-

Posts

2,238 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by clearway

-

you will find planking will straighten some slight wiggles out- are you going gunports open or closed? Keith

- 60 replies

-

- victory

- billing boats

-

(and 1 more)

Tagged with:

-

accents in the u.k are tricky to people over the pond- everyone thinks we talk like the queen or eastenders cast! cumbrian accent is kind of unique along with liverpudlian, lancashire, north east and yorkshire accents- watch open all hours, and james herriott series if available to get an idea of northern accents- along with ant and deck for north eastern accent😁

-

you will need to sand the paint off the ply siding as this will need planked over to allow a better key for glue. Keith

- 60 replies

-

- victory

- billing boats

-

(and 1 more)

Tagged with:

-

i hear you keith, i am thinking of alternatives to the aluminium as well- you need to polish it before gluing and painting though it is soft compared to brass or nickel silver sheet- bit to go before i need to think about that part though😁 Keith

-

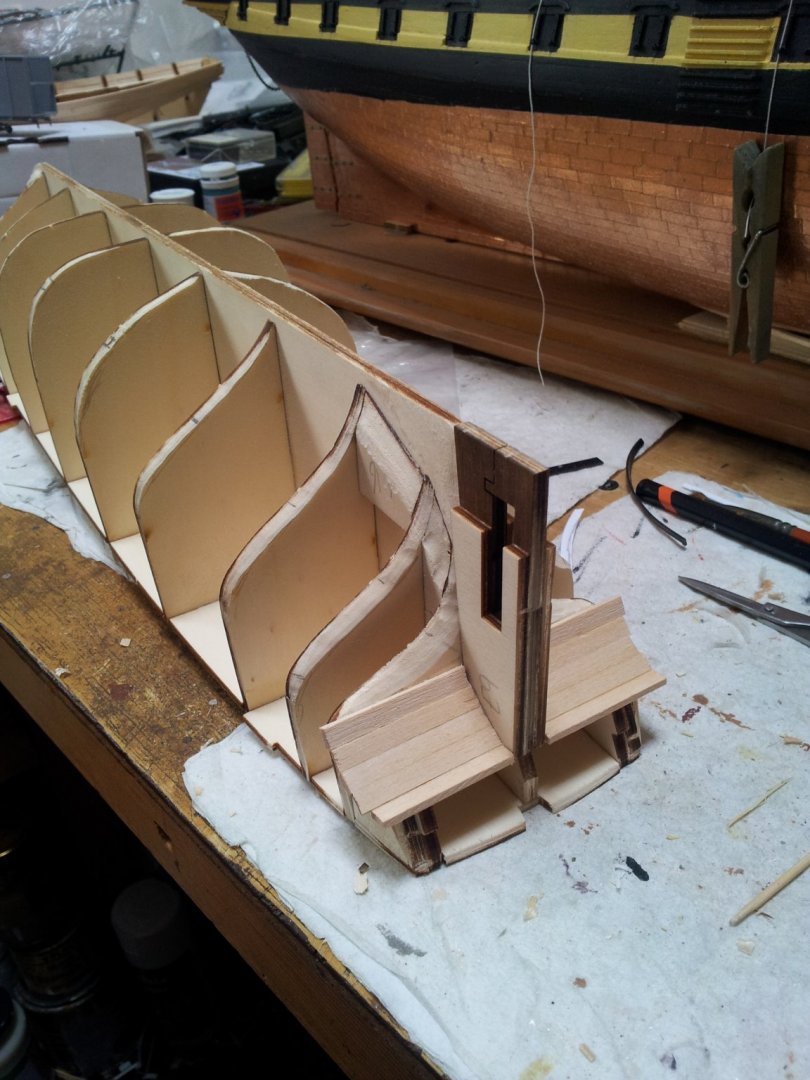

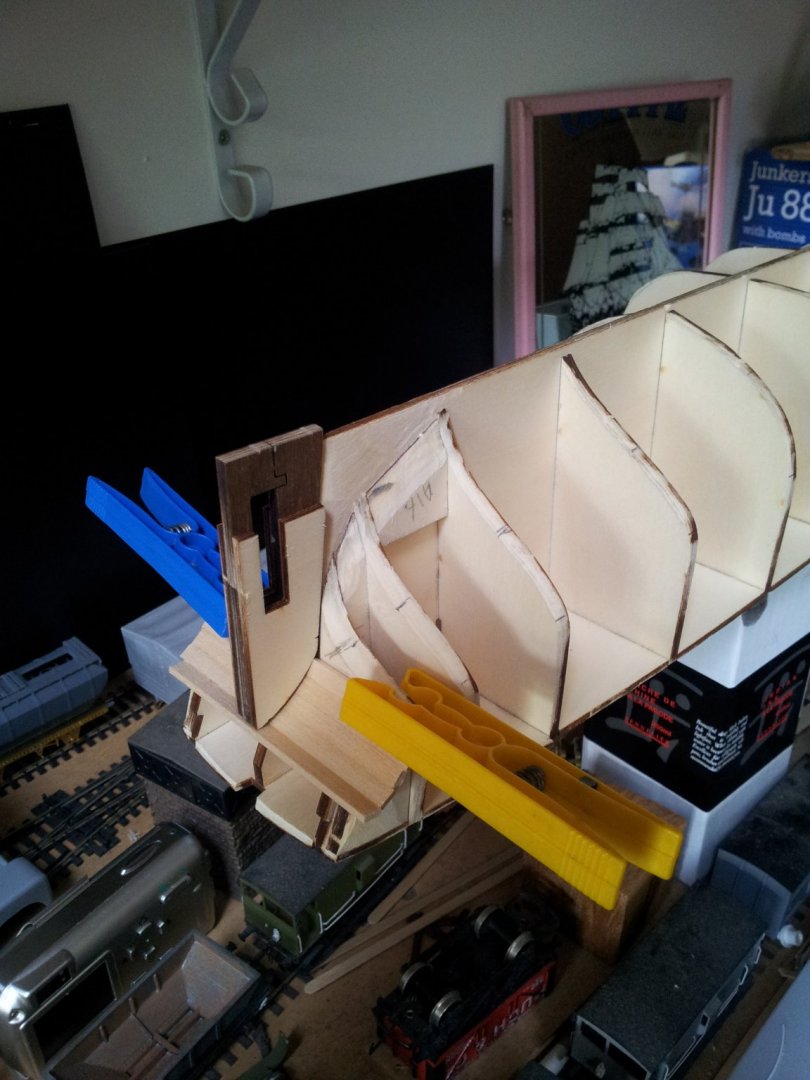

i had to do the same with the ply formers- as mentiond in blog cut and shut them till they sat with less wavy effect- when it comes to actual planking check a few different logs and images of real victory and mark out where the lower whale goes- you will have to start tapering the planking from there down - you can see the run on the stern on my victory- no blocks were used on mine but its up to you. Keith

- 60 replies

-

- victory

- billing boats

-

(and 1 more)

Tagged with:

-

thanks for views and comments -used the last of the full length planks and got a couple of runs with kit supplied planks staggering the joins where it doesn't reach the stern- at 2mm thick it isn't very yeilding! looks a bit messy but should sand up o.k.🤨. take care all Keith

-

ahhhhhhhhhhhhh the memories😉- hope my log helps Matthew- any questions just ask Keith

- 60 replies

-

- victory

- billing boats

-

(and 1 more)

Tagged with:

-

You got there in the end with the frames Emmet i see- give the deck a sanding and let it oxidise for a few days- colour sometimes alters- for example walnut comes out of the box an ugly chocolate brown and mellows to a lovely honey colour- on the real ships though they were painted red to hide the blood! keith

