-

Posts

654 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Dziadeczek

-

I wouldn't worry too much about the filling pieces now. Make all hawse frames first and make sure they all fit and that their external surfaces are smooth (inner surfaces will later be smoothed). And only then try to make those fillers, carefully sanding down their thicknesses to fit to the available spaces in between the hawse frames. I too had a hard time making them for my "Frenchie" (of course, later on I bought the addendum brochure from Ancre with all profiles of the missing frames, including the hawse timbers, but it was already after I managed to shape them all by myself from the waterlines). Tough luck...

-

Planking Question

Dziadeczek replied to Malazan's topic in Building, Framing, Planking and plating a ships hull and deck

Also you can plank your hull with full length planks and afterwards score each plank across with a sharp exacto blade to imitate the joints between individual planks. I think this way might be a bit easier rather than trying to shape each shorter plank individually and identically to the rest of the short ones. -

Could I please. trouble you for a close up photo of your figurehead? What is it made of? Regards, Thomas

-

I think it might be a gouache (a little thicker, less watery watercolor, applied a bit more opaque). To make sure however, it is not a print, you might remove it (carefully!) from the frame and see if the paper has a slight indentation along the edges - if it does, that means that this indentation was caused by a graphic's press, and the artwork is/might be a print, like a lithography. But, in such instance, the artist would routinely write in pencil at the bottom margin the number of this particular issue, and the total number of the issues intended, as well as his/her name and the title of the artwork. Here we don't have any of this, at least I cannot see it. So, probably it is a painting (very well executed!), either a watercolor, or more probably a gouache.

-

Hi Javajohn , Since I built this model a long time ago, I don't remember now how long it took me to carve the transom. A few hours, at most. (I am a painfully slow modeler, I once knew a Japanese modeler, who would build three very intricate models in the time it took me to build one!) Today I took a close up, macro pic of this transom. When I look at this pic, I think that it was rather a thin slice of boxwood I carved, instead of cherry - the color is more creamy/yellowish. The rest of the stern is cherry though. I remember I made for this task a few tiny carving gouges, two from old discarded Dremel tips ground to the desired shape, and two or three from medical needles with their tips ground properly. You cannot buy such small gouges for this work anywhere, as far as I know! Alltogether, this model is quite difficult and tricky to build, due to its small size. I remember they said that it was intended for an intermediate modeler, but I think that because of the size of tiny details and their delicate nature, it should be build by a more advanced modeler. One has to have a delicate touch and respect for the wood, plus very sharp tools... PS: I just first noticed this glue blob oozing from the underneath of the lower left end of the transom; the pic is much larger than the model, so it exaggerates details and imperfections... Happy modeling!

-

A few pictures from the Vasa museum of ship models

Dziadeczek replied to Torbogdan's topic in Nautical/Naval History

Here are some more pics of this magnificent model. 😃 Photos of Vasa 1 : 10 scale model in the Vasa museum Stockholm (modelships.de) -

Should be CA. Sorry...

-

I don't know what size of these eyelets you need? In any case, I once found a plastic box of tiny eyelets (I think they were 1/8 in.) on Amazon for dirt cheap (their shafts were threaded though, and not smooth). But, if you have a pin vise, get a short length (about an inch) of wire, the thickness of which is the same as the size of your eye on the eyelets you need. Shape its end into something similar on the pic you attached above (but do not close the hook completely!). Take a similar length of the wire for your eyelets and bend it into "U". Clamp both ends in a vise and catch the "U" with your hook mounted in the pin vise. Twist the pin vise in your hands until the wire will clamp tightly around the hook. Cut off ends for desired lengths. Release the eyelet from the hook. If you want to have smooth shaft, cover the twists with a melted solder, otherwise left alone, they will act like a thread and pushed into a hole and CD glued, will sit there tightly.

-

If you are referring to tiny wire rings, you can make them by wrapping a piece of wire around a shaft of a drill bit (of suitable thickness) fastened in a vise, to look like a spring. Than stretch this spring a bit and cut off individual rings. If you want to, you can solder the ends of each ring together with a tiny soldering iron. If you are referring to small thimbles, you can make them from a piece of small brass tubing, by cutting off short lengths on a small table saw (I have the PREAC) and than gently hammer each end out with a nail that has its end shaped (filed) like a funnel.

