-

Posts

2,552 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JeffT

-

Looks like a good build to follow. Thanks for the pictures of Ga-Geo Island. I was in Korea for a year and it sure is a beautiful country.

- 15 replies

-

- young modeler

- korean

-

(and 1 more)

Tagged with:

-

Thanks Jay, Geoff, and Wacko. I have a soldering iron that allows me to adjust the temperature, so I hope that does the trick. I also have some scrap brass that I can use for practicing. I finished carving the interior of one boat last night. It took me a couple hours. It wasn't easy and I ended up doing it all by hand. I tried using the dremel like Bob showed but quickly found out that is too risky. Those burrs might be the answer Geoff, thanks!

-

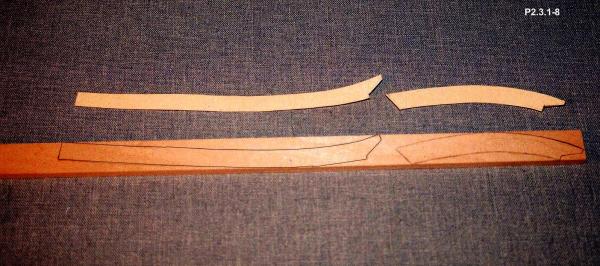

Thanks for the pic Geoff, that helps me build a better mental view. I think I won't paint my deadeyes since I like the natural color of the wood. Another update. I have started working on some of the little details. I got the anchor stowage done and the sheaves. I really would have liked to do the sheaves a little earlier, like around the time I planked the bulwarks. Oh well, lesson learned, don't blindly follow along with the practicum. Its probably better to plan ahead. I also started working on the little boats. These are built bread and butter style in layers and then carved to shape. Its the first time I've tried this so I was a little worried about getting the shape right. It turns out that if you just shave off the edges of layers that it kind of just falls in place. I did take a little too much off at the bottom of the stern on the pinnace. It was the only area I had trouble visualizing and the plans didn't help much. It will be easy to fix with a little filler though once i add the keel. I'll be applying a layer of filler over the whole thing anyway. I still need to carve out the insides, that will be a little more difficult. forward anchor stowage starboard mid stowage and door boat layers glued together here you can see the edges that need to be carved away and after carving

-

You can glue strips together to make wider stock like themadchemist mentioned, but that's assuming you have enough stock to do so.

- 773 replies

-

- san francisco ii

- artesania latina

-

(and 1 more)

Tagged with:

-

- 773 replies

-

- san francisco ii

- artesania latina

-

(and 1 more)

Tagged with:

-

In situations like this I usually cut the curved piece to shape from a wider piece of stock material, if available.

- 773 replies

-

- san francisco ii

- artesania latina

-

(and 1 more)

Tagged with:

-

The Gorch Fock will be an interesting build. Looking forward to seeing your log.

-

Posting etiquette

JeffT replied to dvm27's topic in Using the MSW forum - **NO MODELING CONTENT IN THIS SUB-FORUM**

I don't mind others posting pictures in my log. Its very helpful when I'm looking for tips and advice. -

If there is one thing I love about this hobby, its the history and the stories behind these great sea going vessels we get to see reproduced here. To hear this story first hand makes this build one to watch. Looking forward to seeing you follow in your honorable fathers footsteps in building this vessel as he did.

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

JeffT replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

Thanks for the pictures Doris.- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

JeffT replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

Looks good. How did you do the roman numerals?- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

I'm glad to hear that I'm not the only one that burns various fingers with sandpaper. I though I was doing something wrong.

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

i haven't ordered any yet. i'm still debating but i got the contact info a while back.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Jay, Contact the US rep for morope: Martin Meyer Model Shipswright 5821 N.Navarre Chicago, IL 60631 E-Mail: Curlee11@aol.com

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

a few more. http://shipwrightjournal.blogspot.com/2012/06/uss-essex-by-model-shipways-near-finish.html

-

I'm not sure if this was posted here before but here are some good pictures of the Essex prototype. http://shipwrightjournal.blogspot.com/2012/05/announcing-frigate-essex-by-model.html

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

JeffT replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

The decorations look very nice.- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.