-

Posts

3,854 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by glbarlow

-

-

-

There is nothing the Byrnes saw cannot do, and do better. If you want to keep two saws the reason shouldn’t be because some other saw can do it. (Short of a full size table saw I suppose)

The addition of the Byrnes cross cut table accessory opens even more possibilities. I easily cut lap joint hatches for Cheerful using it.

-

On 3/2/2021 at 1:40 PM, Gregory said:

One of our sponsors, CraftySailor has some that looks good in the pictures.. Not sure how competitive they are,

I tried some Crafty Sailor rope, it is terrible. The .018 size was way to small, .012 at best. When I cut it, the first three or more inches sprang unraveled like a broken clock spring.

I emailed Crusty Sailor, who does have great to scale wood belaying pins, the answer was “that’s the way it came from the manufacturer.” I would not recommend this rope, not at all good quality.

- Chuck, Ryland Craze, mtaylor and 1 other

-

4

4

-

I could buy every tool you own and come no where close to the caliber of work you do. The latest example being your blocks, they are amazing. The stove is incredible, as are details like the charcoal stove.

I hope this model ultimately will reside in a museum, a place that it can receive the admiration it deserves and viewed in person by many.

Well done.

- FriedClams, druxey, mtaylor and 5 others

-

8

8

-

- GrandpaPhil, MEDDO, scrubbyj427 and 14 others

-

17

17

-

Look into a Quad Hands, available on Amazon. It makes all rigging work easier. They allowed me to seize my served shrouds on the model.

My experience is the seizing can be move a little it’s kept loose, but not a lot.

- thibaultron, mtaylor and Ryland Craze

-

3

3

-

On 6/8/2021 at 6:22 PM, Thistle17 said:

I too am working on Cheerful.

It would be interesting for all of us Cheerful builders to see some photos of yours. I think there is a forum post for works in progress you might consider. It’s a great and fun build for sure.

-

-

-

-

-

22 hours ago, Malcolm Greig said:

Some of you don't seem that enthusiastic about it.

I’ve used both, I’d say it’s more than Syren being the Rolls Royce, there is a big difference in quality. Enough that I consider it a big step down to fall back on Amati stuff. To me it’s more Amati being the KIA of rope. There doesn’t seem to be many options in between.

I don’t want to make my own but I may have to learn how.

-

1 hour ago, niwotwill said:

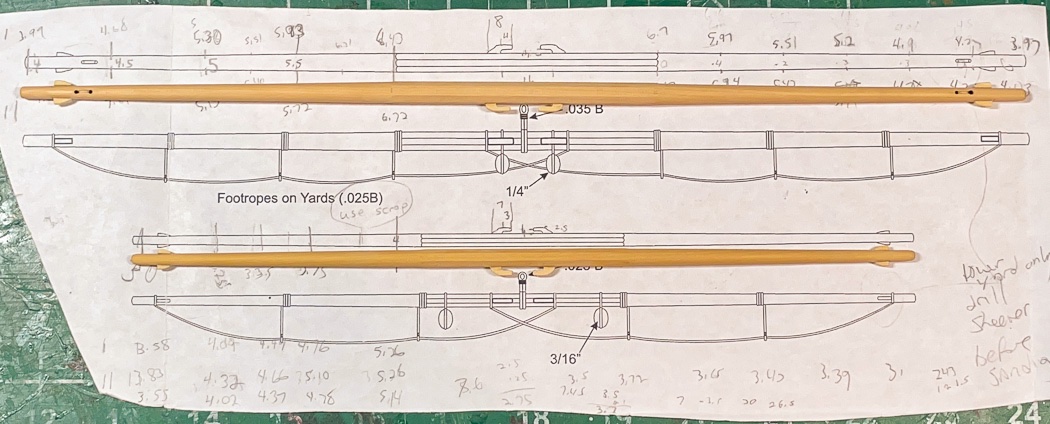

Magnificent work on the yards

Thank you. I enjoyed making them.

-

20 minutes ago, PRS said:

doesn't mark the wood

Not as long as you don’t over-tighten the chuck

-

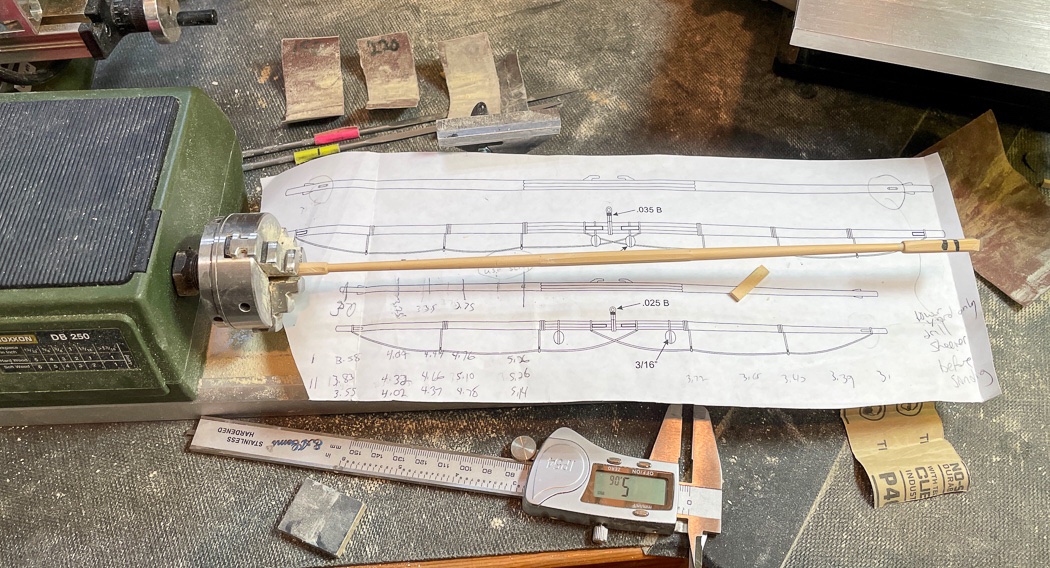

Making the Yards

Aside from the anchors the yards are the last thing I’ll make for Cheerful, my voyage is getting close to the end.

One last trip through the machines. Although the yards will be painted black I elected to use a bit of the boxwood I purchased from Modeler’s Sawmill for no real reason other than I wanted to work with a little box - its such beautiful and easy to work wood. Not that the Yellow Cedar isn’t, they are both excellent woods for modeling. It’s great that Modeler’s Sawmill gives us a new source of quality wood.

First up after cutting square lengths to size was to drill the holes for the sheaves on the square stock, much simpler to do now then trying to add them to a rounded yard.

Back to my octagon jig and the finger plane I’ve described earlier in this log, it’s the perfect tool for this job. First it was marking the wood using the 7-10-7 rule, then cutting to the pencil marks with the plane. I marked the center part of both yards that remain in octagon shape after shopping as shown on the plans, I wanted to be sure to have a nice pretty octagon for that part and gave it extra care.

Off to the lathe, I cut both yards long to provide a good hold for the chuck. I had no problem with the length, not having a tail stock doesn’t present any issue. I just hold the end in one hand and sand with the other. I rounded the side furtherest from the chuck first for extra support. I measure and mark the plans at increments then frequently check those with my calipers as I sand with various grades of sand paper. I also used a 00 file to cut the ends clean and sharp. Although I removed it for this photo I also wrapped Tamiya tape at the outer edges of the center octagon do ensure a clean line there as well, then smoothed out the transition as the last step with a very fine grit sanding stick. Of course the real challenge with yards is sanding the second side to its mirror twin of the first - I mark them side I and side II to keep track and take measurements much more frequently.

It’s true rounding masts and yards can be done with a hand drill. Having done both I believe the lathe makes it simpler and easier to manage the incremental sanding required. Where the lathe shines, or at least this particular Proxxon model, is in the ability to slide the yard inside the chuck to expose only one half. This particularly helped with the 12 ½ inch main yard.

After checking and rechecking the measurements I added the stops and my yards are made, the machines go quiet.