-

kit review 1:120 USS Susquehanna - WoodyJOE

Dziadeczek replied to James H's topic in REVIEWS: Model kits

Hi Erik, Where do you get your Woody Joe kits from? Ages ago I built a nice little model of a Japanese brigantine "Osyoru Maru" from the now defunct Japanese company IMAI (which was subsequently bought by Woody Joe). I remember, this was a nice little kit, good quality materials and pictorial instructions easily understood (I don't speak Japanese). Although, I remember, I replaced kit's wood with my own cherry, pear and maple... So, if Woody Joe makes equally good kits, you won't be disappointed with your Cutty Sark. Where exactly do you live in LA? I live in Glendale, in the San Fernando Valley, between Pasadena and Burbank. I wish we could meet next year in the planned (so far) Nautical Research Guild conference, provided this Covid19 paranoia finally goes away... I am keeping my fingers crossed! We could talk about shipmodeling until the proverbial cows come home, he he... 😄 What are you currently building? I am in the middle of the rigging on my Frenchie in 1: 48 (after mr. Boudriot's 4 volumes on the 74 gun ship). Painstaking task! Regards, Thomas -

Papegojan 1627 by mati - FINISHED - 1/48

Dziadeczek replied to mati's topic in - Build logs for subjects built 1501 - 1750

Mati, Make yourself a few rigging tools, like those shown - to make this task easier. Otherwise, your model looks PERFECT! Congrats!!! -

Papegojan 1627 by mati - FINISHED - 1/48

Dziadeczek replied to mati's topic in - Build logs for subjects built 1501 - 1750

Mati, Hung your coils onto the pins, like it is shown in this video. -

Please open up the link below and subsequently go into the link in my entry there, to read my thoughts on plastic deadeyes and blocks from Billings. For the reason I mentioned, I would replace all plastic fittings into wooden ones and bend them properly (wrap the running ends of shrouds AROUND each deadeye), because the little eyelet on each deadeye will break away in time, under the tension from the rope. Plastic is brittle!

-

Also I found this one: www.jans-sajt.se/contents/Navigation/Galleries/MyModels_Heller_Le_Soleil_Royal_100.htm

-

Frolic style ropewalk plans

Dziadeczek replied to Chuck's topic in Rope Making/Ropewalks's Ropewalk Plans/Downloads

For the modeling purposes the looper is not necessary, just the whirls will suffice to twist ropes. -

Hi, I am not an expert on your "La Creole", so I cannot help you to answer your question, but currently I am having similar problems with my 74 gun ship I am building, following Boudriot's 4 volumes. I noticed that in his books he sometimes says one thing, and elsewhere he contradicts himself. For example, he says that the running end of the fore topmast preventer stay is tied to a deadeye and the second deadeye is made fast to a jackstaff standard on the bowsprit, with a lanyard in between. But on his plans he clearly shows two blocks instead! Go figure! I think that either you will have to faithfully follow Boudriot, or use your own best judgement and perhaps make your stay, say 25 mm thick - something in between 40 mm and 15 mm, (which is on item nr. 26 on your plan). Thomas PS: I always hugely admire your build - it is an inspiration for me with my own build, but I cannot come to your quality nearly enough! 😬

-

Hi Tony, The way I did it, I took a sheet of a grid paper (with 1 mm increments) big enough for the entire frame, and drew two lines on it; one horizontal line near the bottom of the sheet and 2nd line vertical through the middle. Then I drew several horizontal lines, parallel to that first horizontal line, but at various heights, the distances between being exact with the waterlines on your sheer plan. These lines will represent the same waterlines on your body plan (sections' plan). Then take a compass and from your half breadth plan take distances between the keel and each waterline for each frame and transpose them onto your body plan at the corresponding waterline, and repeat this for all waterlines. Finally connect all points into a curve representing the half profile of your frame. In order to obtain a full profile, bend the sheet at the vertical line, place it on a light box and with a pencil trace the opposite profile. Or, when you mark the above mentioned points on your body plan, mark them symmetrically on both sides of this vertical center line. This is done manually, folks with computer programs can do it much faster, but I did not own such a program at that time. This curved line only represent a mid section in between both parts of this "sandwich" that makes a frame. You will have to draw a few more lines like that in order to have a full shape of a frame. See, each frame hypothetically cut horizontally at a given level has a rectangular shape - for the mid frames , but this shape changes as you go towards the bow and the stern of the hull - they become progressively parallelograms due to the hull's oblique shape. You have to determine these shapes - for each frame and each waterline level. At the end you will have four curves - for each waterline, one is for a forward outer profile of a given frame, second is for a forward inner profile, third is for a rear outer and fourth is for a rear inner profile, so the entire process is quite laborious and time consuming, done manually. English is my second language, thus perhaps my explanations are not adequate enough, but I found a pretty good article on the internet, by Gene Bodnar, explaining everything in detail. Here is the link: SCRATCH BUILDING A MODEL SHIP (modelshipworldforum.com) Jean Boudriot is generally very good and precise in his plans and drawings, but as always, there is no guarantee and mistakes happen. I suggest you make your own body plan (transverse sections) for all frames, making sure about their proper heights at the level of the deck and/or rail. Regards, Thomas

