-

Posts

4,015 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by glbarlow

-

-

Great work on the rigging detail!

-

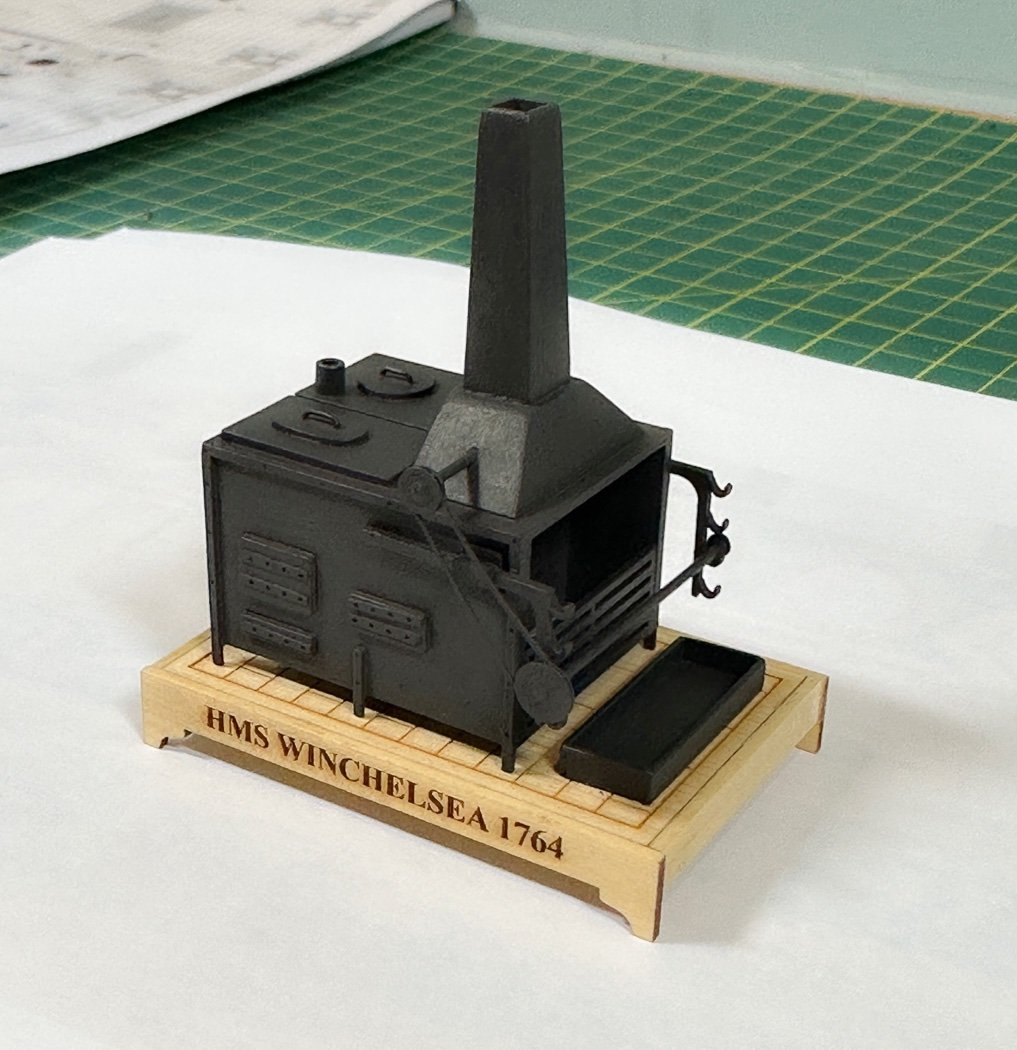

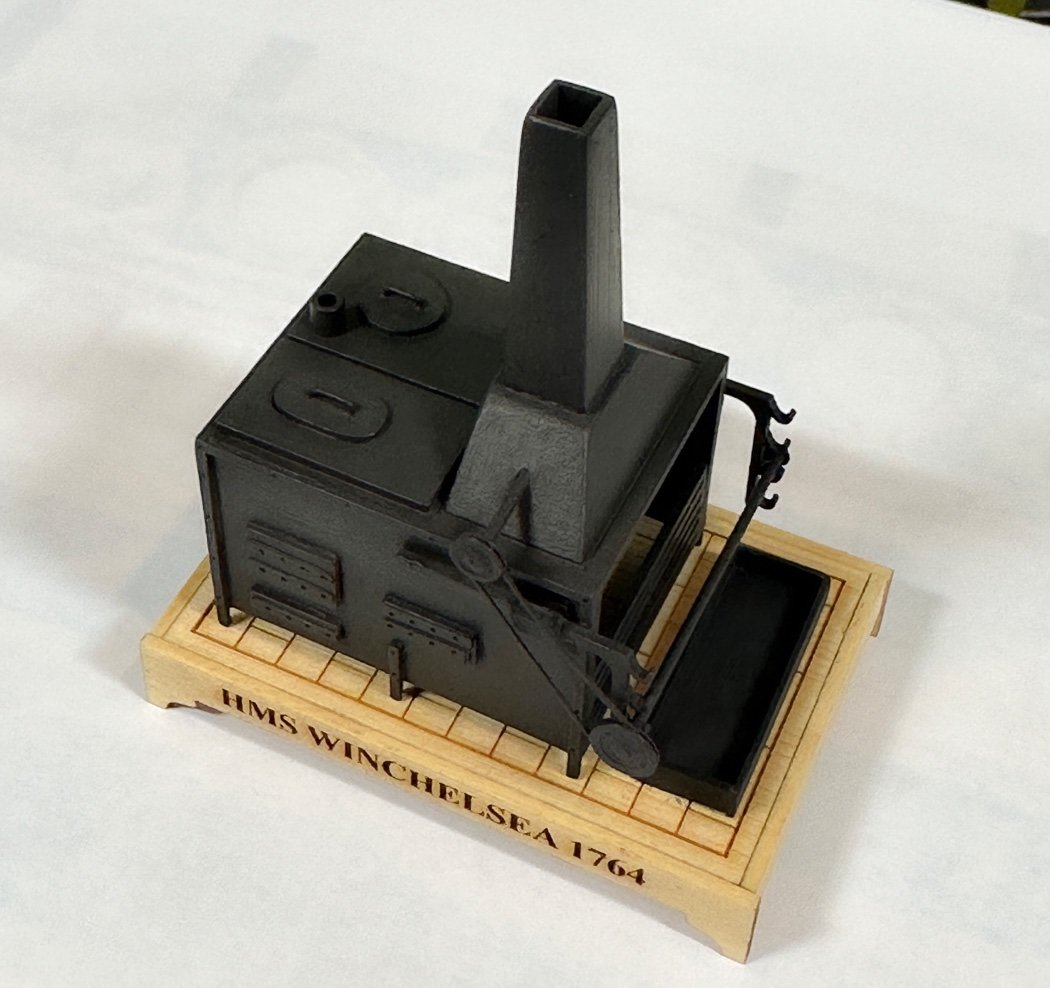

The Stove

It is nice to finally move on from my cannon production line and work on something there is only one of.

So instead of that I started on two things there are only one of, the stove and the capstan, thereby creating a complete mess on my work bench - fun.

I cut some correctly sized blocks from scrap MDF to help keep things square. There are other ways, but this one was easy, in fact one of them is still inside the stove.

Not as silly as it looks, there is an indention on the bottom of the weight that perfectly fit the chimney top. Nice tight glue seal, and yes it is a bit silly. I was constantly checking levels, there aren’t a lot of main parts to the stove but the ones there are need to be kept both square and level.

I sent this photo to my two sons explaining it was the ship's stove - one questioned the wisdom of cooking with a wooden stove.

The instructions are clear, not hard to assemble, attention to detail is important though, and this little jewel has a lot of detail to pay attention to. Those little racks on the front are very very fragile. Getting the pulley installed correctly required a little planning and dexterity, but really fun stuff.

One addition I did make was to plane a small rectangle of wood matching the height of the six tiny little legs and glued it to the bottom center. It can’t be seen and I’m a lot more comfortable with it there than completely relying on my not breaking a leg and something more substantial to ultimately to be glued to the deck.

While following the instructions for this beautifully designed mini-kit I became so absorbed with the work I failed to take any more photos until it was done, so here it is. The pulley system is so realistic I might think its actually metal fly wheels and a fan belt rather than laser cut assembly of 5 separate tiny little pieces. I'm not really clear how it would work though, what caused the meat to be turned on that spit and why does the upper pulley go into the vent....

I first painted it with my Admiralty Ironworks Black, finally using this paint on actual ironworks. Then as Chuck suggests I heavily coated it with Grimy Black weathering powder from the O’Brien set. I almost left it at that but went back with a light application of Rusty Red. I opted to brush and buff it in to an even appearance and will likely use the buff brush further.

It’s a bit of a shame very little of this will be visible one the forecastle deck is installed, but I know its there.

And now for the capstan. Thanks for stopping by, your likes and comments are always appreciated.

