-

Posts

5,951 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

What a beautifully crafted model Antony; you can be justifiably proud of this one. cheers Pat

- 99 replies

-

- turtle ship

- korean

-

(and 1 more)

Tagged with:

-

Slow but steady progress John; an excellent foundation for your future planking. cheers Pat

-

Hi Dave; a very good process with excellent results - that yard furniture looks really good. i hope you are going to add those tiny bolts/pins cheers Pat

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

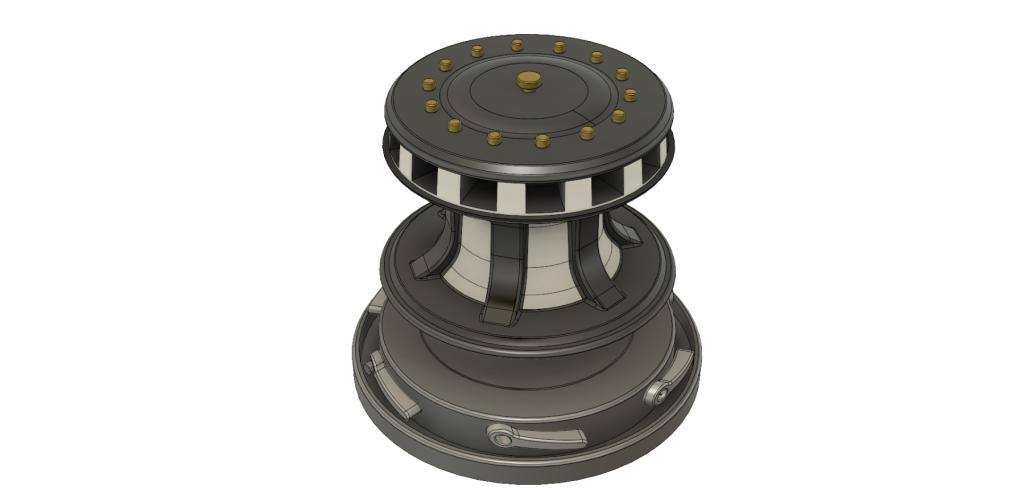

Hi folks some more progress on this build. I have now done a fair mount of the painting. The bulwarks and cap rails are finished but the hull still needs its final coat of black - you can see where I have started final sanding etc. The figurehead requires some touching up of the white to complete it also. The following show progressively how I have been proceeding. First I built a build cradle which is hinged at the front so that I can angle the deck appropriately under a large mill to drill the mast holes. This cradle keeps the ship nice and steady - there are two bicycle spoked from the keel (epoxied in) that pass through the assembly and secured with nuts under the board; the door wedges are for leveling the deck laterally. The next photo shows her masked and the priming coat applied. the last two photos are of her in her current state. the larger holes are for the scupper outlets; the final size is much smaller - a 9" scupper at 1:1. The smaller holes are for the Lang Scuttles mentioned earlier in this log. I have also attached a 3D render of what the capstan will look like. cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Further on those 150mm guns, the independent fire control is the most likely reason, but rather than selective, I note the turrets ere the two central ones. Perhaps they could 'slave' the other 150mm guns on that side to the central one also? cheers Pat

-

Hi Ensign, I have built a model of Endeavour (AL kit heavily bashed) and depending on your locale may be able to provide some help. Your profile does not indicate where you live etc. cheers Pat

-

Nice! That looks great Russ. I can empathise with the research Russ, it seems the smaller the item the harder to 'nail it' cheers Pat

- 420 replies

-

- captain roy

- lugger

-

(and 2 more)

Tagged with:

-

Great story Alan, there are far to few of these 'sharing' guys around. I am happy to say that I have had a similar experience with a very experienced modeller in my club; his willingness to mentor and his patience are much appreciated - and as in your case he wanted nothing but to share his experience. Look forward to your redos; they will be worth it. cheers Pat

-

Hi Lou, I have been having similar problems with posts - I thought it was just me. Almost ready for her maiden voyage Denis cheers Pat

- 378 replies

-

- t78 norden

- billing boats

-

(and 1 more)

Tagged with:

-

Chop Saw from Harbor Freight - Review

BANYAN replied to mtaylor's topic in Modeling tools and Workshop Equipment

Hi, I still have this saw and it performs well. The only issue I experienced was when changing blades I did not put the support flange washers on correctly and it wobbled. Other than that does a grand job of cutting straight - sharp blades are essential as with any saw. Note this saw does 90 degree cuts only if modified as I have. cheers Pat -

Good jig/idea Russ, makes for a nicely uniform and level hatch cover. I hope you don't mind me pasting this? Carl: Cleat - A strip fastened to one part to hold it in place or to facilitate the fastening of another part. Examples: cleats on the inside of a blanket chest used to hold a drop-in tray. A variation of the cleat that woodworker's tend to use a lot is the French Cleat. cheers Pat

- 420 replies

-

- captain roy

- lugger

-

(and 2 more)

Tagged with:

-

WOW Ed, as if your previous work didn't impress. Great result with your gin blocks - you set the bar awfully high cheers Pat

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Welcome back to the peace and tranquility of the modelling desk Denis Some nice added detail to your Norden. I hope you don't mind me commenting but that hose looks a little out of scale mate. That said, if you can live with it then leave it, there are plenty of great details to distract from it. cheers Pat

- 378 replies

-

- t78 norden

- billing boats

-

(and 1 more)

Tagged with:

-

Poor Man's Lathe disasters

BANYAN replied to stevenmh's topic in Modeling tools and Workshop Equipment

Not sure of your set-up Steve and I use a lathe, bu the process would be similar. Are you supporting the end of the yard while turning with the drill? That is both ends of your work should be supported, and if longer, even a third support like a steady rest. I have seen some posts of drills being used as a lathe where the other end is supported in a ply or mdf board with a hole at the appropriate height. More elaborate versions have a bearing inserted in the hole to support the yard end. I use my lathe to turn the stock but use sandpaper and files to shape so it is a very similar concept. IO have successfully turned/sanded down to under 2mm with the use of steady rests. I hope that helps a little; perhaps a photo of your set-up may assist other in providing better advice? cheers Pat -

Nice work again Jim; particularly like the last one Pat

-

Looks good OC; you've got the hang of the new camera pretty quick by the looks of it cheers Pat

- 455 replies

-

- slightly modified

- greyhound

-

(and 1 more)

Tagged with:

-

Very nice work Dan, that coin really shows the scale and level of detail. cheers Pat

- 287 replies

-

- michelangelo

- ocean liner

-

(and 1 more)

Tagged with:

-

Those cranes are very neat with good edges etc for card - i don't think PE could do that much better! Nice work Danny. cheers Pat

-

Beautiful joinery; beautiful details - what more can one say! cheers Pat

-

Making a lot of good progress lately Russ; some free time? cheers Pat

- 420 replies

-

- captain roy

- lugger

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.