-

Posts

5,198 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

Andy it makes a lot of sense working in the stages that you are doing, those shrouds look great. Michael

- 1,148 replies

-

Hi Dee Dee the boat is looking really fine, the contrasts of the dark and light woods works very well. I would be happy to have my models look as nice when they get to your stage. Michael

- 89 replies

-

- muscongus bay lobster smack

- midwest products

-

(and 1 more)

Tagged with:

-

The .024" plastic coated Beadalon 49 strand wire works well. This is with the boom hanging loose and no extra tension, I need to get some smaller diameter black heat shrink. and make the loops bigger but I am happy with the way it is hanging. Also I need to reverse the inside chock. I think I will also make a small saddle for the wire to attach to the block rather than just the shackle. Michael

- 2,215 replies

-

Hi Bob We must have been cross posting, I am going to see what I can do with the smaller beading wire cable first. Michael

- 2,215 replies

-

Popeye, and Druxey. I did put a little tension on the gaff to see what effect that would have and I was concerned that the combined weight of the sail and boom even with some tension would not be enough to overcome the stiffness of the wire which is .047 which in 1:8 scale is 3/8th an inch which seems a little heavy anyway. if I use the .024" wire it is a little over 3/16th in scale. so I will see how that looks. Michael

- 2,215 replies

-

I also agree with Crackers, and Anthony, carry on with the model you are working on and when you get stuck because the tool you need is not in the family go and get it, be it a file or a jewelers saw a pair of fine needle-nosed pliers, whatever it might be. It is a better way in my humble opinion, than just going spending. Michael

-

Akutansin, Elmir, thanks for your kind words. I have been chipping away at the gaff, literally using the shrink tubing i made a wire strop for the gaff and was pleased with my stops set into the gaff they are boxwood And now I know that the drawing in John Leathers book was correct and that the chock stops face the same direction The wire is too stiff though so I need either thinner softer wire or I will use rope, I prefer the wire so will look at what options there are for that. I did haul up the gaff using the blocks it was fun threading the halliards, I did a quick and dirty job of tying the halliards with hitches, I keep running out of shackles and blocks! and I take my hat off to all you folk building and rigging fully rigged three masters, that would send me to the loony bin. It is interesting thinking about the different types of blocks needed for the rigging to function properly though. The thing I need to address now is some cleats and belaying pins. Earlier in the day I was working on the other boat. Michael

- 2,215 replies

-

Carlos thank you for posting those two pictures they are very informative. I am not on Facebook, and have no intention of getting on it either. I do have email and I do enjoy this forum and have a photobucket page. Regards Michael

- 2,215 replies

-

Carlos thanks for your comment. In John Leather's book he mentions the copper plate and said that it also was a cause of problems on the mast and that sometimes it caused some rot under it. Michael

- 2,215 replies

-

Welcome Darryl, Wow! very nice I love the chairs as well. Michael

- 32 replies

-

- interaction hobbies

- c r lamb

-

(and 1 more)

Tagged with:

-

Andy thanks for the confirmation, I was looking at a sketch in John Leathers book The Gaff Rig. Michael

- 2,215 replies

-

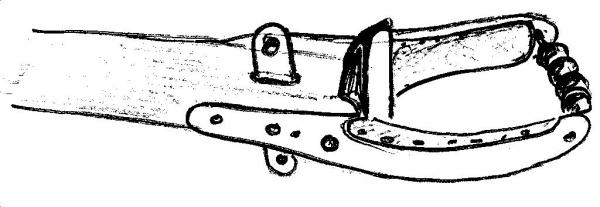

Mark thanks for your comment, Bob I am thinking of only covering the inside curve that could chaff on the mast, so instead of stitching the leather like a glove I am thinking of glue with a row of tiny tacks along the top and bottom edges. more like this Michael

- 2,215 replies

-

The framing looks great so far Alan. Michael

- 86 replies

-

- schooner

- effie m morrisey

-

(and 1 more)

Tagged with:

-

Beautiful model Chuck, I could see myself making one at 1 1/2 inch scale, after I get a couple of other projects finished. Michael

- 49 replies

-

- pinnace

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

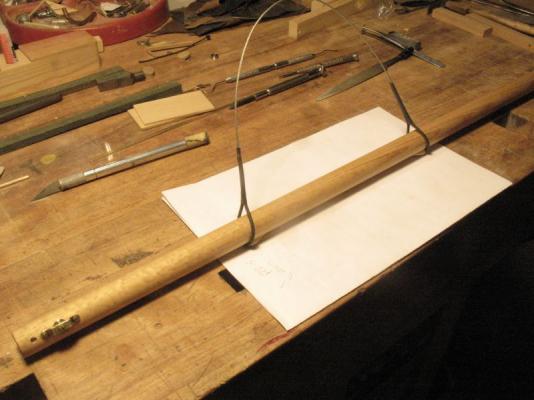

Jay thanks for stopping by and your kind words, yes the weather is being a little inclement at the moment more than the rain on Maria it is rather cool at the moment it was only 16 degrees Celsius yesterday, and is going down to 8 degrees Celsius tonight. After spending a good chunk of yesterday afternoon cleaning and tidying up the shop, I did a little work on the gaff. I made the metal hanger for attaching the Halliard and down-haul it is 1/16th by 1/4 inch brass, also ground a tool for making some beads out of a short dowel of Lignum Vitea The dowel was turned on the lathe from some square stock. that I cut off the billet I have had for perhaps 20 years at least. The rope holding the parrel beads is made from Gutterman black cotton. The beads are a scale 1 1/2" in diameter. I still have to make the slide block it will fit in the 3/16 slot. once I have made the slide I will go back and finish the leather for the jaws. Michael

- 2,215 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.