-

Posts

881 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JPett

-

Ahoy Hamilton Do not despair I am currently correcting a mistep I made. It took me over 25 hours to make and I estimate will take another 40 to fix. What I do is start a side project, something unrelated to the current debacle. It could be the ships boat, some deck item, or even another small kit. This way I do not rush into my repairs making another mistake, but contemplate the possibilities for a few days. Repairs will sometimes require long periods where no work can be completed and these side project fills those gaps. They also help me to maintain the right attitude I have found my repairs to be a source of great pride in my build; I hope you will too. Good Luck

-

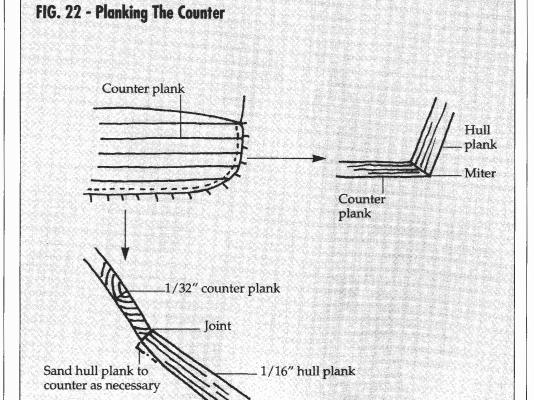

Ahoy Brian The instructions for the MS Rattlesnake tell you to miter this corner at the counter. I made up and pinned to the counter a temporary cover with the correct angle and planked up to that. Then I removed it and planked the counter. I have not completed this on my build but it has worked well so far. I can only assume this applies to the transom too. There is a pic of the temporary cover here http://modelshipworld.com/index.php?/topic/45-rattlesnake-by-jpett-model-shipways-ms2028-scale-164th/?p=870 I have included a pic from the instructions whichcan be downloaded here http://www.modelexpo-online.com/images/docs/MS2028/MS2028_Rattlesnake-Instructions-Complete.pdf

-

X-Y Attachment for Dremel

JPett replied to Martin W's topic in Modeling tools and Workshop Equipment

Ahoy MSW My Vanda lay Drill Press Plus and Proxxon XY table have arrived and I am very happy with my purchase. It holds the Dremel securely enough for my milling/drilling needs. I did have to upgrade the Vanda lay product and contacted the owner “Larry” who was very receptive to my suggestion. The Proxxon table was for the money an “excellent” choice. Made in Japan; it is well constructed and looks like it will serve my needs just fine. Now I just need to learn how to use this puppy -

Ahoy Mark Sorry to hear of the mishap but glad to see that the injury was not as bad as it could have been. "Really" you could have bled all over your ship Thanks for posting this. Having just purchased a new power tool, it has reminded me of the importance of safety.

-

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

CA vs. Wood glue

JPett replied to rtropp's topic in Building, Framing, Planking and plating a ships hull and deck

Ahoy Russ My apologizes I misread the post and thought he was using CA DUH -

CA vs. Wood glue

JPett replied to rtropp's topic in Building, Framing, Planking and plating a ships hull and deck

Ahoy Russ With thin CA and smaller pieces I have had sucess aligning the two pieces and then applying CA to the seam similar to how it is done with some plastic cements. I use a broken needle to apply very small amounts precisely at these seams. Doing it this way allows for better control over the position of the pieces due to the almost instantaneous bonding of the thin CA On a side note: I have used this techque when gluing parts with PVA, epoxy and thick CA that can not be clamped or properly secured. I apply the glue, trying to have as little as possible (none is better) oozing from the seams and then once in postion I tack it with the thin CA. If any glue does ooze out I just clean it off and then hit it with the CA. This helped me secure some very difficult planks on my hull -

Ahoy Robert I like the Scotch-Brite idea, I used a super fine sandpaper. The fact it works equally well on other woods is good to hear. I found it far superior to some of the lesser priced products for Basswood and why I decided to post a review. I will be doing some experiments with tinting and will post those results. I am hoping that because it is a gel it will not suffer from some of the issues that I had with stains and uneven penetration on Basswood.

-

Ahoy MSW Please find my review of “General Finishes” Gel Topcoat, wipe on urethane (Satin) for use on Basswood. I found this product to be very easy to work with, providing a superior finish that complements Basswood (see pic). No easy task in my book Odor was minimal but present and dry time is a full eight hours. Application was simple, I painted it on with a ¾" soft brush that I first soaked with mineral spirits to thin the Gel. Fairly large brush strokes that I thought would require sanding disappeared once dry. It sanded well too, paper only clogging after considerable use. Clean up requires mineral spirits or similar thinner. The first application did darken the wood but it returns to about 80 percent of its original color once dry. Further applications do not seem to have a noticeable effect on the wood color. It does not fill gaps very well and raises the grain only slightly on the first coat. With only one coat the wood retains many of it natural characteristics and seems to be protected. I applied two coats to be safe and prevent any paint bleed when I detail. I would highly recommend this product and find its slightly higher cost justified. I give it five out of five smilelys :) :)