-

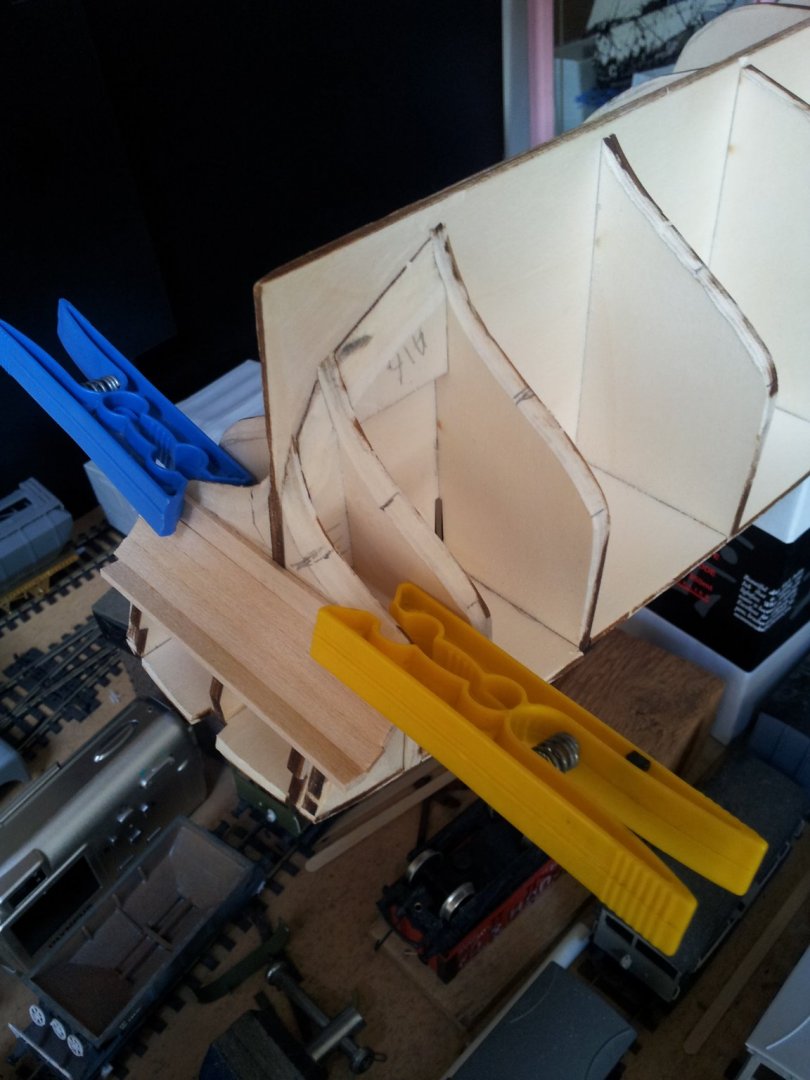

Thanks for views likes and comments everyone- because the planking strips supplied with the kit arn't long enough i dug out some left over from previous billings builds- although a bit on the rough side i did want to have full length planks for the first few runs. First i pencilled off the line where the ply bulwarks will reach too. take care all Keith

-

cheers jeff - still a bit jittery about how it will turn out as i am making this up as i go along 🤔

-

Thank you Keith- it will explain a few things- they might have done things with the rig on exploration ships slightly different, but i imagine the rigging for controlling the yards and sails would have followed standard naval practice- will explain them sheaves set into the bulwarks abaft the masts for example. The kevels just before the steps to the poop deck are for the topyard tyes which lowered the yard and raised it, and the two on the entry way inline with the mainmast are for the mainyard lifts. Keith

-

😁well done jeff- nice job and love the stand. gets the lads on my victory to roll off a 21 gun salute Keith

