-

Posts

9,691 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

Beautiful work..... I also painted the top of the roof black because it made the fine filigree carved details on the roof rail stand out more. Really nice work Ben. That certainly doesnt look like laser cut parts from a kit. It looks like the finest of scratch built quarter galleries to my eye. The carved drop is a perfect match. Chuck

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Yes ...any good laser operator/kit designer knows that you should make allowances for the kerf of the laser as well as the removal of laser char. Too bad though that many do not or havent figured out how. For parts that are to be shown finished you should always remove the char. Nothing shows a lack of patience more than not removing the char from finished pieces. You dont want your model to look like a kit when its done if the design is good enough to not to make that apparent. In most instances however it will fall short that without some level of kit-bashing. Use the edge of a blade to scrape the bad char as much as possible and then some fine sand paper to remove any remaining brown stuff. .

-

Thats the plan....and I hope that folks will start slowing down as well and really doing some more precise work. There will need to be more shaping and some extra tweaking on some of these parts. And I have been noticing the opposite is actually happening sadly...some are not even removing the char from these pieces and just gluing the parts together. Everyone needs to take a deep breath also and treat each fitting as if its an actually mini project. More on the fcastle to come soon. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you all for the kind comments. I am happy that all you (at least those that gave feedback) want to continue as is. I am glad I am frustrating you guys with these designs. I will of course continue as is. I am enjoying it very much but just wanted to make sure you guys were as well. Greg…yes that Amazon model is one of my absolute favorites. I came so close to building that instead of the Winnie. But anyway….six years later I am still thrilled with the Winnie. Chapter 9 may be a while so for all you folks who have caught up, please have patience…I do not want to rush through it. And please do slow down a bit as I wasnt kidding…the headrails will need a bit more care and understanding build. So those will be a stand alone chapter as I suspect a few of you may beed to redo some of those parts along the way.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks very good. Really nice work planking the hull. Just remember to go slow and take your time. I will be following along.

