-

Posts

5,198 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

Workshop issues

michael mott replied to michael mott's topic in Modeling tools and Workshop Equipment

John, its not all its cracked up to be evidently it is full of cracks so it seems I have stripped more off the north wall now because it continues to leak The spring cannot come fast enough i will have to take all the sheeting off the north wall and dry it out thoroughly and then re-sheet, and then put metal on the roof, the inside will need more insulation. I do not see our winters getting less extreme than this one so far. So far today all I have done is dry stuff off and move them out of the way of the flow. I was going to tackle another section of the shop but nature is doing the dictating at the moment. Michael -

Rusty the workmanship looks really sharp, which also leads me to question the sharp edges on the corners of the cleats, will you be rounding them off a bit or are they meant to look squarish? Michael

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Just catching up Remco. Excellent work on the bricks and the pots. Most convincing modelwork, and soot. Michael

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Mark, Your work has to continue to satisfy your desire to continue, when this changes for whatever reason, one sits back and reevaluates the whole process and why we engage in it in the first place. The bottom line is that sometimes there are too many issues to continue, and so a restart or entirely new build usually results. Your reasons regarding the differences in information would most likely become more and more frustrating, so I can see and understand your decision. I have always felt that the journey is far more important than the destination, and you have obviously used this journey well. I look forward to seeing your next log. Michael

-

Not much to report on the model building front. Unseasonably warm weather, and a less than perfect insulating job on the roof of the shop has resulted in some serious Ice dam flooding. Water came down at the window where my lath was and the water splashed over the tools on the window ledge resulting in a major reorganization of where things are situated. I had to take the time to dry off all the small stands of drills reamers and mill bit along with some custom tools, this really was a pain. The silver lining is that this event has forced me to rethink the entire layout of the shop and the equipment, tool and material Storage. So instead of rushing this work I am taking my time to reset these things, building new racks and drawers for tools and materials. It is also a good opportunity to de-clutter the workplace. When the shop was laid out originally i was more focused on model engineering and steam work, now that I have found my true calling (model boats) I am organizing so that the various elements work in better harmony and flow. And now of course I have Gaetan and Mark's workshops as examples of great organization to guide my thinking. Now that I have all the metal work sorted I can start on the wood storage and the tools for it. I will be back to work on the cutter hopefully within the next week or so. Michael

-

Ed I have to echo the comments about the great work on the stern Framing. Michael

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Doris, simply amazing!!! Michael

- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

Very Nice Dan, I shall have to give this a try. Michael

- 241 replies

-

- queen annes revenge

- pirate

-

(and 2 more)

Tagged with:

-

Seems like a normal size to me! The steps look very sharp Rusty. Michael

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Kudos to you Dan for what you are doing with this ship, I had to do a double take when seeing the rework it did not look like the same model. A testament to your skill and kindness. Happy New Year Sir. Michael

-

Gary, thank you very much for the compliment. I have not done much on the cutter for a couple of weeks, I have been trying to finish up a small project that I started 44 years ago, which will be useful for continuing my work on the Cutter, and on future models. Michael

- 2,215 replies

-

They look good Dan. Seems to be one of those things that we are forever coming up against, stepping forward then back and then forward again. Michael

- 241 replies

-

- queen annes revenge

- pirate

-

(and 2 more)

Tagged with:

-

Table Saw Hand Safety

michael mott replied to rtropp's topic in Modeling tools and Workshop Equipment

Richard have a look at this thread It covers cutting slices off a wide plank. Michael -

Table Saw Hand Safety

michael mott replied to rtropp's topic in Modeling tools and Workshop Equipment

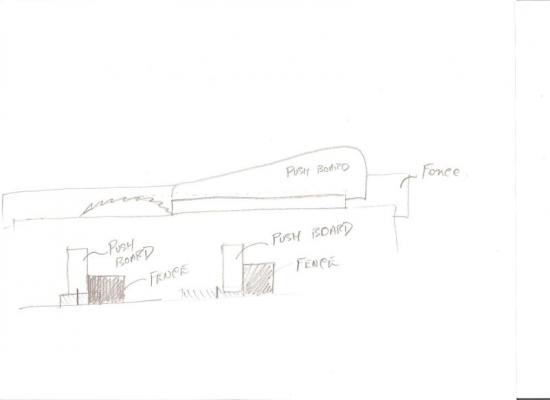

I agree with the general tips about safety, especially the one about not being interrupted until the saw is turned off and the other one about unplugging the saw when changing blades. I personally do not like foot switches. I also prefer to use push boards rather than push sticks. I can and do make them as I need them, they are a disposable tool as far as I am concerned. The ones I make look like this They vary in thickness to suit the work. I would agree that glove are something to avoid. Michael -

I realize this might be a silly question or statement, but could the drawing that mark posted have an error in it, it would not be the first time that a model proved an error in a drawing or plan. I once saved Skidmore Owens and Merrill a Major problem by finding that they had made an error in their plans for a large center in downtown Denver. Michael

-

The work is looking great Gary, your reference to the term "rhodings" made me curious I cannot find an explanation for the term an internet serch produced little info ? I can see that they are bearings but where does the term "rhodings come from? Michael

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.