-

Posts

5,198 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

very nice work Tom, your care with the planking certainly shows. Michael

- 153 replies

-

- model shipways

- bounty launch

-

(and 1 more)

Tagged with:

-

Syren Disaster - moved by moderator

michael mott replied to Tigerdvr's topic in Wood ship model kits

Glad your minor lapse of attention did not result in more surgery! Yes we all have these moments knocked the gaff onto the floor today, fortunately it landed on the unfinished leather glove. Michael -

Well Randy I am one of those three or four people. The ship looks fine and your rework of the rigging looks like a great improvement. I am wondering why a company like AL does not get the message and supply better rope or at least supply no rope and let the builder supply their own, they would either have a better reputation for their kits and they could also be less expensive. plus the rope would not have to be thrown away. Michael

- 384 replies

-

- san francisco ii

- artesania latina

-

(and 1 more)

Tagged with:

-

clever trick with the photograph Mark. it makes sense to do that. When working on a painting I was told to turn it upside down and then you can spot minor errors. I bet you are looking forward to the day that you can cut it loose. If I were working with this method I would trim the builing sheet as soon as possible to get rid of the large flat plane . that would give me the best of both worlds. I could sit it upside down or right side up and also be able to visualize the ship more easily. But that is just me. The first plank looks good only x number to go Michael

-

Cutty Sark by NenadM

michael mott replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

good to see that you are progressing well Nenad. yes sometimes we need the sanctuary of our workspace. Michael- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

ancre Le Fleuron 1729 by rekon54 - 1:24

michael mott replied to rekon54's topic in - Build logs for subjects built 1501 - 1750

Wonderful metalwork, My question is what silver solder and flux are you using.? Michael -

B.E. Thanks for stopping by glad you like the boat. Bob, the thought of taking down the mast when I want to go sailing would be more work than on the Maria. Mark, the leather work is challenging to say the least. Michael

- 2,215 replies

-

Mario what a wonderful project, I have always loved these types of launches they just simply exude leisure. yours looks wonderful, the small details add so much. Michael

- 78 replies

-

- victorian steam launch

- constructo

-

(and 1 more)

Tagged with:

-

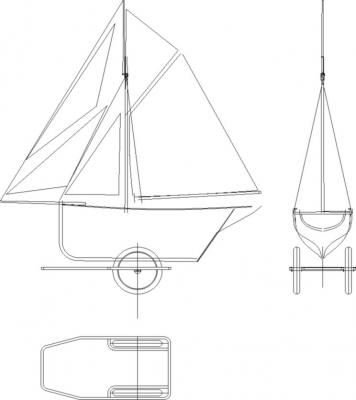

Brian, thanks for stopping by, I am sure that I would not have the patience to make something with more than one mast. Druxey the short answer is no, that said I am a glutton for punishment when it comes to solving a problem, it is why I have such a large scrap box(es). Made me laugh Popeye. In between some of the myriad projects that I seem to have on the go I found a frame with some wheels at the dump, it is from a child's bicycle carriage, and after straightening it up and pumping up the tires I measured it up and I have the foundation for the transport trolley. the wheels are 15 1/2 inches in diameter. I will make it so that there is some springing on the undercarriage so that the rather rough road gets compensated for. It will need a few bits of wood added and will need some mudguards, but I have a few bikes that I have collected from the same place so it will be great to get the trolley sorted now that I have the basic frame. Michael

- 2,215 replies

-

Allan what a great project I will definitely be following along. Michael

- 86 replies

-

- schooner

- effie m morrisey

-

(and 1 more)

Tagged with:

-

Adrieke, all those railings and windows look like a ton of fiddly work, it looks great. Michael

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Doris, your work is that of a true Master!! It is difficult to comprehend that it is mostly card and foils. Congratulations also on your birthday. Michael

- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

Andy, thanks I did a little experiment this evening. Russ I am going to use Lignum Vitae parrel beads on a line. The experiment looks promising, I think that i prefer the light colour leather better. it was from an old wallet. The light leather was sewn in situ but I used way too heavy a thread, the dark leather from a ladies leather dress (Great source for very fine thin leather) I picked up at a second hand store some time ago for $10 to make some leather seats for a model coach, was sewn off the wood like a finger for a glove. If I decide to add the leather I might glue it on first then I can create a neat seam. and also add some tacks along the side of the spar. Michael

- 2,215 replies

-

Mark that might be true but I am sure that there are lots of details that you builders of fully rigged ships add that I would not. John thanks for that. Russ thanks, your own restoration work and attention to detail and research have given me inspiration. Druxey you are absolutely right the hard knocks of being a working boat will no doubt take its toll. Andy Busted! I told Gulliver it would be found out one day. Greg thank you. The proof will be in the pudding as they say. Jaerschen, thanks Like everyone here I am always looking to do a better job on the next piece. I don't think I could say itany better myself! Beautiful! Posted 20 June 2013 - 08:10 PM JMaitriMichael, I'm totally blown away by your work--you sir, are a master craftsman and then more! Jay Jay and Sherry thanks you for those kind words. Last night and today I did a little bit of woodwork on the gaff. I had already planed up the spar and so the jaws were cut out of a piece of Apple wood that I have had kicking around for a while now. I started to fret it out with the coping saw and discovered that it was tougher than cutting brass, so I dragged out the scroll saw(I don't really like using it )and put in a brand new blade and still struggled with the apple. Then a lot of work with a coarse sanding stick to rough shape them. then planed a couple of flats on the sides of the spar and glued on the apple rough shapes. After the jaws had glued overnight I set about doing the final shaping, using some small carving chisels and the #11 blade A couple of hours later I did some final sanding and then a good rub down with some fine steel wool, and a coat of golden oak polyurethane. Next I need to cut the slot for the Tumbler and fit the throat halliard attachment and the parrel beads. I will use Lignum vitae for the beads, I also need to add the through bolts for securing the jaws to the spar.. I am torn whether to add the leather over the jaws because I like the look of the apple. But some fine leather stitched might look pretty as well. Perhaps I will do an experiment with some leather on a bit of scrap and see how it looks. Michael

- 2,215 replies

-

Gary the incredible amount of detail that your are putting into the interior I hope that you can see it as you work on the upper levels it seems that it would be sad not to be able to see it later. Beautiful workmanship needs to be seen, Although to quote Ruskin and I am paraphrasing here "Just because something is out of sight doesn't mean that you should do any less quality work on it" Michael

-

ancre Le Fleuron 1729 by rekon54 - 1:24

michael mott replied to rekon54's topic in - Build logs for subjects built 1501 - 1750

Rekon, I just stared at those sets of pulleys in the posts and the fittings, and shook my head!! inspiring work that gives me a mark to climb to. Michael -

Russ the single piece looks like you nailed the shape well, with regards to the grain which I can see would it be possible to give it a coarse sanding to simulate the grain along the portion near the bow and then a finer sanding to smooth it just enough to leave some of the (grain) scratches in and as B.E. suggested fake in some scarph joints. Just a thought. Michael

-

Cutty Sark by NenadM

michael mott replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Nenad, overall our time is what we make of it, it is good to see that you are progressing with the hull planking, this is like building the foundation of a house when the hull is finished then you can lavish over the small details of the rigging. Michael- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.