-

Posts

3,844 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by glbarlow

-

Thanks Garthog, I appreciate the comment. You should get the mill. Relatively inexpensive and very handy.

- 776 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Bob, that is my hope.

- 776 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you. The Alaskan Yellow Cedar really is pretty wood, and easy to work with for a model.

- 776 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I appreciate all the likes and those taking the time to comment. For Chuck to refer to my post as outstanding is special. I can respond that Cheerful has been and continues to be an outstanding experience. Thanks to all for the encouragement. I hope the log helps others to enjoy this model as much as I have.

- 776 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

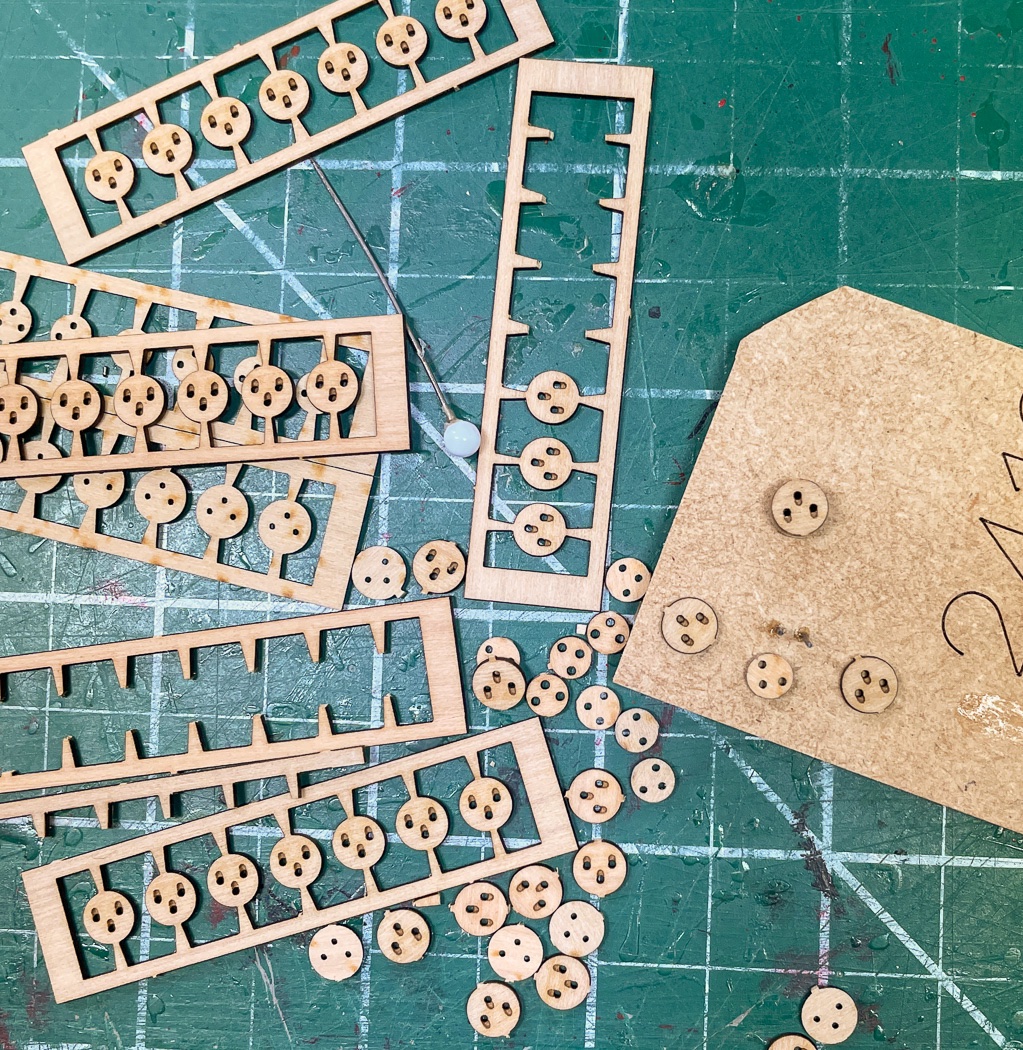

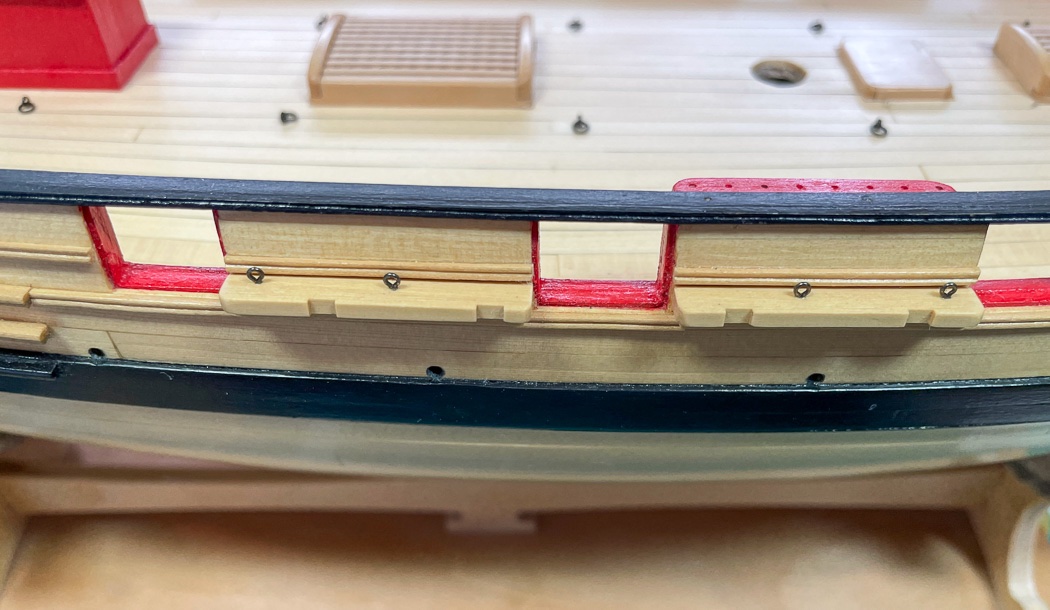

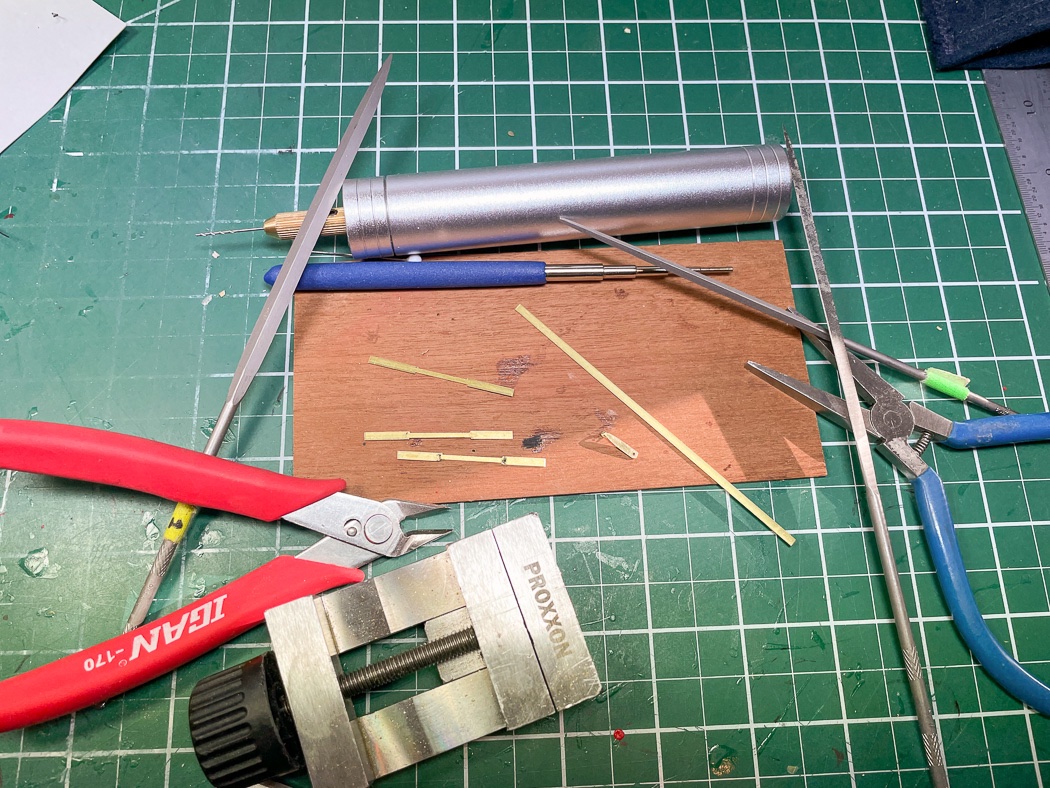

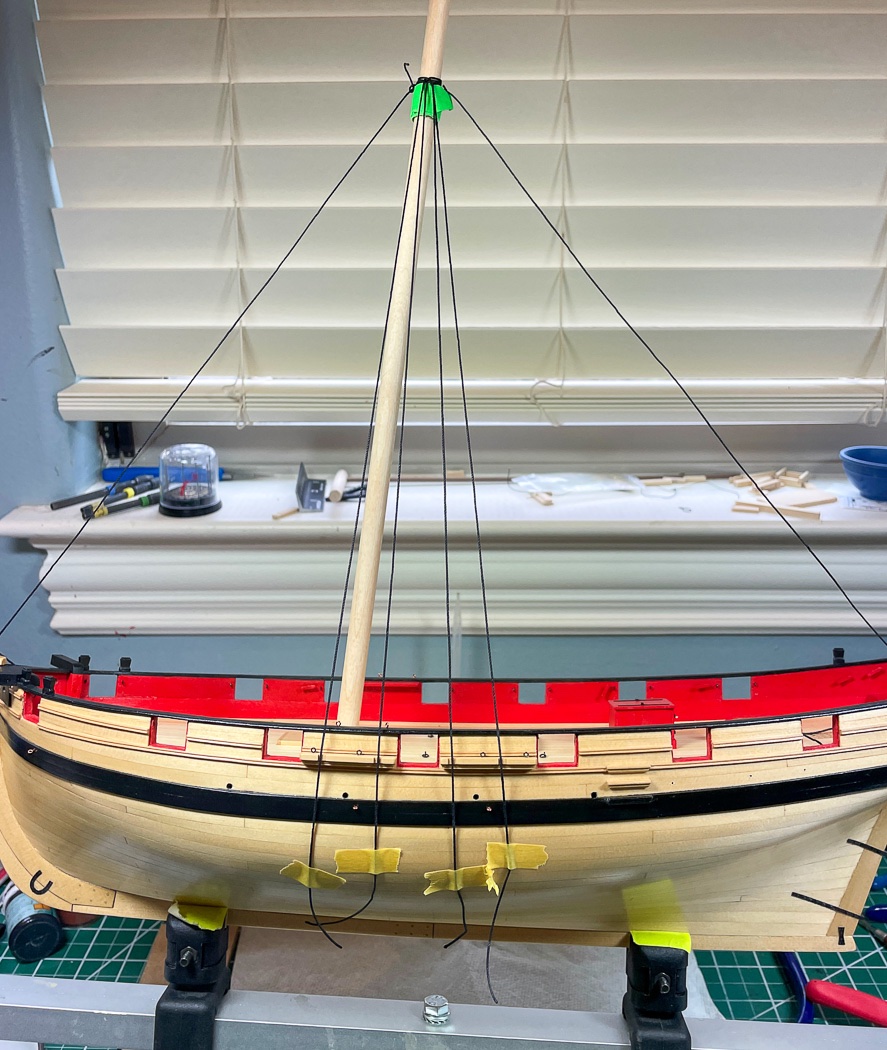

Channels, Chainplates, Dead Eyes, and Strops This is that moment when you know you’re not in kit world anymore. No PE to cut out and assemble and or laser ready wood to shape and paint, for this segment of the build everything is made from scratch. By now I sound like a broken record, but here again was something I’d never done. While Chuck’s monograph was as clear and helpful as always, I still had to figure out a way make each of these components. I had never worked anything from metal, I know - what limited skills I have. First up is the channels, take a stick of wood, make it pretty and capable of holding deadeyes and chainplates, then make four of them. The best purchase I’ve made for my modeling is my Byrnes saw, nothing beats it. Quickly moving into second place is my Proxxon MF 70 Micro Mill. I’m learning more and more how to use it, still basic stuff, but things I’m not really sure how I would have