-

Posts

881 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JPett

-

AHoy Zev When I beefcaked my fillers I stuck another piece of wood behind them pushing them out. Then I resanded. I had to put mine on the bulkhead side but see you would be better served putting it on the keel side The little corner I would sand flat and glue wood to then resand PS: if you do this make sure you have the grain running the same way in both pieces

-

Ahoy Buck I am not a native Texan but have traveled The people here rock Don't drink Shiner B either, maybe I should start "lol"

- 515 replies

-

- artesania latina

- whaleboat

-

(and 1 more)

Tagged with:

-

Ahoy Tex I would put the kit away and spend all my free time with the Admiral In a week she will be telling you to work on your hobby And then you will be "golden"

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

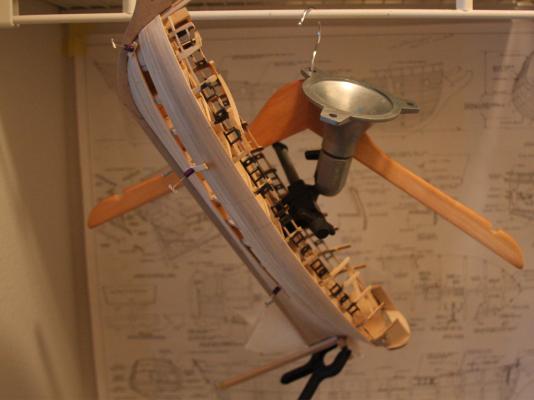

Ahoy Mates Thank you all for coming to my planking party, “last call for planksl” Mark: If I am a master, it is of listening to others like you. Thank you, your log has been very helpful. Martin: not all of us can afford mink. Back to the build: The last plank on my hull was installed last night. I started planking on 01/10/13 and finished 05/06/13. There was a three-week interlude and I estimate it took me no less then 120 hours to plank this hull (Best guess is 150). As much as I found planking a very enjoyable experience, I am glad to be done. The last plank went in without any resistance, which was nice; the second to last took six attempts to fit. As for planking the Ratt, please find below my overview/notes. 1) Mark the entire hull as per the planking practicum here on MSW. This work, which I called Ratt-Lines, was long, tedious, and boring as hell when I did it: I will do this with more enthusiasm next time because now I know how much work it saves. 2) Double, triple and quadruple check the fillers before starting. Especially in the stern. Once you commit it takes ten times longer to correct any problems here. The planks need to run up to the stern post and counter. Not make sharp turns into them. Test, test, test, then check them two more times. While were here the battens you use to test the fairing of the bulkheads must be right. Do not proceed unless you are good here. 3) Spiling is a must. I fought it and in the end, this was a mistake. Yes, it is more work and the learning curve is a little steep, but once you make sense of it, it really is not that big a deal and actually easier in the long run. 4) Where the planks turn up in the stern requires some difficult bends and the planks need to twist. For me, this was the most difficult part of the hull to plank. The planks also taper then flare out here. Run all these planks long, combing two plank lengths into one worked best for me. This can apply to the bow too. For this reason work towards the mid section coming at it from both ends, not from stern to bow or bow to stern. Fitting planks in the middle section are the easiest and should be done last. 5) Unless fitting; if possible all planks should be soaked and dried “long”, cut to the correct length only just before gluing them. Cutting them short here really hurts too, so measure twice. 6) Just throw away the bad planks and start again. Yea it hurts when you spend an hour on one plank and it is not right, but realize that you will look at it forever if you put it on. Basswood is cheap. 7) I soaked all my planks and allowed them to dry on the hull. I avoided having to forced them to make a bend or twist when it came time to glue them. Fitting the planks this way was slow but it allowed me to make sure the plank was right before I glued it in. It also made gluing much easier. 8) Do not forget to give yourself a break. Getting aggravated because of a mistake or problem only takes away from the experience. I had to walk away a few times. Planking was a very long process for me and I chose only to enjoy it. Sorry “no Pics” She is in the spa, getting all pretty for her reveal

-

Has any one built the Elsie by Model Shipways?

JPett replied to DSiemens's topic in Wood ship model kits

Ahoy 4whelr NP I am not sure which books I recommeded. The practicum I posted is a free download. Click on the "documets tab" on the bottom of that link. Ohh and Chuck is a Moderator too, Sorry Chuck. You should post a log before you start filling up the dumpser. It is easier for others to help and a much easier way to learn. You will get done sooner and spend less time figuring everything out yourself. Helps with the fun factor too. -

Ahoy Buck I worked with Willy a few times. Lets just say it was an experience. The second hand smoke only adding to it. I am not a big fan but love him personally. He is a great guy.

- 515 replies

-

- artesania latina

- whaleboat

-

(and 1 more)

Tagged with:

-

Has any one built the Elsie by Model Shipways?

JPett replied to DSiemens's topic in Wood ship model kits

Ahoy Daniel Welcome to Model Ship World The Elsie is a solid hull and an entry level kit. I would love to say that makes it easy but it only means it is easier then others. All of these kits require a commitment and time I would start a log here. Read other logs, they don't have to be the same ship. Take your time and post questions, review the responses then act. The key to success with these kits is to find out first then do the work. Test and practice before committing to the model Perhaps 4whelr will start a log and the two of you can work togeather to reslove any issues associated with this kit Here are some links "Hopeful" is a very skilled builder and has a similar build here http://modelshipworld.com/index.php?/topic/1603-phantom-by-hopeful-model-shipways-scale-148/ One of the Moderators did the practicum (advanced instructions) for the Sultana here (under the "Documents tab" ) http://www.modelexpo-online.com/product.asp?ITEMNO=MS2016 Both of these will help I am new too and just finished planking my intermediate level kit. Took me over 120 hours Good luck with your build; they are a lot of fun. -

- 515 replies

-

- artesania latina

- whaleboat

-

(and 1 more)

Tagged with:

-

Ahoy Tex CONGRATZ She looks proud I especially like the third one down in post 123. With a different background you would think it was the real ship.

