-

Posts

9,455 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Chuck

-

-

-

Thank You...

In preparation for planking the deck, I added the waterway/margin planks. For my purposes here I talk about them as two separate pieces. First the wider margin plank was created with scarf joints next to the bulwarks. I used card stock to make templates first. There are three lengths as shown below. This required a lot of tweaking until I got it right. Then the templates were traced onto a 1/16" thick sheet of boxwood and cut out. The deck planking will be 1/16" thick.

I spent a lot of time carefully shaping the scarf joints with a #11 blade and some needle files until they were a nice clean and tight fit. Then they were glued onto the deck area. The back edge needed to be beveled so I could get a tight fit against the bulwarks in many areas. Particularly at the bow. A pencil darkened the seam of scarf joint just like the hull planking. Eventually the deck planking will be nibbed into these margin planks.

When finished, I added the waterway on top of the margin plank. It was a 1/32" strip that was slowly sanded to become a 1/4 round. I basically sanded off one corner edge and rounded it off. It was glued on top and the seams between the pieces were carefully lined up with the scarf joints. So again three lengths were used. This way they look like they were done as one piece. These thin strips also needed to be beveled to fit tight against the bulwarks. The bulwarks are unfortunately not at a nice 90 degree angle to the deck so the bevel was an absolute necessity.

Now its time to start building the hatches, coamings and gratings and skylight. Then I can plank the deck around them. I cant wait until thats done,. After this step its just about the small details...and that is a lot of fun.

Chuck

- Model Mariner, reilly, ioannis and 35 others

-

38

38

-

Thank you guys.

Just a real quick update. Not to much except I did drill the hawse holes and the hole for the bowsprit. As simple as this procedure may sound it is actually rather tricky. I had to be really careful to drill these parallel to the keel and straight back. There is always a tendency to just drill through straight in. But instead, the bit must be held so it enters the bulwarks parallel to the keel. I started with a small hole so if the angle was wrong it could be corrected. Then I switched to needle files and then an even bigger round file to finish it off.

The angle is super important because the hole for the bowsprit must be drilled the same way. Straigh back and parallel to the centerline. If the hawse holes were drilled at an "off" angle then there wouldnt be room to properly create the hole for the bowsprit. I used a graphite pencil to darken the hawse holes but I may go back and use a dull flat dark gray instead, No rush to decide.

Now I can move on and start creating the waterway in preparation for the deck planking.

Chuck

-

-

-

-

Of course you can...Just take the parts list and see how many you will need. I cant break down a package for so few blocks...so you will have to buy a complete package of each size. Otherwise I would only be selling 15 blocks of various sizes. I am sure you will find use for the extras on future models.

Chuck

-

-

Dont overthink it......it looks perfect. I think the planking will go just fine. Its about what I had too more or less. That little bit wont matter and it could be so many factors. Press on with the planking.

Chuck

- Erik W, Stuntflyer, Mirabell61 and 6 others

-

9

9

-

Thanks guys...its nice to be back working on her. The deck planking is the last major project on the model. I have to start with making the coamings and gratings first.

Chuck

- justsayrow, cog, GLakie and 7 others

-

10

10

-

After planking the bulwarks I painted it red. The finished bulwarks were 5/32" thick. Maybe slightly thinner. Then it was time to add the caprail. It will be added in two pieces. First the main rail which is 1/16" thick. This was sanded flush both inboard and outboard. Another strip will eventually be placed outboard as a fancy molding. It is scraped like the others and is 1/6" x 1/32". But it wasnt added yet.

First I had to create the hawse hole plates....which are essentially 1/32" thick pieces with the holes ut for the hawse holes and the bowsprit. This sits flush with the top of the caprail so I had to add it first before I could add the fancy molding strip along the caprail outboard. I didnt drill the hawse holes yet. This will be done next. But the hawse plates in position makes it easy to find their locations. So that will be done in a day or two.

Lastly I added that fancy molding strip outboard for the cap rail which stands proud of the hull planking and finishes it off. This is where I am to date and after drilling the hawse holes and hole for the bowsprit I will make preparations to start planking the deck. Its getting there...

I am contemplating painting the hawse plates and the stem above the ear molding black.....along with the fashion pieces at the stern. But I have time to decide that. So I will live with it as it is shown for a while before I commit to it. Maybe after I drill and file the holes for the bowsprit and such...we shall see.

- Remcohe, Kevin, Senior ole salt and 39 others

-

42

42

-

Model Shipways didnt have the fractional size strip available and so it was decided to go with the 1/8" wide strips. I mentioned this a few times in other logs. BUT yes the plans are correct in every respect...always follow the plans...

