mort stoll

NRG Member-

Posts

541 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mort stoll

-

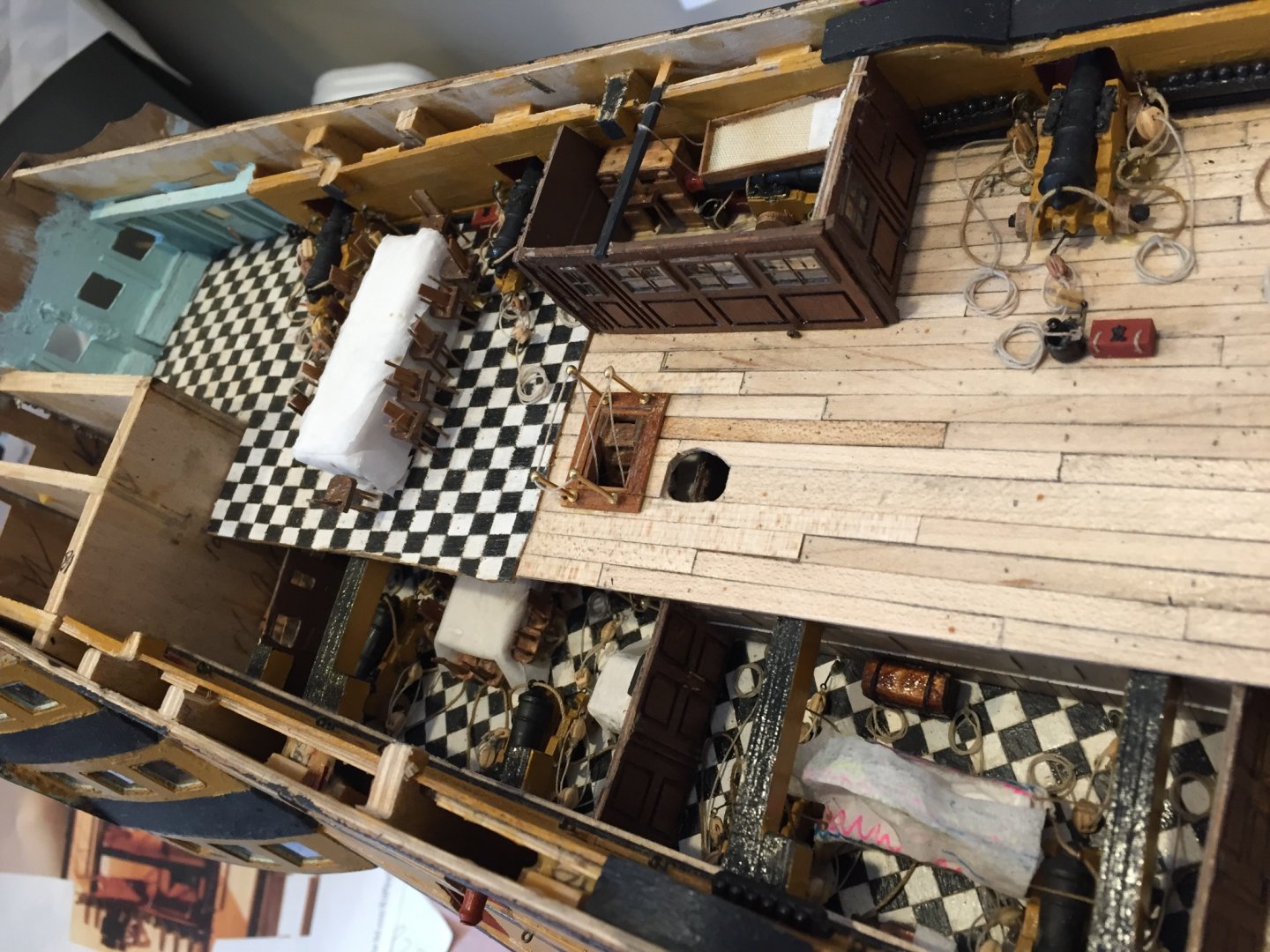

Hi, As you can see I've completed the beakhead bulkhead and timberheads. The bulkheads for the Captain's dining and day cabins are installed. I've also completed the Captain's dining and day cabin. The dining cabin has 2 side tables and a liquor box in addition to the dining table and chairs. The day cabin contains 2 clothes trunks, a dresser, a chest and a desk. I'll probably add a small circular table. I tried to remove the center keel piece and the other bulkhead # 105 thereby opening the remaining area of the day cabin, but It's too involved for my skill set. You can also see the template for the poop deck dry fitted, there exposing the Admiral and Captain's cabins. I thank you Heinz very much for your support. You're the best. Stay safe and well, Mort

- 60 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

- 60 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

I think it depends on the size of the rope you're serving. I've used both sizes - Gutermann's - for years and am happy with the results. Stay safe and well, Mort

- 527 replies

-

- caldercraft

- victory

-

(and 1 more)

Tagged with:

-

Hi Jason, No it won't be necessary to adjust any of the deck beams. The only adjustment is the removal of the right half of the beakhead bulkhead. My concern is amount of the upper gun deck visible when looking at the model bow on. The windows are mica. It was a gift from a fellow NJ Club member ages ago. He doesn't remember where or when he got it, but he bought it on line. I got the idea from looking the models in the "Rodgers " and "Kriegstein Collection" books. Hope this helps. Stay safe, Mort

- 60 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

I've a question concerning the beakhead bulkhead #205. I'm thinking of removing the right side of the bulkhead in order the make the bow interior more visible when viewing the front of the ship. As you can see if you check my 2/15 post - the first picture - the starboard bow portion of the upper gun deck is exposed. With the marines walk, bowsprit etc. will removing part of the bulkhead provide more visiblity and do you think it's worthwhile? Thanks, Mort

- 60 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

As you can see I removed part of #105 in order to build part of the captain’s area. In retrospect I should have removed both of the top parts of #105 and the keel piece but I couldn’t visualize if it would work or not if the stern fascia #374 would properly fit. The pictures show the captain’s quarter gallery with a hanging lantern and commode. Also shown are some furniture dry fitted in the captain’s day cabin.