- 86 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

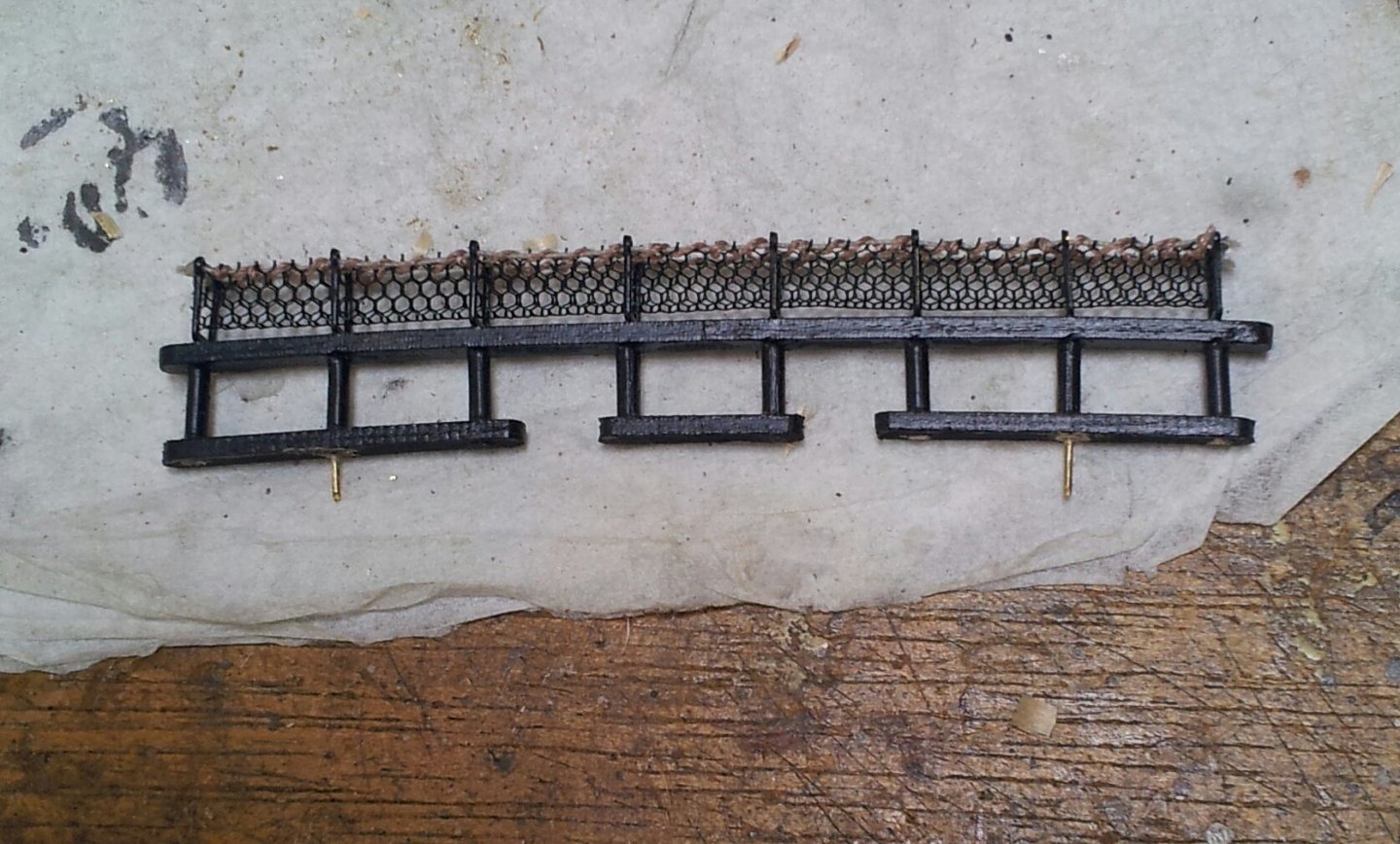

Thanks as always for views likes and comments everyone. Got all the rigging on the quarter deck stored away on the belaying pins and made progress on the foreyard- omg foreyard at last! Nearly glued the railing in place before the mainmast, but realised i will have to rig the mizzen crossjack braces so will need access still. enclosed this shot of the rail to show the brass pins that will hold it in place. take care all Keith

-

Thanks for views and likes everyone-if i hadn't built a few already i wouldn't have tried either Keith and yours looks o.k. - to be honest we will have to see how it turns out in't end🤨. While waiting for some glue to dry on my Victory i fettled the planking on the counter to take the sternpost. take care all Keith