When I designed the kit I actually used 5/32" wide strips for thwarts. It matched the plans. But just as MS swapped out the hull planking for a different size recently they did the same with the the thwart material because they dont have 5/32" wide strips anymore. This was done a while ago but they actually had the thought to change my dimensions in the instructions. Something they forgot to do with the recent change for the hull planking. My guess is that as time goes by more changes will be made on the MFG side without addressing the model ramifications.....yes it can get confusing..but always follow the plans. It is something that they cant change too easily.

Chuck

-

Remember this is an advanced kit...

The shape and size of this thwart is clearly shown on the plans. It can be made in several ways...whether you use a one piece strip and shape it or build it up with two doesnt matter. I am not sure how this detail could paralyze your progress. Not a great deal of aptitude and reasoning is needed.....I did in fact make it from two pieces...I used a 5/32" wide strip for the main thwart and then glued another 3/32" strip to it along the center for the area thats even wider. Then it was shaped to match the plans by sanding and filing the circular shape to accept the mast. If you can see the final shape on the plans and were given the thickness of the part along with photos....it really shouldnt be that hard to figure out how to cut it out....whether in one piece or with two. But for folks who need a little hand-holding...consider the text in bold an addendum to the page of instructions...always follow the plans.

Model Shipways didnt have the fractional size strip available and so it was decided to go with the 1/8" wide strips at some point. I mentioned this a few times in other logs. BUT yes the plans are correct in every respect...always follow the plans...

When I designed the kit I actually used 5/32" wide strips for thwarts. It matched the plans. But just as MS swapped out the hull planking for a different size recently they did the same with the the thwart material because they dont have 5/32" wide strips anymore. This was done a while ago but they actually had the thought to change my dimensions in the instructions wherever I mentioned 5/32" wide strips. Something they forgot to do with the recent change for the hull planking material. My guess is that as time goes by more changes will be made on the MFG side without addressing the model ramifications.....yes it can get confusing..but always follow the plans. It is something that they cant change too easily.

If this step is what tripped you up then then I am certain there will be more that do. Its not real difficult. ....yes maybe the dimensions were reversed...but will someone tell me how someone could get paralysis analysis..because they couldnt figure out that 1/32" x 1/8" is the same as 1/8" x 1/32". If thats all you found to be stuck on so far I think things are going pretty good. I think too many people want every last detail and step written about which is a far cry from other instructions. I am not trying to be a smart *** but really am having trouble with the level of detail needed for some folks. For any model with so many complexities and parts, the designer and writer needs to assume that advanced model builders would know how to do some aspects without writing 300 pages of instructions. This is why this kit was labeled as an advanced kit.

Also...the reason for this group build area is so that if anyone gets stuck, they can just pose the question in their log...or send me a PM and I would explain as it is sometimes difficult for me to check and read every post on this site. I could miss the question.. I am sure you would have received many way to achieve the same results. Please remember that for the future. When in doubt...send me a PM.

If anyone finds additional weirdness, please let me know so I can set the record straight.........SEND ME A PM PLEASE.

Chuck

-

-

For whatever reason, Model Expo decided to change it. It was not something I designed for. That would be the appropriate final thickness however. But because the kit has really soft basswood it isnt a good idea to use it. I recommend going with 1/32" thick basswood wood having a bit of meat to then sand down to the proper .025 thickness.

OR if you decide to upgrade to a harder wood like boxwood then it would be ok to start with a thinner wood. But as designed for basswood I recommend the 1/32" thick stuff. Cleaner edges and more room to sand out rough planking jobs if needed.

Chuck

-

Nils,

Cheerful was NOT clinker planked. I know that its a simple thing to just think that all cutters were planked that way (like Alert). But its simply not true. This class of cutters was carvel planked. Just as the contemporary model of Surly shows. I suppose that folks could clinker plank the cutter but it would be historically incorrect.

Chuck

- Stuntflyer, Rustyj, mtaylor and 4 others

-

7

7

-

That looks very good.. Well done!!!

- Archi, robin b, Dimitris71 and 1 other

-

4

4

-

-

Just a quick note from admin...

What Mr Frisoli did was grounds for being banned from this site. You cant pretend to be someone else and play games like that on this forum. So a quick warning to Tom....dont get cute. He knew what he was doing. I personally think the laser cutter is well overpriced for what it is. You can alter it and work for days adding new parts like Mark did on any Chinese machine bought on Ebay for $750. When you spend $2000 for one that performs the same way and needs just as much attention there is definitely an issue. But I will give you the benefit of the doubt so you can try and help these good folks who read on your site that they just needed to "plug it in and start cutting".

