paulsutcliffe

Members-

Posts

974 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by paulsutcliffe

-

Very nice Michael must be great to work at that scale and show all the lovely joints etc Regards Paul

- 2,215 replies

-

What a great looking model, tempts me to have a go at this one myself, Nice work love the old dreadnoughts Regards Paul

- 467 replies

-

- mikasa

- wave models

-

(and 1 more)

Tagged with:

-

Looking great on the stand Michael, I'm getting Confused which is the model and which is the real boat😀😀 Regards Paul

- 2,215 replies

-

Beautiful work as usual Ed and thanks for the arrow 😀😀

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Mike I find polishing the Liberon sanding sealer with wire wool removes the shine, makes very smooth and imparts a sort of satin finish that is very acceptable, and can be polished even further with a light rubbing of oil Regards Paul

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Unfortunately no work in the Sirius this weekend as had orders from above to make handles for the wife's sewing machine screwdriver and her unpicker thingymagig, First try at turning with the screwdriver and then went mad with some glued together strips for the unpicker, the small one in the middle is a piece of naturally two coloured ebony The machine is a 1932 Jones in beautiful condition so I thought I had better put some effort into the handles to match the workmanship on the machine, she chose three so that means I get to keep the bottom right for one of my xacto saws bargain!!

-

Hi Alan I'm not sure the planks would be nibbled into the waterway as Mark suggested, this was a later arrangement with the advent of power saw mills etc, Druxey mentions this in his comet book If you have twenty planks amidships you would need to taper them to fit at stem and stern where they come down the side if their width would be less than half the plank they were scarfed into the next plank, hope that makes sense see below at the right of the windlass And here in the bow Hope that helps Regards Paul

-

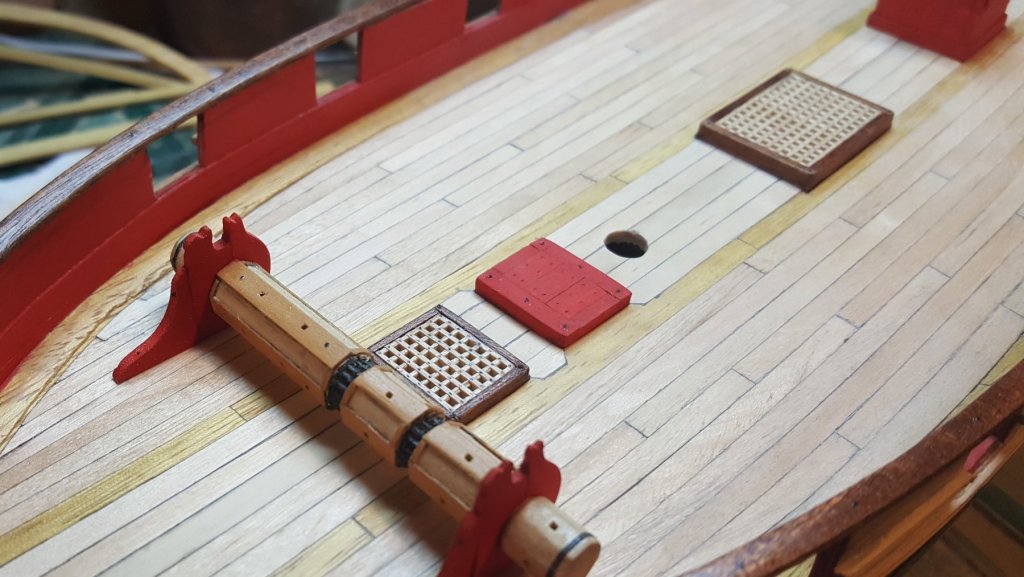

The forecastle is completed apart from some lodging knees, I have also cut the skid beams ready for cambering, brodie stove finally hidden under the beams after all this time Foremast partner is in the process of being test fitted, I also added some chocks on either side of the fore bitts as seemed very weak area, the two iron knees can just be seen in the photos Regards Paul

-

Thanks recording now

-

Awesome work ed as usual, please keep adding the arrows on your pictures sometimes I can't work the lines out and it was a great help thankyou Regards Paul

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Fantastic work as usual Ed, ,lovely to watch Regards Paul

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.