-

Posts

881 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JPett

-

X-Y Attachment for Dremel

JPett replied to Martin W's topic in Modeling tools and Workshop Equipment

Ahoy Joe How did you think the Proxxon Compound Table compared to the Sherline. Did the Proxxon at least perform up to a level that would allow you to mill small items? Were there any major faults. I also found this, which I have added to the list. Weight 13lbs http://littlemachineshop.com/products/product_view.php?ProductID=2008&category= Sent an email to Proxxon requesting additional measurements similar to the drawing link on this page The Vanda-lay base is 6"x7" and I would like to try to center the table under the Dremel if possible. The mounting point for the press rods might prevent this. My only concerns for the Vanda-lay so far are minor. 1) It holds the Rotary tool around the body and does not reinforce the head. The plastic Dremel tool body will have to deal with any lateral forces. The good news is I will be mostly cutting wood "mostly". 2) It looks like the Tool mounting bracket assembly is only attached at one point. This allows the tool to rotate but also allows it to slip. I did not see any graduation marks here to confirm a 90-degree home position. This might be my first mod. As I am not spending thousands these issues are far from deal breakers. I am only looking to put a toe in the milling pool, which is where I believe Martin is too. -

X-Y Attachment for Dremel

JPett replied to Martin W's topic in Modeling tools and Workshop Equipment

Ahoy David Can I ask what Lathe and mill you purchased, whether they were just for model ship building and how you like them I have owned alot of power tools but these were for my business. Would love to own a mill and a lathe but can not justify their expense right now. I also think stepping up, although sometimes more expensive in the long run is cheaper overall Hence my recent purchase -

Ahoy Tex On my Model Expo kit, a few of the bulkheads were wrong. Some were asymmetrical, others the cutout for the keel was wrong. If you have not already, I would suggest checking this against the plans.

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Slowing down the Dremel Rotary tool

JPett replied to JPett's topic in Modeling tools and Workshop Equipment

Thanks Vince -

Ahoy Kieth "Lol" My kids only know how to type with their thumbs.

- 153 replies

-

- constitution

- revell

-

(and 2 more)

Tagged with:

-

Ahoy Tex It is best to also "link" the two different builds. Then when you post in other logs anybody can just click on either one to come to that log. Here's how Click in the address bar while on the first page of your build. The address should should turn blue. Hold the "Ctrl" key and press the "C" key. Then edit your signature. Put the cursor at the end of the ship name and again hold down the "Ctrl" key but press the "V" key to paste it. Then press the enter key to make it a link. It should turn blue and be underlined. If you already knew how to control copy/paste "sorry". I just like to cover the bases

- 153 replies

-

- constitution

- revell

-

(and 2 more)

Tagged with:

-

X-Y Attachment for Dremel

JPett replied to Martin W's topic in Modeling tools and Workshop Equipment

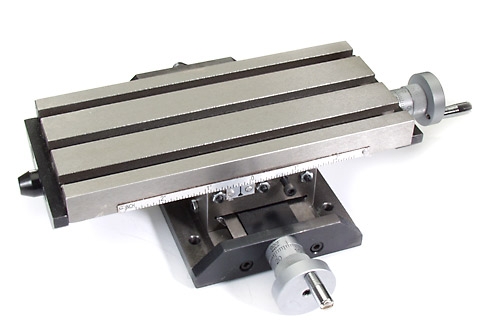

Ahoy Bob It weighs 47 pounds I am really leaning towards the proxxon. It will be for the hobby "closet" But I am searching the web to see if there is another. The amount of movement on the Proxxon is a slight concern -

X-Y Attachment for Dremel

JPett replied to Martin W's topic in Modeling tools and Workshop Equipment

Ahoy Martin OK Ordered the Drill Press plus from Vanda-lay Three weeks for delivery which is fine for me Should order the Proxxon Micro Compound table KT70 in the next few days. I see there are some other choices that I want to research. http://littlemachineshop.com/products/product_view.php?ProductID=1765&category= Double the price and it might be overkill but like I said. Need to do some research -

Ahoy Ferit Thank you When I start this build I will do a log in the kit section and look forward to your comments Until then, please feel free to post your thoughts on the kit here

-

X-Y Attachment for Dremel

JPett replied to Martin W's topic in Modeling tools and Workshop Equipment

Ahoy Martin It is a real conundrum. As someone who has enjoyed working with tools his whole life, I know there are other forces at work here. Do I buy the tool to satisfy my needs or my ego? -

X-Y Attachment for Dremel

JPett replied to Martin W's topic in Modeling tools and Workshop Equipment

Ahoy Adrieke NP Keep working with the hand tools. After a while the power tools will make more sense. -

Ahoy Tex There is no rush. I think our logs prove this

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

X-Y Attachment for Dremel

JPett replied to Martin W's topic in Modeling tools and Workshop Equipment

Ahoy Adrieke Really, I do not think there is a Drill press/milling machine for the hobbyist. Nevertheless, I still want one A Milling Machine is a tool that is used to shape items by cutting excess away using horizontal movement (X and Y-axis) against a rotating cutter blade called a mill. Some will also cut vertically (Z-axis) A Drill Press holds your drill straight, something humans cannot do Google them for more info and pics. There are also links in my earlier post For me I want a drill press that will allow me to do some milling. One that would hold my Dremel Rotary tool (think dentist drill) and allow me to drill precise holes in precise patterns. Then accept a mill and allow me to make very precise cuts along the wood and at very precise depths. One example Framing a hatch, you can now create the shelf for the crating, miter the ends to build a better box. This done on a piece of wood 1/16 thick. You want treenails in your mitered corners, no problem, use the drill press. They will be straight and exactly where you need them. A mill will allow you to cut wood into shapes you could never do, a drill press to drill the tiniest holes precisely where they need to be. The problem is that a drill press moves the bit downward using an arm or wheel and does not hold a vertical position. A mill uses a threaded rod which is turned and can maintain the same exact vertical position needed for milling. Milling machines are Insanely slow for drilling As you can see these uses are specialized and you will not be using these tools enough to justify their expense. Well at least that is my problem. Martin: If mount the Proxxon compound table to the Vanda-lay Drill press I might have something. Cost around $230.00 There is a stopper screw that will secure the Dremel's vertical position for milling -