made without it. I chose to make these from my stash of boxwood. I like the yellow cedar but boxwood works better for more intricate pieces, it is a harder wood and holds shape nicely. The boxwood and yellow cedar are complimentary on the model, adding just a little tone difference. Chuck’s mini-kits come in both woods, I chose the boxwood for all of mine, even the ones I painted. - Next up is making the 6mm deadeyes. I made a simple jig to line up the three pieces, a small center and two outer pieces, basically a vanilla Oreo cookie, glued together after removing the char. I wanted to give the deadeyes a little character, a bit too neat right off the sheet, so I tumbled them in this MicroMart block tumbler. It has a 220 grit sandpaper bottom, sides, and a 4 part spindle also covered with 220 grit. I connected the spindle to my drill, tossed the blocks inside and spun it until I liked what came out. Two things if you haven’t used one of these; I was more successful with it sideways as shown and I needed to reverse the drill (as in screw out not in) to match the the sandpaper. I’m left-handed so maybe I assembled it backwards, I do that on occasion, it’s a right-hander’s world. I finished them up with wipe-on poly. Then is was time for me to become a blacksmith and work in metal, I'd put it off as long as I could. I approached this step with a bit of trepidation. The monograph was clear enough on what to do, I just wasn’t sure how I was going to make 6 (near) identical backstays and 8 (near) identical chainplates from a strip of brass. For starters, it hadn’t been easy to find the right thickness and width of brass, but fortunately I’d completed this hunt a few months ago. Now I have enough to make 176 chainplates, just in case. My first step, seemingly as always, was to find out how many different tools I could use - this is just a sample. I always hand drill everything made of wood with pin vises. However, this