-

Posts

4,289 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Baker

-

1930 BENTLEY 4.5 LITRE by MadDogMcQ - AIRFIX 1:12th Scale

Baker replied to MadDogMcQ's topic in Non-ship/categorised builds

No skills?? Very nicely done -

Thanks Steven The fore top is only 2mm smaller in diameter than the main top. This really doesn't look good and the conversion is now underway. These are the "charms" of scratch building a model without plans, haha.

- 756 replies

-

- galleon

- golden hind

-

(and 2 more)

Tagged with:

-

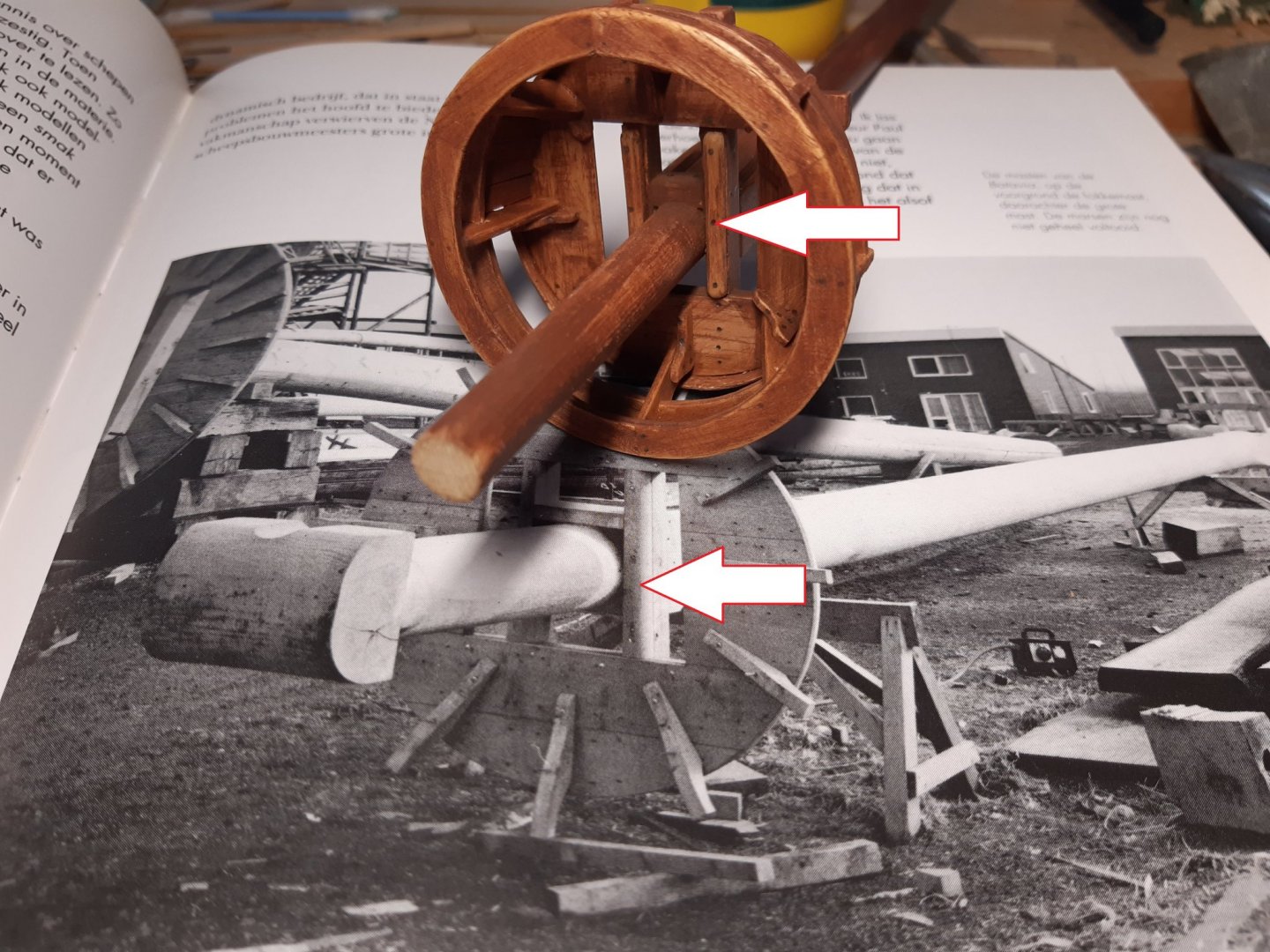

Thanks Chris. It is useful to take a photo now and then. And then take a good look at it I see that the mast top of the fore mast is actually a bit too big. So I'm going to rebuild this top a bit smaller. Better now than later

- 756 replies

-

- galleon

- golden hind

-

(and 2 more)

Tagged with:

-

Beautiful models

-

-

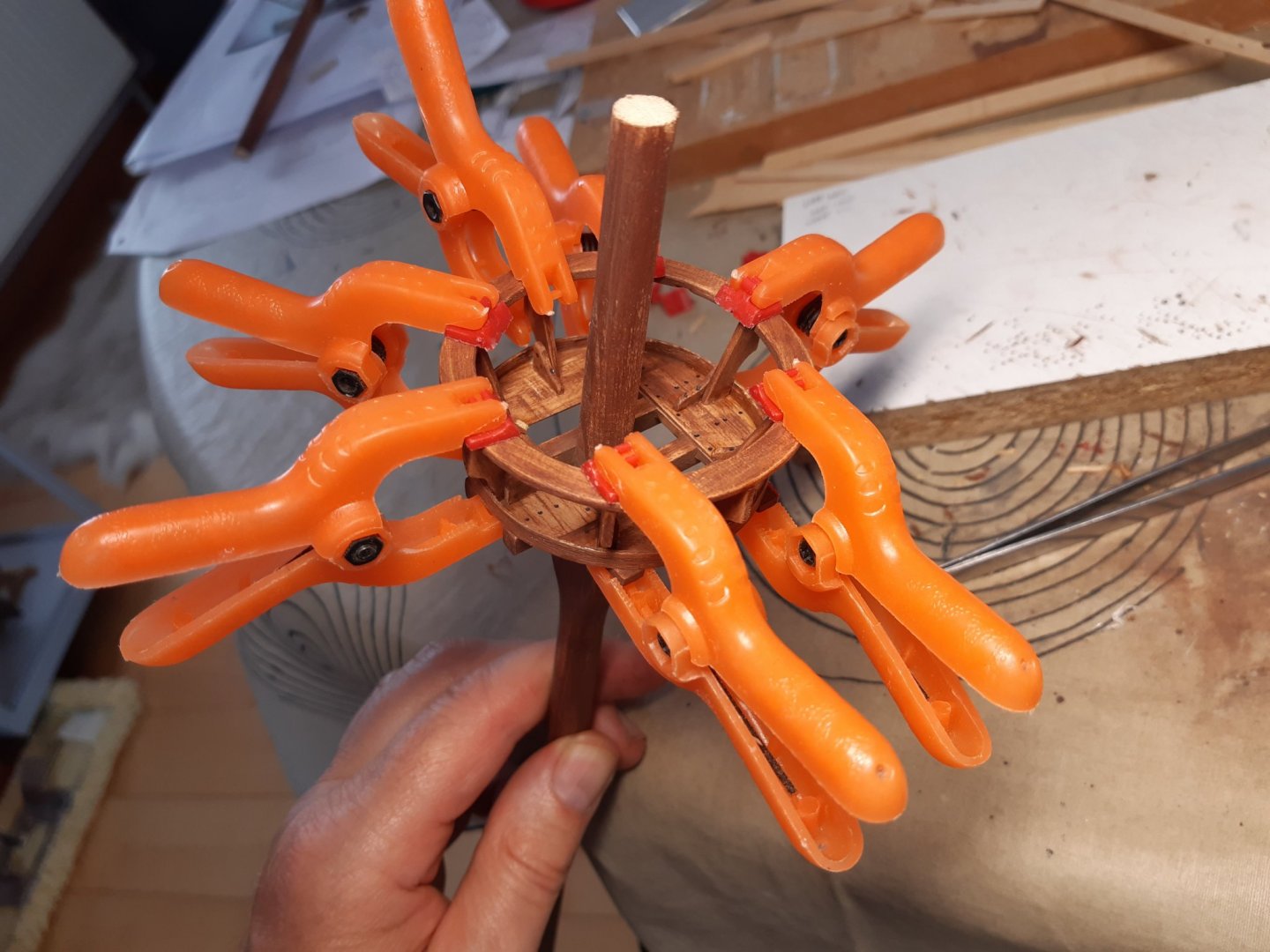

Slow progress Further finishing the 2 mastops. Added these Now I have to make 80 small planks (40 for each masttop) . None of them are identical. And add more knees. Work in progress Thanks for following

- 756 replies

-

- galleon

- golden hind

-

(and 2 more)

Tagged with:

-

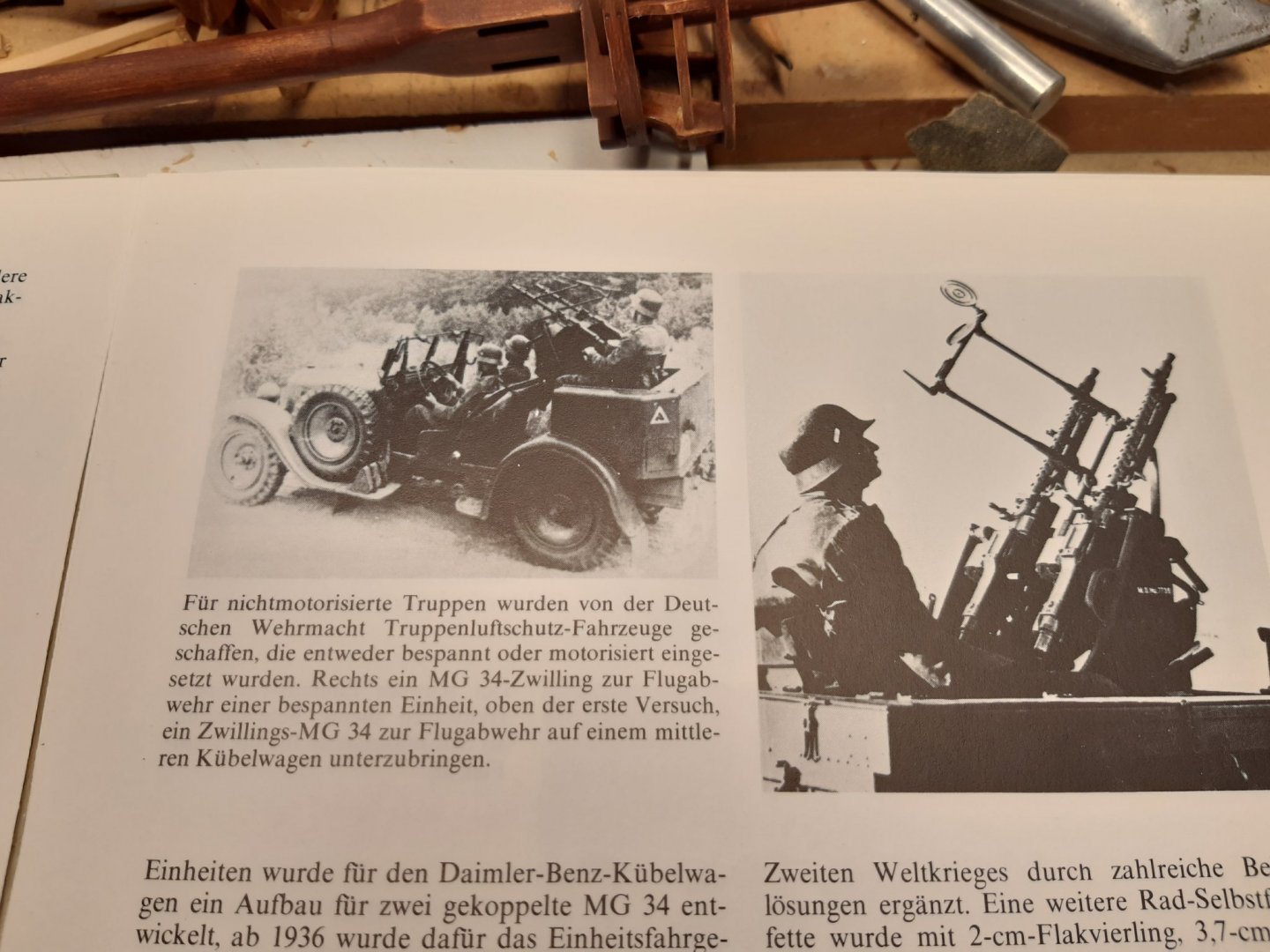

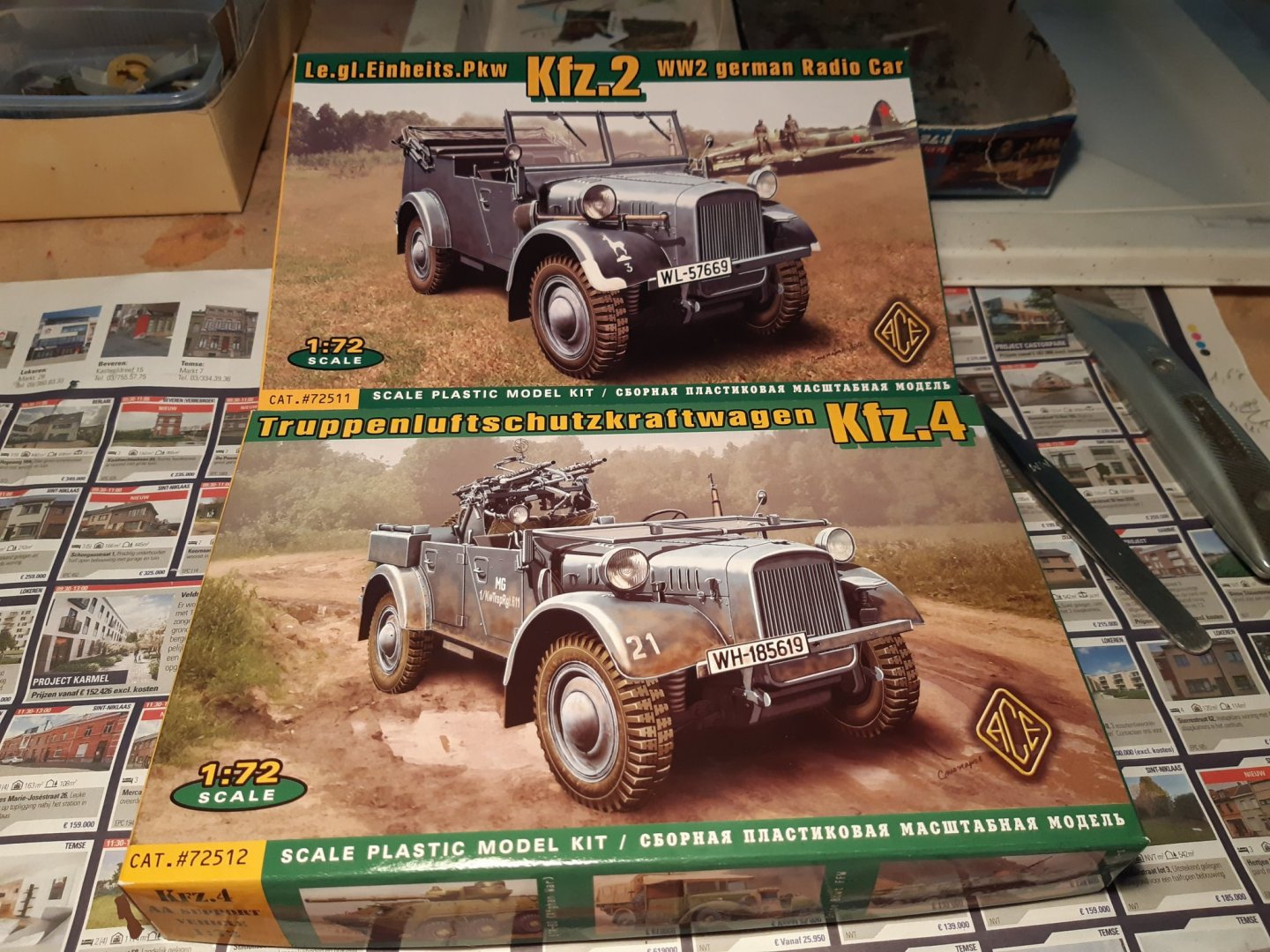

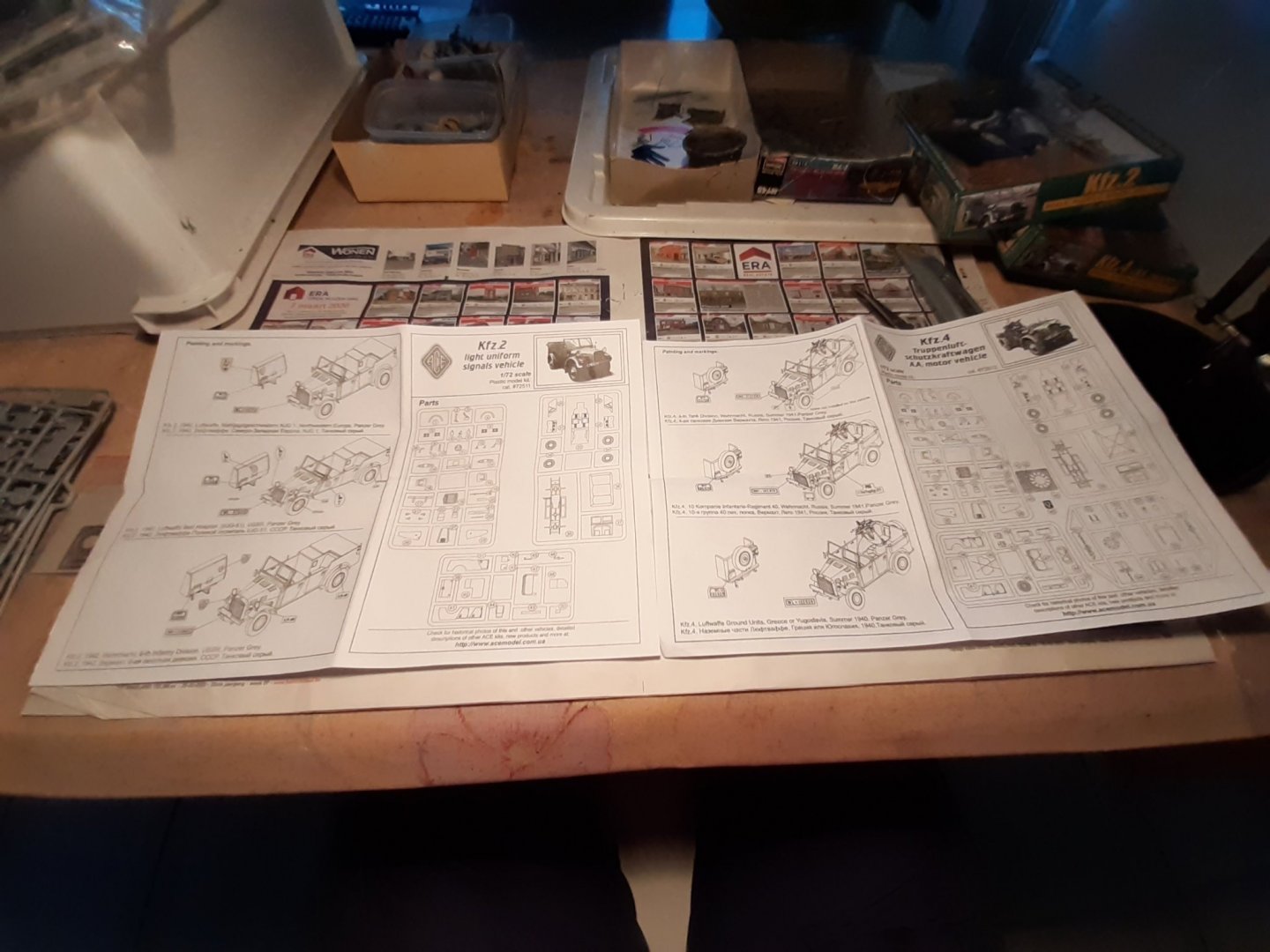

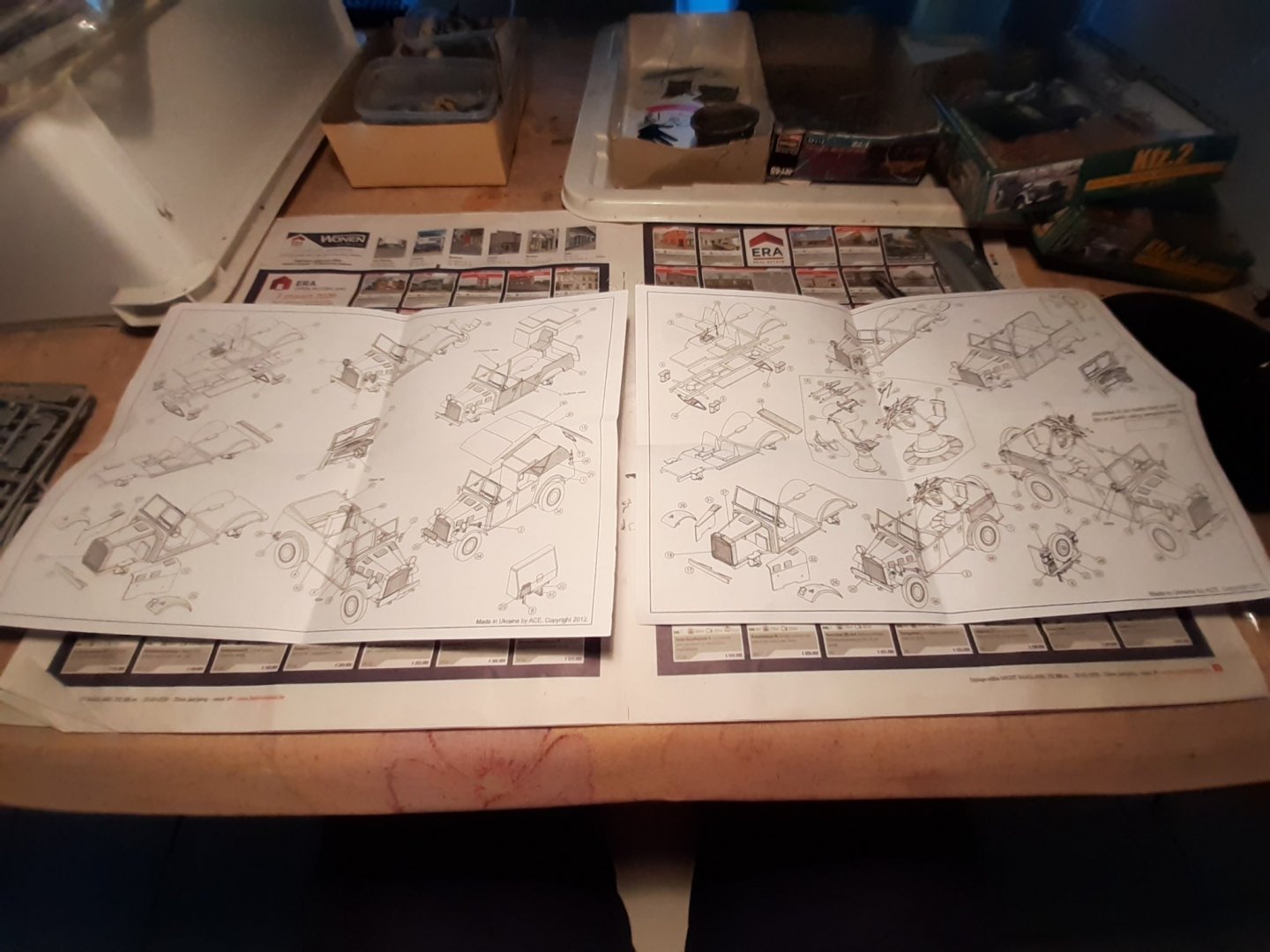

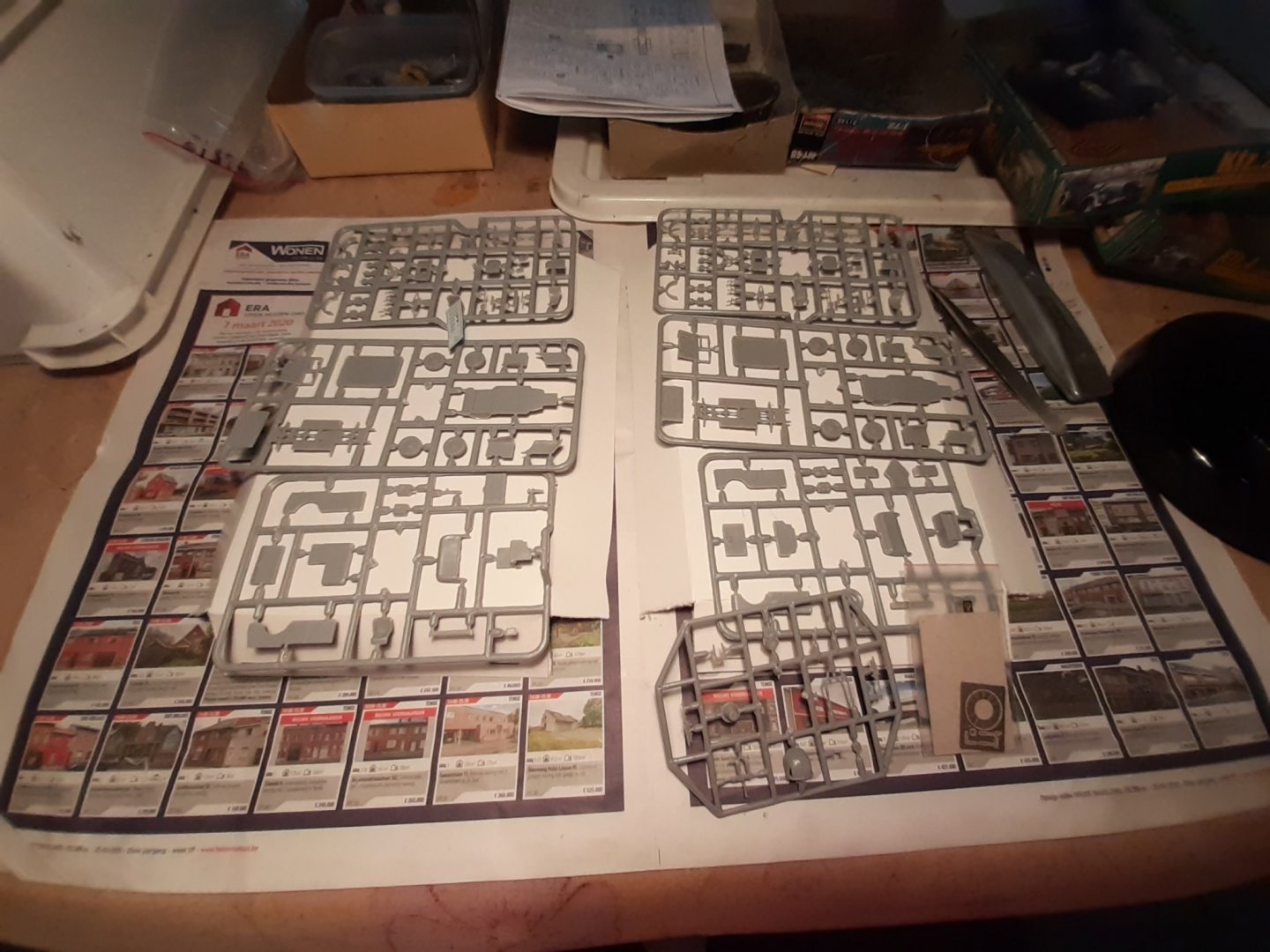

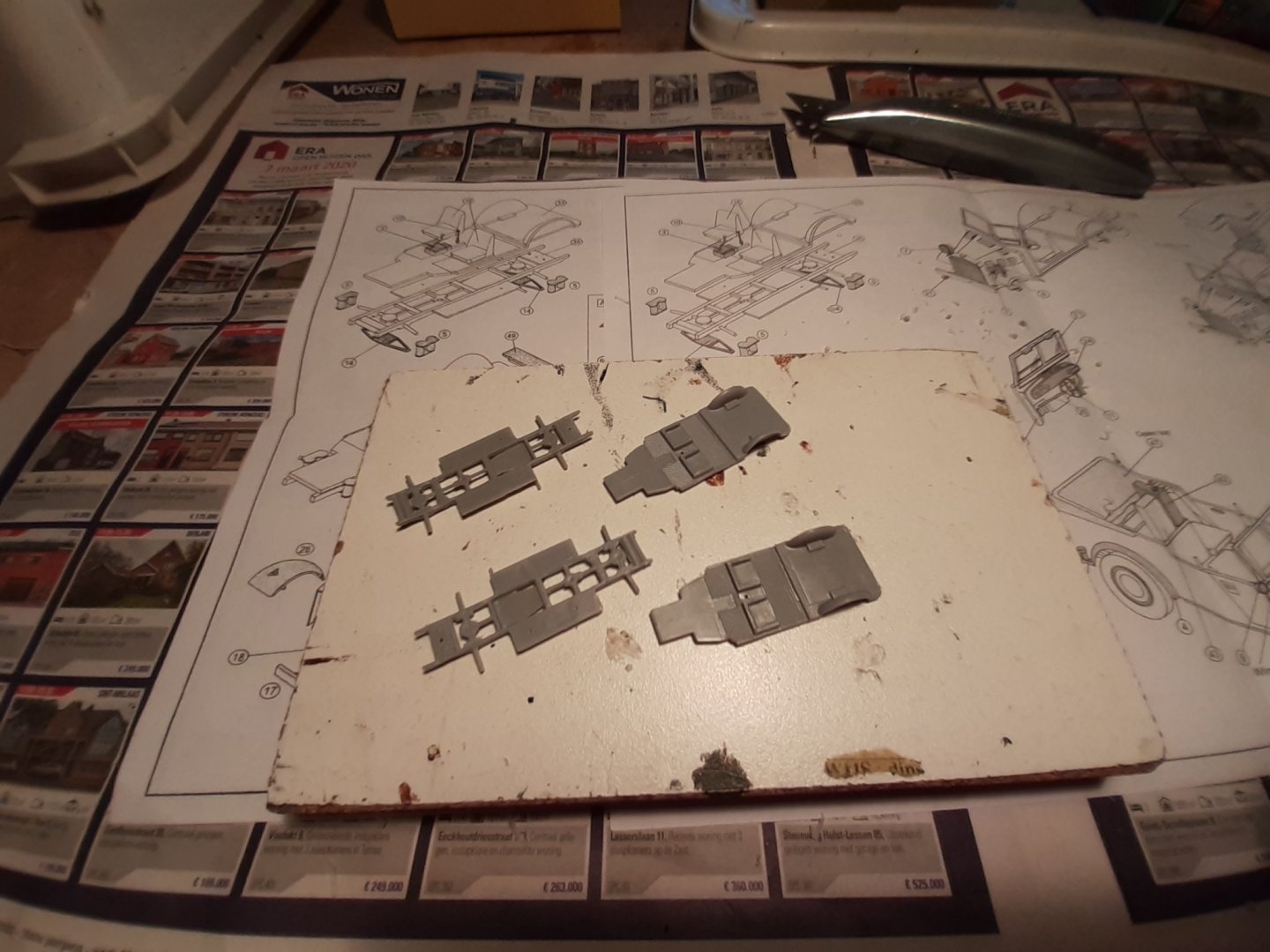

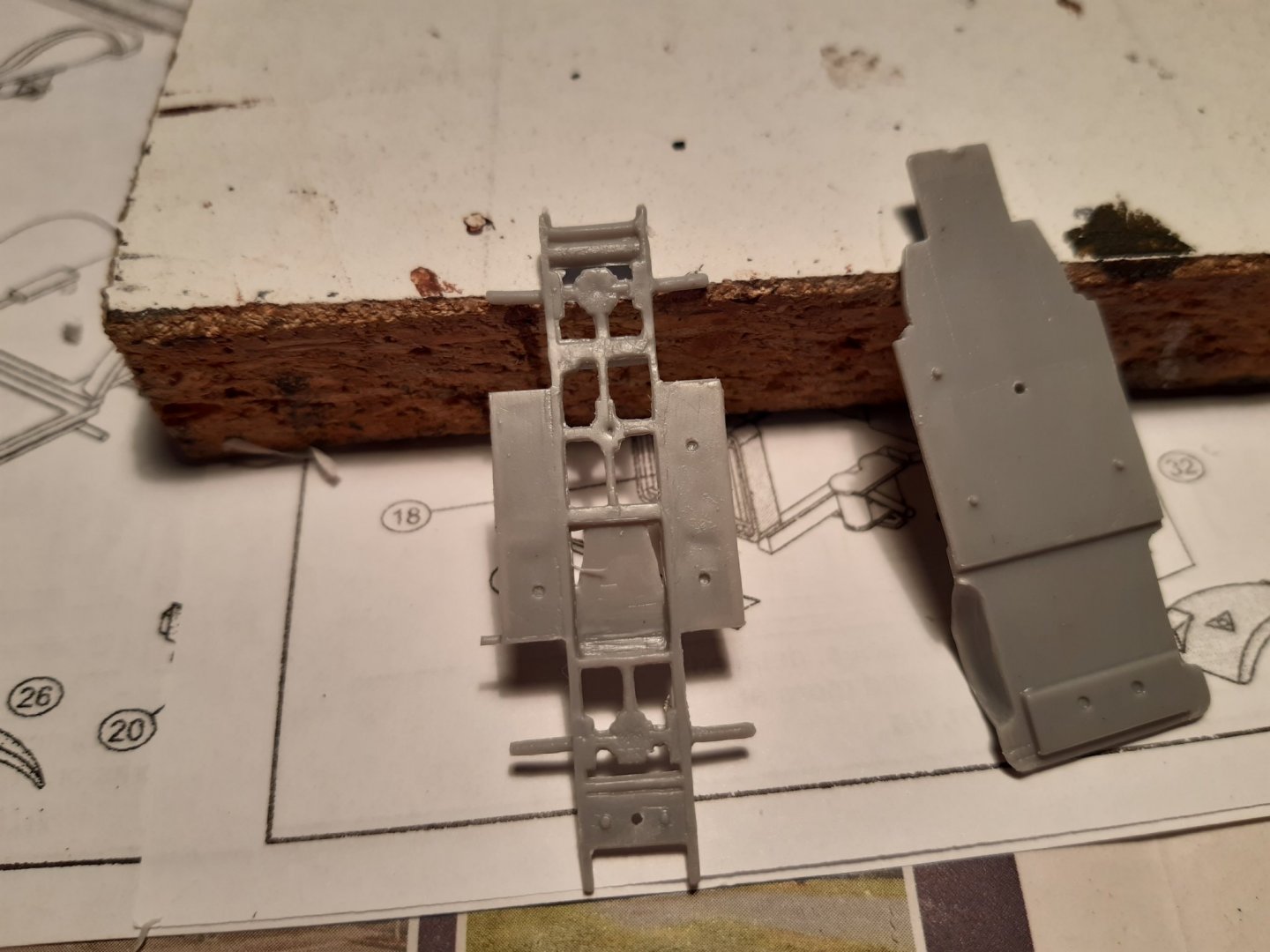

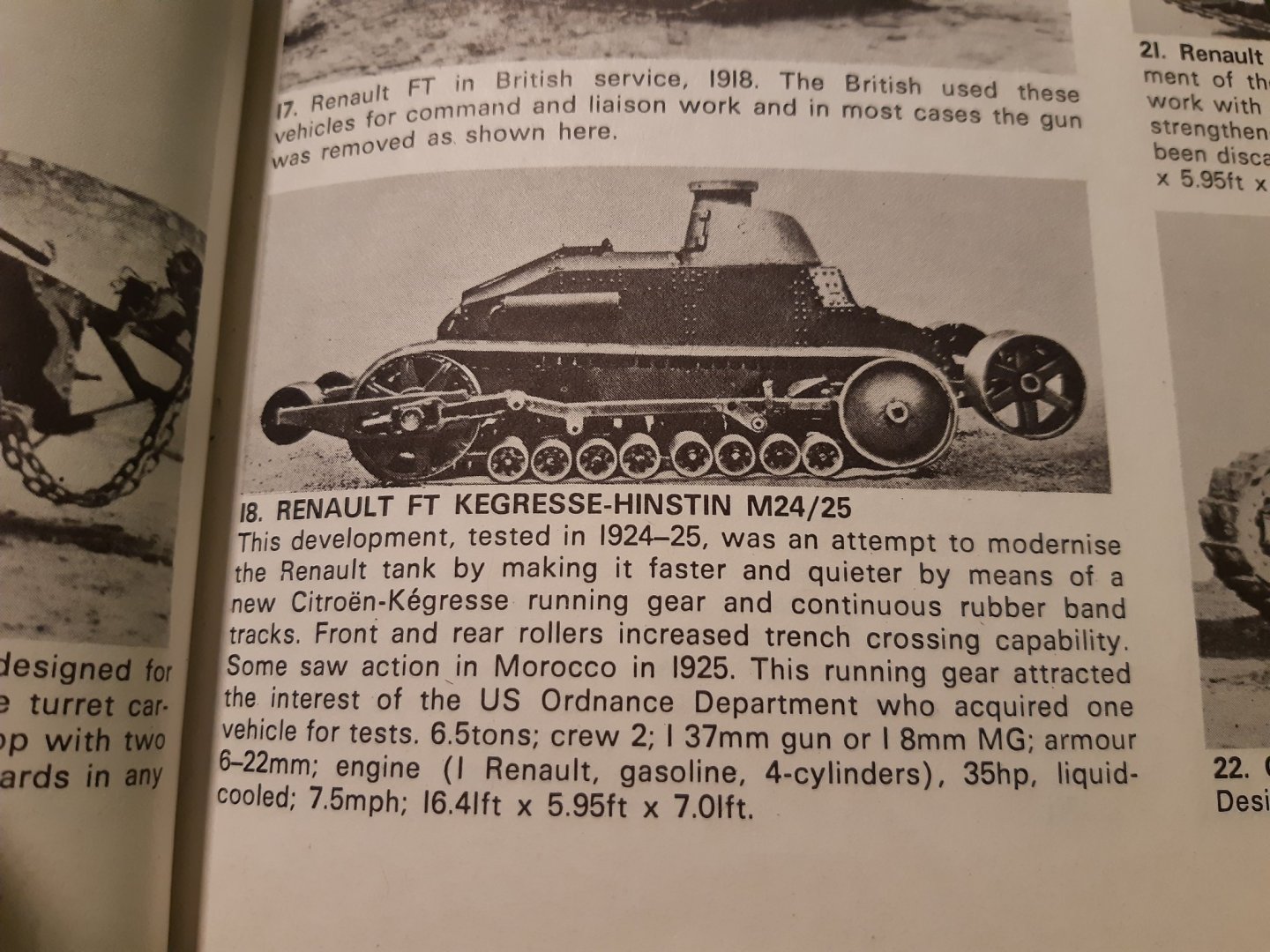