- 60 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

- 60 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

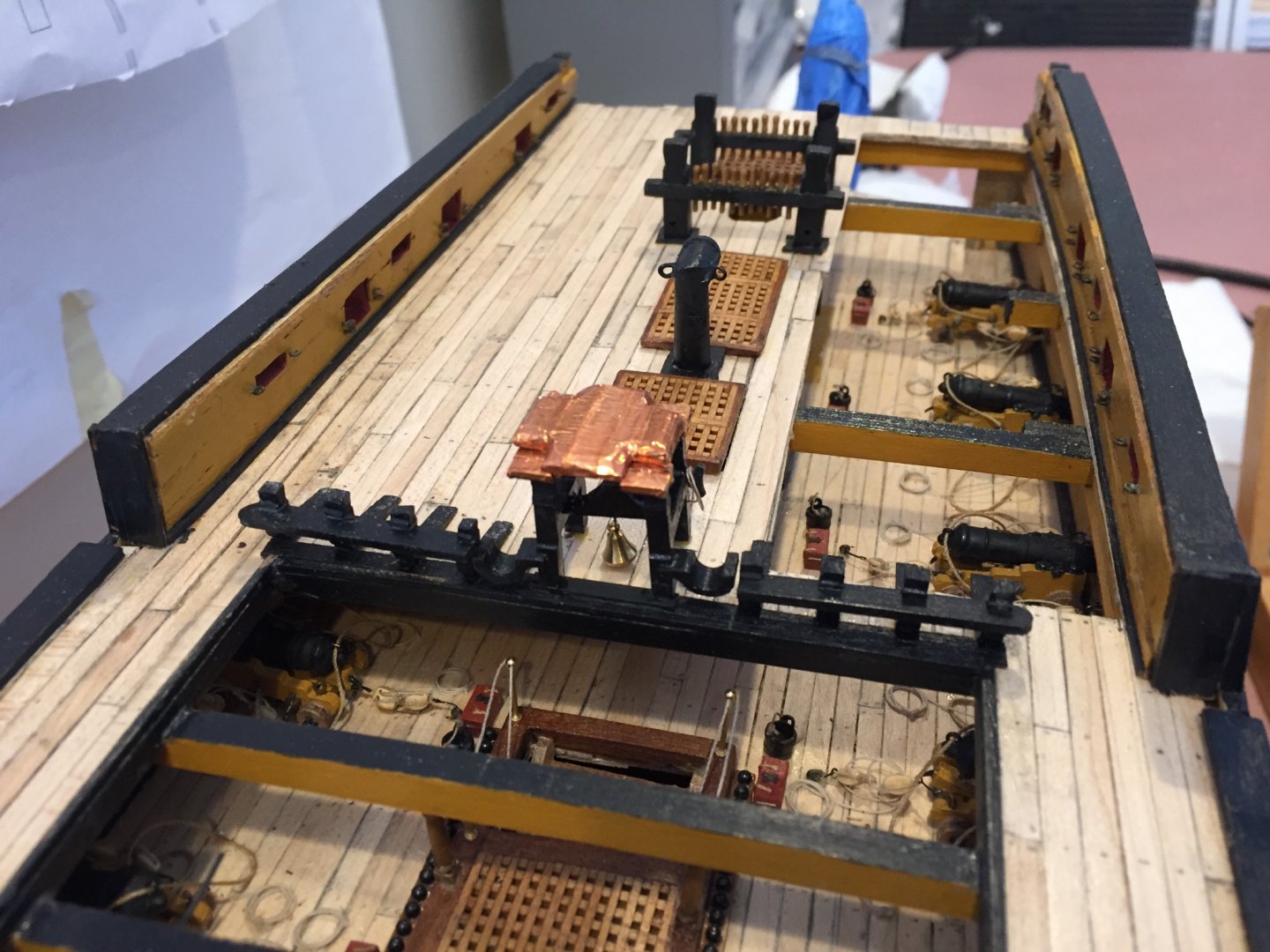

Hi, I think I've figured out how to post pictures, which don't do any justice to the real life appearance. Hopefully I can do it again. I'll try post earlier ones. The above show the forecastle breast beam assembly, with the exposed port side upper gun deck, the masters cabin - with bed, desk and clothes trunk - the admirals sleeping cabin - with wash stand, clothes trunk and bed - partially exposed admiral's dining cabin and the captains dining and day cabins. I'm awaiting more parts from Caldercraft and then I can complete the captain's dining and day cabins. Stay safe and well, Mort

- 60 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

- 60 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

Well done sailor. Very, very well done. Mort

- 171 replies

-

- artesania latina

- bounty

-

(and 1 more)

Tagged with:

-

Help! Deadeyes and rings issue. Mamoli Constitution Kit

mort stoll replied to jfitzjr1's topic in Masting, rigging and sails

You can make your own dead eye rings out of wire or black thread. Simply wrap them around the dead eye, mount them and you should be good to go. Hope this helps, Mort -

Can't thank you enough for your posts. You have no idea how much I admire and respect your build. Keep up the great work Stay safe and well, Mort

-

Hi Robert, If it were me I would paint them black so everything matches. Be safe, and keep up the wonderful work. Mort

- 527 replies

-

- caldercraft

- victory

-

(and 1 more)

Tagged with:

-

impressive, very nice, very very nice. mort

- 366 replies

-

- bellerophon

- victory models

-

(and 2 more)

Tagged with:

-

Well done sailor. Very, very well done. Mort PS Where did you get those figures? They are wonderful.

- 122 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Well done sailor, very, very well done. mort

- 414 replies

-

- caldercraft

- victory

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.