cheap battery powered drill was essential to drill the holes in the brass, I’d have been twisting forever otherwise. The vise from the Proxxon mill proved equally handy off the mill to firmly hold the pieces. To make both the backstays and chainplates requires a bit of shaping and filing. I kept the shape simple so I could repeat it multiple times, jewelry making is not in my future. I of course could have filed these by hand, but hey, there is a mill sitting right there. It was slow going, for me, to set zeros on two of three axis for each side, 22 times (I did the backstays working from the center as shown in the previous photograph). Having finally completed the chainplates it was time to determine the proper angles using a temporary mask and string, a process most of us know and applies to any model (well not modern war ships I suppose). With the holes marked and drilled then it’s a dry fit to confirm everything is lined up. I only needed about a third of the length to attach the strops, but I didn’t know that when I was making them. And then off to the blackening station. I chose to blacken rather than paint these. The result is a more worn, gun metal look. I was originally going to paint them Iron Work Black like other parts of the model but then decided I liked these. I think it provides a little character, more of a ‘I didn’t buy these from the store’ look. I normally like to explain how I did something in the hopes it will help others in some way, or at least provide a way they don’t want to do it. I had someone ask me recently in a PM to explain how I did seizings, so I went into great detail and even linked a YouTube video. The person replied, oh I don’t want to do it like that. Sigh... Anyway, my advice for making deadeye strops is go find another build log. I had to learn every step of the way here. I’ve never soldered anything for a model, never used solder paste (though its kinda cool, you