-

Posts

407 -

Joined

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Bitao

-

-

6 hours ago, B-Ram said:

Excellent work on a great subject. I will be looking forward to seeing your progress.

Bill

Always trying to...

- mtaylor and Keith Black

-

2

2

-

-

7 hours ago, BANYAN said:

Great subject to do hwy; I am sure Ed will be thrilled to see you making this model. With your skills I am sure you will do a very creditable job.

cheers

Pat

Thank you for your encouragement. Mr. Ed's design of the boat is excellent; I also hope to be able to reproduce the details with my own efforts.

cheers

- mtaylor and Keith Black

-

2

2

-

8 hours ago, Tony Hunt said:

Wow. I can't wait to see how this progresses. It's looking great already! Young America was a very beautiful ship.

I like Ed's boat very much. . After entrusting a friend to buy back the drawing, he couldn't wait to start work. . .

- Keith Black and mtaylor

-

2

2

-

On 7/13/2020 at 2:36 PM, MEDDO said:

Excellent subject! Will be looking forward to your progress

Thank you for your attention, I will update the progress, please advise

cheers

- Keith Black and mtaylor

-

2

2

-

The last production of Gemma 1863 is nearing completion, but due to the limited space at home, which is occupied by a large number of tools, it will be difficult to store when finished; So stop the rigging for a moment and start work on a new theme, Young America 1853. This is also one of the five all in house sailboats I plan to build in the future; I only bought the first two copies of this book, and appreciate that the author's good subject matter can be shared with you, hopefully through my craft, to recreate the brilliance of the original work.Thank you for your attention,Also wish to give positive advice。

- MEDDO, Vladimir_Wairoa, RichardG and 13 others

-

16

16

-

12 hours ago, BANYAN said:

A very nice hull and the machine is superb. The resulting rope appears much more consistent. i also have a 'universal' style rope walk (Byrnes) and one of the issues I also experience is the 'jumping' you highlight. If I read correctly, you put put this down simply to uneven pressure. Are you referring top the tension on the individual stands being uneven, or at the take up spool (or both)?

cheers

Pat

Thank you for your attention. My month of trial and error has taught me that to get the perfect rope, the following three things must be done: The spools on the original single spool must be even; that's why I have to make another spool machine; Secondly, and most importantly, it is necessary to ensure that the tension of the three wires on the winding machine is uniform when running, otherwise there will be a "jumper" phenomenon, the point of intersection of the three strands determines the degree of tightness of the line (i. e. the angle of inclination of the Single Strand) . The whole winding process must be as far as possible to ensure the smooth operation of the line, to reduce the deviation caused by the swing. And that's what separates me from Byrnes in design!

- Keith Black and mtaylor

-

2

2

-

Is now entering the final stage of the rope. However, there are some problems in the winding process, after improving the previous production of the winding machine, or not very satisfied. It took nearly a month to build a new, much larger version. And added a rewinding machine. Finally, a satisfactory rope. Avoid the jumper caused by uneven tension during winding; at the same time, it can be adjusted according to the needs of the tension!

-

12 hours ago, Li Qinxiang said:

狼叔你的甲板边缘(不知道说得对不对)是后期在制作甲板的时候一条一条修的,还是事先想好怎么做了后设计的?

wolf uncle, do you make adjustment for each deck strip to fit the edge so perfectly at the stem? or you designed it according to the Plans?

这个必须是逐条根据曲线去修(包括周围一圈的围板)。没法事先设计好。毕竟任何再精密的加工也会有偏差的存在,何况是容易变形的木材。即便可以避免,但组装偏差是无论如何也无法避免的(不说别的,中心基线略微的变化都会对后期的部件产生巨大影响)。为了吻合紧密必须根据实际情况去做调整。

Translation:

This must be repaired one by one according to the curve (including the surrounding hoop). It cannot be designed in advance. After all, no matter how precise the processing is, there will be deviations, not to mention the easily deformable wood. Even if it can be avoided, assembly deviation is unavoidable anyway (not to mention anything else, a slight change in the center baseline will have a huge impact on later parts). In order to fit closely, adjustments must be made according to the actual situation.

-

8 hours ago, wefalck said:

Very 'high tech' ... the difficulty would be to get the pull equal on all three strands.

"Don't say I have a lot of copper... ha ha

" - I noted that in Chinese one doesn't seem to distinguish between brass and copper (I have seen this often also in ebay offers ...). Google translator tells me:

brass = 黄铜 (Huáng tóng)

" - I noted that in Chinese one doesn't seem to distinguish between brass and copper (I have seen this often also in ebay offers ...). Google translator tells me:

brass = 黄铜 (Huáng tóng)

copper = 铜 (tóng)Is this true ?It is true that language is an obstacle to our correct communication. But I think I can get the gist of it. Just be happy. . .