-

After coppering Pickle, I was fine with it. After spending forever coppering HMS Vanguard and quitting modeling for three years after finishing it I vowed to never ever copper another ship ever never again. Aside from the mind blowing tediousness of it I really don’t like the look. Bit what do I know 😁

- hollowneck and mtaylor

-

2

2

-

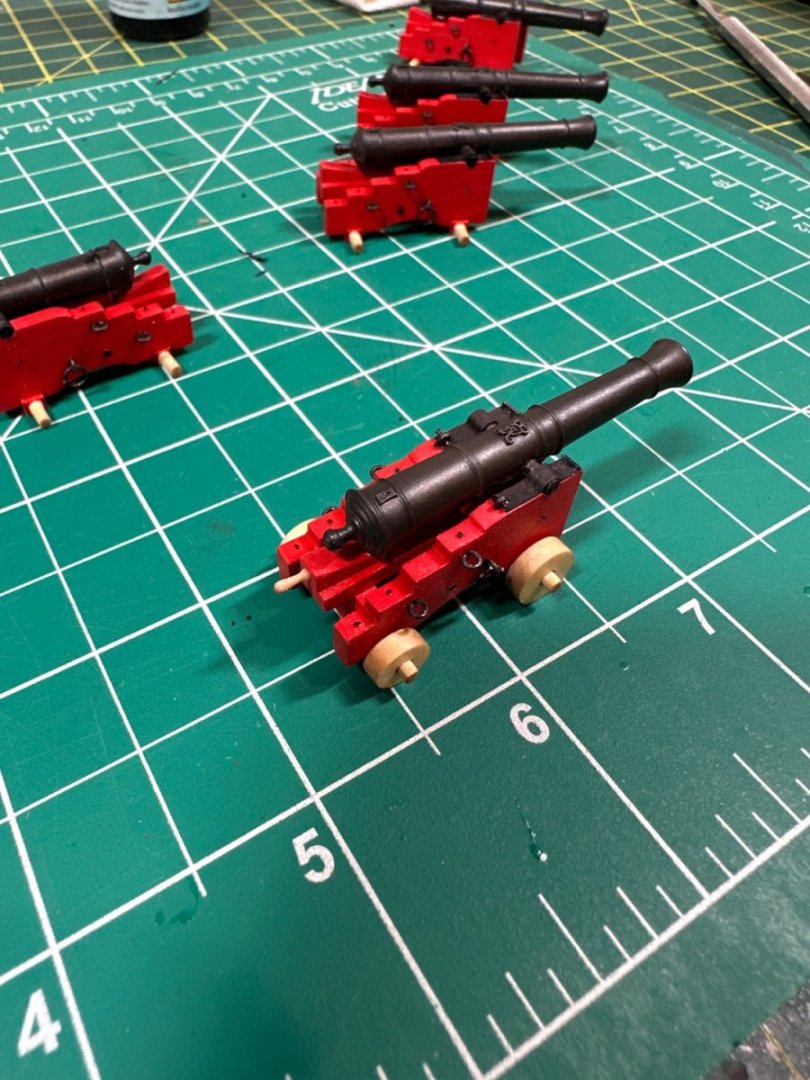

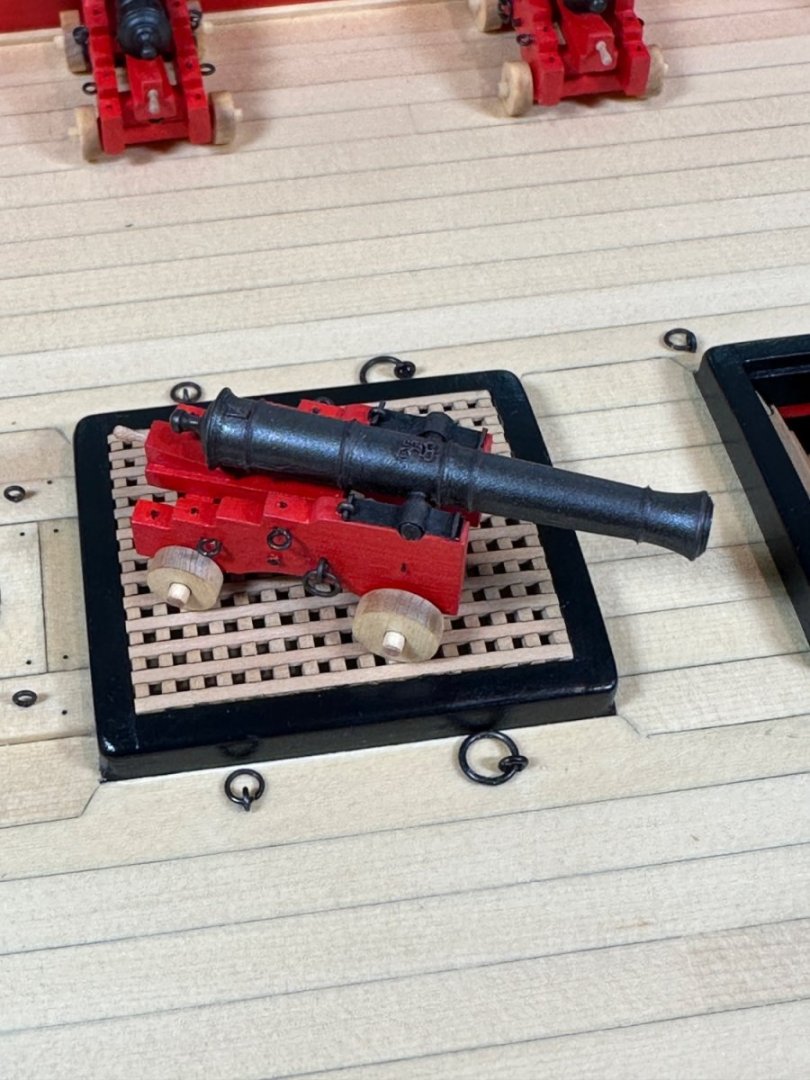

Cannon Weathering

Just one more thought on the cannons. I mentioned this before but worth emphasizing for future owners of Syren’s resin cannons. The combination of these with Ironworks Black paint, or any Matt Black I’d imagine, and Doc O’Briens Rusty Red weathering powder (why the Rusty Red works best I don’t know), and a set of soft, single purpose brushes creates such a nice gun metal gray barrel. Well worth the time and effort to do it and highly recommended.

-

1 hour ago, Thistle17 said:

turned/sanded them on my lathe

Thanks for sharing that. I also spin them on my lathe, though pairing two is a great suggestion. I can get all the char that way but was feeling like the resulting wheel would wind up too small. Plus the impact of the grain from the board they’re cut on creates an inconsistent char pattern on the wheels as I sanded it off. I almost wish I’d just sanded them very lightly and left most of the char on.

im sure I’m being ridiculously picky, I like the detail and how they turned out otherwise.

- FrankWouts and Dave_E

