-

Posts

1,383 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Snug Harbor Johnny

-

-

I did a VERY small scale U.S.S. Arizona from Metal Earth (completed build on MSW), so working with small, delicate (and losable) bits of metal is appreciated. On the basis of your fascinating build (I'm a Civil War buff), I got this kit to do some time between other projects. (The larger metal Missouri is in my stash as well).

Great tip on using CA as required. I found that kneadable JB weld epoxy putty can be mixed in small amounts to stabilize certain parts of a metal build.

-

So I got out those boxed figures to see how I could re-paint them to be approximately OK for my build. On 'old school' hobby shop is still in business in a nearby town - mostly because the son of the owner decided to keep it going as a business ... they have a LOT of 'old stock' as well a new stuff aligned to fantasy gaming. Quite a mixed bag, and these stores are disappearing one by one as Hobby Lobby and other chains become dominant. Still, there are lots of things available on the internet - old stuff as well as new.

The picture below shows two groups of HO scale military at attention - all manufactured and painted in Germany - and another group not shown are firemen. 3 figures of this size should stand on either side of the cherubs (or are they putti ?) beside the wheat sheave on the stern. BTW, the babies are naked on the original but I decided to give them loin cloths (diapers ?) for modesty's sake - and didn't want to model little privates for them ... not at 1:100 scale.

You know, Steve from down under (aka Louie da Fly) is working on Henry Grace a Dieu where the original was nearly the size of the Vasa ... but in 1:200 scale !!! Size does matter, mate.

Now the figures on the Vasa represent Emperors, classical Heroes, fighting men and such ... most with bare arms and legs beyond tunic arms or skirt. So I mixed some flesh color (not too light, since they'd likely have sun tanning) to paint on the figures arms and legs. On the ones with legs close together or relatively close, some gel CA was dolloped to fill the gap and treated with a touch of accelerator to lock in place. Then tunics (hauberks, kilts, whatever) were painted in polychrome - from looking at other builds, a lot of different colors are used - so I let my imagination run wild.

Some of the figures stand together on a base, and others have little bases of their own - both fit into a little gap in one half of the box, so it served to hold a group of figures together nicely. I held onto the plastic box half with one hand and painted enamels with the other. The finished HO figures are pictured below, and they may be good enough to pass on the model.

Then I had to paint the N scale (N-gauge RR) figures that go in various places around the stern. That was finicky, but then there are some Z scale figures that go at the bow - one of them (as yet unaltered) can be seen in the shot of the N scale figures below.

I won't mount any of them just yet because there are a lot of things to do that require manipulation of the hull. Have to think of the 'order of assembly' - which things to do first to make later progress easier. So we'll see how long it will take me to 'putter through' all that.

-

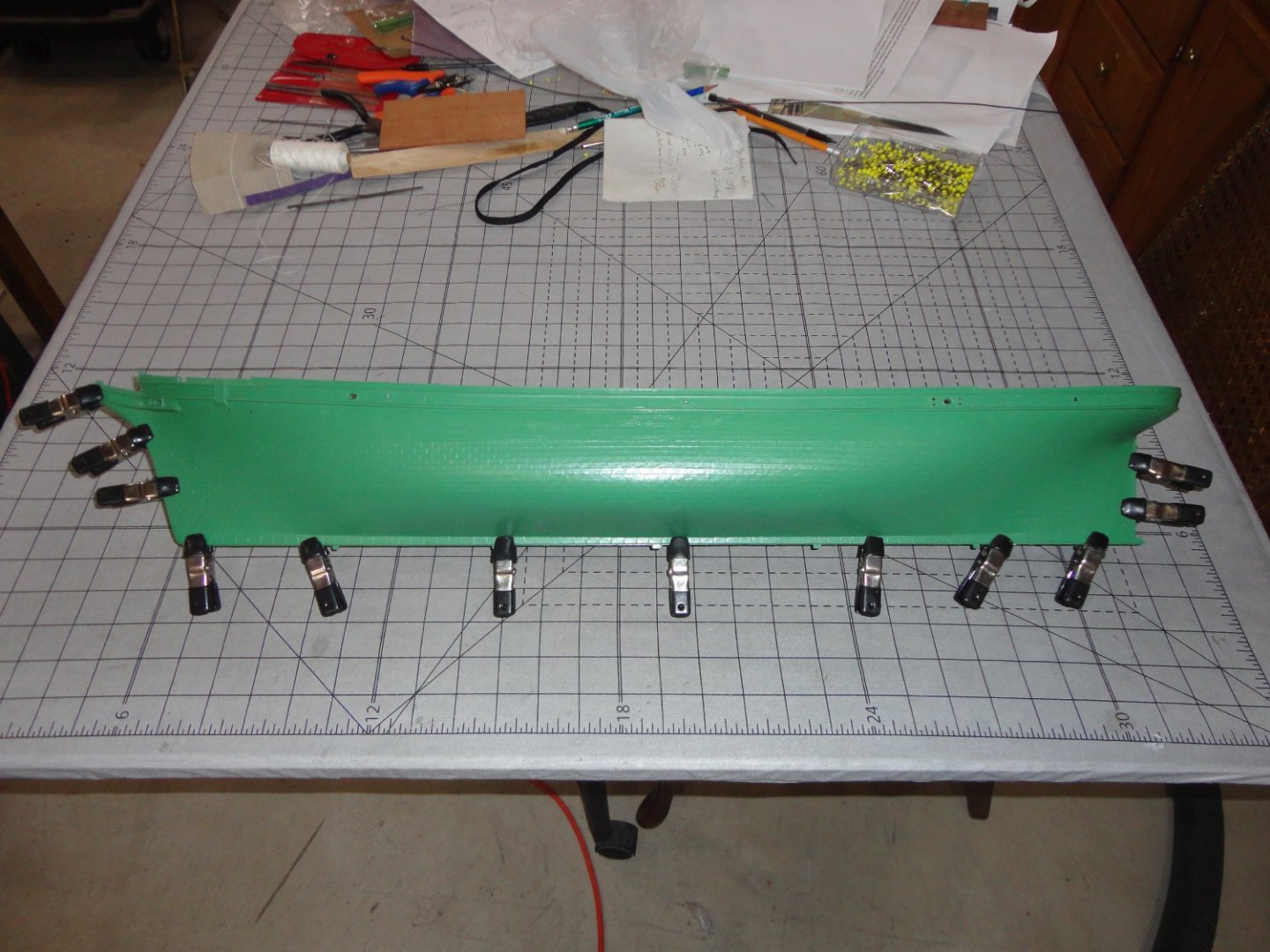

Hello again, The cupolas were glued in place (titebond) and I cut some balsa 'filler' to serve as a support for the roof clapboards that need to go on. Another approach might have been to make small frames, then plank them - but the balsa was handy and won't show.

The planking with mahogany veneer was a little fiddly in places - as it was doing the cupolas. I started using aliphatic resin, a 'go to' glue for wood-to-wood applications - but it takes a few minutes to 'grab' and I found myself using 'finger clamps'. Still, the smaller pieces for the end of the upper gallery would tend to move, and before installing the next row in any case - I had to let the glue cure at least an hour because some trimming and cleanup was needed before moving on.

OK, so I thought I'd try using gel CA which bonds much quicker. (Note that even dry wood has some moisture content that aids in CA bonding.) Once positioned, a dauber was used to transfer a very little 'accelerator' to the edges of the last clapboard glued ... and there was an almost instantaneous solidification of the CA. I could do trimming, filing sanding right away.

I know of recent CA discussions on the site, but there are some times when it comes in handy, as there are times I used 2-part '5 minute' epoxy and even kneadable epoxy (JB) as a filler. 'Guess its a matter of whatever works for the builder. Anyway, the roofs are done and I applied some flat acrylic paint ... and things are looking ever more 'Vasa like'. I glued in the turned brass half-cannons astern for the picture this time.

It occurred to me that the somewhat larger (and improved) Vasa kits sold these days have all the small figures of various sizes needed to decorate the places on the ship where ornate carvings were used. What I've done so far was hand-sculpted and tedious, and the process of making the many dozens of various kinds of figures, etc. is daunting. The approach will be to use some HO and N scale molded military (among other) figures re-painted to look more like Emperors or whatever, then bond them around the stern roughly where they appear on the original. This leaves something to be desired (as often happens), but at 1:100 they should be adequate - and certainly better than nothing.

- clearway, Ian_Grant, Wintergreen and 4 others

-

7

7

-

I read about how Charles Goodyear 'changed the world' in a big way with Vulcanization of natural rubber. Yet he never prospered from all his work, since once an innovation is made public there are many who capitalize on it for their own benefit.Suffering the adverse effects of years of exposure to dangerous chemicals, Goodyear collapsed at a hotel in New York City on July 1, 1860, dying later that day. At the time of his death, he was 59 years old, penniless, and deeply in debt.The Goodyear Tire and Rubber Company, founded in Akron, Ohio by Frank Seiberling nearly 40 years later, was named in honor of Charles Goodyear. Neither Charles Goodyear nor anyone in his family was connected with the company.Reflecting on Goodyear’s achievements, the historian Samuel Eliot Morrison wrote, “The story of Goodyear and his discovery of vulcanization is one of the most interesting and instructive in the history of science and industry.” But, as he added, “It is also an epic of human suffering and triumph, for Goodyear's life was one of almost continuous struggle against poverty and ill health.”Goodyear himself was philosophical about his failure to achieve financial success, writing that he was not disposed to complain that he had planted and others had gathered the fruit. “The advantages of a career in life should not be estimated exclusively by the standard of dollars and cents, as is too often done. Man has just cause for regret when he sows and no one reaps.”

-

-

I see that my last post on this 'build' was March, 2022 ... and its been nearly a year. 'Lots of learning and intervening tasks have happened - and participating in MSW has been a fascinating diversion. I have some plans on projects to come, and I've resolved to finish this present one first before moving on - which will give me 3 out of 3 completed MSW builds. As stated elsewhere on other threads, there are some major gaffs in this earliest version of the Billings Wasa (the Swedes prefer Vasa - take your pick) - and rather than try and make the masting and rigging kosher when the inaccuracies from the deck down are not correctable for the most part, the idea is to represent it still 'under construction' in dry dock.

That means having the first sections of masts plus fore stays, shrouds and ratlines (not unlike what is seen on the restored original) on a substantially complete (but not fully fitted out) hull. BTW, the Vasa kits offered these days in a slightly larger scale are much better than the ca. 1970 version I'm puttering around with.