- 153 replies

-

- constitution

- revell

-

(and 2 more)

Tagged with:

-

Ahoy Buck I really like the little guy, “Misty” lots of hardware, which you do very well, but it is a bit to much like the whaleboat in this respect Then there is Dallas, looks like a nice little build, but then so is the Eagle Got it: Go with the big one. Start it and when you feel like it is getting a little stale, which the bigger, longer projects can, start one of the smaller ones as a side project to keep it fresh, then finish the Golden Hind. You can do the other two while you are working on the other big one Just my two cents, but I like interludes, and understand some don’t

- 515 replies

-

- artesania latina

- whaleboat

-

(and 1 more)

Tagged with:

-

Ahoy Buck Thats not a pitchfork He's trying to hand you something to open the box and get started

- 515 replies

-

- artesania latina

- whaleboat

-

(and 1 more)

Tagged with:

-

Ahoy Jay Rif Winfield's book "The 50 gun ship" also goes into this From Pg 31 "Although in the case of the 48-gun ships, these were to be of 8 ½ ft length rather then the 9ft variety allocated to the 50-gun ship (and the 54). The main difference occurred on the upper deck where the 50-gun ship carried twenty two 6 pdrs compared to twenty for the 48-gun ships, in both classes these were 8ft guns compared to the 8 ½ ft weapons of the 54 gun-ship" It looks like where the cannon is located on which ship also needs consideration.

-

Ahoy Buck If you're ready, it's the wrong kit

- 515 replies

-

- artesania latina

- whaleboat

-

(and 1 more)

Tagged with:

-

Ahoy Popeye Your build is a jewel, many facets, all flawless. I especially like your treatment of the sails. Thanks for posting

- 377 replies

-

- america

- billing boats

-

(and 1 more)

Tagged with:

-

Enamle vs Acrylic

JPett replied to Timothy Wood's topic in Painting, finishing and weathering products and techniques

Ahoy Russ Do you use these on the metal parts too I have been experimenting with the "Winsor & Newton" Water mixable oil paint to color wood with very good results. . -

Enamle vs Acrylic

JPett replied to Timothy Wood's topic in Painting, finishing and weathering products and techniques

Ahoy Mates I prefer enamels for these reasons Better coverage: Less coats mean more detail. Not as important if you airbrush, very important if you hand brush. The paint flows better too. Better durability: I tend to handle these parts more then when doing plastics. With water based paints a clear coat is required to protect the finish and when brush painting it results in another heavy coat softening more detail. Enamels do not require a clear coat. Better color: This might just be me but I find enamel has a much richer color. Don’t get me wrong, I use Acrylics whenever possible. Painting bare wood, doing effects over enamels just to name a few but if you are only looking to own one type, I would recommend enamel. Used properly the fumes are very minimal. If the project is big then they can be an issue and proper steps should be taken. -

Ahoy Michael Excellent work on both the ship and the way in which you posted. I can clearly see what you did so well and how you accomplished it. Thanks for taking the time to share

-

Ahoy Mates Thank you all for your encouraging words Ben: Getting consistent results has been very difficult for me. Some tests come out great; others look like “hell”. I really want to avoid a crapshoot when I do my hull and continue to try to refine my technique. The wood has not been very helpful. Popeye: The problem in the stern is they taper, and then flare. It has been a difficult area for me to plank. Eric: Anything you have to offer, especially when it comes to finishing would be greatly appreciated. I am not the teacher, just the guy who does his homework. Ferit: This would be true if I had your skill. Currently I am on a ship called ‘persistence”. Sam: I looked into darker stains you mentioned. I can not however get Basswood to take them in anyway that would be considered acceptable. Carl: I have found that for me to write them down I have to properly work out the steps. This is the biggest benefit for me Back to the build: It should be noted that my “brute force and superstition” to get that last two planks in at the same time method might need to be rethought. I had what only could be considered a mild disaster. The last two planks would not go in all the way where they met the stern post; glue spread everywhere including the starboard side. It was not a good day in the shipyard, fun ran out of the room like it was on fire. It was a kick in the ars to say the least but thankfully in the end, repaired with some creativity. Only one pic, I was a little too busy at the time for them. On the bright side, this did result in an interesting way to fill seams on basswood planks. Comments welcome First, I apply painters tape to both sides of the offending seam, then use a cut toothpick to trough PVA glue into it (like when doing sheetrock). Remove the tape, then use a paper towel moistened with alcohol to clean up any glue outside the seam (very important). Heat with RC heat gun to dry the wood, then sand the area forcing dust into the seam. When done blow off excess and liberally wet area with brush. I will post pics if there is any interest.

-

Ahoy Ferit The cannons look great . You set a high mark, I can only hope to do as nice a job on my build. Can I ask where you found the blocks for the rigging of the guns, and what size you used? Did they come with your kit? My kit was a recent purchase and they are not included. I will need to add them. I would also like to know the line used too if it is not too much to ask.

-

Ahoy Buck I'll do the broken record thing "Outstanding" Your craftsmanship is amazing WASA, WASA , WASA

- 515 replies

-

- artesania latina

- whaleboat

-

(and 1 more)

Tagged with:

-

Ahoy Andy Congratz :) I hope you will be posting more pics, either here or in the completed projects forum Following your build has been fun, thank you for taking the time to share your project Your Connie looks great

- 246 replies

-

- revell

- constitution

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.