-

2

2

-

58 minutes ago, Matt D said:

What do you mean about the wheels being over sanded? When I read that, I was expecting to see rounded edges, but they look nice and square. Also, did you make those perfect looking quoin handles?

Thank you! The wheels aren’t as free of char as I’d like, my comment was I didn’t feel I could get them that way without over sanding, meaning too much reduction in diameter/size. I’m sure I’m just being over-picky.

I made the order to Crafty Sailor for the quoin handles (actually belaying pins) does that count.🤣

-

2 hours ago, Dave_E said:

What kind of lines and ropes are omitted?

All of them. This ship won’t have masts, the cannon have no rigging, even the ships wheel rope is left off. Basically no rope anywhere.

It’s a good look on this model, not to mention not rigging 32 cannons. 😁

- Rustyj, Matt D and FrankWouts

-

3

3

-

Welcome back. Very well done! So cool to see one near finished.

- CaptMorgan and FrankWouts

-

2

2

-

15 hours ago, Chuck said:

Looking very nice.

Thanks Chuck, I did well I think on everything except the wheels. Just can’t sort how to clean them without over sanding. At least they’re consistent.

12 hours ago, scrubbyj427 said:Moving right along.

Thank you, even though it’s been at a glacial pace lately.

12 hours ago, Rustyj said:thought it was a firing squad

Thanks Rusty. The thought occurred to me after making so many. I like the little buggers but there sure are a lot of them.