-

Ahoy Popeye This is truely an amazing build. Your rigging method is very interesting. I am sure these pics will be a big help to me later on in my build. I like the rigging minions. I will of course have to add a hanger to mine. Thanks for posting them

- 377 replies

-

- america

- billing boats

-

(and 1 more)

Tagged with:

-

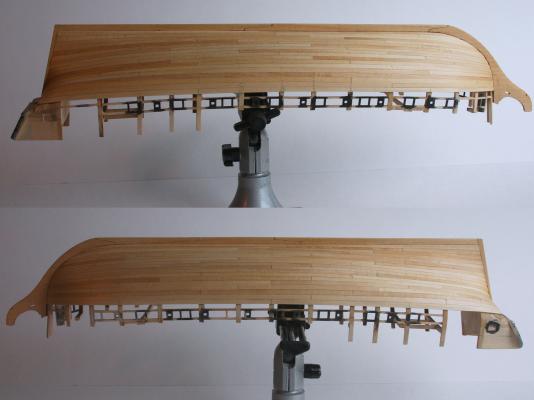

Ahoy MSW Thank you all for the comments: They are very kind and much appreciated :) In reality, it is you guys that deserve praise more then I. If my planking proves anything, it would be the benefit of sites like MSW. I merely applied elbow grease and persistence (my only real talent). It was following the example and advice of others that took the time to post in their logs or respond in mine that allowed me to reach this point in my build. Thank you all. Back to the Build: Other then contemplating some changes to the paint scheme as a result of an image I received in a PM, I have been on a small break from building. I decided to clean the shipyard and reset it. Over the last four months, working on this project produced a lot of little mementos which are now very neatly organized in the trash bin and vacuum cleaner. I will be doing treenails, additional coats of poly, my transom and redoing for the third time my gunports. I understand that with Decks, three times is the charm. I hope that this will be true for Gunports too. This decision will all make sense in that post which might not be for a week or three. Again “thank you all” for your help on my journey. Till then. Let this Pic document that my little closet work area was actually clean.

-

Ahoy Jay My apologizes to you Your post had nothing to do with shopping locally, although my post implied differently, Sorry; I think I may have combined response symtom. That or it was the beer. Let’s go with the beer ‘lol”

-

Ahoy Jay Go back and look at their veneers. They stock ebony. They also, although not on subject have a great selection of tools As for pricing, if you choose not to support your local brick and mortar they will just say good bye. I buy online but always support the locals, even if it cost me a little more. This does not include Walmart. Sorry

-

Ahoy Zev I would suggest you use the 1/32nd by 3/32nd wood in your kit and pin it to the bulkheads like a plank. (predrill it too). When it comes across the fillers it should run into the sternpost and counter without too much effort. With what you have now they will need to make a sharp turn (bend) to get there. That is what you don't want. You will clearly see this with the plank. Use the wood "Luke" PS: I glued sandpaper to a dowel to sand this close then on a piece on wood the same width as a plank to finish it. On mine, I should have sanded it more then I did and paid for it when I planked Take the time to do this right, it will pay off later

-

Ahoy Mates There are also some chain stores that do carry a very nice selection of wood. "Rockler" being my favorite http://woodworking.rockler.com/c/wood-products

-

Being a newbie, I am still a danger to my kit with a piece of sandpaper. I could only imagine the havoc I could cause with one of those

-

Ahoy Mates Sorry for the delay, BUT As we all know the ladies can take some time to get ready After much deliberation, testing, posts and some beer, well maybe a lot of beer, I have decided to let the lady show some skin. Many hours of testing only confirmed that for this build “not staining” would be my best move. After wiping down the hull with mineral spirits I found that this “look” suited my lady better then any other. Thank you all for your patience and help on my build. I would have never reached this point alone, “Really” Thank you, (place bowing emoticon here) Back to the build: Using Buck’s suggestion to make patching dust with finer grade sandpaper I came up with Basswood Patch Mk2. The finer dust was collected and then water added. About five times as much as needed. The dust was then allowed to ‘soak’. After which I stirred in a very small amount of PVA glue. Then I put drops on areas I needed to fill. The surface tension used to keep the mixture in place. It usually took three to four applications to fill a small void. As for the Sanding gala. I used an eraser as my sanding block. It was one of those moments when you look at something completely unrelated to the task and say, Hummm. The finish so far is one coat of “General Finishes” satin Gel Topcoat wipe on Urethane thinned with mineral spirits. I want to paint the wales black and keel tallow, and then I will put on a few more coats of Poly: Oh yes, and a million more treenails Suggestions, comments welcome and “again” thank you MSW

-

Ahoy Mark Home Depot sells neoprene washers. Their in the metal drawers in the hardware department

-

I'll guess I will talk to you when you get back from your trip

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Ahoy Tex All kidding aside, Take care of the Admiral As for the build I think with your Connie and Sop you have more then proven you can handle this These first steps are important, extra time spent here will pay off through out the whole build. Good luck

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.