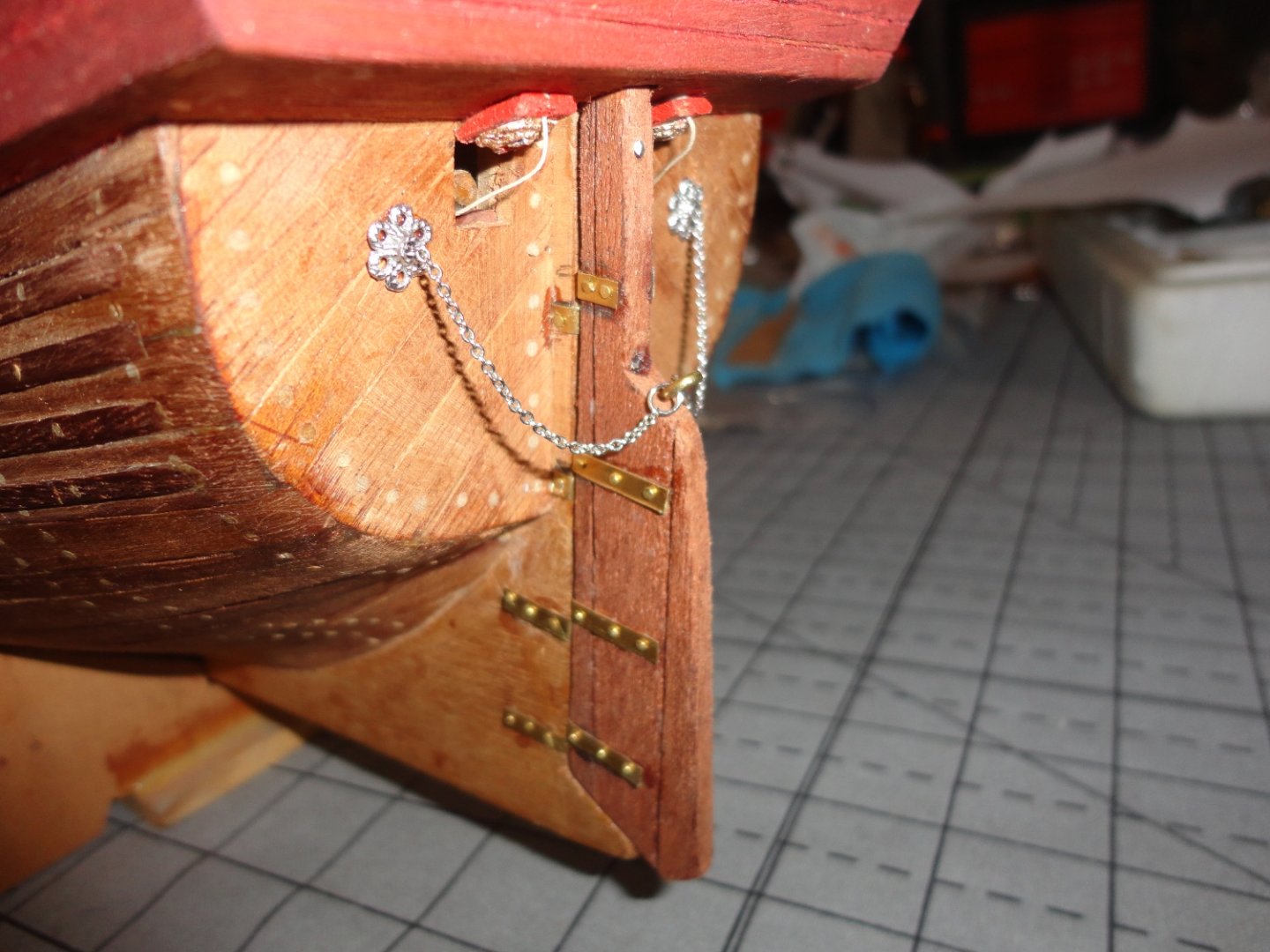

Theres nothing like renewed interest and a sense of direction. So I decided to continue working on the stern area and work forward. The kit rudder was mere plywood and broke while trial fitting, so I made a new one by laminating left over planking mahogany and cutting it out with a small scroll saw - a Dremel scroll I got from my dad, which is noisy but works well enough for occasional cut outs.

I'm not opposed to taking a few shortcuts (I'd rate myself as a permanently 'intermediate' modeler, so 'good enough' and 'standoff scale' work for me) - and I decided to shear some strips of thin brass shim on a paper cutter to bend around the rudder and matching keel area (offset, of course). The picture below shows the original part, the re-made part and a strip of the stock used to do that in three layers. (I love mahogany for a wide variety of things - but certainly not for decking.) The brass strips were CA'd in place temporarily, marked with pencil, 'linked' lightly with a prick punch and just drilled through with a wire drill for putting tiny brass plated brads into. The new ridder shows some of these steps.

As noted in another thread on glues, smooth metal does not offer much 'grip' for Duco or CA ... maybe Epoxy might have done better - but it occurred to me (too late) that lightly sanding the underside surface of the metal before bending would have given it some 'tooth' for the cement to adhere to, as the process of even light punching caused glue failure in places. (A little de-burring is also a good idea - note to self for later.) So I had to nail (with the aforementioned brads) from the outer edge on both sides and work my way in.

Also said elsewhere is that I don't want to go through a whole bunch of new pages to wrap up this build, in part because the techniques are familiar to most. The stern geometry I'm stuck with left little room for the two rear gunport lids, but it gave me practice on how I might do all the ones needed for the sides. I took a piece of planking stock the width of the ports (which were made exactly one plank wide some years ago ... yeah, out of scale) and drilled a tiny hole with a wire drill on either end (as I wanted to make 2 lids and holding the plank was a convenient way to work) for the pull rope. No need to make the opening rope since there would be no way to see it.

Before passing a line through and knotting the end to prevent pull-through, the periphery was painted with scarlet acrylic. I recently got some modeling flat paints in acrylic, as Testors enamels seem to be all gloss and take longer to dry. I glued a small lions head previously molded in dental plaster (similar to Durham's water putty) in a latex mold I made of a master sculpture in plasticine clay, and painted the lion's head in metallic gold - with white eyes (and a dot of black for the pupils) plus a little red in the mouth. When dry, I simply cut the port lid off the end of the stick with a fine saw (Atlas track cutter for O-gaige model railroad track). The lids were glued in place (BTW, I used CA for all the gluing - gel type), and the pull lines stuffed into the opening and glued to one side.

There are half-cannon barrels that fit into the 'dummy' gun carriages with dowel receivers. The dummies are visible through the ports, but I have not yet glued in the brass barrel halves that will protrude through the gun ports. The rudder was pinned in place with 3 thin iron nails - drilled first - (yup, why fuss with pintles (or are they gudgeons) when (at this scale - 1:100) they'll look well enough. BTW, the brass plated brads were harvested from an AL kit used for parts and stock. I found a threaded brass eye (from a Steingraeber parts kit) to mount on the edge of the rudder to accept the rudder chains - which were found in the jewelry section of a JoAnn's fabric/craft store. Two holes were drilled to either side of the rear cannon ports (where fittings are on the original ship), jewelry fittings were slid over the chain before stuffing the chain ends into the drilled holes and CA glued (accelerator provides REAL quick setting !). Then the fittings were slid unto cover that and glued. The picture below shows the result of a good day's work in my shop.

It seems that around 27.5 degrees (or thereabouts) is the maximum that a rudder should turn to either side before it become both an inefficient brake and an inefficient rudder. Rudder chains are suppose to limit travel to either side. The second function is - in case rough seas cause a rudder to become unseated and come off - to retain the rudder and keep it from being carried away ion said rough seas. 'Funny the stuff one can learn in the process of modeling. I won't go into the list of boo-boos, but rather think there is a certain 'charm' to it, at least in my eyes. Two more pictures of this area appear below.

Fair sailing ! Johnny

- Vladimir_Wairoa, Ian_Grant, Cirdan and 5 others

-

8

8

-

The 'Chicago ' variable speed flex-shaft drill (sold at Harbor Freight) I've enjoyed BOTH power and lower speeds (modulated by a foot control - like my 'old school' sewing machine). I do have to use an Enco mini pin chuck (has three small collet sizes) to use 'wire drills' for the best results. Yeah, there is that flex shaft attached to the motor that hangs from a provided wall hook. 'Same would be true for a old-style dental drill ... my brother got that from my dad's estate 'cause he was there first.

-

5 hours ago, Dr PR said:

I have one wooden POB model ship that is 53 years old that was glued together with Duco cement (or a similar wood glue from the 1960s) and it is still holding together with no problems.

Nitrocellulose has been used in wood finishes on guitars and finishes for metal musical instruments for more than a century. It was also used for photographic film.

Of course guncotton is nitrocellulose, and it is used for rifle powder and used to be used for the powder charge in large naval guns. So don't set your model on fire or expose it to a strong shock or the nitrocellulose might explode!

Per the History Channel, late in the 19th century they tried using nitrocellulose as a substitute for ivory billiard balls. There were pool games that had explosive results when the impact from the cue ball was too great !

-

5 hours ago, VitusBering said:

The first half of my backordered paint shipment (white and a couple of shades of brown) arrived yesterday so I was able to get the masts painted and assembled. The second half (black, silk finish) has been shipped so it won't be long before I'm able to finally mount the spars.