That is clearly not the case....and it still says this on your site. I find that very misleading since you just admitted as much and so did old Mama bear

"But, as with using any delicate instrument, and as Mr. Taylor pointed out, a bit of technical savvy goes a long way toward achieving early success.

Now . . . I'll kid you not. To develop use of the machine to its full potential, you're going to have to spend some time with it, and learn the various techniques and tips and tricks"

Tom, if you are serious about being fair and straight with your customers, I would expect you state the same on your website and in your catalog. But I am not holding my breath. So please be respectful to our members unlike Mr Frisoli. I own a much better machine which actually did work straight out of the box with no replacement parts and in one hour I was cutting parts.....and I will recommend to all folks that they should consider another machine. It might cost you more but they are proven machines....also wait for more reviews of this MicroMark Laser knife machine and tales of success or hardship before you dive in. The research is key here.

Chuck

MSW Papa bear

-

-

George you are kind of correct...

The Frisoli's actually own MicroMark. John is the president and owner. So he isnt exactly being fair and truthful....Yes he does own a MicroMark Laser Cutter

.....or you might say he owns them all

.....or you might say he owns them all  , until they sell one of those inferior machines to someone else. He just left that part out of the post.....

, until they sell one of those inferior machines to someone else. He just left that part out of the post.....

Link below.

https://www.linkedin.com/pub/john-frisoli/35/a7/8a1

Chuck

-

-

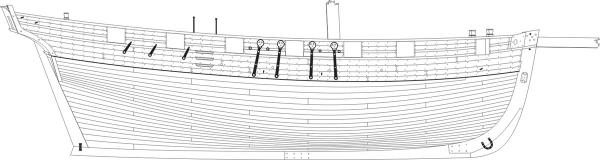

Finished planking the bulwarks on the port side after installing the false deck. The false deck was 1/16" thick. Then I added some filler strips at the bow and stern where I thought I needed it. At the bow to beef up where the hawse holes will be. You can see these strips below which I used 1/16" thick scrap strips for these filler pieces.

The first plank (3/16" wide and 3/64" thick) was placed right below the gun ports. The planking below the ports inboard is thick and stands proud of the planking between the ports. This will be accomplished in two layers much like the wales. Placing the plank directly below the ports first allows me to get the run of the planking correct as it must follow the bottom of the ports. Then the remaining planks were added below that and above. Once completed the second layer of thicker planking was added. This is the spirketing. It runs from the deck to the port sills and is thicker....but not by very much. The original planking draft has the spirketing just 1/2" thicker. I used 1/32" thick planks for the second layer and actually thinned them down a bit more. Then I softened the edge where it stands proud along the sills. I try to soften all of the hard edges like this. The thickness of the hull where the caprail will be is 5/32" thick after planking. The cap rail will be 3/16' wide hanging over a bit outboard.

Once I get the planking done on the other side I will install the cap rail.

-

HM Cutter Cheerful 1806 by Chuck - FINISHED - 1:48 scale - kit prototype

in - Kit build logs for subjects built from 1801 - 1850

Posted

Thanks,

Today I started making the coamings for the hatch gratings. There are three, but only two need coamings. The main hatch is shown here. The second smaller grating will be just aft of the windlass.

The gratings were made using the Syren grating kits with camber already built in them.

Then the coamings were built up around the finished gratings. Too often I see folks build the coaming following the plans and then when it comes time to add the grating it wont fit. Sometimes you end up with holes along the coaming or have to shave down the grating too much to fit it into the coaming. By building the coaming around a finished grating I wont have this issue. Now my grating may end up being a hair larger or smaller than the plans but that is less important than having it look correct. We are talking about maybe .025" larger or smaller...thats acceptable.

The coamings were made with the usual lap joints. Note the fore and aft sides have a roundup. These coamings are 1/4" high. Others will be less and not as thick...they are all different but for the two gratings the coamings are 1/4" high x 3/32" thick. But dont forget that the planking will go around them so only 3/16' will be above the planked deck.

Then a right angle jig was used to round off the corners except for what will be the bottom 1/16". The jig is 1/16" thick which will be the same thickness as the planking. I added a strip inside the coaming on the port and starboard sides to create a lip to support the grating as well.

To finish it off I softened the hard corners all around the top edge of the coaming. I may or may not paint the coaming red and leave the grating bright. But I dont know yet. I have seen Cutter models done both ways. There will be a lot of other deck fittings painted red so I dont want to go overboard... . Tomorrow I will make the coaming for the smaller grating behind the windlass.

. Tomorrow I will make the coaming for the smaller grating behind the windlass.

Chuck