-

Posts

2,001 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Trussben

-

Piece of advice when you start again Iran, make your own keel clamp that holds the ENTIRE keel, not a few points or half the keel, the entire keel! I used some scrap wood screwed to a 2x4 which worked great for me, and don't take it out of there for more than a few minutes. I look forward to seeing you start up again. Ben

-

Hi Iran, sorry to hear the twist/warping has not abated, can you try and get a head on pic so we can see where and how bad it is if possible???? Is it down the long length of the hull or one bulkhead just twisted? If it's down the long length you may be able to correct it with some stragically placed fillers, but if ME will send you new parts then I would agree with Chuck to restart. Nothing more important than having that skeleton perfect, even if it takes a month to get it that way! Good luck man! Ben

-

Well done on the repair Grant, these things do happen unfortunately, but nice recovery. Ben

-

Echo by Maury S - FINISHED - Cross-Section

Trussben replied to Maury S's topic in - Build logs for subjects built 1751 - 1800

Great to see you off and running again Maurey! Ben- 324 replies

-

Thanks Chuck. Albert - I got the plans from Admiraltymodels.com and the TFFM books from Seawatch books, the other plans were from the National Maritime Meusem in Grenwich. For some of the parts I have scanned in the plans to acad 2006 so I can manipulate and print out specific parts as I need to. Ben

- 889 replies

-

Really well executed mast partners Toni, very neat indeed. Ben

- 1,449 replies

-

Thank you all for the interest you have shown in my Pegasus build. I am currently pulling bamboo treenails though the Byrnes plate for the keel bolts, down to the smallest hole in the plate to match a #77 drill for a scale 7/8 bolt - tedious work but I don't need many at the moment. Ben

- 889 replies

-

And Druxey drops the challenge on Remco again, this should be great to watch!!

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

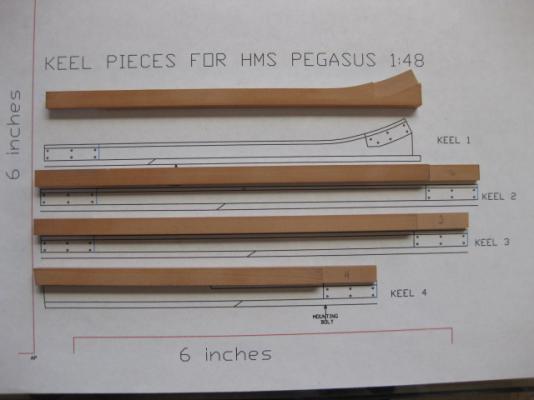

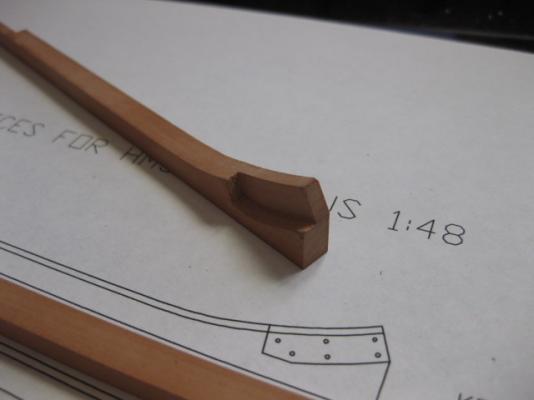

Hi, I will be starting my second scratch build and I chose HMS Pegasus 1776, Swan Class sloop, using the plans from Admiralty models and all four volumes of the TFFM books by David & Greg. Also a full set of plans was bought from NMM and the wood package from Hobbymill in Swiss Pear wood with some highlighting in Boxwood. I intend to leave her mainly in frame with a small amount of external planking - maybe from wales up, and will be using fully chocked joints and correct framing using the Disposition of frames plan. Internally I'm thinking of only framing Upper Decks with some planking, possibly the lower deck but just framing. Depending on how I feel when I get to that point will be the decision on Rigging her. I include pictures of the main keel parts completed, halving joints were used and cut on the JimSaw, the forward keel piece with the boxing joint was cut from larger stock on the scrollsaw and the joint was chiseled out with care. This will be slow starting as I am in the middle of rebuilding my workshop and I am also going to be working on my Confederacy when I need a rest from Pegasus. Here begins another journey. ben

- 889 replies

-

As always Gary, your work and attention to detail is great. I will remember the tip about the sensitive drill attachment. Ben

-

Ahhhh Rusty!!!! As sherline lathe is in my future at some point I will consider it a good omen that you will take the first plunge, I haven't used a metal lathe in 20 years but I have a lot of experience with my wood turning lathe and there are just some things, especially small items that are very difficult to do which is where the metal lathe come in. Don't forget a four jaw chuck if you plan on doing proper masts on it. Ben

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Will be watching you and this build Sjors, it's been brewing for a while and I'm sure you will do a great job. Ben

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Hi Ir3, Glad to see that you are using a longer keel clamp, the hull is so long on this kit that she is Very prone to warping, it's happened to a few people so be aware, every now and again take her out and check that your keel is perfectly strait, but whatever you do don't leave her out of the clamp for long until all the port sills/lintels and upper hull planking is complete, this way there is almost no chance of it warping. Ben

-

Looks perfect to me Augie, I can't see any sheen in the paintwork, did you try buffing the paintwork with a rag, that gave me a really flat effect when mine were a bit shiny. Happy new year, and yes, I will be picking back up with my build in a couple of weeks

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Hi ir3, If you are going to use boxwood you shouldn't have to stain it at all, I used boxwood for some parts and the color matched the stained 30/70 golden oak basswood very well, but do some testing before you commit it to your model. As for staining basswood you have to be very careful not to go too dark as it causes a blotchy effect, that's what I have found anyway and believe me I've done quite a few experiments with different stains, I even tried a ebony stain for the wales but it just didn't take it well and I ended up painting them. Please think of doing updates as you go, it's great for us people watching and will help somebody else doing the build in the future - I just love to see progress like that and how different people tackle the problems that arise. Ben

-

Hi, nice to see another Confederacy build, I had the exact same issue when I started her, did you buy the kit when it first came out 18 months ago? I have seen some of the recent ones and they don't have this issue. I just covered the gap with the beakhead deck planking and it hasn't caused me any issues so far. Or you can contact MS and get new stem pieces to see if they are any better. I look forward to following along with your build. Ben

-

HMS Naiad 1797 by albert - FINISHED - 1/48

Trussben replied to albert's topic in - Build logs for subjects built 1751 - 1800

Awesome Albert, great craftsmanship. Ben -

Awesome Gary, I second or third the idea of leaving that planking a while, it will darken in time just like holly does I'm sure. Can't wait to see more of your beautiful work. Ben

-

Hey Augie, 30% golden oak for the upper works is what I used and it will make a contrast with un stained lower planking, you won't really see it until you totally complete the lower planking. Look forward to seeing your progress next year, I hope to start modeling again in January when I finish rebuilding the workshop. Ben

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Coming along great Rusty, I do like your timber choices for this build. Ben

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.