apply it, hit with a torch and it flashes into a finished connection). Now I’m going to use it for some ring bolts just for fun. I had many fails. First make a circle and solder the opening (ok, got it, at least after I learned how to use the solder) then shape that around the deadeye in the traditional shape, Pop, there went the solder joint, start over. I settled on a length of wire 22mm long. I couldn't get 21mm to work without the joint popping while bending it around the deadeye, I started with 24mm, tried 23mm - really these small differences mattered - they were too big, so 22mm it was. After many attempts I got 8 to shaped around the deadeyes and mounted on the chainplates. So yes, I made it all myself from brass strip and black wire. But I’m not the one to ask on best practices even though it turned out ok and I held to my standard of doing it over until I got it right. This stage took me a full month. Of course it was partially due to Snowageddon here in Texas, rolling power outages, the lowest temperatures since 1949, real snow to play in with the grandkids. I was playing outside with them on a Friday after it finally warmed up to 24 (F) degrees (from below zero earlier in the week). On Monday, three days later, it reached 76 (F) degrees…Texas… I admit was frustrated a bit during this phase, so many fails. I thought more than once to use some retail ready fittings in lieu of my own but none would really work without cheapening the model, and I would have regretted it later. I am glad I did it all myself, I would encourage anyone who gets this point to do the same, if I can anyone can. The next time a model calls for metal work I now have some experience, I bet I could do it in half the number of fails. On to fun stuff, I'm not far from finishing the hull. I'm going to finish making everything including the bowsprit before gluing anything on. Thanks for stopping by, I hope you were mildly entertained.