- Dave_E and FrankWouts

-

2

2

-

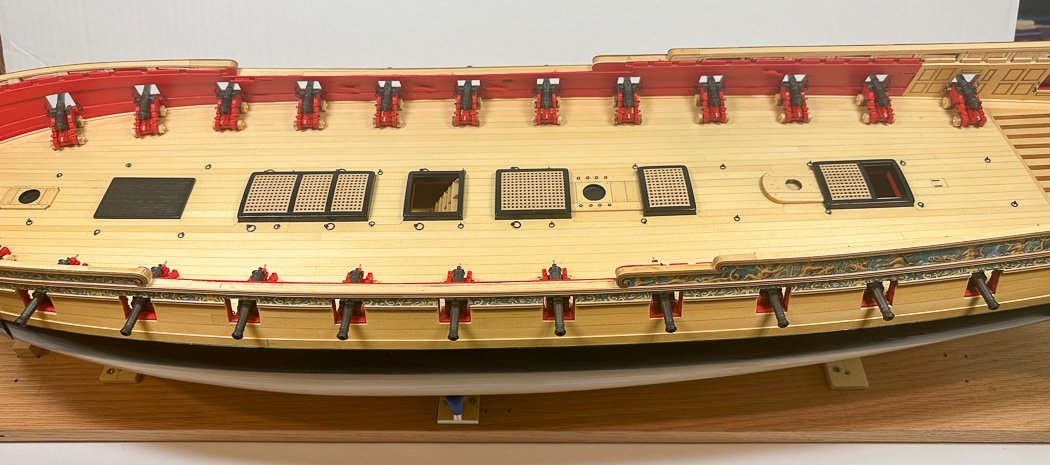

Main Deck Arsenal Complete

I’ve finally completed the 24 (plus a spare) main deck cannon (with just 8 more in my future for the quarterdeck).

I’m glad to have them done. Just sitting there for now. There will NOT be rigging involved as I’m embracing the admiralty model concept - no ropes anywhere including these guns. I wish I had cleaner wheels, but it was not to be, at least for me, without sanding more than I wanted to sand. Oh well.

I’m going to build the ship stove and capstan before starting chapter 7. They should be fun and will allow me to put off painting deck beams a while longer. Good stuff

Thanks for stopping by to see a few more cannon.

-

Wow, this is really cool!

- mtaylor and FrankWouts

-

2

2

-

I’m in a never ending search for quality drill bits at the size we need them. They are worth the search.

Nicely done!

-

Where’s the fun if we don’t break stuff and have to fix it. Great looking work Matt, well done!

- Rustyj, Matt D and FrankWouts

-

3

3

-

-

34 minutes ago, GRATEFUL LITTLE PHISH said:

avoid or minimize developing a paint line at the eater line

Thanks for your comment. I exclusively use Tamiya tape, available on Amazon. Really excellent for the tight masking for our models. Multiple thin coats and smooth long brush strokes help prevent build up at the tape line. Hope that helps, main thing is to go slow, take your time, know the first model is about learning (as is my 12th for that matter) and have fun.

Check Vanguard Models for your next build. @chris watton offers great, well made kits with quality materials. More importantly his plans and instructions are second to none.

-

The mitre bar, extended fence are essential, the cross cut table is of great benefit and a must. Zero clearance inserts are handy, but I seldom use it. The 3 inch, 90T, .03 slitting blade is all I ever use. I’d get a couple of those. I have the micro meter stop and never ever use it. I’ve had my saw since 2008 and never replaced the belt. The other might be useful, but not for me.

- Ryland Craze, mtaylor, Reggiemon and 5 others

-

8

8

-

Great work as always BE. I believe the planking problem is as much corrected by adjusting the edge bending (bend up to curve down) as it is with the tapering. I’ve found the third and fourth bulkhead are is the most challenging to get a proper fit, good idea to sort it out early, it only compounds the further you go if not.

- Mr Whippy, hollowneck, mtaylor and 1 other

-

4

4

-

Amazingly well done. True craftsmanship!

-

Amazing work, well done!

- Saburo, Knocklouder and mtaylor

-

3

3

-

You’re doing really excellent work with this model and with your log, I just stumbled on to it today. You’ve done a great job leaning into other logs for advice. @DelF is an outstanding builder and a great source. For a near first model your workmanship is excellent.

Yes those holes are for rigging, easiest way to determine size is to look at the plans for what size rope goes through it and drill accordingly, it will be fairly small. Four anchors is fairly common, two rigged and two lashed on as spares.

-

11 hours ago, Nunnehi (Don) said:

using your Cheerful as my primary reference

Thanks, I’m glad it’s helpful.

- Nunnehi (Don) and FrankWouts

-

2

2

-

Excellent paint work, very impressive.

- Thukydides and chris watton

-

1

1

-

1

1

-

Congratulations on reaching the finish line. A great sense of accomplishment no doubt. Well done!

- Nunnehi (Don) and FrankWouts

-

2

2

-

We’ll done, the cherry looks great!

- FrankWouts and westwood

-

2

2

HMS Winchelsea 1764 by Frank Wouts 1/48

in Member Build logs for the HMS Winchelsea

Posted

Exquisite work!