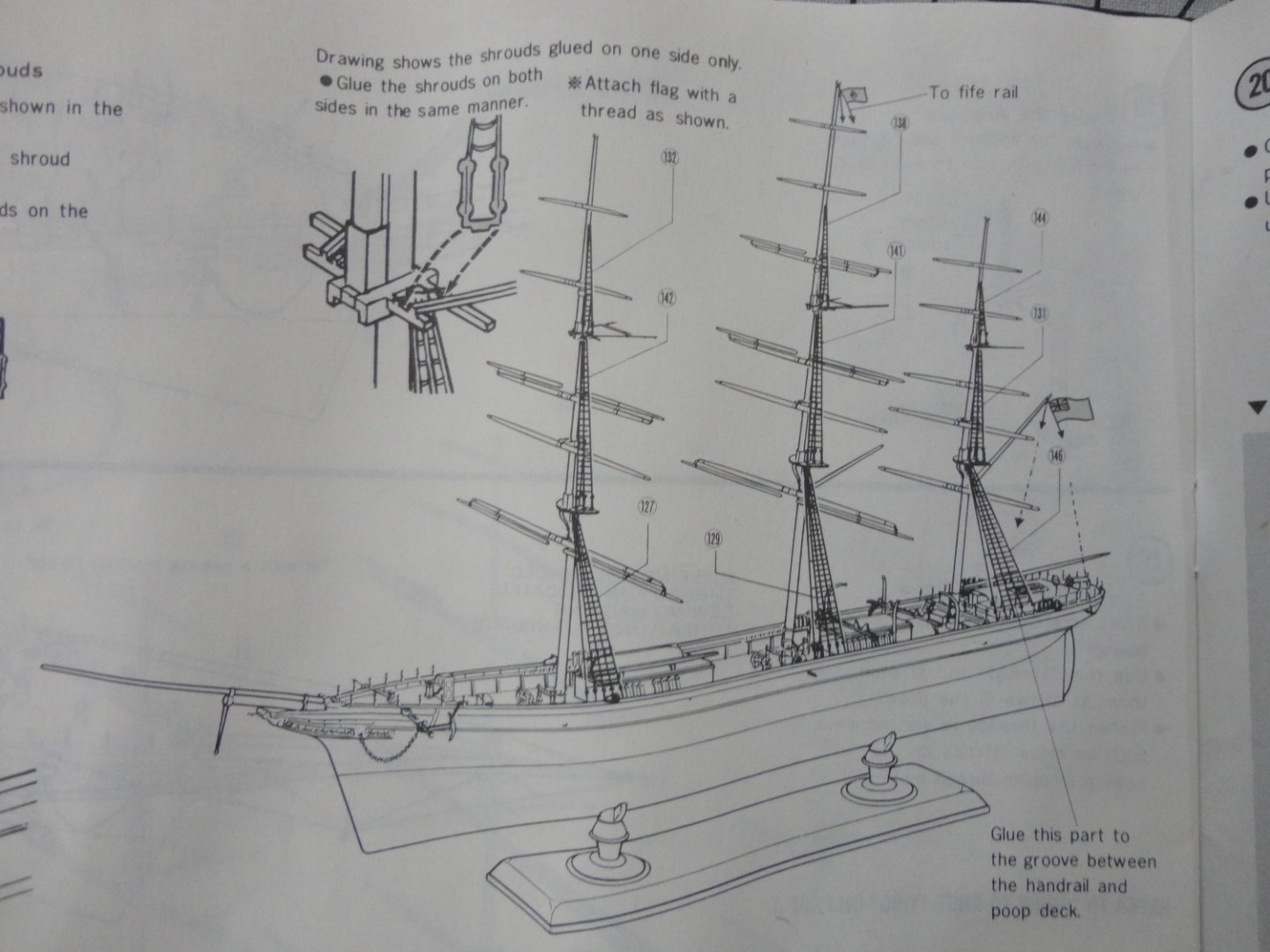

On that note, I'm unsure whether to set the spars perpendicular to the centerline, or offset at an angle. The 1974 kit instructions show them set perpendicular and the 2017 kit instructions show these positions as optional but give no guidance at all about which to choose. I'm leaning toward an offset, what do you folks think?

The 1:96 Revell CS has masts that one 'builds up', so I wonder why choose a given position and then bond (glue) the yards permanently in place? I've seen a couple builds where the yards were modified so that can pivot - thus be adjusted as one re-thinks exactly what angle is to be depicted. The rigging might even be made to function as to allow adjustments. I have a suspended build to finish before I do anything new, but continue to read, study and look at other builds with great interest - which certainly helps to "learn the ropes".

-

Reference Noel C.L. Hackney's book Cutty Sark - Classic Ships and How to Model Them (#3) in the series - which was originally meant for the 1:168 Airfix plastic model to be substantially enhanced to conform to the extant CS ... but takes a very skilled miniaturist to accomplish at such a small scale. However, the same book can be used for larger scales successfully. I'm studying it on and off and can relate the following for the mizzen yard lifts - rigged the same as the fore and main yard lifts (for the course - or main sail).

The masts all have a mast band accessible from the deck with belaying pins all around, and these correspond to attachment points on a ring of mast foot eyes almost at deck level beneath the mast band with belaying pins. Finding a picture of these items aids in understanding. Belaying pins on the mast band of all masts for the port and starboard yard lifts are the ones located directly port and starboard.

A line for the yard lift on each side of the yard is attached near the end of the yard, then routed up to a 10" (at full scale) block attached to an eye on the lower mast cap, then down through the the top (mizzen top in this case) and attach the end of the line to a 9" double block roughly halfway down the mizzen mast. Then, from the becket of a 9" double block hooked (or otherwise attached) to the proper mast foot eyebolt (port or starboard as applicable), make a double purchase between the two blocks (that is, from the top eye of the lower block up to the hanging double block, then back down to the lower block - 'first purchase' - back up to the upper block and down again to the lower block - second purchase). End by taking the fall (free end of the line) from the lower block directly to the mast band pin and belay.

'Hope this helps.

-

On 2/22/2023 at 8:13 PM, 72Nova said:

Thank you, Shipman, I checked out the numbers on my box and it's dated 1/20... nothing special and the only parts that had excessive amounts of flash were the deadeyes which I knew I wasn't going to use anyways and the trestle-trees, rest had the usual amount you'd normally find.

Johnny I'll be looking out for your review/pictures of the Monogram CS as it's piqued my interest .I appreciate the information guys.

Michael D.

Ahoy Michael ! The kit review has been posted for the 1:120 CS Monogram version in the kit review section (plastic). 'Hope it servers for now. Johnny

-

As indicated elsewhere, I sprang for a Monogram release (early 80s?) on 4 color plastic sprues at a true scale of 1:120. I gave up trying to fiddle with a 'so-called' (per the box) 1:130 CS Airfix "Vintage Classics" release (only a few years old) that turns out to 1:168 by Noel Hackney's book on the original kit - having a 15.7" hull and VERY small parts & quite thin yards (among other pieces) made nearly 'rubbery' due to the soft nearly blonde plastic used. There have been comments on softer plastic used in 'later releases' of many kits (originally well-regarded) where aging molds have less definition and more flashing. First and second releases of the Airfix molded in better black plastic come up on Ebay now and then for around $50 (USD) or so, and may be doable for someone with the skill and inclination to accomplish miniature work. Note: other than on the cabin, no stanchions for railings are in the Airfix kit.

A 1:150 Academy CS I examined for a while (said to be a 'shrunk down' version of the original IMAI 1:120 CS) was molded in 4 colors and, apart from only having fully extended studding sail booms on the yards (some have cut these and re-glued in a retracted position), it is in my opinion a much better kit (but not large - having about a 16" hull) suitable to encourage a young builder to try the hobby. And thus I gifted that kit to 6th grader who expressed an interest in models. I binned the 1:168 Airfix. Below is the boxtop of the Monogram kit.

