the forces of a recoiling gun, it was not the breach ropes that were relied on for that, they had other important uses. All the large guns I was around used distance and drag to control recoil while storing energy in a counter recoil system to return the gun to battery. The cannons of old required the same control, physics are the same, just used different technology to deal with potentially damaging forces. Time and resistance, not brute force, was proven to work long ago.

jud

- thibaultron and Canute

-

2

2

-

The tackles left to run would act as a shock absorber, and a good one, as anyone who has pulled blocks apart have discovered. I suspect that the breaching ropes were there as an emergency stop and never intended to bring the gun to a sudden stop. To service the gun, the rear set of blocks were probably used to pull and hold the gun at the limits of the breaching ropes until it was time to return the gun to battery. Any mass like a gun and carriage brought to a sudden stop would cause damage, experience would have taught even those uneducated seamen that, and they would have quickly done something to prevent it.

jud

- mtaylor, thibaultron and Canute

-

3

3

-

The object was not to clean, it was to swab with a wet sponge to extinguish any embers and to force out any remaining explosive gasses, then to load, ram, run out, prick and prime. Being forced to stand alongside the barrel to do these things was a safety measure, even used ashore, so there was no difficulty or anything unusual in serving the guns from the sides. If an individual was handicapped, the gun captain would not place that individual in a position to slow or disrupt the working of the gun.

jud

Greasy hand in RVN

- thibaultron, BANYAN, mtaylor and 2 others

-

5

5

-

The direction of the load should control the direction of the deck mounting configuration, the extension is there to resist rotation and a foot on the deck does better than one held by bolts. Also remember that a man can lift more than their own weight if they are in shape, when hanging from the bars there is only weight and if something lets go, flight, so the setup must be so the bars are lifted. It is the direction around the drum that controls where the seamen must stand to lift on the bars. If a dog is not trusted or fails the bars and deck could be used as a stopper, but only if the rig was orientated to allow for that and the load line was lead to the drum so the turns were in the proper direction. When any load is to be controlled, the direction of the forces must be thought through, one size never fits all..

jud

-

I have a drawing that was one by Leonardo of a ball bearing set up.

Michael

Looked it up michael. A drawing can be found in 'Leonardo da Vinci's Ball Bearing'. First filing for a patent of the modern bearing was by Phillip Vaughn in 1792 in England. Just had to look that up and spread it around.

jud

-

-

To answer your question about the vac pipe - doing it now would be easiest. If you do not ultimately install a

remote central vac, all you will be out is the fee for the time it takes the carpenter to drill the holes and

the cost of the plastic pipe and cement.

I would use at least 2.5" if not 4" pipe. Run the pipe to three locations: the wall with the window and each of the

walls perpendicular to that wall. There will be several "T" connectors and right angle units involved but again,

now is simple, after it is finished, it can get ugly to retro fit.

Run some 12 G Romex along with the pipe. That will make easy to supplement your power needs in the future.

Very good suggestion from Jaager to place the vacuum plumbing and wiring in place now, even if not planning to finish the system, when or if you choose to finish, the cost will mostly be for equipment, not instillation.

jud

- druxey, Nirvana, thibaultron and 1 other

-

4

4

-

Grandad had an ozone generator that was claimed to charge or change the polarity of the particles suspended in the inside air and cause it to fall to the floor. It had about 4 or 5 hollow glass tubes that glowed, different than neon and made a buzzing sound, the visual and sound effects were there. Don't know if it worked, could always smell it when we visited and it didn't kill him, stomach cancer did that.

Snake oil, don't know, but he liked it and it was his house.

jud

-

You could put that cyclone system outside and plumb your shop with PVC pipe like a central vacuum system. It is very dusty here, 'volcanic ash', When I bought my side by side utility vehicle and took it out across some summer fallow, the air cleaner quickly filled, dust got by and damaged the carburetor. It was a design flaw that I thought the factory should have payed for but it was me that bought a new carburetor. The air intake was under the vehicle, right down in the dirt, so I rerouted the intake using exhaust pipe up high and behind the cab. Bought a cyclone pre-cleaner and a larger air cleaner filter and housing. Did that because I had seen those pre-cleaners work for years on farm tractors working in harsh dust and knew they work. Your cyclone would do the same and if sized right, and vented outside, would probably only need a catch container for the solids. Sure beats listening to a shop vac or if not wanting that you could loose a lot of your hearing like I did, that doesn't help a bit either but makes a good story.

jud.

-

You just gave many of us a nice, one stop source of, making for ourselves, successful Third Hand guide and ideas.

Thanks !

jud

- Canute, thibaultron, michael mott and 3 others

-

6

6

Where is the deck?

in CAD and 3D Modelling/Drafting Plans with Software

Posted · Edited by jud

Fletcher's had flush decks. This is the USS Ammen DD 527 after a collision in 1960, killed 11 shipmates and injured 25. You might be able to pick out some deck details from these photos. These photos are of her configuration after the post war upgrade when one 5" 38 was removed along with one torpedo launcher between the stacks replaced with 3" 50 guns. Hope you can pick out some useful hull details from these photos.

jud