-

Posts

1,239 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Papa

-

Wow almost 2 months since my last post. Been busy with other projects but I also had a VERY difficult time with the sheer rail at the bow. The laser cut pieces were constantly breaking. Every time i tried to work near the bow my hand would slip or I'd put too much pressure on something and snap, the rail would break along the grain. i think every layer of grain now has been glued together. Finally got it in and inserted the bulwarks; also a difficult task getting them all aligned. I couldn't figure out how to feather the waterway into the ceiling planks without the ceiling planks in place. So I modified the build order and laid a few ceiling planks and this provided a reference to feather the waterway. As one can see in the photo, more sanding is needed for a smooth transition. The Morgan will go on a 10 week hiatus as my wife and i are traveling up to the Canadian Maritime Provinces. Specifically, New Brunswick and Prince Edward Island.

- 294 replies

-

- charles w morgan

- model shipways

-

(and 1 more)

Tagged with:

-

Hobbyzone building slip for wooden ship models

Papa replied to aydingocer's topic in Modeling tools and Workshop Equipment

-

The bow and stern blocks are in and mostly shaped. They still need a bit more shaping, but i will wait until I confirm how the planks will lay down before I take any more wood off.

- 294 replies

-

- charles w morgan

- model shipways

-

(and 1 more)

Tagged with:

-

I have shaped the counter block and started the transom framing. I made a quick jig, not in picture, to hold the frame piece at the correct angle until the glue dried. I will trim the frame pieces to length when they are all in place. I found the counter block was very difficult to get right. There are a lot of angles and bevels. In fact, I messed one up and had to start again.

- 294 replies

-

- charles w morgan

- model shipways

-

(and 1 more)

Tagged with:

-

Hobbyzone building slip for wooden ship models

Papa replied to aydingocer's topic in Modeling tools and Workshop Equipment

The side pieces are an excellent idea. i will have to add those to mine. Ron Gove -

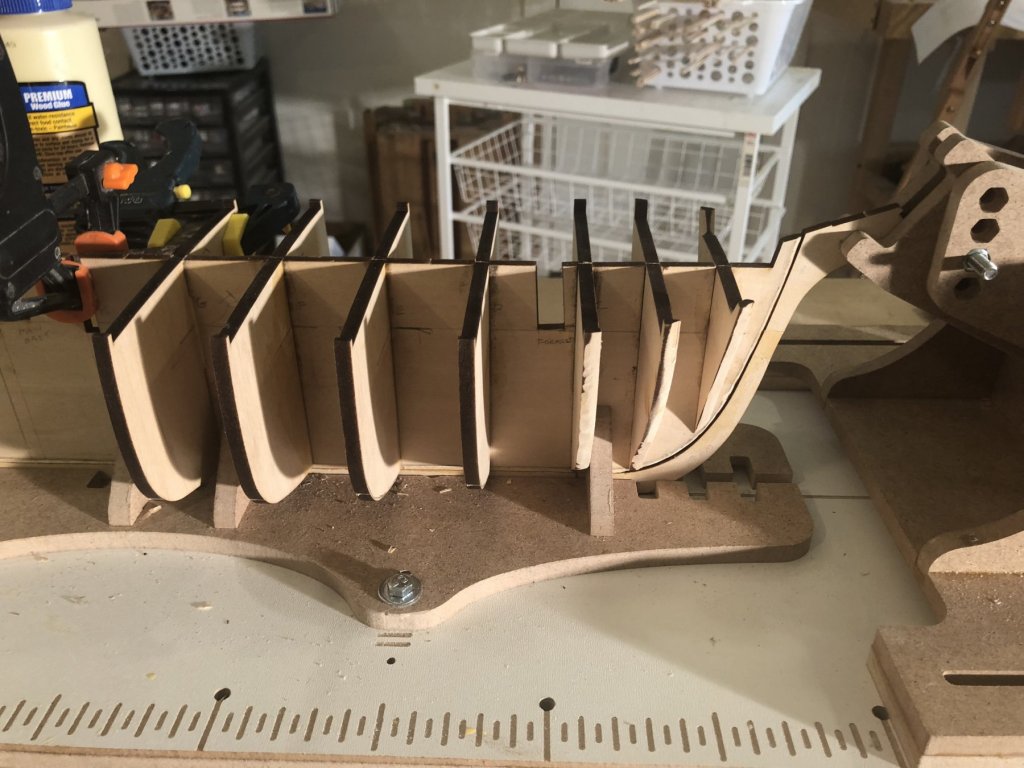

Finished the bulkheads and, following the building instructions, attached temporary battens along the bulkheads verifying that the spacing was identical port and starboard. I did this by cutting spacers that would just fit between bulkheads at the center keel and then used them to properly space the outside. Only tiny adjustments were necessary because I had been very careful to square up the bulkheads as I glued them in place.

