-

Posts

13,393 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

Nice subject, Maury. Looking forward to your posts!

- 525 replies

-

- anchor hoy

- hoy

-

(and 1 more)

Tagged with:

-

Cutter Cheerful 1806 by rafine - FINISHED

druxey replied to rafine's topic in - Build logs for subjects built 1801 - 1850

Lovely and very neatly done, Bob. And, as you say, sooo much less work than a three-masted vessel!- 525 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

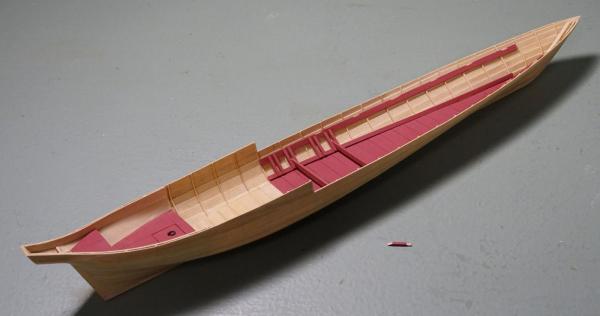

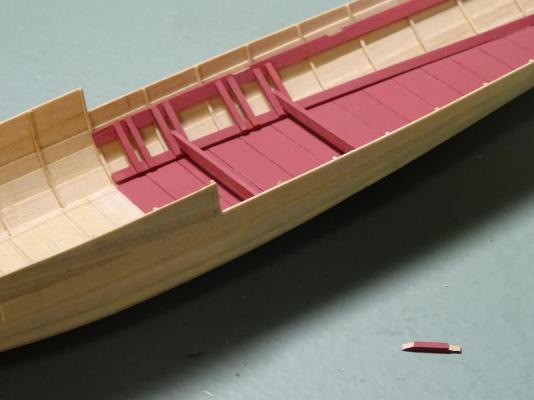

Well, the 48 batten pieces have been cut, shaped and installed, along with the six footboards. Next will be the thwarts. They should be a simple job, but are complicated by the fact that the edges are moulded and need to be mitred to the longitudinal strip running down the mid-line of the boat. Also, six turned supporting pillars are needed to support the thwarts. Stay tuned.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

filling pieces between frames

druxey replied to AON's topic in Building, Framing, Planking and plating a ships hull and deck

Presumably this was carried out as frames were erected - not after the fact. -

That's dedication: making the complete set of oars, Steven! Good for you. The completed ones look very good. How long would the full-sized ones have been?

-

ancre La Salamandre by tadheus - 1:24

druxey replied to tadheus's topic in - Build logs for subjects built 1751 - 1800

Those mortar beds are very substantial! Nice work, Paul. -

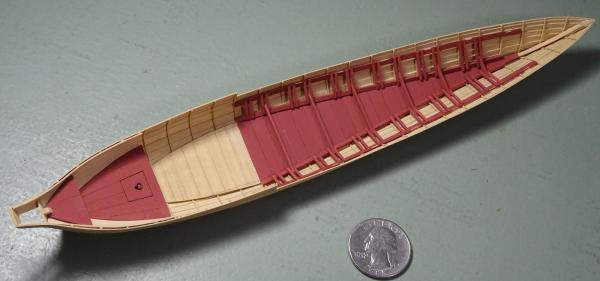

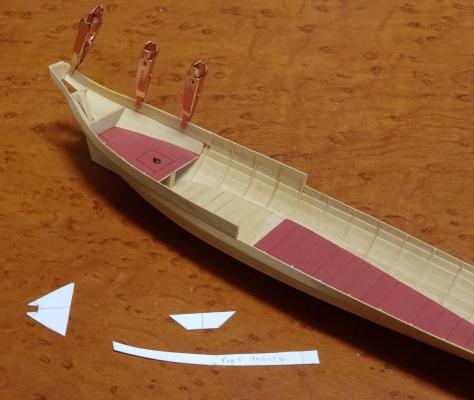

Again, my appreciation for the complimentary remarks you have posted on this model. The footboards for the rowers are more complicated than one might think. They are moveable - for long and short-legged crew - and have battens that hold them in place. For six thwarts there are a total of 48 battens to be cut and fitted. There are no two pairs alike. No wonder this detail is omitted from nearly every model! If you look carefully, you will see a rejected batten showing the joints that need to be cut at each end. It will be a while until all six sets are completed....

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

For the scale you are working at, impressive stuff! The sense of activity with the figures is especially nice, Dafi.

-

Nice dodge for the cont splice, Chuck! Something one can't do as effectively with three-strand line.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

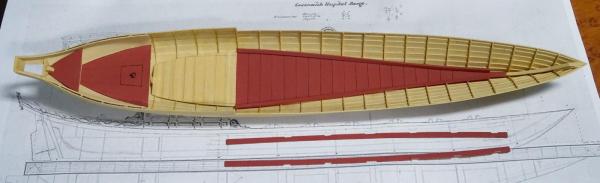

Further news from the shipyard. First the side strakes of footwaling were installed (there is probably a proper term for them, but I don't know what it is). They required a twist through almost 90 degrees along their length, achieved by steaming. Next were the risings. I misspelled the name as 'risers' earlier - sorry. The risings were cut after a card pattern established their shape and the pair were made while rubber cemented together, ensuring symmetry. The height of each below the gunwale was marked out at various points along the hull and the risings glued in. Note that paint was scraped off where the thwarts will attach. Next will be the footboards for the rowing crew.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Well, Mark, you could always have your cake and eat it for your next model. A number of British ships were built to French lines. Examples are the Echo class of sixth rates, as well as the purpose-built fireships of the Tisiphone and Thais classes. In the case of the Echo class, even the decoration was in the French style!

-

Aren't you glad that you only had two to make? I'd have cheated and gone with the old 'cut nail' shape.

-

Effie M Morrissey by allanyed

druxey replied to allanyed's topic in - Build logs for subjects built 1851 - 1900

Nice to see you back building, Allan!- 15 replies

-

ancre La Salamandre by tadheus - 1:24

druxey replied to tadheus's topic in - Build logs for subjects built 1751 - 1800

How did you turn the ends so cleanly? Was it possible to put them in a chuck? -

A good call, Chuck. They look much better now - not that they ever looked bad!

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The inner bulwark sheathing proved interesting. It took several pattern pieces to figure out the developed shapes of the planks. The first photo shows one plank being wet-bent into position. The card pattern for this is in the foreground, as well as patterns for the steersman's bench. The second photo shows both inner sides complete and the vertical portion of the steersman's bench in position. The top of this has been made and painted. The same strategy as for the other horizontal surfaces was used to build it. The paint is in the process of drying and I'll install the top tomorrow. There are several possible items I could now tackle, but I think that the risers (horizontal planks that support the ends of the thwarts) should be next.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Mechanical Solar System by jim_smits - Eaglemoss

druxey replied to jim_smits's topic in Non-ship/categorised builds

Just found this thread - your project is sooo cool! I guess that the company don't export to N. America, or I'd be tempted. I remember seeing orreries in museums when I was young, and being fascinated. All the best with moving and your upcoming nuptials, Jim. -

Congratulations on a fine model, Vaddoc. Very nice indeed.

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.