- 112 replies

-

- Cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

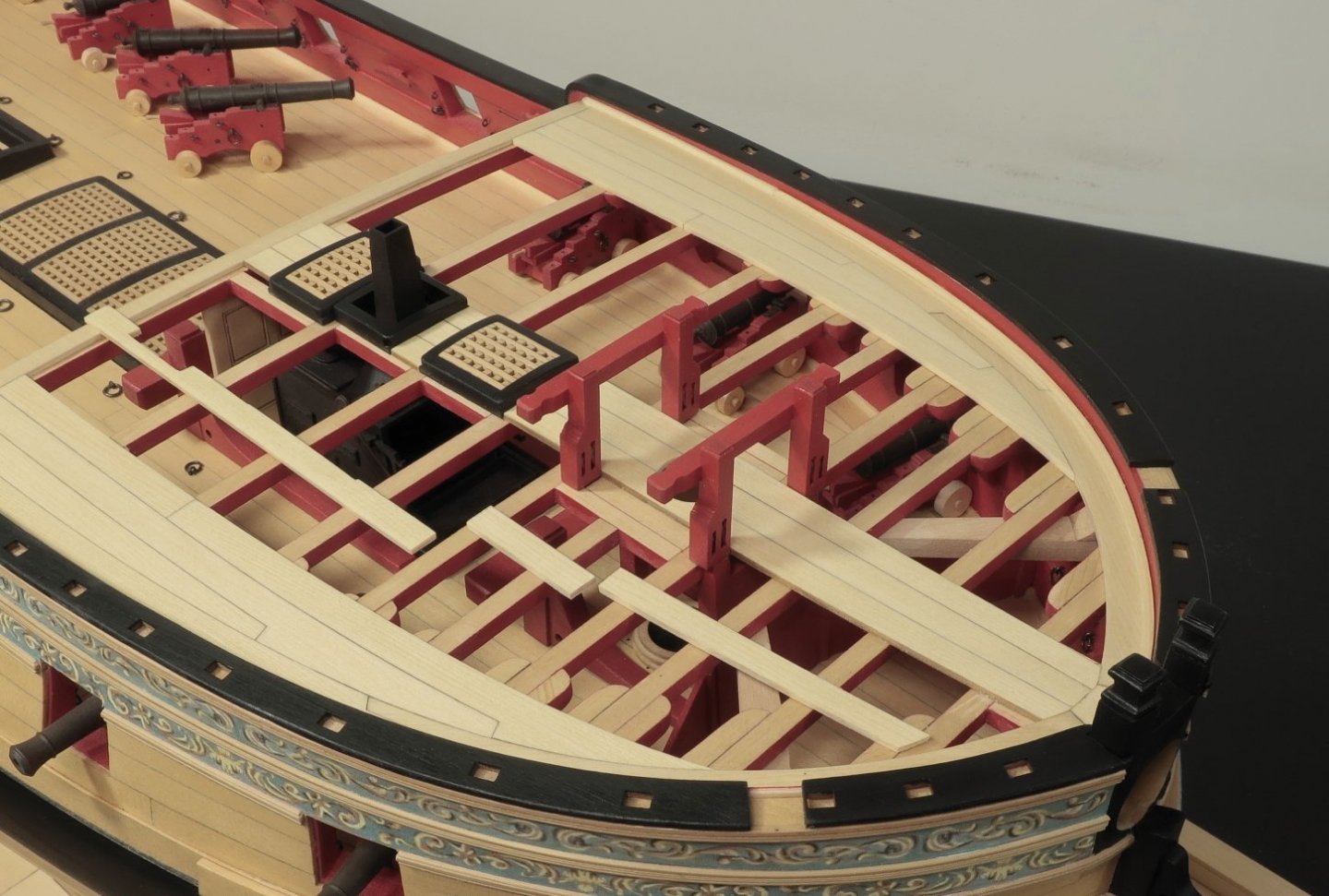

I have collected them over the years and also know where to find them and yes many I have taken myself. But there is a treasure trove closer than you might think. Just look in our gallery. The gallery of "contemporary" models is an absolute treasure. Many of these photos are taken right from there. I wish that folks would use that resource more and post more in there. Every chance you get to see a contemporary model...just pick one or two and take about 50 photos of each. Get close up detail shots of everything. Then post them in the gallery. No other forum in the world has such a valuable source of wealth. Take some time and go through some of them.....some I took but others have contributed a great deal. If you are close to any museum...help add more. For example....check out one of my favorite albums in the gallery.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