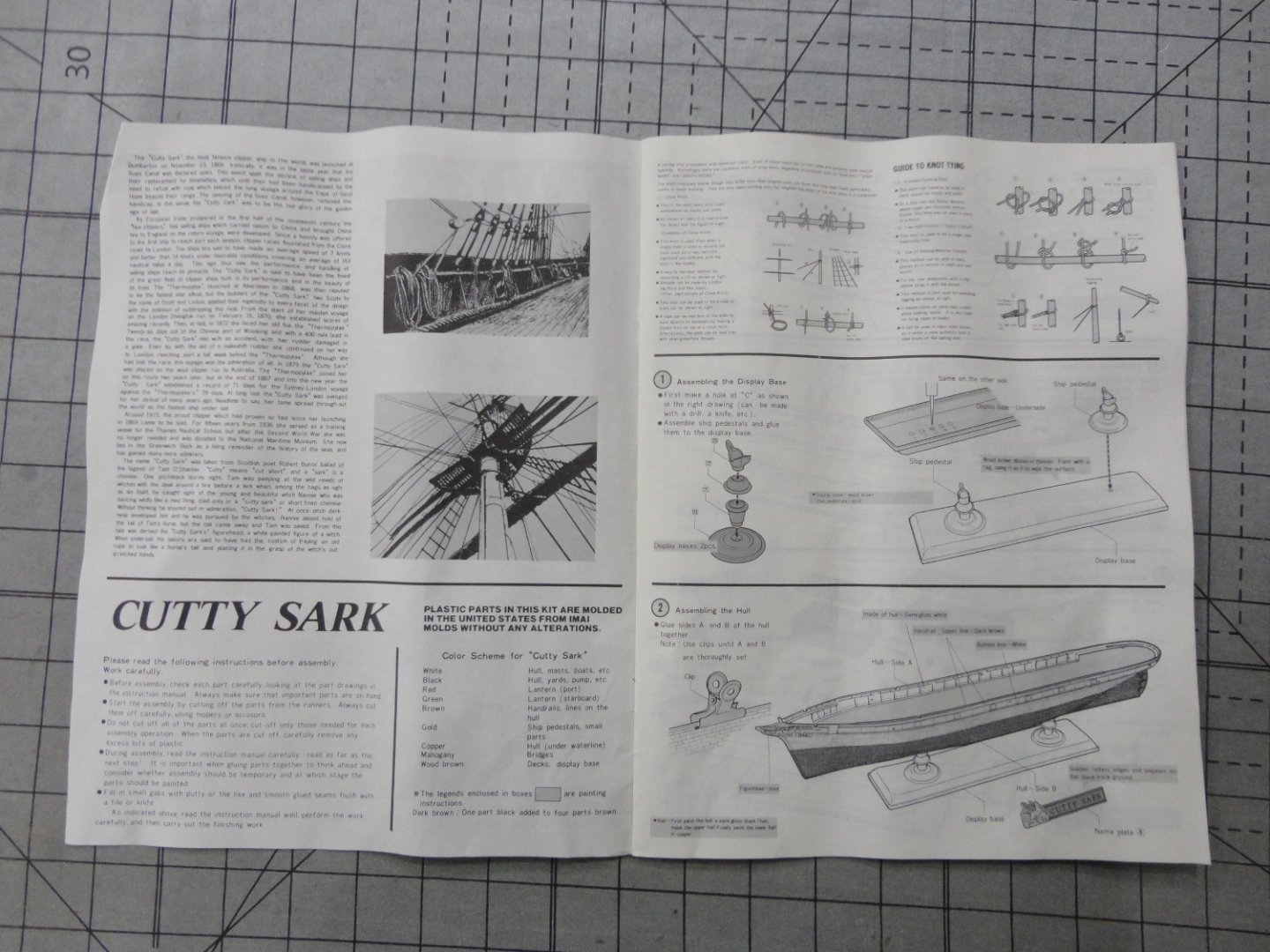

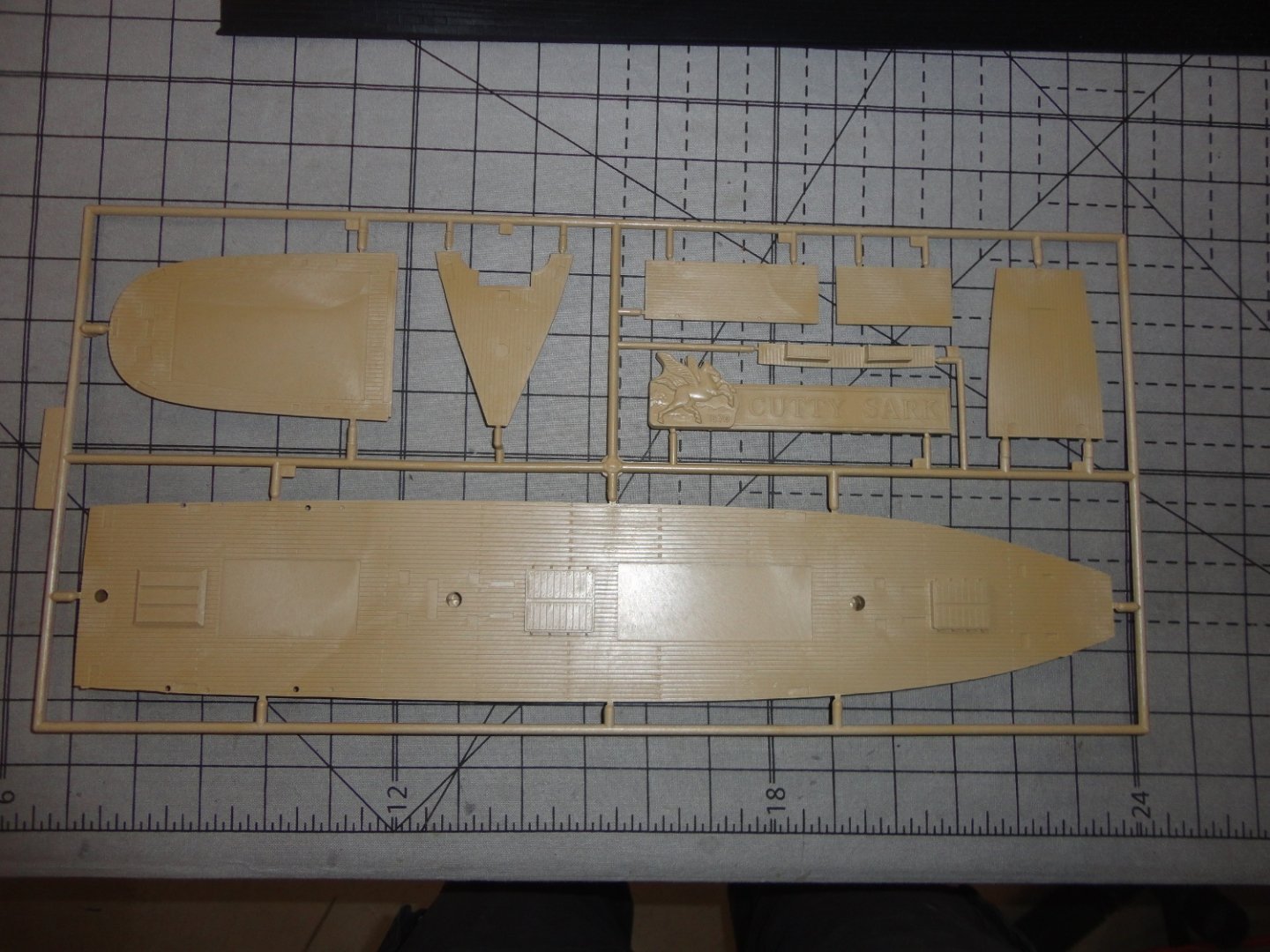

But I've digressed ... the short history is that Imai of Japan produced a fine 1:120 Cutty Sark plastic model having a 22" hull (compared to the nearly 28" hull of the 1:96 Revell CS or Thermopylae). That makes it halfway in terms of length between the Revell and the Airfix versions. Monogram acquired the molds a some point (others will be more familiar with the history of this kit, as well as the convoluted history that follows ownership of the Airfix molds). Aoshima produced the kit next, followed by a hiatus and then a re-manufacturing period early in the present century. They were considered 'pricy' for a plastic model (and still are, since production was limited compared to other sorts of kits and even the later Aoshima kits are now 'out of stock' according to retailers ... that leaves Ebay - and a few other sites, or the odd model kit collectors' show - as the most likely source for it. I paid $125 plus $15 shipping from New Jersey (UPS truck) to my small town well West of Philadelphia. Having examined the contents I'm pleased with it as a means to get a hull ready without having to stick-build, so I can practice rigging it as well-explained in Hackney's book - which can serve as a decent set of instructions to make up for the cursory sort that came with the kit, mostly valuable for the line drawings of assembly.

I figured the Monogram booklet would be in English - which it is, as the Japanese versions are only in ... Japanese. Having built a Woody Joe kit, I got Google translate on a phone - and it did indeed translate (more-or-less) what would otherwise be unintelligible lines of unfamiliar characters. But I think the Hackney book, 'Cutty Sark' ... just one book in the 'Classic Ships - Their History and How to Make Them' series sponsored by Airfix goes well with the 1:120 kit, as most of the modifications and all of the rigging information is applicable. In 1:120 scale, this project is far more practical for a builder not wanting the rigor of a nearly 4 foot long 1:70 wooden kit - nor wanting something nearly as large size of the plastic 1:96 kits (nearly 3 feet from stem to stern). I believe I've found a very good compromise. So let's look at what's in the box. First, some of the instruction booklet.

