-

Posts

1,811 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DocBlake

-

Brig Eagle by robnbill - 1:48

DocBlake replied to robnbill's topic in - Build logs for subjects built 1801 - 1850

Great job igging the guns, Bill. That is one awesome model you've built! -

I'll be watching the next phase closely, Elijah. Keep up the good work. Your shipyard looks great!

- 701 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

Good to see you back at it, John. I was wondering where you went! I agree with the epoxy and scratching of the poly as Denis has suggested, although in reality, if those cannons are hidden and don't get jostled at all, the PVA should be fine. Scratch off the poly, though. PVA will not stick to it.

- 194 replies

-

Had to do a little work on the cannons and swivel guns. The cannons themselves needed the bore enlarged. A 3 pounder had a bore of about 3" - 3/32" at this scale. The cannons were at 1/16" so I bored them out with a 3/32" bit. I got the swivel gun barrels from Cornwall Model boats. The problem was that the bore was way too big for a 1/2 pound swivel gun. The specs call for slightly over 1-1/2 ", or about a #54 or #55 drill size. I filled the bore with solder and re-drilled the bore with a #55 drill. I've got some Jax Pewter Blackener on order. It should blacken both the brass and the solder.

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

Glad to have you aboard, Mario!

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

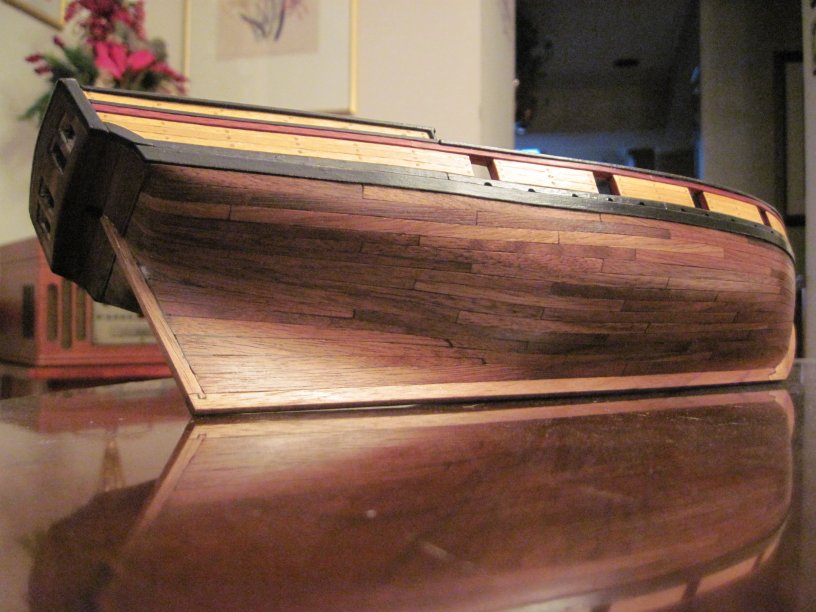

Great job on the planking, Greg! I know it's been said that any hull can be planked without the use of stealers or dropped planks, reality is a little different. I suppose if you've planked a few dozen hulls you could make it work, but with this hull shape some stealers at the stern (and a dropped plank at the bow) will make your life much easier. besides, I think the stealers look cool! On my AVS I had 3 stealers at the stern and one dropped plank at the bow.

-

She's looking like a proper ship now. Good job!

- 701 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

I'm ready to start work on the swivel gun mounts. My outboard bulwark planking is boxwood, and the wale is rosewood. Any recommendations regarding the wood for the mounts? Boxwood? Rosewood for contrast? Cherry? Holly?

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

Thanks, guys...I'm getting there! I spent some time yesterday carving the timberheads. They are made of boxwood for a nice contrast with the black rail. The plans call for 12 : 6 per side. Also, the plans say they should be 3/8" tall. I thought 12 looked too busy, so I decided on 8 total instead. I also went back to Dr. Feldman's book on constructing the original AVS and found that his timberheads were 1/4" tall. I made mine 9/32" tall; sort of a compromise!

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

Your hull turned out beautifully. I attempted a solid hull kit (Newsboy) many years ago, but never got beyond completing the hull because fairing to the proper profile was so difficult. You have learned very quickly and your work is first-rate. You've got a bright future in our hobby. Keep it up!

- 701 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

I mounted the rudder to the hull. The system used to create the gudgeons and pintles is different from what I've been used two. In my last two rudders, the pintles were short lengths of brass rod, soldered to the brass strap that attached them to the rudder. The gudgeons were likewise brass tubing soldered to the straps attaching them to the hull. This method is different. After cutting the recesses into the rudder to allow the pintles to slip over the gudgeons and into place, the straps are glued in place. The pintles are simply pins pushed into the wood of the rudder. No soldering! The gudgeons are made of little wood semi-circles with a hole drilled in to receive the pintles. They are then painted black. The straps for the gudgeons are just strips of bras glued and nailed to the hull on each side. Again, no soldering! The rudder has no false keel and is mounted so the bottom edge is about even with the bottom of the keel itself.

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

Your work so far is spot on. How many hawse timbers are there? In building my Lauck Street POF AVS there were three hawse timbers on each side, and fitting them and fairing them was the most difficult art of the framing process. Good luck, I'm sure you'll do fine.

-

Nice recovery, David. I can't tell which it is for sure!

- 117 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Check my build log for what I did at the bow of the boat. The kit has you fasten the foot of the bowsprit to the undersurface of the crosspiece of the forward riding bit. That would never have been done on any actual vessel. I fastened the sprit to the deck surface with a metal bracket to hold it down and got rid of the bitt altogether. Much more accurate. The new bowsprit angle fits more with the sheer of the ship, also. One change I would have considered in retrospect is to lengthen the bowsprit some. I think that would enhance the profile of the ship, Don't be afraid to experiment a little! This is fictitious vessel, so there is no "right" or "wrong".

- 114 replies

-

- swift

- artesania latina

-

(and 2 more)

Tagged with:

-

Thanks for all the nice comments and "likes" guys! Ken: I used the stock parts of the kit to form the hull. The scale change comes in with decisions about things like plank widths and lengths, the size of deadeyes, and dimensions of deck furniture, cannons etc. The model built to the scale the box suggests (1/35) would have been the smallest colonial schooner ever known to have been built. Smaller, even, than "Sultana", which Harold Hahn called "the smallest of them all". My scale change makes Independence intermediate in size between Sultana and Halifax. I used redheart for the inboard planking on my POF AVS also. It ages to a more reddish brown than the bright red it appears when freshly cut. That's OK with me. If I really wanted to have the planking stay really red, I'd use bloodwood, as I did on my MS AVS. That stuff is a real b*tch to work with, though.

-

Great job on the planking, so far. it looks like you've got the process down pat. Well done!

- 79 replies

-

- lady nelson

- amati

-

(and 2 more)

Tagged with:

-

Your deck looks super, David. Great job!

- 117 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Ken: Nice job on the "hooked" deck planking. That's a lot tougher than nibbing into a margin plank!

- 481 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.