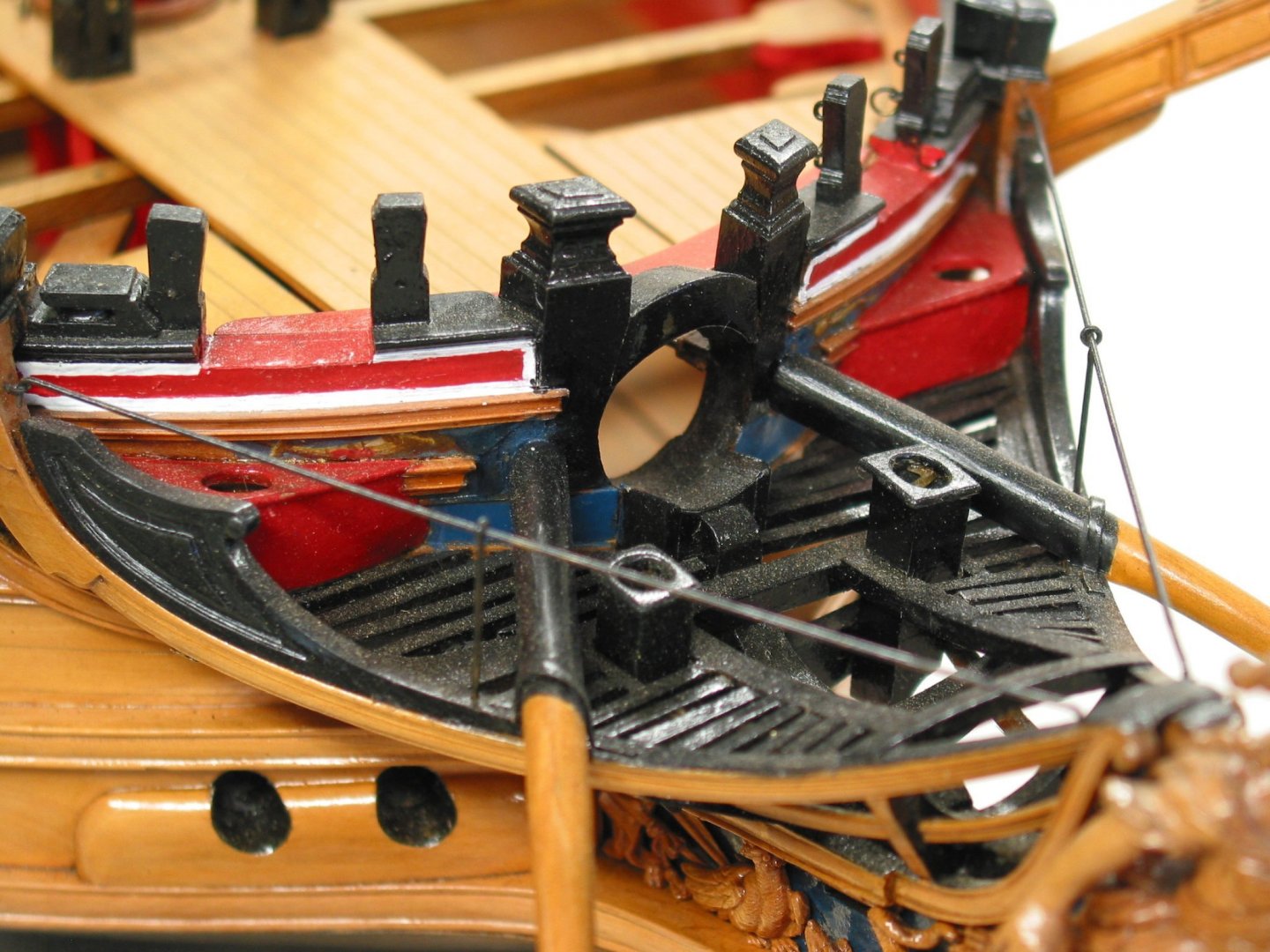

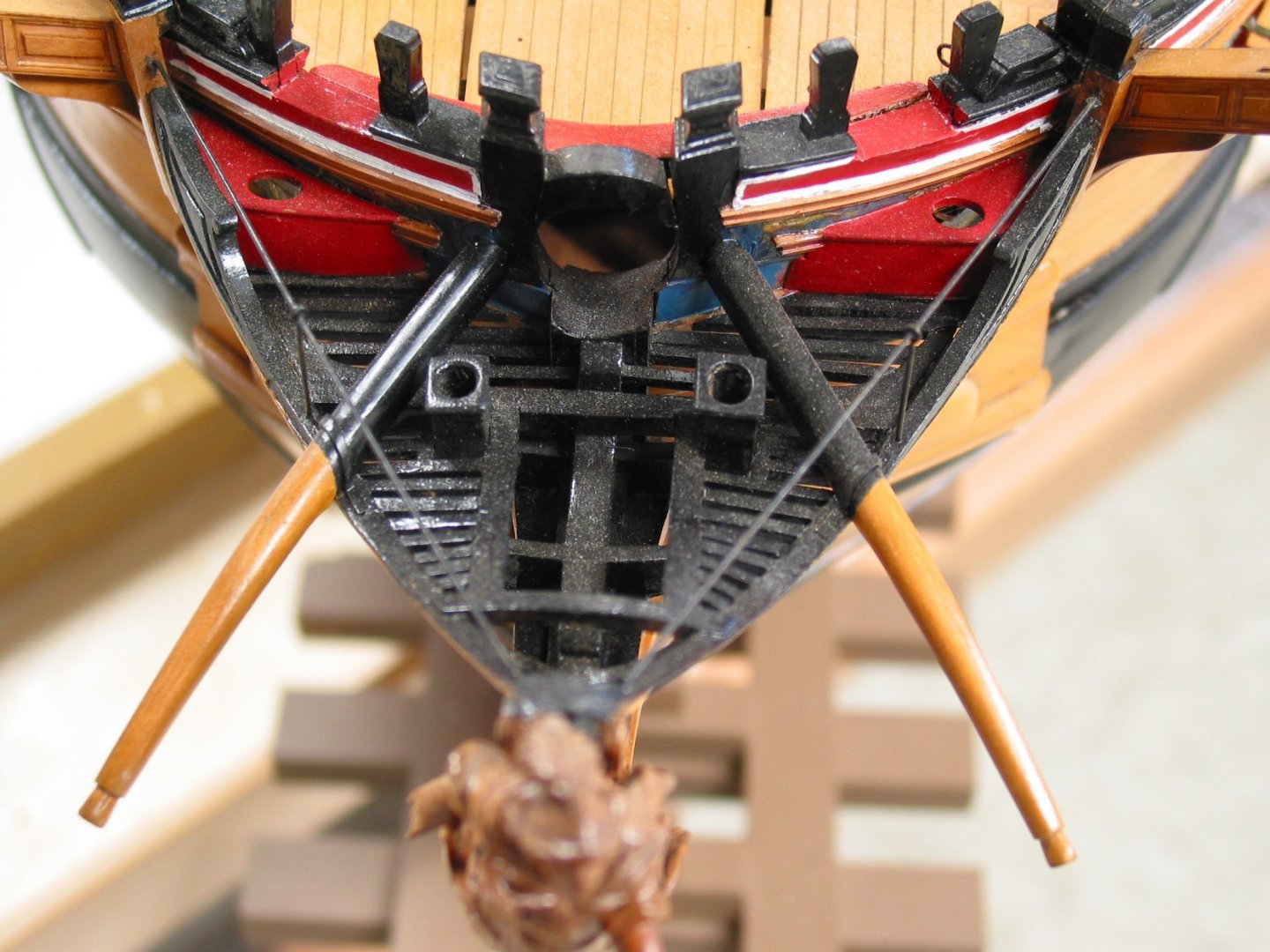

Yes I will add the bumpkin....I think its an essential element. The rigging however isnt essential for a model like mine. But absolutely folks can add it. Including a little length of rope for the belfry running down to the gun deck as well. There are so many options for you guys. You folks dont have to build it exactly like mine...as your wonderful model shows. Here is Amazon with bumpkins and no rigging. Look at those headrails...amazing stuff. Truly inspired by them. Note on both that the top edge of the main rail is painted black. Not always the case but in many instances... And a bunch more photos of other headrail porn.....really soak it up and enjoy. Contemporary models are an integral part my process. I cant get enough detailed images. The last several of the Minerva show the seats as I will depict on the Winnie. As you can see I kinda get obsessed with what I am working on at the moment which makes it very hard to do anything else. I am so behind on making rope and blocks it isnt funny. But my brain wont let me focus on anything else when I have solve the problem of headrail design. I hope all of those people who need more rope and blocks will understand...this may take a while to get through. Its super complex. I want you guys to immerse yourselves and study them too. Its what I do for every detail. dozens and dozens of photos and I cant explain how much goes into the design and construction of these. Lots of hours of planning. You should devour these images in preparation.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank You gentleman....I have decided to finish up the forecastle in its entirety for chapter nine. That means building the fancy rail and the catheads etc....which are important for finally tackling the headrails later on. I need to make these parts in a way that they not look kit-like. I havent gotten much feedback on how folks are finding actually building these parts. So I needed some feedback if I should change up my approach for the next parts which will require a bit more care to build actually. I have been following the latest kits of frigates which are from CAF and Vanguard, and some of the other MFGs etc. They are all decent kits but personally I think some elements still look a bit too simplified and kit-like for my tastes. But everyone seems to love them and seem satisfied with the results they get from those. I dont want to make folks miserable while building the parts on my projects if they dont think the differences in the final results are either noticeable or worth the fiddly extra care needed to build them. Personally, as Beckman mentioned, I