- 294 replies

-

- charles w morgan

- model shipways

-

(and 1 more)

Tagged with:

-

Work on the Morgan has been slow. I am taking my time making sure that each bulkhead aligns to the reference marks and is square to the keel. I am letting the glue set at least overnight before moving on. I have found that shaping the bevels is so much easier with solid wood bulkheads. Beveling plywood is a pain.

- 294 replies

-

- charles w morgan

- model shipways

-

(and 1 more)

Tagged with:

-

On my Granado I thought the supplied chocks were too small and I made new ones using scrap wood from one of the parts sheets.

- 421 replies

-

- caldercraft

- granado

-

(and 1 more)

Tagged with:

-

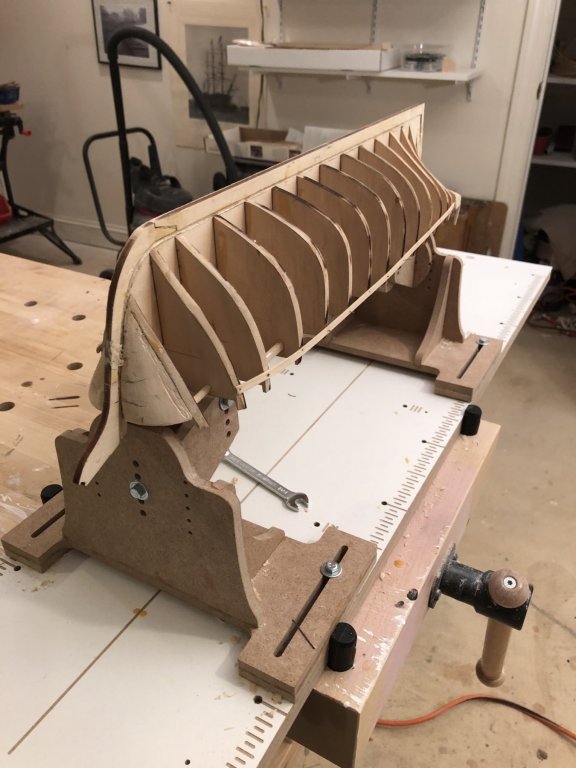

At long last I have started my CWM. This kit has been in my stash for quite some time. I saw no point in photographing the kit contents as there are quite a few Morgan build logs showing the parts. I will note that, contrary to the instructions, the center keel was a single laser cut piece, not 2 pieces. I do not know if this is still the case, but it makes for an easier start to the build. The photo shows my building slip set up to start test-fitting the bulkheads.

- 294 replies

-

- charles w morgan

- model shipways

-

(and 1 more)

Tagged with:

-

Your work is an inspiration Dan. Just slow, steady, precise, with attention to detail. I may give card another try. Your build log is a practicum on card models. Ron

-

Fantastic work Dan. I am giving up on Helgoland. It is not worth the effort it takes. I will stick with wood where I mostly know what I am doing.

-

Very nice looking model. I did the Monitor about 25 years ago. I used the copper strips i had left over from coppering the Essex to simulate the plating. I embossed rivets (man was that boring) around all the edges. Once painted it look great.

- 26 replies

-

Perhaps the clamps have been improved. I purchased mine quite a few years ago.

- 421 replies

-

- caldercraft

- granado

-

(and 1 more)

Tagged with:

-

I had some of those c!amps. I think I got them from Model Expo. They are not high quality; the metal is soft and after a few uses the screw part snapped off of the handle. Also, they split the bulkheads.

- 421 replies

-

- caldercraft

- granado

-

(and 1 more)

Tagged with:

-

I like the methodical work preparing the keel and bulkheads. Nice job. I hope I can do as well on my next build.

- 164 replies

-

- first build

- model shipways

-

(and 2 more)

Tagged with:

-

This is a beautiful ship. I will watch this log.

- 45 replies

-

- woody joe

- sir winston churchill

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.