- 776 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I have this on my shelf as well. I’ll look forward to following along with your build.

- 185 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Those look great, like BE I did them for my Pegasus, mine are still looking good after all these years. Like most rigging I discovered getting the right tension without being too tight was the key - that and gentle tugs a line at a time to get it right. As always a nice tutorial!

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

Thank you for taking the time to tell me it was helpful. That has always been my primary goal of my logs. I have learned so much in this forum. I’m happy to try and help pass it along to others.

- 55 replies

-

- lady nelson

- victory models

-

(and 2 more)

Tagged with:

-

Have you tried the usual figure 8 seizing method, seems like that would make it a lot easier?

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

Of course😀I drill 3 different size holes to make up the gun carriages, so... Note they’re color coded too as are a number of my tools using these little rubber sleeves I got from a dentists supply website after seeing my dentist’s assistant use them to quickly recognize instruments. I actually have 5 pin vises, you never know😀

- 776 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

With the weather, electricity, and heat (lack there of) situation I decided to work on building my remaining 5 carronades. I described my process way back early in this log when I turned to them after my first frame was shattered in a fall to the floor so I won’t repeat it here. I like to use as many tools as possible it seems 😀. These I can do in the short intervals I have available to have ship time right now. Here’s hoping things get back to normal this weekend when it should warm up.

- 776 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Just amazing work. Just as with any tool from a #11 blade on up, having the CNC means nothing without your artistic and technical skills to use it. I see nothing controversial with using all the tools available today to create such a masterpiece.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

We’re having rolling power blackouts here, 40 minutes on, 40 minutes off with no end in sight. -1 degrees may not be a big deal in the east, but it’s not happened here since 1949. Consequently I’m not getting much boat yard time in. Too busy trying to stay warm and grab a little internet time when I can. Hopefully by the weekend.....

- 776 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

You’re really flying building this. And doing such a great job.

- 201 replies

-

- Duchess of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I think it’s ok to leave them off altogether. They were easy to move in reality. To me they seem a bit of clutter to the otherwise graceful look of the frigate. I didn’t replace mine on Pegasus, but I should have.

- 164 replies

-

- fly

- Victory Models

-

(and 4 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.