dont think they are any more difficult to build than those other kit designs but they do require more care and attention when putting them together. So I wanted to clarify before I spend the time designing the next group of parts for the fcastle and Qdeck. But we will finish the fcastle to complete chapter 9.....and then the qdeck will be chapter 10. I was beginning to think I over-stepped and you guys prefer the "Mckit design approach" for your leisure time. Please do continue to give me feedback because I am building this stuff for you guys the way I think you guys want to build it. But maybe I am wrong so I thought to ask. Sometimes you guys are so quiet I hear crickets. If you havent read between the lines yet I am trying to subtly prepare you guys for the fact that we are getting very close to making the headrails. They are probably the most difficult aspect of any model project and I really dont want to design them in way that detracts from what we done so far. I havent seen one kit on the market today that has done them justice. So I am trying to gently suggest folks slow down at this point and mentally prepare for them...Just take a look at the headrails done on the kits by those other manufacturers. These will be very different. And yes...I could have simplified them but based on your feedback...lets give it a go and build something special. Because I design this stuff well in advance, I am preparing them now actually....I needed to know how far I should push it. Should I design a 10....or settle for a quick 4 in results. I wish I could have uploaded some pictures of the rails from these other kits folks are gushing over so you guys can do a quick comparison. But anyway.....just start slowing down your pace in preparation for them. Because the headrails on the Winnie wont be something you can finish in a day like I have seen folks do with these other new kits. I might also mention that we wont be building that unusual seat of ease. I dont think it was actually used. I think that was made just for the model and I havent seen one like that anywhere. So we will build the typical seat on the head when the time comes. So prepare yourselves mentally to make some headrails like none you have seen on a kit project before. It will require a bit more care and yes you will need to go slow. I am trying to mentally prepare you like a coach does before the big game...use the next two chapters to slow down because the one after those will probably be the headrails. Its time to put on your game-face. Print out these photos and start studying them.....look at those angles. Look at the complexity. How would you attack them?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