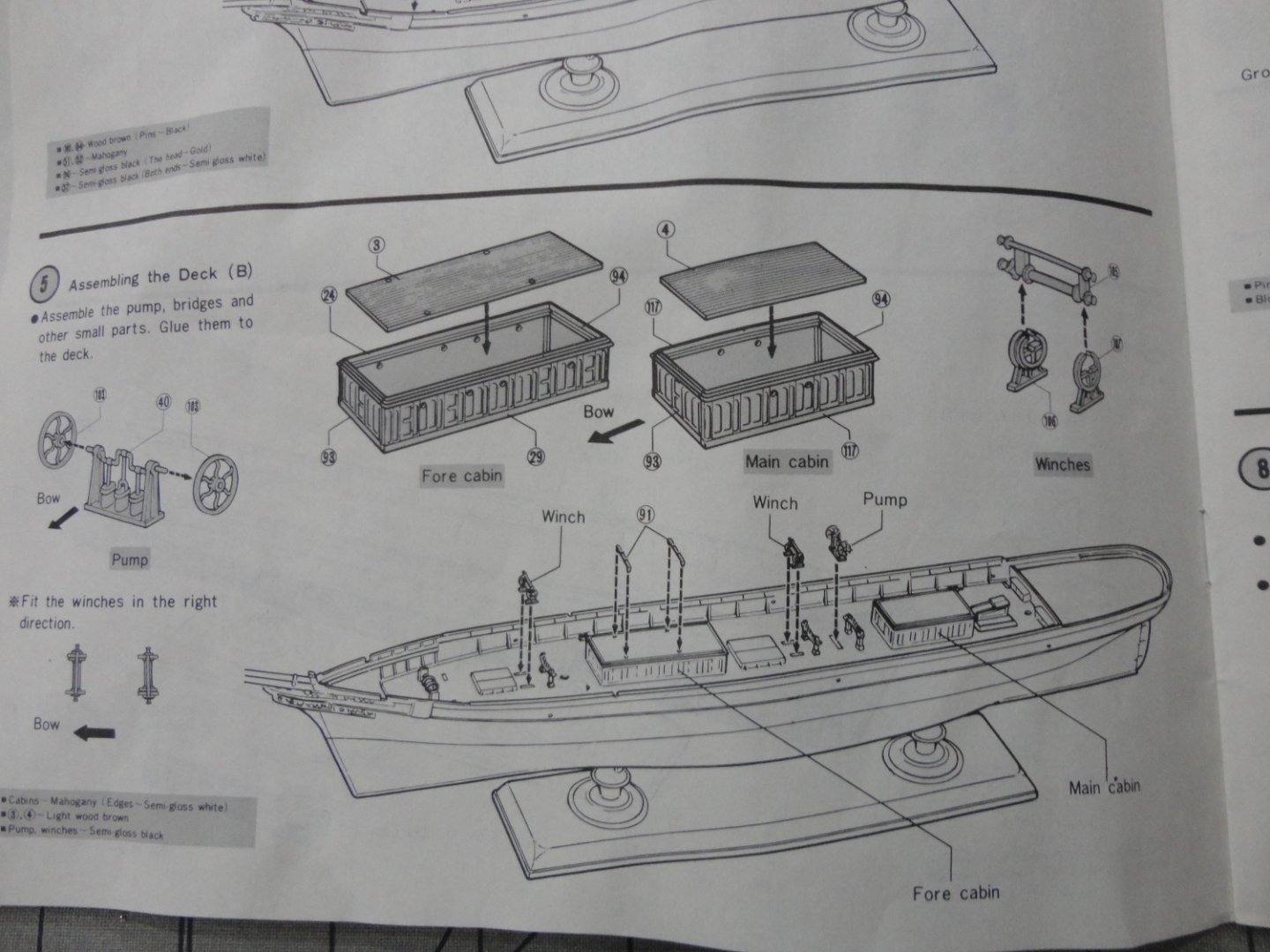

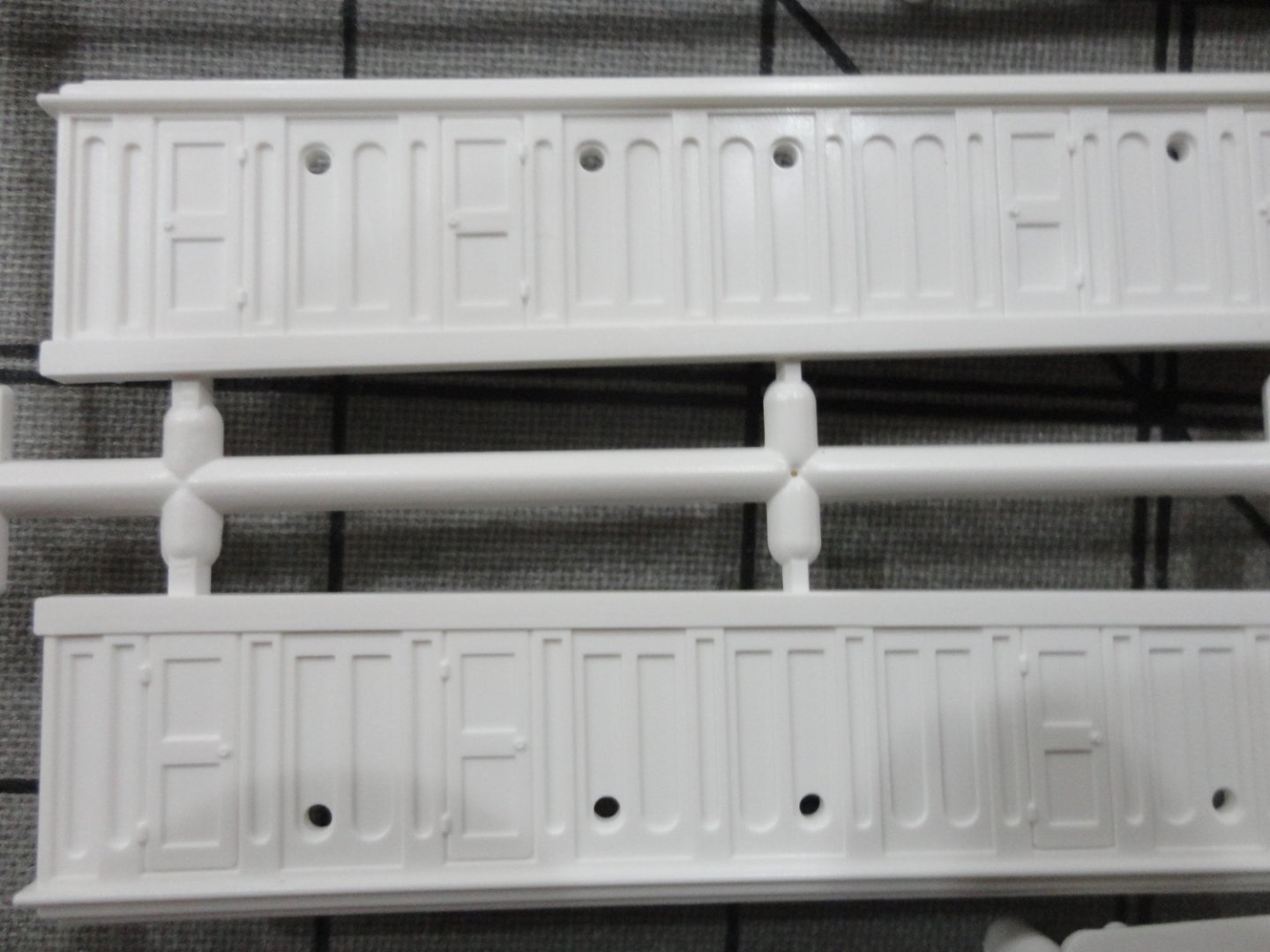

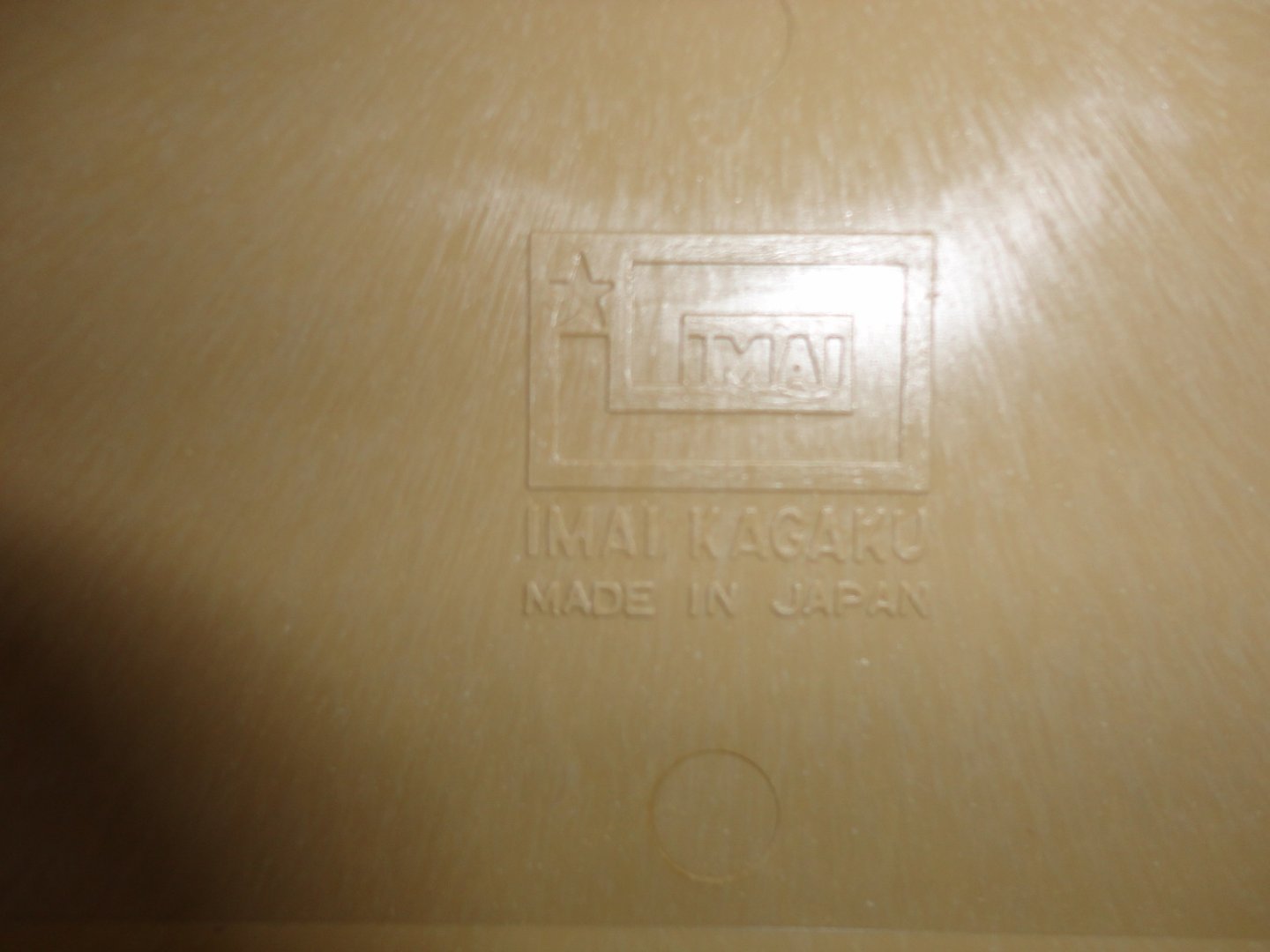

I found 'Made in Japan' on at least one sprue, and the IMAI mark on the underside of the display stand. But one can see able that Monogram identifies the parts as made in the US from unaltered Imai molds. BTW, there are several locations marked on the underside of the stand for the builder to choose where to drill through for the stanchions the hull will sit on. I plan to fashion a wooden base of colored hardwood and turn metal stanchions. The page shown below hints at excellent detail on the cabin sides (and I found this to be true), but also to the most obvious mis-calculation on the design of the hatchway on the weather deck just in front of the poop deck. Others who have modeled this kit advise correcting the goof using sheet styrene - not too hard to do.

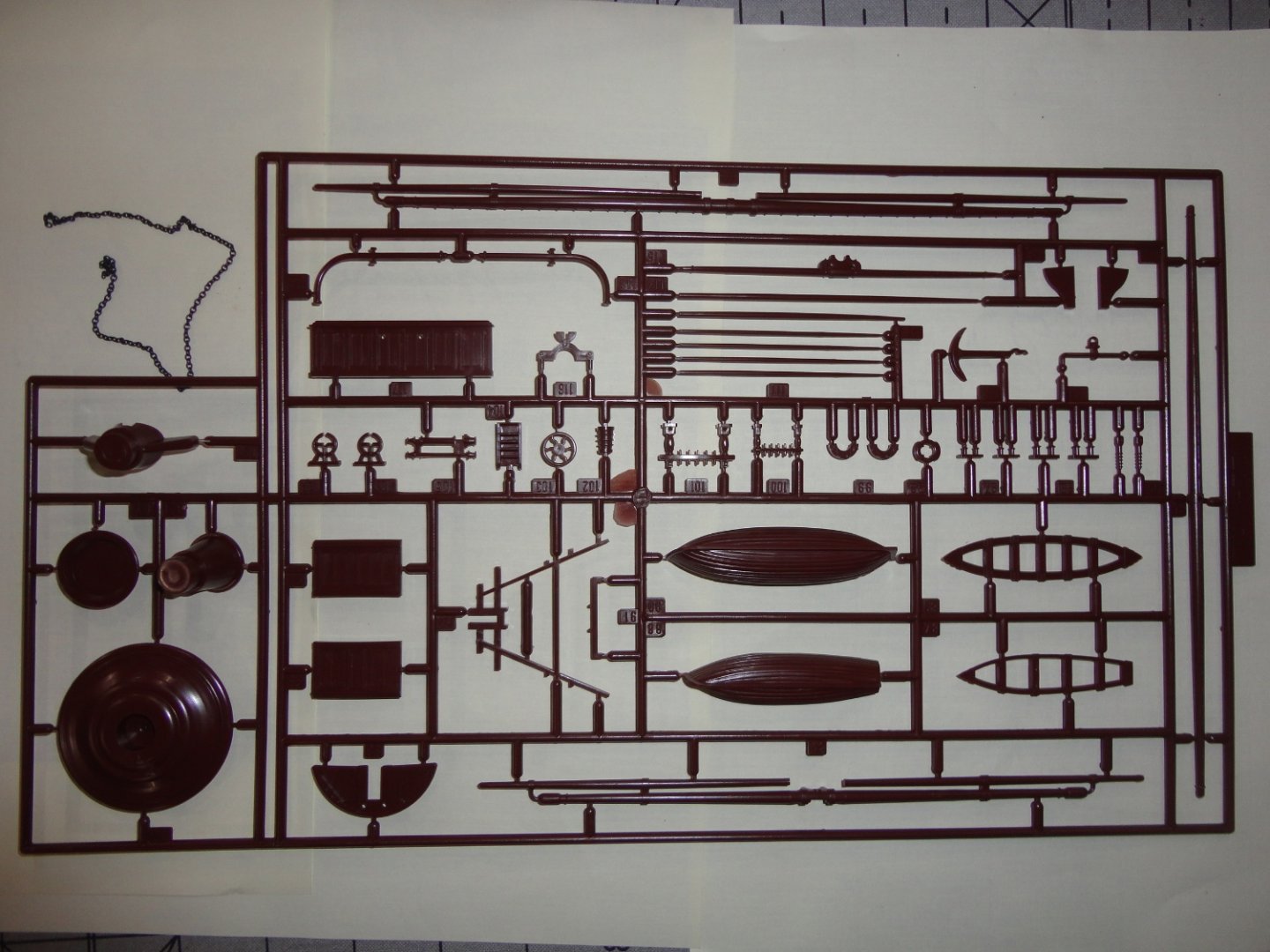

Also, both winches each have one cable lifter (another mis-interpretation of the Campbell drawings), thus one rom the rear wench must be cut off and applied so that the front winch will have have lifters on both side for the anchor chain. Some reasonably fine chain was included in the kit, but perhaps a longer length would have been better.