-

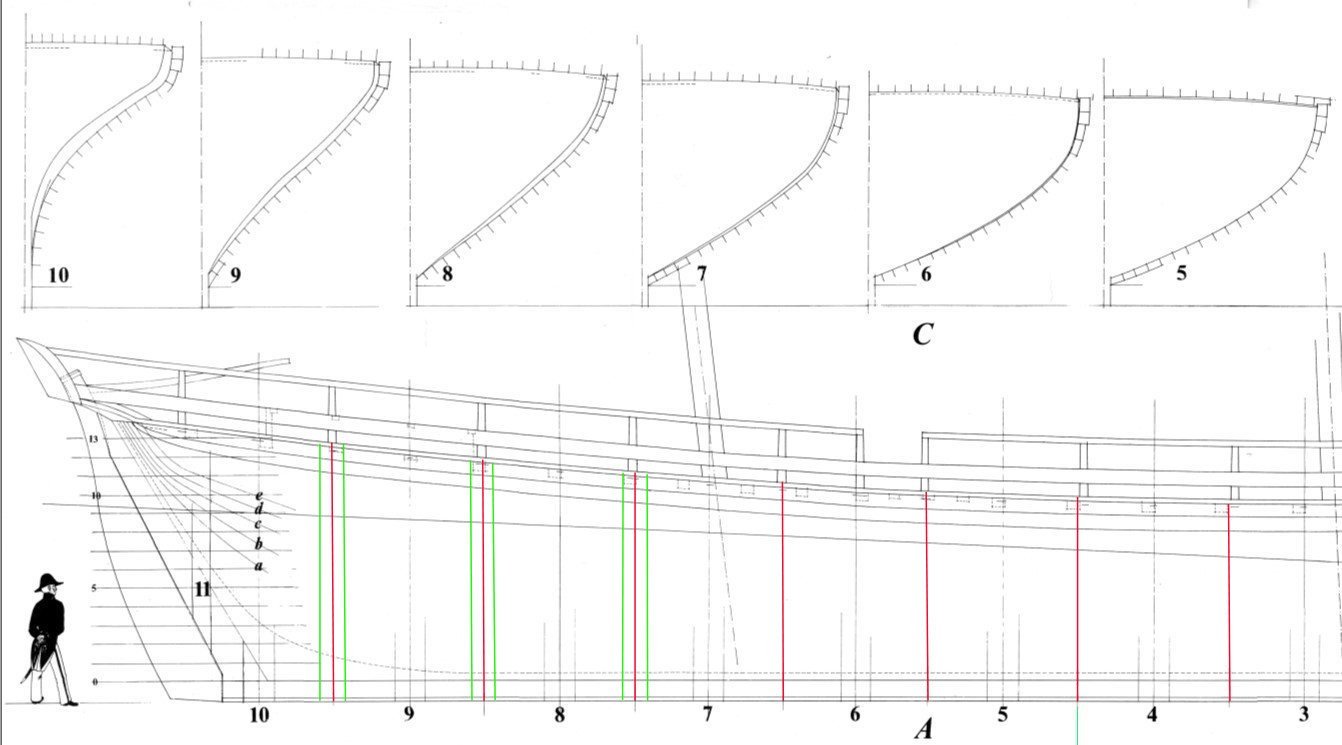

On the drawing you provided, Boudriot indicates spacings among the frames - the middle spots shown as short vertical lines between frames 1-10. From these points I would draw vertical lines up to the deck (in red on my copy) and from those, I would draw two (green) lines parallel to the red ones showing the "thickness" of your missing frames, and thus placing the "rest" of the frames on the plan. La Jacinte was not a big, heavy, Navy ship having many tightly spaced frames, like the ships-of-the-war, so I would assume that in between station frames (1-10) there was another, one ordinary frame (unless someone has a better info). Do the same on your half breadth plan (vertical view of the hull). On the intersections of these lines with your waterlines (on your half breadth plan), you will have points, delineating shapes of your missing frames.

-

Ages ago I had to hand draw missing frames from Boudriot's plans for my 74. He only drew the so called station frames, but "for the clarity of the drawings" omitted the others. It took me considerable time to do it (of course, like mustard after dinner, later on Ancre issued addendum to the 4 volumes with ALL frames included, lucky me... 😬 ). I remember I used waterlines from a half breadth plan as well as a body plan to draw missing profiles. It worked...

-

Poor piano...

-

Treenail holes

Dziadeczek replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

Why don't you impress into the wood tiny circles imitating treenails, with a sharp edge of a medical needle of appropriate size, or any other metal tube? They look perfect after slight push and twist of such needle into the wood and one coat of Danish oil. (besides, that way it's lots less work...)

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.