-

Posts

5,198 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

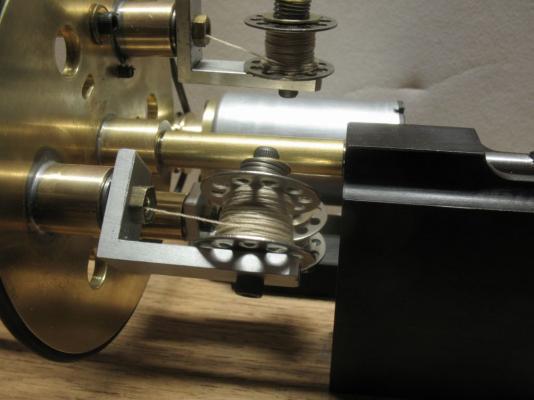

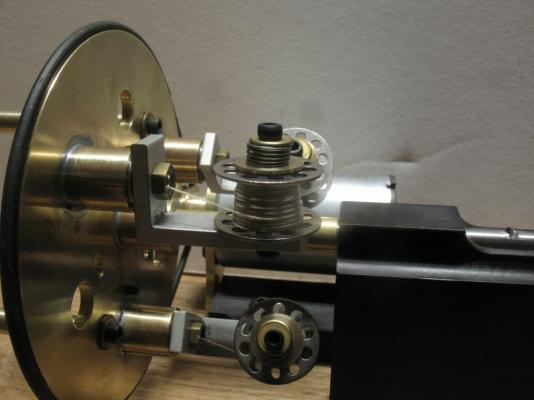

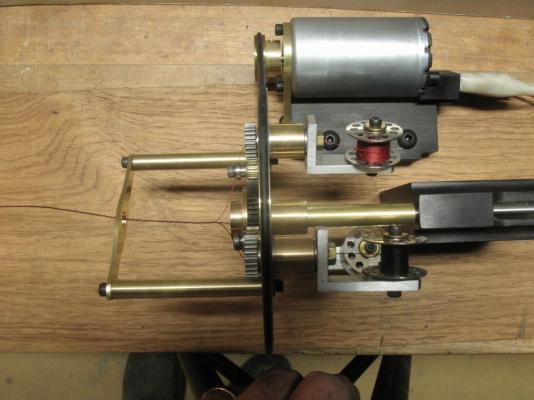

Some good news and some not so good news. First the good news I made some springs by winding some spring wire around some 3/16 rod. I used the lathe and clamped the wire next to the rod then ran the lathe in back gear and with the wire slipping through my welding gloved fingers spooled it up onto the rod .After the tension was released the wire wound open to a 5/16 diameter spring. I cut three springs and then parted off some spacer washers to create different tensions on the bobbins. I replaced the bobbin shafts with three longer ones that were 5/8 long. The 4/40 cap screws lock the retaining washers solid to the shaft. the tension is changed with the spacer washers. I have .025 .035 , and .050 spacers. With the .25 spacers the machine worked quite well just pulling the rope away with my fingers at this point. The rope looks a bit like old hemp rope. Now for the Not so good news. Yes about two nano seconds after the thought crossed my mind that I could easily break a tap this way.... that is precisely what happened it was a first tap through silver steel and because I was in a hurry and did the tapping with the rod in the ebony mount so I did not use any lubricant (bad choice) because of the wood below. When my tears have stopped flowing tomorrow, I will use the cut off disc in a Dremel and remove the offending piece and re do it.. Michael

-

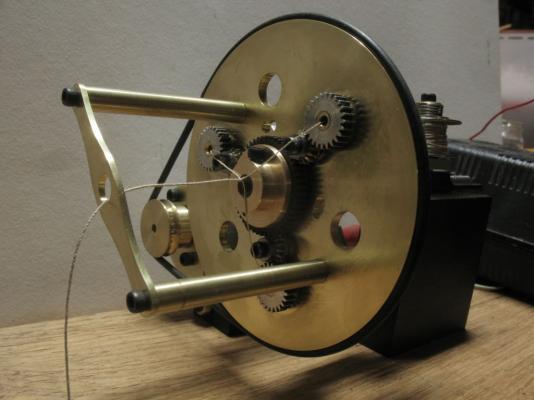

Because my pilot cutter needs longer ropes than I can make on my 10 foot long traditional ropewalk, I have been working on one inspired by the design that Alex Domanoff designed. My machine uses an "O" ring belt drive and is only 3.5 inches in diameter. it uses the bobbins from my old Cepel treadle sewing machine the bobbins seem to be a bit wider than some they are .47 inches wide.I have started testing the machine and still have to make the take up spool. The whorls are set in double 3/8 x 3/16 shouldered ball races. I am testing it with three colours so that I can sort out the tensions on each whorl. The threads are just what was already on the bobbins. The base is Brazilian Rosewood and the mounts are Gaboon Ebony. The sun gear is phenolic 48DP 49 teeth The idler gears are made from 48DP x15 Pinion stock The moon gears are 48DP x 24 Duralumin gear that was 6 inches long salvaged from some equipment 30 years ago. Electric motor is a surplus 9v from princess auto, mounted on a piece of 1/8 thick brass with a 1/4 steel rod set through one of the ebony mounts. The 1/4 inch hole in the guide plate will accept some silver steel dies, once I know what I'm doing. Thanks again Alex for the inspiration. I had the time and materials on hand. Michael