All by hand....I just eyeballed it. I sanded an angle into the ends of the molding by eye and just tested it. There is more than enough supplied to do that. No need for a saw or even those tiny miter box things. That will just tear up the edges and look sloppy. I did the front section first by eye and glued it on, and then the two smaller sides folowed. The angle of the smaller side sections were trial and error. I just used a sanding stick and keep changing the angle and testing it. Because only one side needed to be beveled I started with a slightly longer piece and when the miter fit good I glued it in position and sanded the non-mitered end flush. If that makes sense. Sometimes the easiest solutions are the less complex and those that need less tools. At least it works for me. They are not nearly perfect 45 degree miters and they dont have to be. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

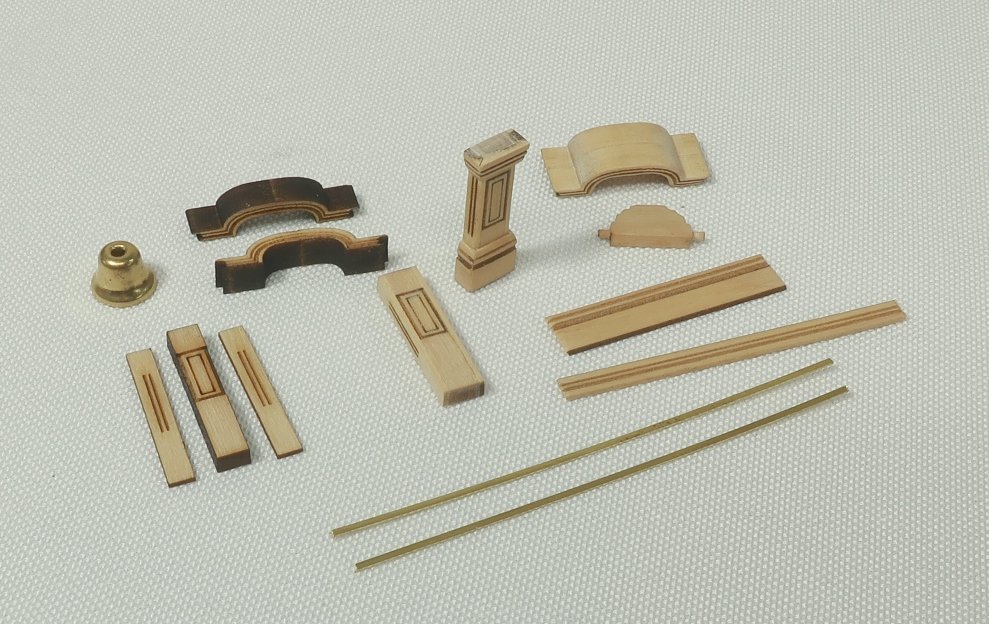

OK the belfry ….all the parts are laser cut and etched in boxwood. As I explain how its built refer to this photo for details. The belfry roof... The roof is laser cut in two pieces. Nothing terribly difficult about it. You could just glue the two haves together and sand it to remove the char. BUT....the goal here is to make the seam between the two halves as invisible as you can possibly make it. So before gluing it together, thoroughly clean the edges that will be glued together. Keep them flat so there will be no gaps. You may even want to scrape the char from the top surface where the seam will be. Use Tite-bond or similar glue. Dont use CA. You want to be able to position all the parts for the belfry carefully so they are lined up. With CA once it cures instantly if the two halves are not aligned....it will look awful. Then clean the char off the top and bottom of the roof. I started by using a sharp number 11 blade and scraped the bulk of it free before using sandpaper. Ten I used various grits to finish it up. But the corners where the round top meets the sides was problematic. So again I turned to my #11 blade. A new one that was very sharp. I literally shaved the corner. I sliced an microscopic layer of the charred wood in that are away to really clean it up. This alone took a full 45 minutes to one hour. I rounded off the outside edges slightly and cleaned the char from the sides. Note how clean you can get these pieces with some time and care. The uprights... Step one...For these you have a laser cut and etched center with a simulated raised panel. This piece needs to be cleaned. There is a another thin strip with two etched flutes that will be glued to the side of these pieces. So you need to clean the char from the sides of the center piece. This is so the seam will again be nearly invisible. Keep the sides flat to avoid any gaps. The two thin pieces are wider than needed so use the tite-bond to glue them on before you remove the char from the edges. They will over hang the edge of the center column on both sides so you can sand it smooth and remove the char from the edges at the same time. Just remember to try and center them so the flutes are in the center of the finished piece. Use a very fine sandpaper.....say 320 grit to finish all four sides. See above. There is one finished upright. You can also see the unbuilt parts. Step two...The top and bottom of the uprights will have a molding placed on the three sides. The inside of the belfry is flat and doesnt get a molding. This is the important part....the molding should have the corners mitered. If you dont miter the two corners, the end grain will show much darker and the profile of the fancy molding wont carry around the entire piece. So take your time here. The molding is laser cut for you. You must clean the char from the top edge of the molding before you start using it. This is the thin edge will show once glued on the upright. The molding along the bottom of the upright is wider than the molding on the top. You will more than enough to cover both uprights. Again the molding is only on three sides. Step 3...The molding is flat. But it is now after you just finished gluing it on the three sides. So the fancy part of the molding needs to be carefully tapered thinner. I mean really tin towards the edge. It will give the proper angle to the finished uprights. I hope that makes sense. Look at the photos. When you have the two columns done... The bell... Carefully sand and file all the char from the wooden piece that the bell will be glued to. Then use 1/64 x 1/32" brass strips to make the straps that are glued to it. Just cut tiny lengths like shown on the