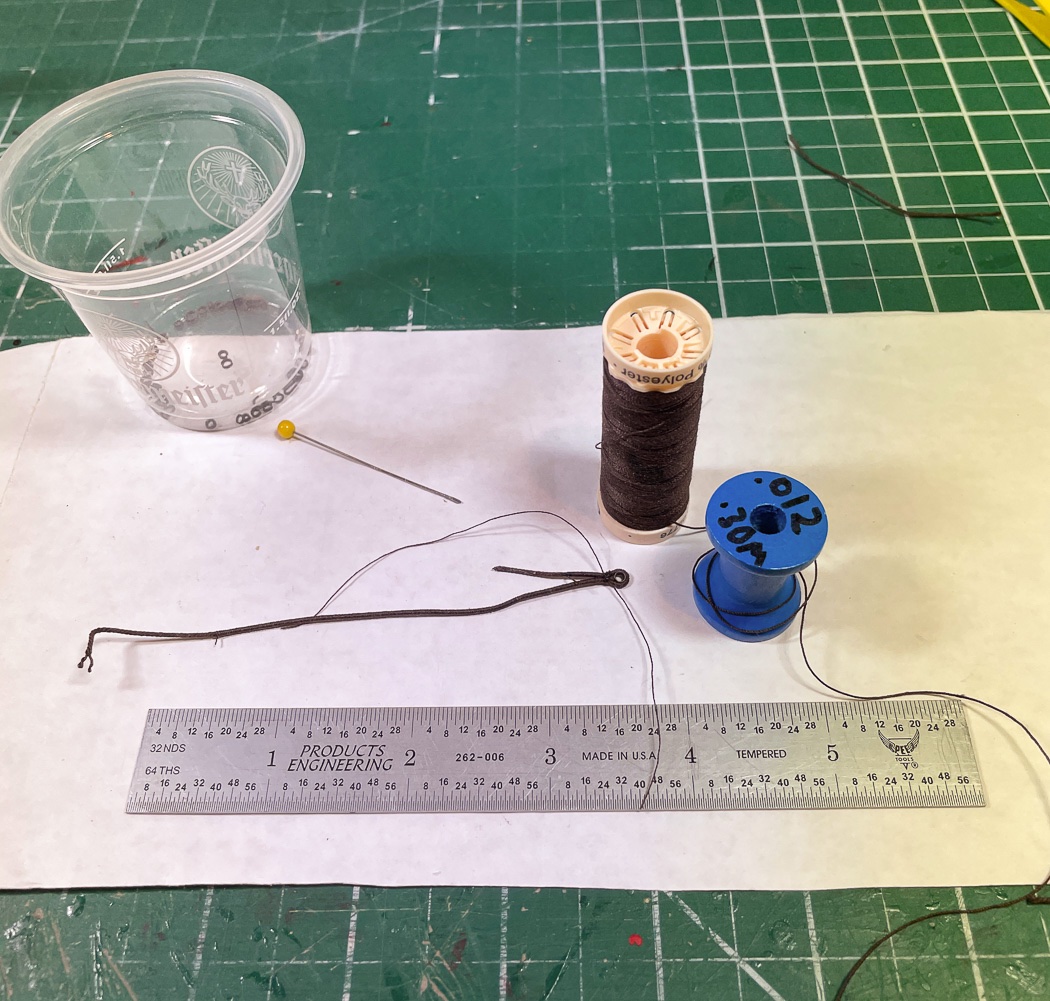

The main yard sling is first served then a thimble (selected from my jar-o-thimbles) is added. The short end of the sling is cut off just short of the thimble (done after this photo) and the long edge turned and glued using CA to form the loop.

I seized it with twelve turns, crossed the two ends of the seizings twice through the center, and finished off with a square knot on the bottom where it won’t be seen. The seizing covered the two glued ends of the loop, you’d never know it was there.

The topmast sling was made the same way except it isn’t served and of course is shorter.

I added the topmast lift and tackle, working near the trees to complete the block seizing. Once again I marvel the difference the addition of the Quad Hands has made for my work. I have the medium plate size but added a 4th 16” arm. This tool comes in handy so many times throughout the rigging process, I can’t recommend it enough.

So with that the yards are complete - oh wait that’s not how they go. 🙂 It seems I have some rigging to do, back to the Quad hands and my dwindling rope supply.

Thanks for the likes and the comments, they are always appreciated.

-

The little mini kits are all a highlight of this build. Well done.

-

I don’t think I was paying anything extra for a US shipment, does that change?

- KentM, mtaylor and Old Collingwood

-

3

3

-

-

2 hours ago, BenD said:

I'm working on that

That would be great if it meets Syren quality, I’m looking forward to see your offering!

- mtaylor, BenD, Old Collingwood and 1 other

-

4

4

-

My one request for your consideration is to provide the best quality rope to go with such an amazing kit. Normally I replace kit rope with Syren products but that is no longer an option and I have little interest in making my own.

-

Wonderful, can’t wait to get mine.

-

I’m really impressed with the quick service and quality of the wood from Joe’s Modeler’s Sawmill!

I purchased some boxwood of various thicknesses just to have on hand. I’m too far along with Cheerful to make much use of it but just for the joy of working with boxwood I made the two yards from what I bought.

Really excellent quality wood!

I’d encourage everyone just to buy some stock to help get Joe’s business off the ground. Most of us know how much we miss Hobbymill, let’s contribute to keeping a great source in Modeler’ Sawmill.

I’m so tempted to build ‘Surly,’ paint it blue and make it from boxwood. 😜

- mtaylor, Ryland Craze, Chuck and 3 others

-

6

6

-

1 minute ago, PRS said:

Thanks for the advice.

I know the places that gave me an extra challenge or two, getting the bow right was one of them.

-

Remember a plank has to run smoothly from the bow rabit slot down the side, the angle there is tight. It looks like from the photos you have more to do at the bow. The transition from the second to the fourth bulkhead is also a challenge, maybe just the angles but it looks like the second is lowere than 1 and 3. Also the first gun port area can be tricky. Running battens, even actual planks over and over is time well spent.

- FrankWouts and BobG

-

2

2

Dying/coloring rope; sources for purchase of quality rope

in Masting, rigging and sails

Posted

Looking forward to giving your rope a try