Ahoy Tex If it helps these next few steps are very important. Double check everything and post if your not sure. The rabbet was a little unnerving for me but it seems we all get through it. Looking forward to your progress.

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Ahoy Tex Welcome Aboard I breezed over the PDF instructions for you build over coffee this morning. Looking forward to your build.

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

X-Y Attachment for Dremel

JPett replied to Martin W's topic in Modeling tools and Workshop Equipment

Ahoy Martin I have heard the same regarding the Dremel drill press. It has been called junk on some reviews I too am researching a small tabletop drill press with milling capabilities Proxxon MF70 http://www.proxxontools.com/store/pc/viewPrd.asp?idproduct=63&idcategory=31 One concern is the amount of movement on the table 5-9/32" and 1-13/16" I have also read that the accuracy/movement of the hand wheels is average. Not bad just not up to a Sherline or Taig Proxxon also make a drill stand that has recieved excellent reviews (don't think it works with the Dremel) http://www.proxxontools.com/store/pc/viewPrd.asp?idproduct=32&idcategory=33 The Vanda-lay is a very good looking product http://www.vanda-layindustries.com/html/acra_mill_plus.html Advantages: 3" and 4" of travel with the Y upgrade. I need to do more research on this product Cost for a working xyz mill stand ($342.97), this includes a 10% discount on the upgrades but not the base or a Motor tool. The Proxxon MF70 would cost me (427) at my door making the Vanda Lay slightly more after the tool. The Proxxon Rotary Tool IBS/E being the best choice (the head is better designed for side loading) The Vanda-lay does have more options/functionabilities The Sherline and Taig products are in my option "overkill" They also require upgrades to get the higher speeds needed to work at our scale. This is a big problem for the Micro Mark and Harbor Freight Mills "no speed upgrades I know of". Speed also a problem for the Nano Machine. http://littlemachineshop.com/products/product_category.php?category=824543683. This site however is an excellent source for upgrades to most of the mills listed above (possibly even speed upgrades for the MM and HF units) Right now I am leaning towards the Vanda-lay and using my Dremel 935 Mark also had a post reviewing his Mirco Mark unit that I kind of tried to hijack http://modelshipworld.com/index.php?/topic/256-micromark-micromill-review/ -

Congratz Augie Our should that be Captain

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Ahoy Augie I was going to recommend he post it here, LOL

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Ahoy Texxn5 I have the Morgan on my "bucket list". Looking forward to your build log.

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

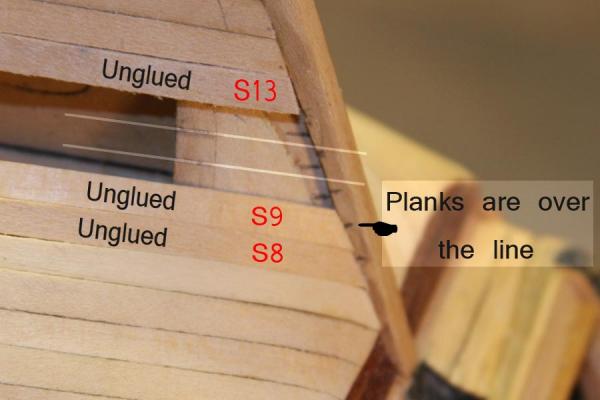

Ahoy Mates I am still struggling to compensate for the fact that planks cut at less then or greater then 90 degrees measure greater across the cut then the width of the plank. I also think there is something I am not “getting” when it comes to marking the plank positions on the complex curves at the stern. I have brought the Ratt into PS and am posting a pic. I do this when things in the real world just do not make sense or need to be checked. Checking them in a world where there is one less dimension, infinite and instant ‘redos”, works for me. I have highlighted the fact that there is enough room for the needed planks even though my ticks marks say otherwise. Comparing the plank widths I see that I can reduce S8,9, and 13 slightly and maintain an even plank width across this entire area. I would prefer not to have a plank I call “Olive Oil’ on this build: Sorry Popeye. I am also considering a change in my planking method. I will not be doing belt “B” in strakes but sections. I believe I can completely fill in the stern on belt “B”. I will try this first without gluing any planks. If successful, I will go back and glue them in; then move to the bow. Due to the spiling that is needed in the bow, I have to glue each plank as it is made. This because they become so thin if I sand them to the needed width off the hull they can and do break. The entire midsection will be filled in last. What I am also liking about this method is the last plank in each section does not have to be in the same strake as the other "last ones". My hope is by breaking up the filler strake it is less noticable. Tiny is my new “oversized” concentric pin. Wish I had made her three months ago. There is no arguing with her. Comments welcome, especially if this is a “really bad idea”.

-

Ahoy Ben Been lurking here to long to not to say hello and compliment you on this build Congratz on the bonus check too. I am sure it was well deserved. Enjoy the toys

- 147 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.