-

Thanks for views ,likes and comments everyone- got the replacement frames in the bow faired and the planking on the transom- always makes me nervous altering the way a kit is built- go too far and one ruined kit🤢. glued the three parts for the sternpost assembly (still need sanded to final shape) and trial fitted to stern- need to rebate into top and bottom planks to get it sitting right' the first planking will finish at the frame the will be rounded off to do the tuck with the second planking. after the planks on transom have been sanded to shape can start planking- yeyyyyyyyyy. take care all Keith

-

wow you were up early martin! hope you got it as nice as we have in cumbria this morning- yep model shipbuilding is a pleasure/ pain thing along the lines of sado/masochism😏. also google cutty sark and click on images- nothing like real thing for info🙂

- 12 replies

-

- artesania latina

- cutty sark

-

(and 1 more)

Tagged with:

-

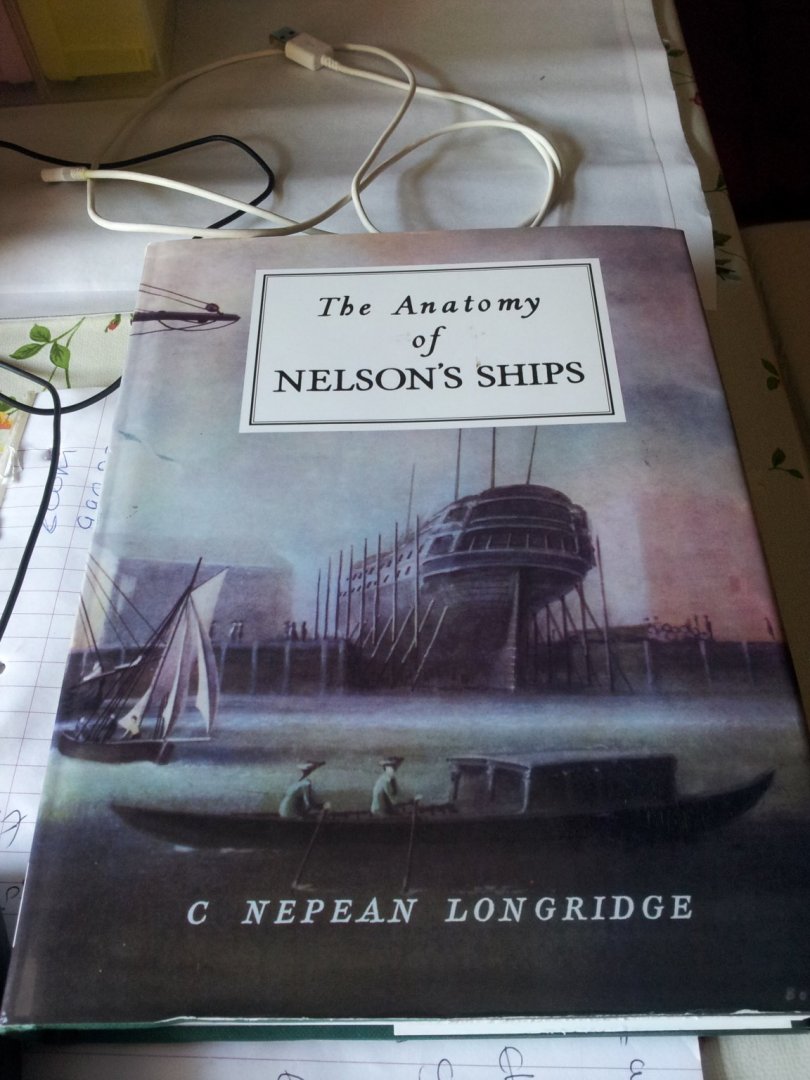

hi matthew my longridge anatomy of nelsons ships is in a smaller thicker format but an essential must have for victory modellers😉 just take your time and double check everything Keith

- 60 replies

-

- victory

- billing boats

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.