-

Posts

4,284 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Baker

-

That's not good Fortunately, most tomatoes survived 🍅 And indeed, more wood for ship models

- 86 replies

-

- whaling

- clinker built

-

(and 2 more)

Tagged with:

-

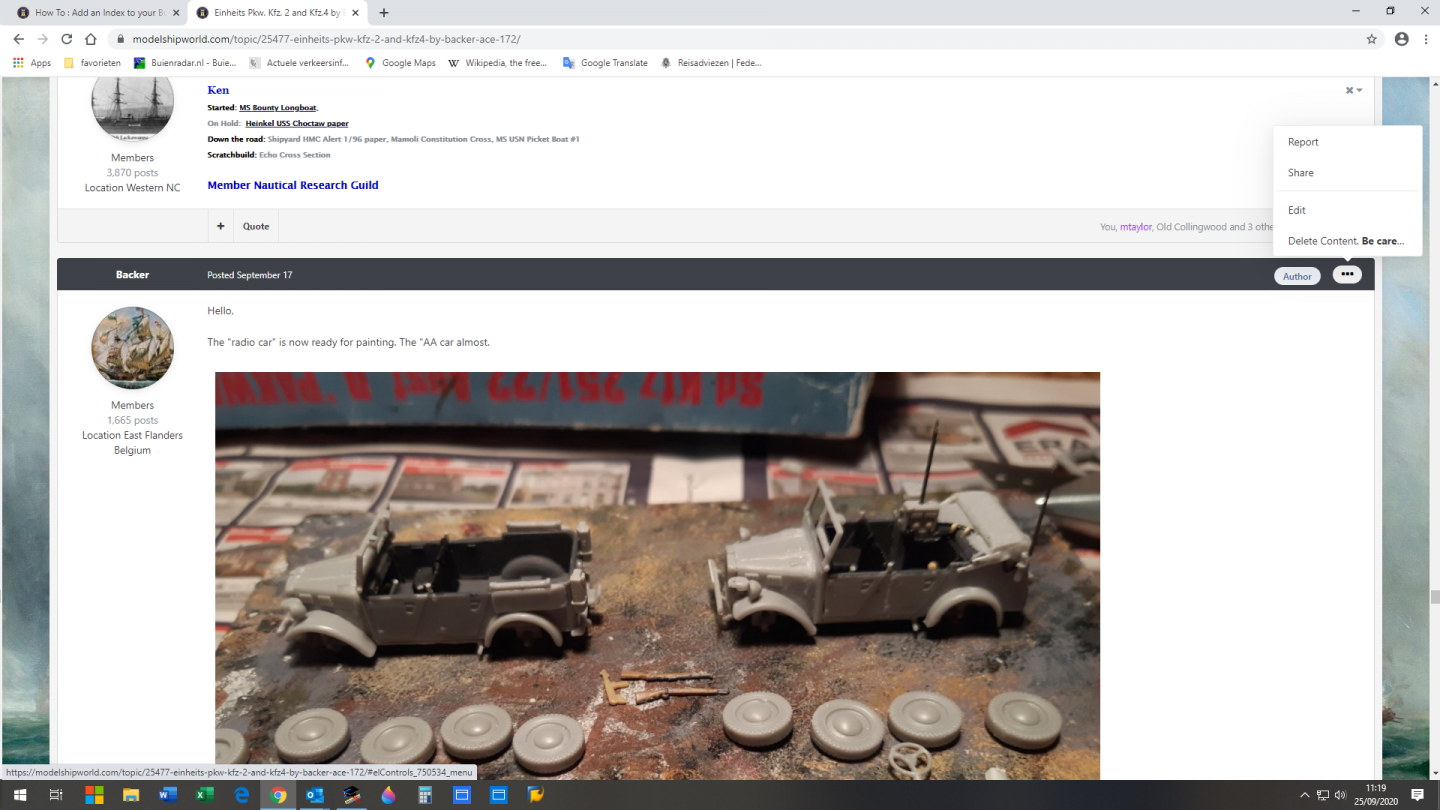

Finished Apply the decals Final painting job Glued on the base and a wash of diluted mat black Numbered The Stoewer Einheits Pkw. family. The 2 on the left are from the French company Al-by (resin) Looking at the numbers, these were built at least 25 years ago An ancestor of previous vehicles : The Stoewer M12 (build from parts of Hasegawa, Airfix and Esci) Basically a normal car "sawn" in 2 and extended Thanks for following, comments and likes.

-

Can happen to anyone, noticed just in time. If you only know what I've already had to rebuild on my models

- 16 replies

-

- Golden Hind

- Constructo

-

(and 1 more)

Tagged with:

-

question Normally this deck is not bent. Are you sure nothing is wrong. Now you can still adjust this if necessary Greetings Patrick

- 16 replies

-

- Golden Hind

- Constructo

-

(and 1 more)

Tagged with:

-

And welcome to MSW

-

Nice Patton (M48A3 ?? )

-

New member from Johnstone, Nr Paisley, Scotland

Baker replied to Marshall54's topic in New member Introductions

-

Thanks for this nice French text. Great that you speak four languages (always handy) I once learned French as a second language at school. Some German during my military service in Germany And some English in between. Looks they had interesting models. Too bad the company no longer exists. You can apparently still contact them according to the website http://www.aeropiccola.com/index_eng.html In the meantime, the second mast top is finally ready. Now continue with the top part of the main and fore mast. And now we make a "ezelshoofd" (donkey head in Englisch ) What does a donkey have in common with a mast part? Thanks for following

- 756 replies

-

- galleon

- golden hind

-

(and 2 more)

Tagged with:

-

And for general information about your model it is best to look in other logs You can find it in this topic And there is a pdf with links to the models.

- 42 replies

-

- first build

- artesania latina

-

(and 1 more)

Tagged with:

-

Nice model Dan. Everything you need to know about planking

- 42 replies

-

- first build

- artesania latina

-

(and 1 more)

Tagged with:

-

A beautiful model with many details and full of life Congratulations on all those self-cut figures 👍

-

-

ASlrWnt2C asking permission to come aboard

Baker replied to ASlrWnt2C's topic in New member Introductions

-

New member from Monterrey, Mexico.

Baker replied to Eugenio Treviño's topic in New member Introductions

Nice models

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.