plans. The strips are not included so you will need to get some. There are 3 strips on both sides. Easy enough. Then make the handle from the same brass strip size. Bend it as shown and glue it to the top of the wooden piece. Next, remove the cheap clapper from the small bell. You wont want to keep it. Then glue the bell to the bottom of the piece. Make sure to center it. Note how the the little pegs on the side of the wooden bell stock were carefully rounded off. Drill corresponding holes on the flat sides of the belfry uprights to accept these. Dont drill all the way through. Just make little indents. Assemble the bell between the uprights and then glue the roof on top. Thats it!!! I made a long-winded explanation but its pretty easy. The most important thing is to make this a clean fitting. Clean the char. Make the seams as invisible as possible. Take your time. Fill any gaps. You can build this in 20 minutes or you can take your time and spend a nice afternoon making a really impressive fitting that will be prominent on your model. . I need feedback.... The belfry doesnt have a lot of parts. Its not hard to build at all. At least I dont think so. But instead of taking 25 minutes to assemble it. Slow down and take a several hours to "craft" it. Or is this too much? Please do provide feedback. Do you you guys prefer a simpler approach? Maybe I am making this stuff too detailed and finicky? I start to second guess if I am taking the part design too far based on how folks gush over the simpler designs of other projects which I find lacking. But I havent been getting much feedback lately. I ask only because some of the fittings we will be building soon....including the catheads and headrails....they will look fantastic but maybe it will be too much. Should I dial it back before I make these fittings too advanced? Are you guys finding this project too hard to build or too advanced... or not enjoyable to build because of it?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I could have built it in 45 minutes. But I wanted to make sure that you guys slow down. I have seen so many people rushing through the build. Some are barely cleaning the laser char and it looks awful. I am not just talking about the Winnie build. I am talking about build logs in general. As kits get more sophisticated with more laser cut parts….Instead of seeing more care, I see rushing through the steps and “assembly” like a plastic kit. Folks. are not even removing the char….they are just gluing the parts together. I think folks see my final results and dont really understand how much time I actually spend on each piece. I thought this would be an excellent opportunity to talk about that. Its why my model is taking so long to build. I could rush this model and finish it in 3 months if I wanted to. So I purposely want to mention that even though I could have assembled the belfry in 45 minutes…I chose to spend 6 hours on it. Carefully cleaning the char…and shaping the pieces for a best fit. I wanted to mention it because the areas we are modeling now will show very prominently. The belfry…the ships wheel….the binnacle….the upper capstan….etc. This will make or break how your model turns out. So I want folks to really slow down. Everyone can do it. They have the skills. But they suffer from the number one nemesis of ship modelers…..impatience. Impatience can take a model that would be a ten and quickly make it a five…and I dont understand it. Everyone needs to slooooow down. Because it shows. If I am being honest, when I look at the progress photos in a log for someone....again not just Winnie logs.....I find myself saying, "That looks pretty good but why didnt they slow down, clean the glue smears, clean the char, or fill the gaps." "Just an extra hour and that would have been excellent." So I know I have said this 1000 times but I thought this would be the proper time to to offer again some sage mentoring and advice. Force yourself to take twice as long or even three times as long to build the next chapter. Slow down and really take your time with the next two or three chapters. It will transform your model.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I bought about 200 bells for the Winnie project. The Bell will be included in chapter 9. But I dont have enough to sell for projects other than Winnie. they are cheap metal bells sold in bulk for wedding invitations and favors. They look great if you remove the clapper etc and just keep the bell part. Do a google search for “bulk gold wedding bells” etc. its amazing what you can find out there.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