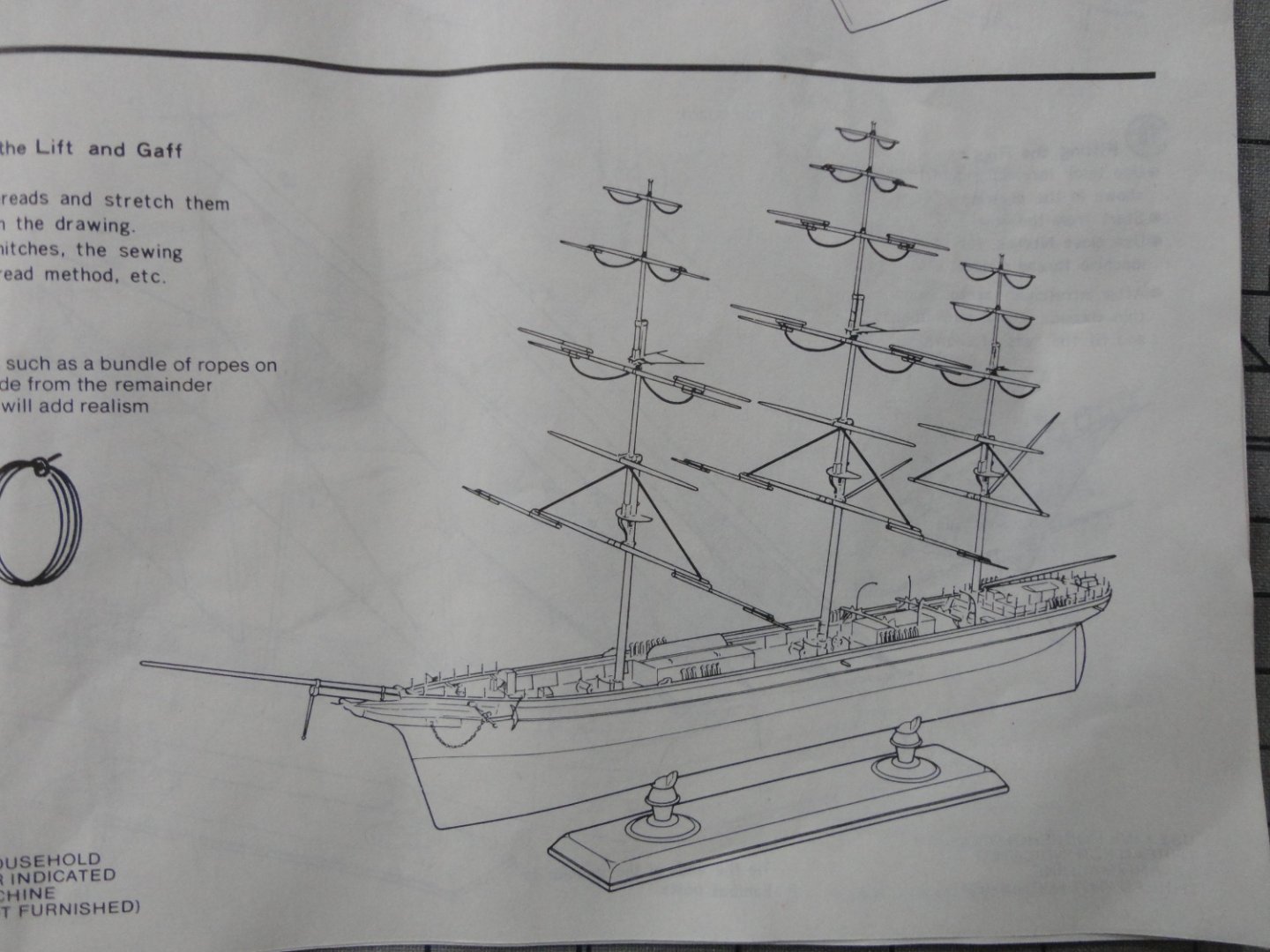

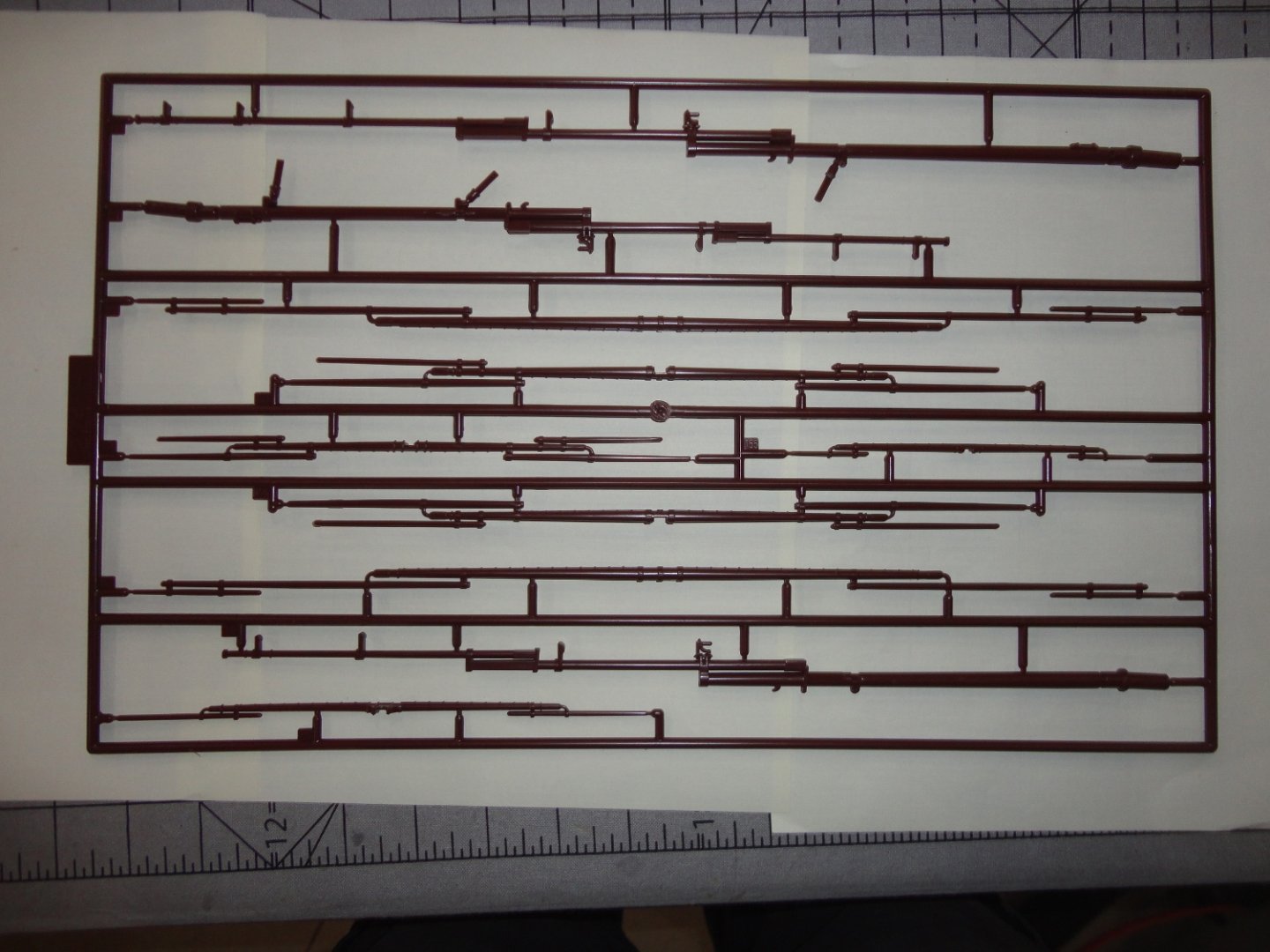

The next shot depicts fully extended studding sail booms - which I expected would be provided in the kit. But the presence of SIX masts (each molded as a single piece ... might have been nice to 'build them up' like in the Revell kit) had me confused, 2 Foremasts, 2 main masts and 2 mizzens ! Only by looking all the sprue over did I discover that the 7 yards having booms ALSO have them molded with the booms in the retracted position ! This is cool, so the builder can choose which to use. All the other yards are common to either way of building.