-

1 hour ago, wefalck said:

Could you show the other end of the rope-walk in close-up as well ?

This was made four years ago. This year, if there is time, intends to be further optimized and improved to make a larger.Don't say I have a lot of copper... ha ha

-

-

-

-

31 minutes ago, Keith Black said:

The increased weight of stud-link chain (33%?) vs standard link may have been a determining factor to use or not use stud-link chain on a particular ship.

I see. Thank you for your knowledge

- mtaylor and Keith Black

-

2

2

-

1 hour ago, BANYAN said:

Sorry for not getting back earlier HYW; distracted with other matters. I think Tony and Wefalck have answered the questions you had. As there is not a lot of material on the subject, your model, representing a smaller vessel, may indeed had standard link cable only.

Either way, you are doing a wonderful job with the build.

cheers

Pat

Thank you for watching my production. Because I didn't know enough about something, the only thing I could do was follow the drawings, but I wanted to do as much detail as possible to make it perfect. I hope you can point out the mistakes. I don't mind.

-

23 minutes ago, wefalck said:

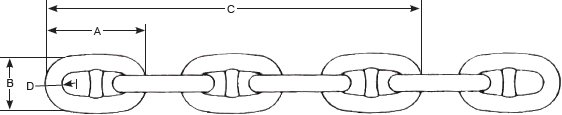

Pat was referring to this kind of chain:

From: http://www.cqhisea.com/m/productshow.php?cid=112&id=1123

It is common among larger ships and from the early(?) decades of the 19th on. Due to the difficulty in reproducing it, it is often neglected by modellers. There are now some apparently very good 3D-printed products on the market.

However, we were discussing, whether studded chain would be really appropriate for your type of ship and period. In any case, the thickness of the material of your chain seems to be rather thin.

Wefalck, I get it! I noticed that before I did this, there are a lot of boats that have this detail. But I'm sure it's not in the drawings or the books, and the same is true of the three Italian masters I've been reading. If so, it won't be hard, but it will take some time. I love the pursuit of every detail that has accurate plotting data, and this is the highest level we can aspire to. Thank you very much for your help! There is a real difficulty in understanding different languages.

-

9 hours ago, BANYAN said:

HYW, I am very impressed with the quality of your work and the model, but in this instance I feel that you are reducing the overall quality of the model in not using 'studded" or stud-link chain for your cable. After making that excellent swivel link, I think the cable deserves to be studded? This chain can be sourced reasonably cheaply, but with your skills I think you can make it? The more 'learned' here may be able to offer better advice, but I think English and French (pretty much all) ships were using stud-link cable at this point?

Please accept this as a very MINOR criticism/suggestion and I remain an avid onlooker of your very fine work.

regards

Pat

Hi. I read the introduction to the book today. I still don't understand that bolt. Maybe I misunderstood. I wanted to see if I could do it again. If at all possible. Can you send me a detailed picture? Thank you

-

1 hour ago, BANYAN said:

HYW, I am very impressed with the quality of your work and the model, but in this instance I feel that you are reducing the overall quality of the model in not using 'studded" or stud-link chain for your cable. After making that excellent swivel link, I think the cable deserves to be studded? This chain can be sourced reasonably cheaply, but with your skills I think you can make it? The more 'learned' here may be able to offer better advice, but I think English and French (pretty much all) ships were using stud-link cable at this point?

Please accept this as a very MINOR criticism/suggestion and I remain an avid onlooker of your very fine work.

regards

Pat

Thank you for your comments and suggestions! That's all I need. After all, I've been building sailboats for less than five years, and I still have a lot to learn. I don't know much about the ship, but I only have drawings and reference photos of the winning work. Of course, I think I'll do my best, it's my ability, but it's my fault for not doing it. I think in the future only in the production process more strict can be better. I hope you can point out my shortcomings. Thanks again!

-

-

Thank you for your attention and affirmation, cheers!

- Ryland Craze and mtaylor

-

2

2

-

-

-

YOUNG AMERICA 1853 by Bitao - FINISHED - 1:72

in - Build logs for subjects built 1851 - 1900

Posted

Ha, ha. Actually, I'm a very independent person. You don't rely on other people to do what you love. Promote "efficiency" , "accuracy" and "distinctiveness" . In my 20 + years of amateur model making, I have completed 104 plastic models of various subjects in a maximum of one year. Because you love it, you're in it. No less than 10 hours a day in your room!