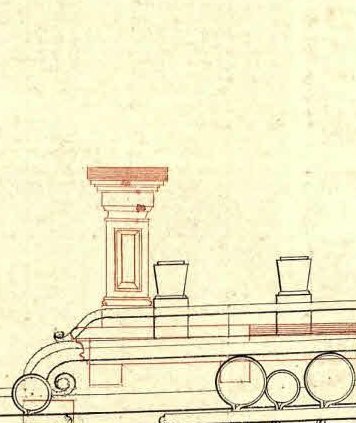

First crack at it....This took all day to make. The original draft actually has quite a detailed drawing of this which is a bit wider and shorter than the contemporary model depicts. Its very interesting and helpful when you find a draft like this. So I will share it with you. I will explain the step by step..

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The Belfry.... A very important fitting that is often simplified on kits. Its almost always kit-like when finished. Almost always painted on kits. I think we can do better. But this will absolutely be one of those fittings you must take your time with. There are plenty of details on this tiny fitting. It is that important like the ships wheel or binnacle or capstan....these are going to show if you rush it. They will ruin a decent model for sure if done sloppy. You have to slow down and take your time. Have you ever seen a belfry on any kit that looks like this built out of the box? Even the latest so-called wonder-kits. Lets see what we can do on the Winnie.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

You could end it like this if you chose to. I may in fact still do that. I may take a sharp chisel to the point and flatten it. But at some point you are going to get a point. It just depends on how severe it is. I kept going back and forth on it. But now that you started me staring at it again…I may just have to chisel the point free.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

At least one would end in a point. Its possible I could have put another scarph joint there but it was a toss up.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Yes probably just a wind break. It is shown on the original draft and on a several contemporary models. Some have doors but those were not called for on the Winnie. They had doors when the riding bitts were on the lower deck. When a partition was used within the bitts as on Winnie no doors were used. I imagine it was portable and easily removed when they needed better access.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks great. Its amazing how much larger the rigged model is compared to when you were working on the hull. That took some getting used to.