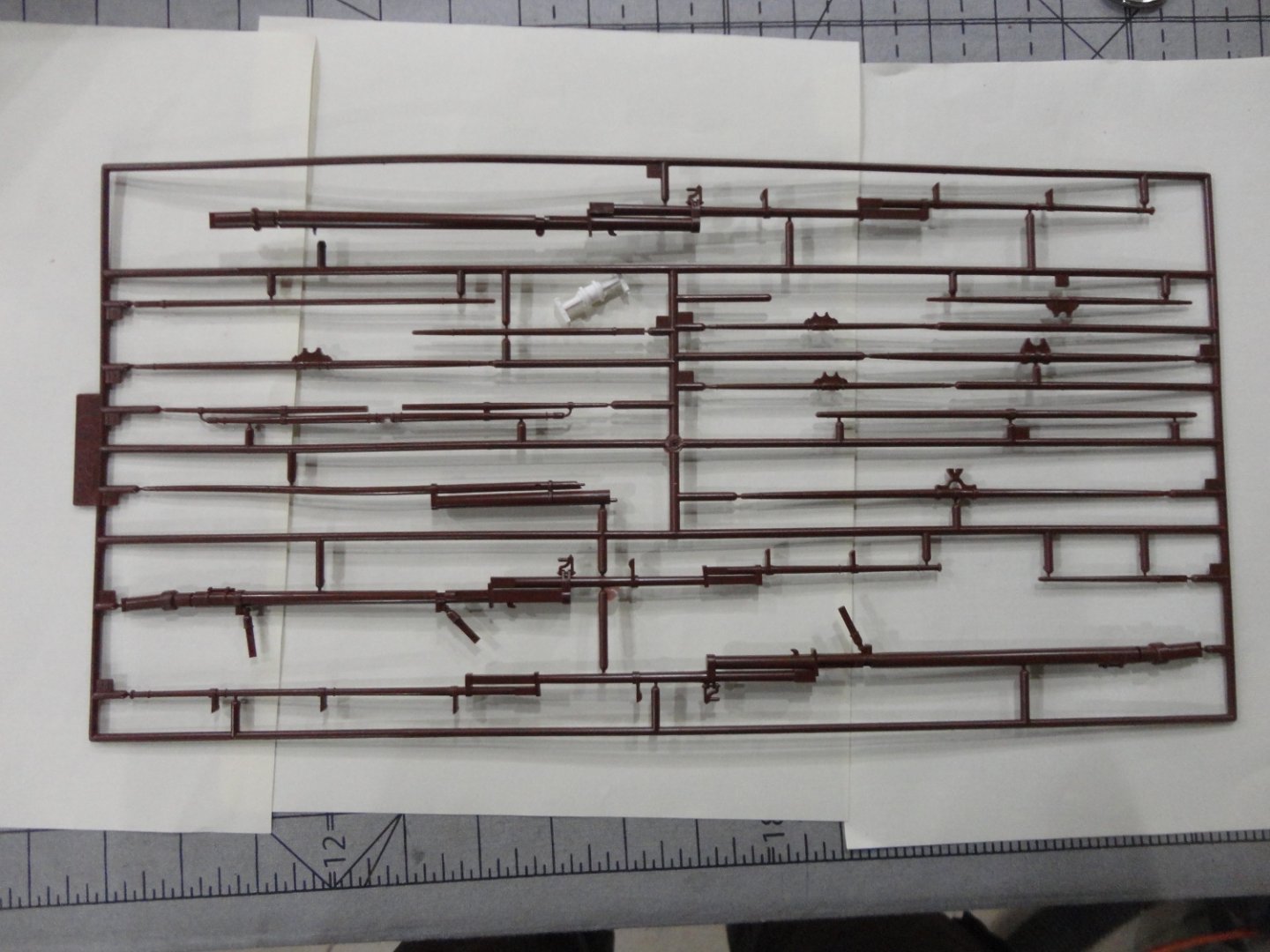

Below is a picture with the booms in-board ... the sensible way to make the build, since if the booms are fully extended one HAS to put sails on them or the model will look odd.

Thin plastic sails are included (quite typical), and I'd only use them as forms to mold lighter material pretreated with watered-down PVA or other stiffener.

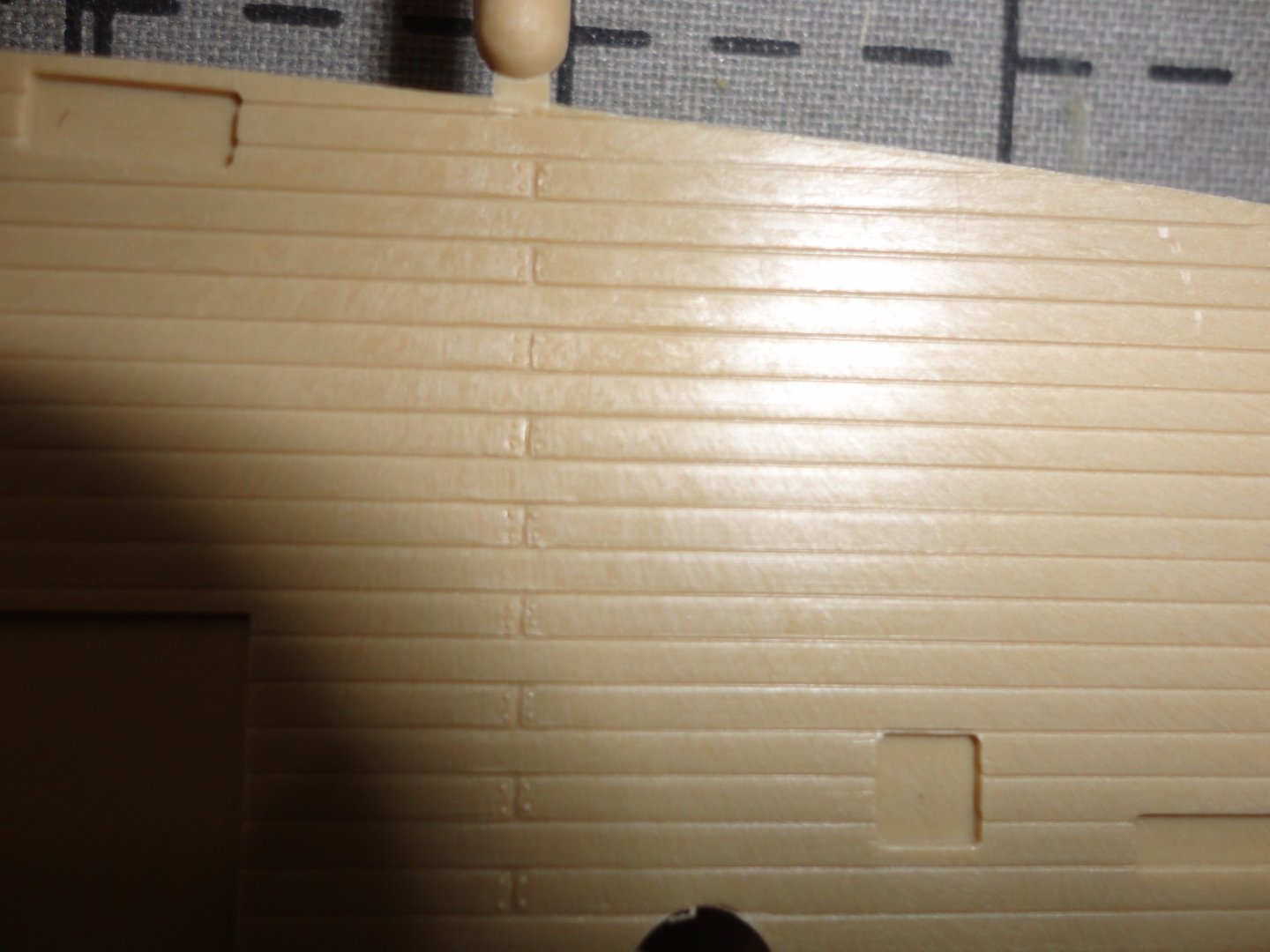

The decking is molded in tan, and has negative caulk lines between planks. There is no joggling, and the jointing may appear to regular for some - as a more staggered pattern might have been better. But the weather deck is all one piece ... no sectional joints to deal with like in the 1:96 kits.

A closer look. I'm pleased with the detail on most of the parts - yet plan on using veneer for decking rather than paint, just one more way to go. A closer look is below.

Now the hulls look well formed, but my attempts to get close shots with the lousy camera used didn't turn out. The detail at the bow means no decals are needed there. A decal is included for the stern decoration. Whether is can still be used is uncertain, but I could carefully cut it out and apply to tie a low profile 3D appearance. 'Don't think there is any PE for this kit. The fretwork at the bow is not pierced, but this might still be done. The rudder is molded on.

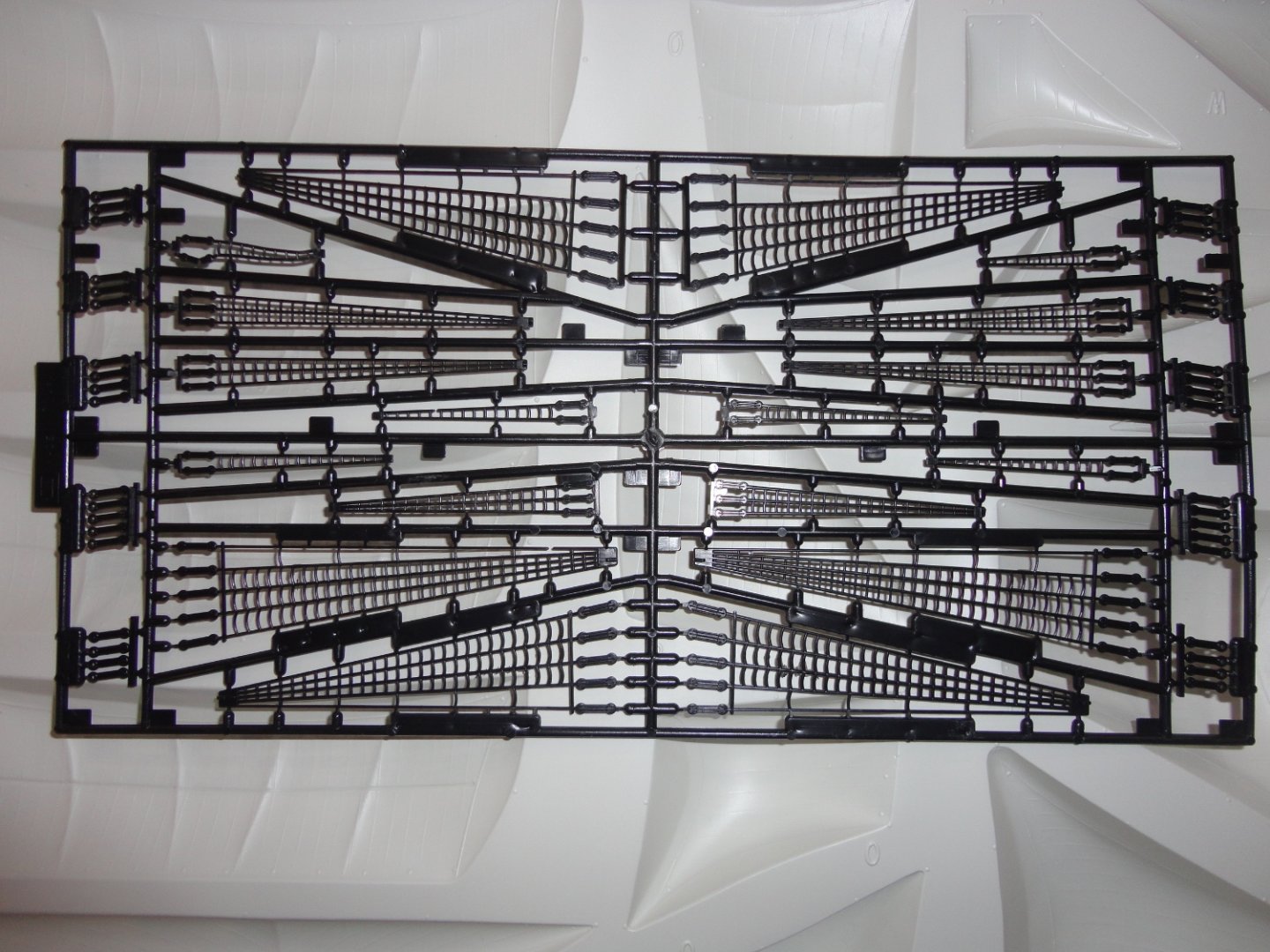

The ratlines are molded (often typical), versus having to weave them one's self as with the Airfix. But the 1:120 scale is large enough to do actual deadeyes (as well as blocks) - even if they go a little out-of-scale.

