-

Posts

13,392 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

Even a shallow bowl of water in the shop might help things, Ben. Ideally a humidifier is best, but it's better than nothing. Varying humidity due to seasonal change is the enemy of wooden models. Try to keep things relatively stable year round.

- 889 replies

-

This will be the last update for a few days: the frames have now all been bent in. I'll be back in a week or so. Thank you all for following and liking this log.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Remo: I've seen your beautiful work and you are under-selling yourself. I'm trying to be in your league!

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Cutter Cheerful 1806 by rafine - FINISHED

druxey replied to rafine's topic in - Build logs for subjects built 1801 - 1850

Looking good, Bob!- 525 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That sounds very convincing, Glenn. The discussion and process of arriving at this conclusion I found most interesting.

-

I have no idea, as it will depend on the specie of wood you will be using, Steven. You will need to experiment with both moisture and heat.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Frégate d'18 par Sané , la Cornélie

druxey replied to JohnE's topic in CAD and 3D Modelling/Drafting Plans with Software

John: did you receive my PM from the other day? -

Beautiful work, as ever. Thanks for the early treat on Friday instead of Saturday! Enjoy your family weekend. Still working on the assumption of quadruple boilers?

-

Excellent method and result, Mike. Well done!

- 452 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Aft frames are now in, with some fine adjustment still required. A ruler is included in the photos as requested.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Glue 'em damp, and clean up any excess glue with a damp brush, Ed.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Ed, have you tried bending frames using moisture and a thermostatically controlled iron?

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Ed: The frames are bent in wet, without any heat necessary. They are of such small dimension that this is easily accomplished under slight compression to 'spring' them into place.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

If it's of any assistance, when I've cut frames, generally I cut to the outside line, or no more than 1/64" outside it. Bevelling (except for bollard, hawse timbers and transoms) is left until fairing a complete section of the hull. If you are going to bevel each frame, would it not make sense to paste the pattern on the 'narrow' side, cut to the 'wide' line, then bevel back to the 'narrow' line of the pattern, rather than try to align patterns on both sides?

-

Sounds like a very effective method, Gerald.

- 281 replies

-

- falls of clyde

- tanker

-

(and 2 more)

Tagged with:

-

HMS Naiad 1797 by albert - FINISHED - 1/48

druxey replied to albert's topic in - Build logs for subjects built 1751 - 1800

Lovely work in progress there, Alberto. Inspirational. -

Thank you, one and all. The frames butt to the keelson in the model, Joel. It might, in hindsight, have been easier to notch the keelson to locate the floor ends. I'll include a rule in the next batch of photos, Chuck.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Started bending in the frames today. They are spaced at 18" intervals and, as previously mentioned, are ¾" square. In the real boat, there were floors and futtocks united by a side overlap. However, as this will be completely invisible in the finished boat, I will omit this detail. As I have other work on hand, the next update will be a few days away.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

For some reason I missed seeing this thread until this morning. Fascinating research and interpretation, Woodrat! You are doing a terrific job in these rather poorly charted waters.

-

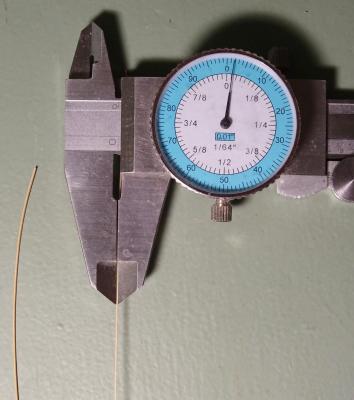

Next is to cut stock a scale ¾" square. This is next to impossible without a zero-clearance table and a slitting saw blade. So I made an insert of aluminum sheet and raised the saw blade through this, as shown (upper left). Note that, on this saw, I have an Accuriser II fence. I attached a secondary scale measuring in inches at 1/48 scale. This avoids having to translate from thousandths of an inch (actual) to scale inches. I cut several sheets of 1/64" Castello stock and rubber cemented them to a sacrificial piece of softwood. In this case it was simply a paint stir-stick (upper right). This was then run through the saw and the pieces separated and cleaned up, giving the 1/64" square section required for the frames (below).

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Thanks, Michael. I use white PVA, slightly thinned, applied with a small watercolour brush. The outside is washed down with a damp brush immediately, and the inside is cleaned up afterwards with a dental elevator (looks like a bent mini-chisel). If there is a stubborn bit of glue, a drop of water on a brush does the trick. Should a little of the joint give way, I run more dilute glue into the crack and clamp it shut with one or more of those mini-clips. This rarely happens, as the bevelled land creates a tight joint.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.