- 274 replies

-

- Cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

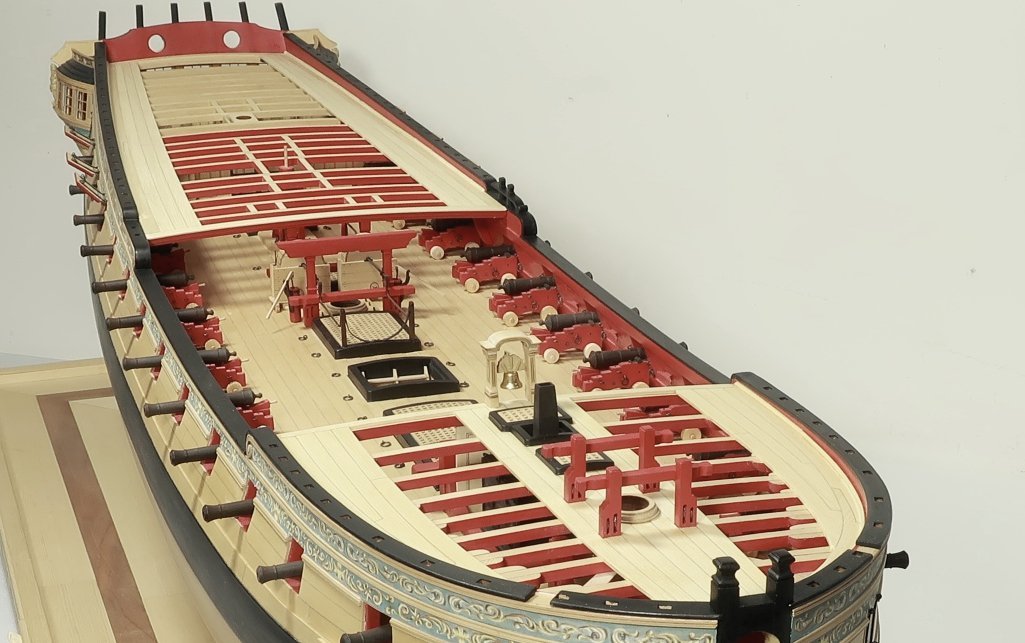

Fcastle planking is completed. I also added the mast coat as you can see in the photo. This is also the same as the earlier ones we built. The open areas of the decking reveal plenty of the gun deck. Just remember, you can add more deck planks if you prefer. You can also plank one side completely and leave the other side just showing the deck beams and knees. Its up to you. Now its onto either the belfry rail or jump over and start working on the qdeck coamings. I havent decided yet. There is also a large knee at the bow to make. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Its all done for you….i have created templates with all of the individual planks drawn out. All of the scarf joints drawn and butt joints. Cut the template apart into i ndividual planks to test them on your model. Tweak them if they need it. When they fit….either rubber cement them onto a wood sheet or trace them. You really cant get any simpler. Its all done for you.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

This is an important picture as I plank down the center. Note that the center 3 deck planks were cut using the template as a guide. These are glued in first. Then the two bitts we made are glued into position in front of and aft of the fore mast hole. It would be very difficult to cut and add those three center planks with the bitts in position already. Once they are glued into position the two remaining strakes of deck planks on each side can be completed. In the photo you can see that I have already cut and shaped the three lengths for the next strake. I will finish up the deck planking on the fcastle tomorrow. Any questions or comments. Remember that all of the planking is tapered and curved. These planks were cut from a 3/64" thick sheet of cedar. I glued the template on it and cut the next plank I needed with a sharp #11 blade. I sanded it smooth and close to the lines and tested it and retested and retested....you guys get the idea.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Just wait a few weeks and they will open up again. If not maybe other services in other countries are shipping there. Maybe send it to another kind Winnie builder in the UK who can then turn around and ship it to you from there. When they buy the next chapter they can allow your parts to piggy back to them to save on shipping.

- 137 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Coamings are completed on the fcastle with gratings. There is one that is for the stack which will have some cover boards. Note that this coaming sits against the one aft of it. So the aft edge doesnt have the corners rounded off. Rather than repeat the coaming making process I will just say ...dont forget to use your 3/64" thick right angle jig when making them. Also use that to round off the corners leaving a sharp edge corner where the planking will done around it. This is the exact same thing we did with the gun deck coamings. With these completed I can start planking the center strip down the fcastle. I will take some pictures of that process because we need to also glue the bitts onto the model we made in the previous chapter. The ones fore and aft of the foremast. More progress shortly but does this make sense....do you guys need any clarification as I there really is nothing different with these coamings than all the others....a 5/64 x 1/32" strip was inserted inside the coaming so we can sit the gratings and cover boards into them. Everything is laser cut. The gratings are made the same way as well.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.