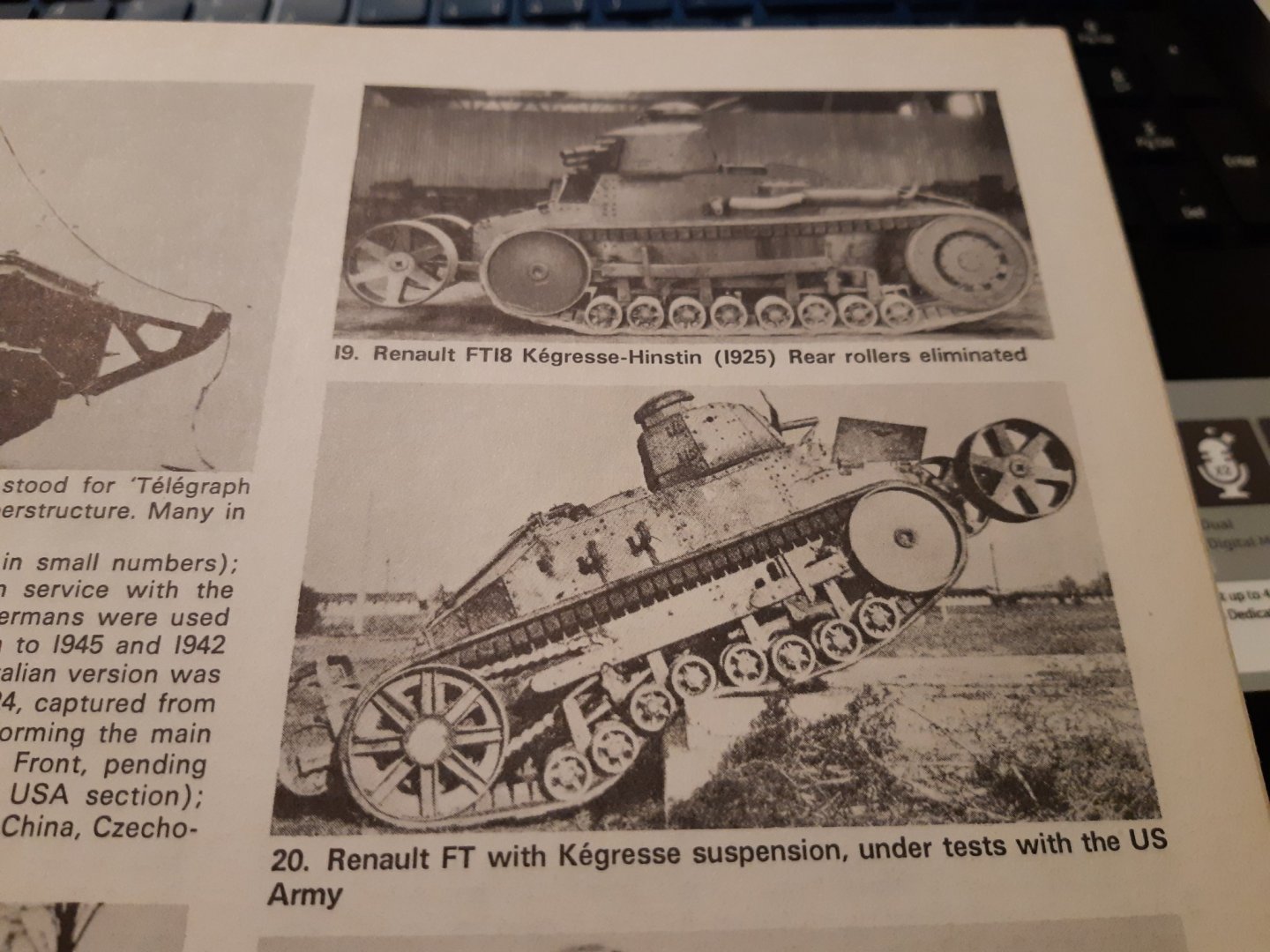

Next build, 2 models from ACE. The Kfz. 2 radio car http://acemodel.com.ua/en/model/448 The Kfz.4 anti aircraft http://acemodel.com.ua/en/model/576 General information http://www.kfzderwehrmacht.de/Homepage_english/Motor_Vehicles/Germany/Einheits-Fahrgestelle/le__Einheits-Pkw/le__einheits-pkw.html