-

Ed The use of the ribands is a great touch and as you say a more simple method for gluing. Michael

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Nils, thank you for putting this wonderful model into the build log section, I enjoyed looking at the model in the gallery and wondered if you had a build log. I will follow along. Michael

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

Gaetan, I like the table. on the shelf is a red English Locomotive, that looks like a Great Western Hall class that was used in the Harry Potter Films. I recognized the type because I grew up 5 miles down the main line from Paddington Station. Michael

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Workshop issues

michael mott replied to michael mott's topic in Modeling tools and Workshop Equipment

Thanks for the comments and concern. As it is back down around the -20 mark, the water is solid again and I will only be able to fully solve this when it is spring (late April to May) I will remove the outside sheathing to let the wet that is inside dry off and deal with the roof. Michael -

Hi Mark, thanks for the kind remarks, I find that the problem solving aspects of this hobby to be almost a hobby in themselves. I do enjoy reading about and seeing how the builders on this forum go about solving the different aspects of putting together both the models and the tools. Michael

- 2,215 replies

-

Thanks Bob, Now I know I'm not loosing my marbles;~) Michael

- 26 replies

-

- Ropewalk

- Linen Thread

-

(and 1 more)

Tagged with:

-

Bob, you mention that the moon gears turn once for every turn of the solar disc, I think that the sun gear would have to be the same diameter as the moon gear for that to be the case. It look to me like the moon gears turn twice as fast as the sun disc because the sun gear appears to have 28 teeth and the moon gears appear to have 14 teeth. I could be wrong would not be the first time. Michael

- 26 replies

-

- Ropewalk

- Linen Thread

-

(and 1 more)

Tagged with:

-

I have a few Chinese dies, I must say i am not impressed with them, I was just trying to thread a little mild steel with a 3/8 x 24 and I gave up because it would not cut. It worked fine as a chaser to clean a thread on a bolt though. Most of my dies I have purchased as I have needed them in the past, and they are good quality ground ones and they cut beautifully. Michael

-

Bob Alexey's Machine looks very nice , thanks for the review. Michael

- 26 replies

-

- Ropewalk

- Linen Thread

-

(and 1 more)

Tagged with:

-

Manual Angle Sander ( Finished )

michael mott replied to Bugra's topic in Modeling tools and Workshop Equipment

Burga, the results speak for themselves. Michael -

You know one could get a serious case of tool wants looking at links like these. I don't know if there is a known cure! michael

-

This small board works well for plastic. or wood. I use a low angle block plane on a 1/4 inch acrylic base. the base is stroked with a little candle wax to lubricate the plane. In the video the plastic block is approximately 3/8 inch thick x 1 inches wide the plastic is evergreen styrene strips glued together. Michael

-

Manual Angle Sander ( Finished )

michael mott replied to Bugra's topic in Modeling tools and Workshop Equipment

I really do enjoy seeing very creative solutions to our modelmaking tasks. Michael -

Wrapper ropes (Serving Machine)

michael mott replied to Romanov's topic in Modeling tools and Workshop Equipment

Romanov, I do not need to buy a machine I already have one but you design is brilliant! I would recommend yours to anyone. the design is clean looks good and works very smoothly. I take it that there is some tension on the feed spool. Michael -

Nigel According to my sources the Tulip Tree (Genus Liriodendron tulipifera) also goes by the common name Yellow Poplar, and Whitewood, is native to N America, is used in Carpentry furniture and boatbuilding, that it does not spit easily. This would account for the common name that you know it by as well Bob. Limes Lindens and Basswoods (Genus Tilia) T americana American Basswood or Linden is used for matches, boxes, furniture paneling carving and especially for the the manufacture of pianoforte keys. Michael

-

Table Saw Hand Safety

michael mott replied to rtropp's topic in Modeling tools and Workshop Equipment

Sam your comment reminded me of a kickback many years ago, it was a small piece of maple trim for an exhibit the size was approx 1/4 x 1/4 with a slight bevel to create a wedge shaped length about 18 inches long. I always stand slightly to the side of the line of the blade and the blade caught this piece and shot it across the shop I heard it hit something on a bench about 10 feet away. I went over to retrieve it, and noticed that it was laying in front of a tin of black paint which was now leaking onto the bench. I was amazed by the power of this small bit of wood to puncture a hole in the side of this gallon of paint, but I was in for an even bigger surprise... when I went to pick it up I tipped over the tin thankfully the lid was on the stick had penetrated right through the tin and was sticking out the other side! I thanked God that there had not been anybody in the line of fire of that stick it would have done the same thing to them. Michael -

Q thanks for the link for the small bit Sharpening Jig, that is a good one. Michael

-

Good afternoon Steve, Thanks for you commendations. As I have mentioned on this thread, I am stalled on the work while I sort out the problems of water penetration into the shop. I am really missing not working on the cutter but hope to be back to her shortly, The temperature has dropped significantly so the dripping has stopped for the time being but it will restart as soon as it warms up again. I am going to rework the bench that the cutter is sitting on to make some better storage underneath to hold the various areas of the project. A drawer for all the blocks and rigging raw materials and so on with the other areas as soon as I get materials better protected. Michael

- 2,215 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.