-

Posts

13,353 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

The lower left one in the illustration above is strange: normally there are two compasses, one on either side with the lamp in the center compartment. Why two compasses? One can be seen no matter whether the helmsman stands to the left or right of the wheel. Also, as planned redundancy, should one compass fail.

-

Dan: The issue with the 'gratten' tops on the NMM model is that the openings are at least 6" square: a real hazard. Were they finer mesh, it would be more plausible.

-

Boring? Hardly. Your step-buy-step is most instructive. Lovely work, yet again. Break out the winter woolies now, Keith!

-

Welcome aboard! I recall seeing St Roch in Vancouver some years ago, She makes an interesting subject. Looking forward to seeing your progress. And there is nothing like good ol' fashioned manual drafting! (I'm also doing some this afternoon.)

-

NAIAD 1797 by Bitao - 1:60

druxey replied to Bitao's topic in - Build logs for subjects built 1751 - 1800

Beautifully done! -

Swan-Class Sloop by Stuglo - FINISHED - 1:48

druxey replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

Because the pump runs through at an angle, the athwartship opening needs to be slanted to match, which may account for at least part of the fitting issue.- 475 replies

-

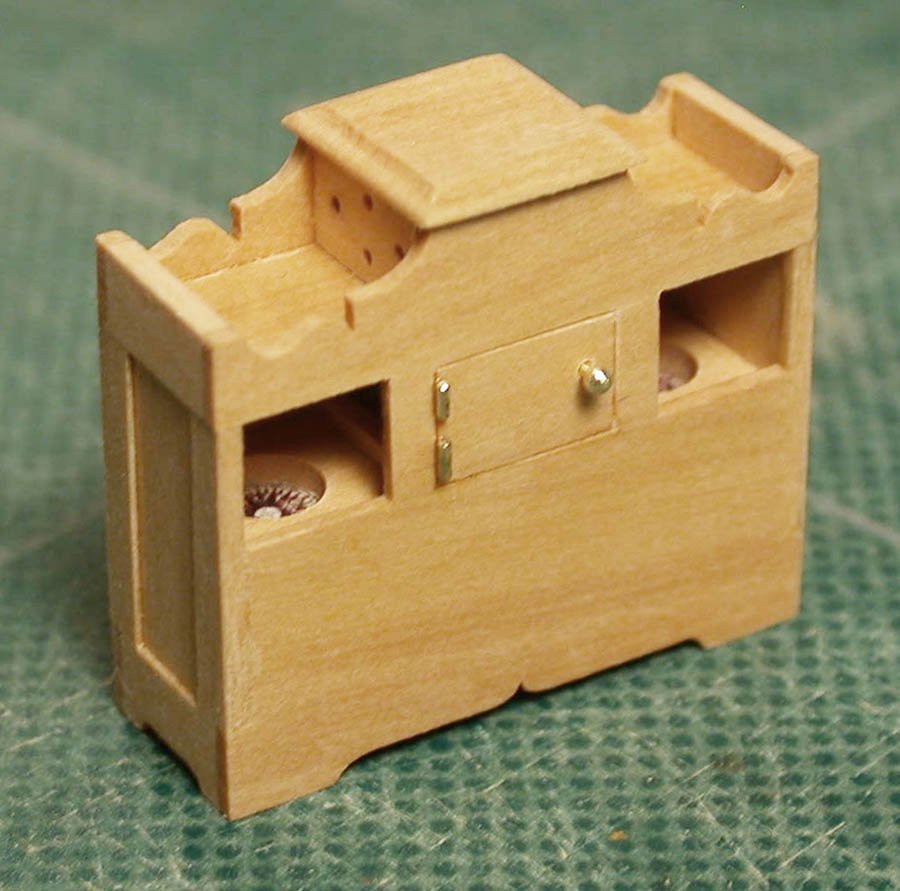

There were always vents, but not a funnel or chimney. The latter seems to be a 19th century development. An Amazon class model in the NMM collection shows the form used in the 1770's: https://www.rmg.co.uk/collections/objects/rmgc-object-66276 Hard to see in the photo, but the sides of the central raised portion have several vent holes (five in a diamond pattern, one hole in the middle, if memory serves me correctly). o o o o o

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

druxey replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

Well done: Grooving those posts accurately is tricky!- 475 replies

-

It goes together by trial and error fitting. If you have some re-stickeable 3M Magic tape you can lay a piece down in the gap and trace the shape you need. Peel off the tape and stick it on your planking stock. Cut the plank a hair oversize and sanding stick it down until it just slips into place. Labor intensive? Yes! But, with care, the result is well worth the trouble.

- 1,129 replies

-

To avoid distortion (and for safety's sake!), make an outer plaster of Paris two-piece jacket with the joint at right angles to the split line in your RTV mold.

-

Well re-worked, Alex. Fixing 'oopsies' up is a skill every model-maker has to develop. And you've learned to be gentle and patient when ungluing!

- 23 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

I believe that there was a V de V exhibition at the NMM some years ago, and a large format catalog volume was produced at that time. Am I remembering this correctly? Also, (if you can get there!): https://www.holland.com/global/press/news-resources/exhibition-of-van-de-velde-marine-art.htm

- 7 replies

-

- Marine artist

- Dutch

-

(and 2 more)

Tagged with:

-

Thank you for bringing this book to our attention, Marcus!

- 7 replies

-

- Marine artist

- Dutch

-

(and 2 more)

Tagged with:

-

Archaeology of a 19th century Great Lakes shipyard

druxey replied to JKC27's topic in Nautical/Naval History

Excavation by Brock University archaeology students and professionals have been held up the past two years by the pandemic. It is hoped that the site will become active again next year. It is known that an abandoned 'canaller' is buried at a deeper level on this site.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.