Ace makes short run models. So with molds that are worn out after a certain production number. Seeing is buying. Once out of production, the models are almost no longer available. Box, plan and parts. There is already a first problem at the start of building the chassis. The pins and holes do not fit. Pins removed and the parts fit now. Chassis parts glued and clamped.

-

Indeed. The Vasa model has found another home (sold). Maybe i make a "2nd edition Vasa" one day

- 756 replies

-

- galleon

- golden hind

-

(and 2 more)

Tagged with:

-

- 756 replies

-

- galleon

- golden hind

-

(and 2 more)

Tagged with:

-

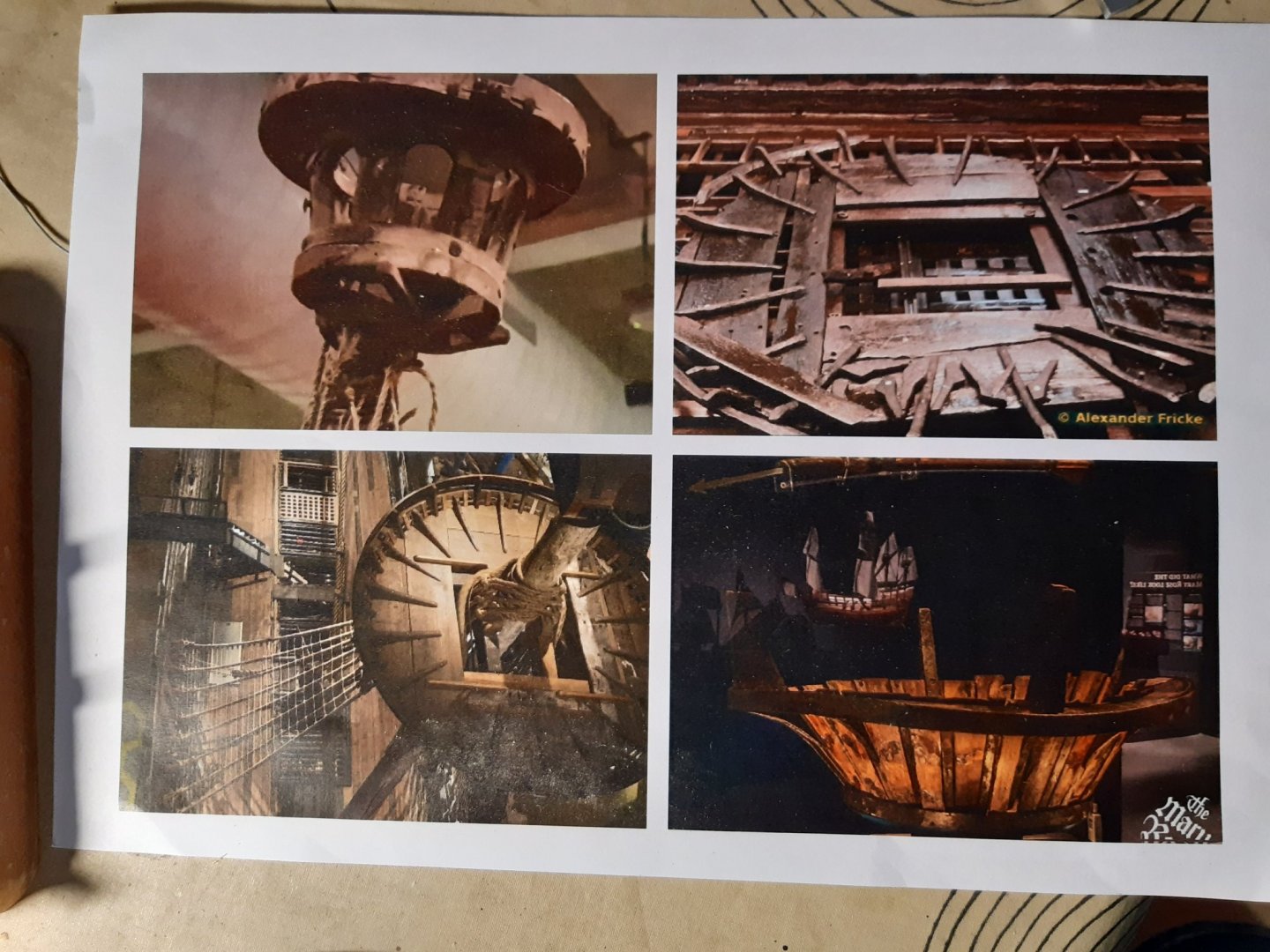

Continue with the construction of the mastops. This is more thinking time than construction time. The intention is to make something with these as examples. (Start at the top left clockwise Mataro model, Vasa, Mary Rose, Vasa) An uninvited guest at the shipyard ... Adding the main "supports" as on the Mary Rose. Making the "upper ring" from several planks Glue the ring to the supports. Still a lot to do Main mast top under construction, fore mast is following. Thanks for following.

- 756 replies

-

- galleon

- golden hind

-

(and 2 more)

Tagged with:

-

-

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.