I did not a slight deformity to one upper molded ratline molding - still fixable. There was a slight bending to some of the sprue, but the individual parts look OK. The bowsprit has a slight bend to it - again correctable with care, but I plan on replacing it with a turned piece of wood - since I want to drill through for fore stays. Below is the sprue with the yards having extended studding sail booms - very wide ! Note also the three masts. Some have carped that the top gallant mast sections are a little thicker than they should be. I really don't notice it, and as molded there shouldn't be deflection is the rigging is not overly tight. I note that all the yards (as molded) will be in the raised position, and I intend to have the lower able yards in the lower position (Hackney's "harbor rig"). So the mounting pads for those yards will have to be re-positioned.

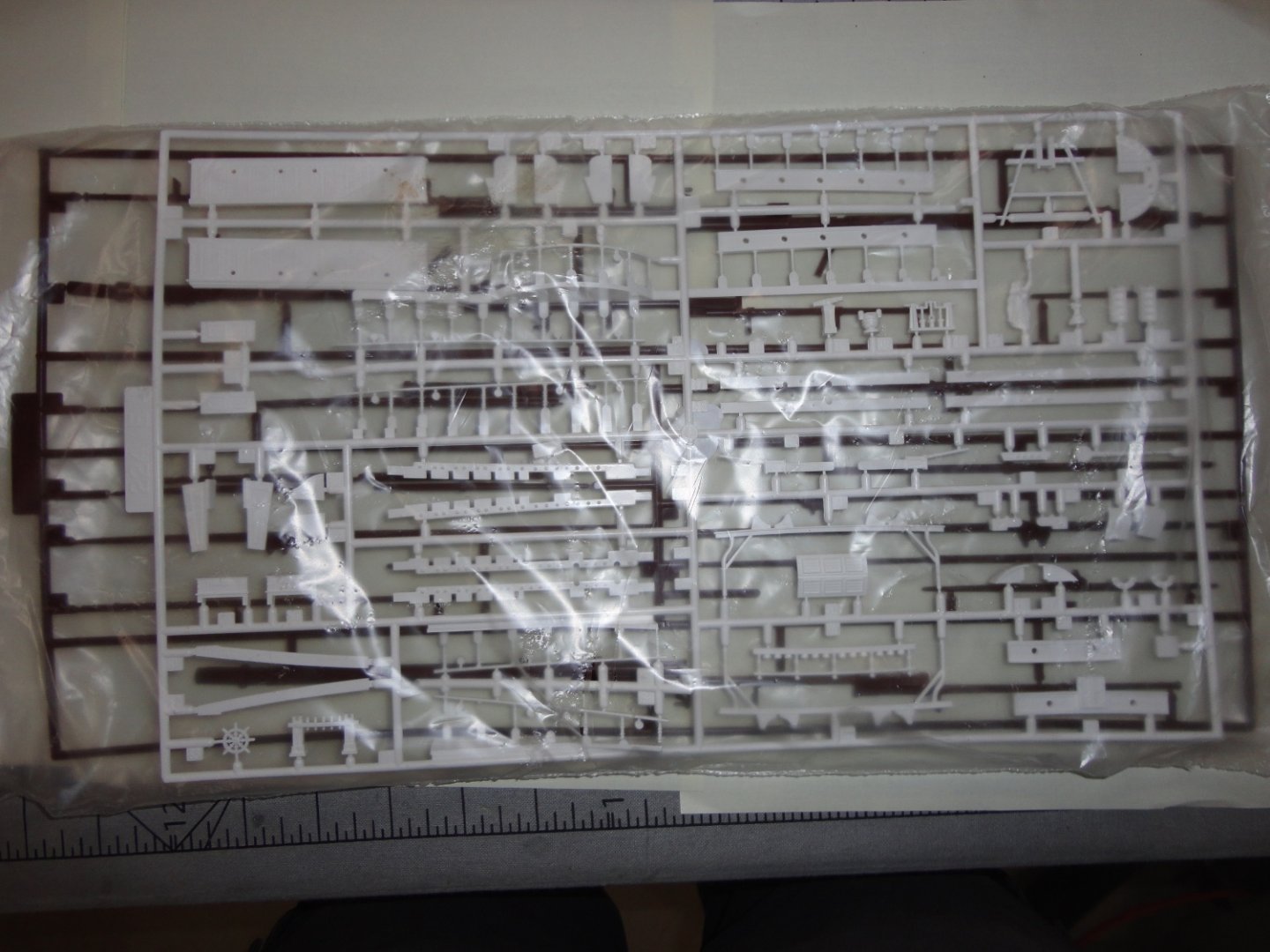

There were two sub-bags each having two sprues - the parts shown thus far were not in plastic bags.

Below is the sprue with the yards having booms NOT extended. Note the loose white piece - a few parts had come off but were in the bag, due to handling over about 40 years. I note that one thin railing stanchion had broken off (but was present), and two others were not fully molded. This is fixable with sprue or styrene - but I might also turn my own railings since I have a Unimat miniature lathe with a universal 3-jaw chuck (it came in handy in the Khufu Barge build).

A closer picture of the cabin detaining.

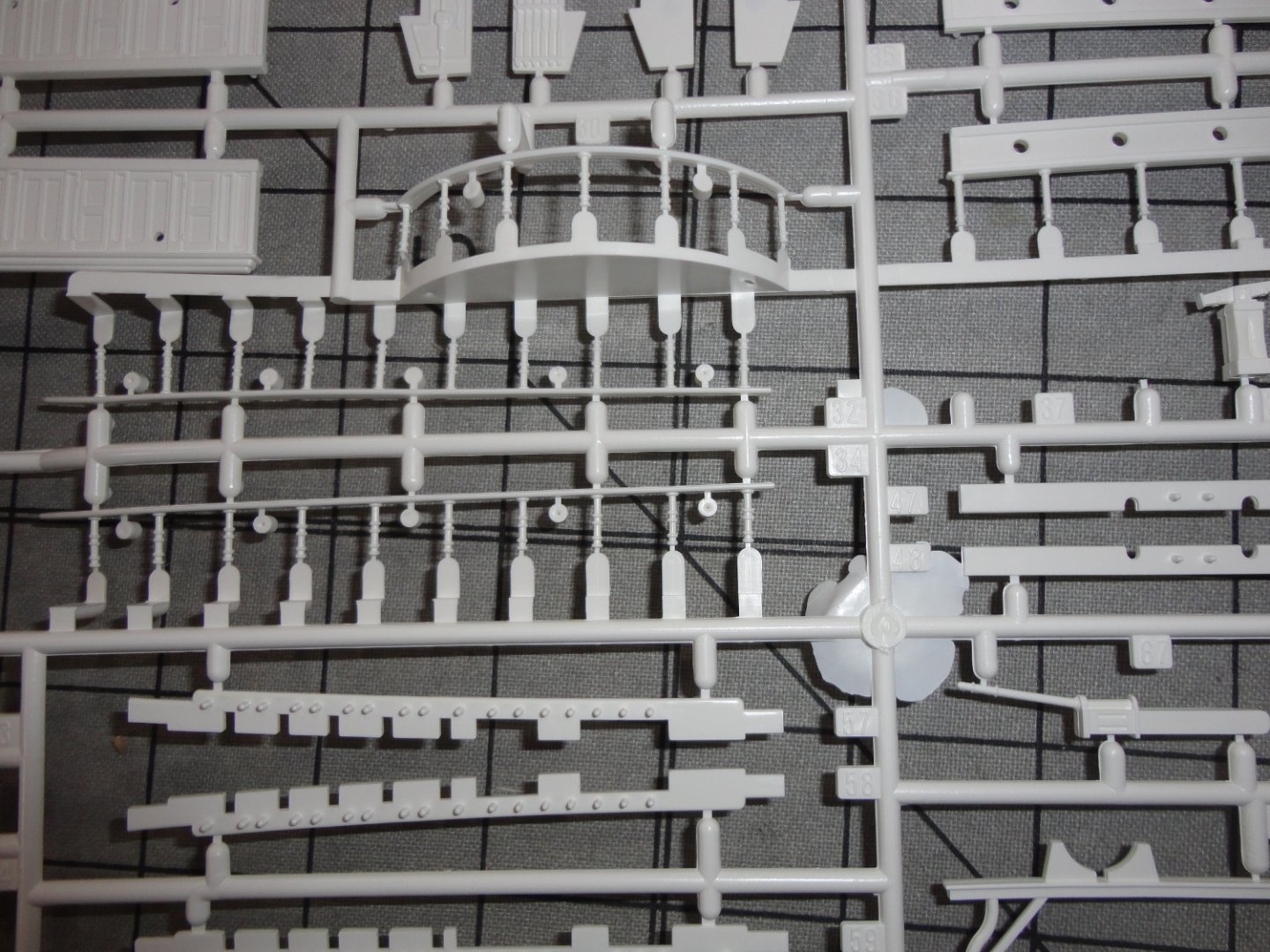

Various parts on the white sprue.

The boats seemed OK. The tops were not pierced, than can be done with care. To rig more authentically, a builder will have to make lubber holes, but any notion of individual fair leads may be impractical - so those lines can pass through where the slats will be pierced linearly.

Below is a closer shot of the boat interior - nicely done, and a little dressing is all thats needed.

A closeup of a top. The molded deadeyes/ratlines would glue in the depressions - but for rigging with actual deadeyes or beads, the voids must be filled in, the slats pierced and holes drilled for the deadeye fastenings as needed - all optional, of course.

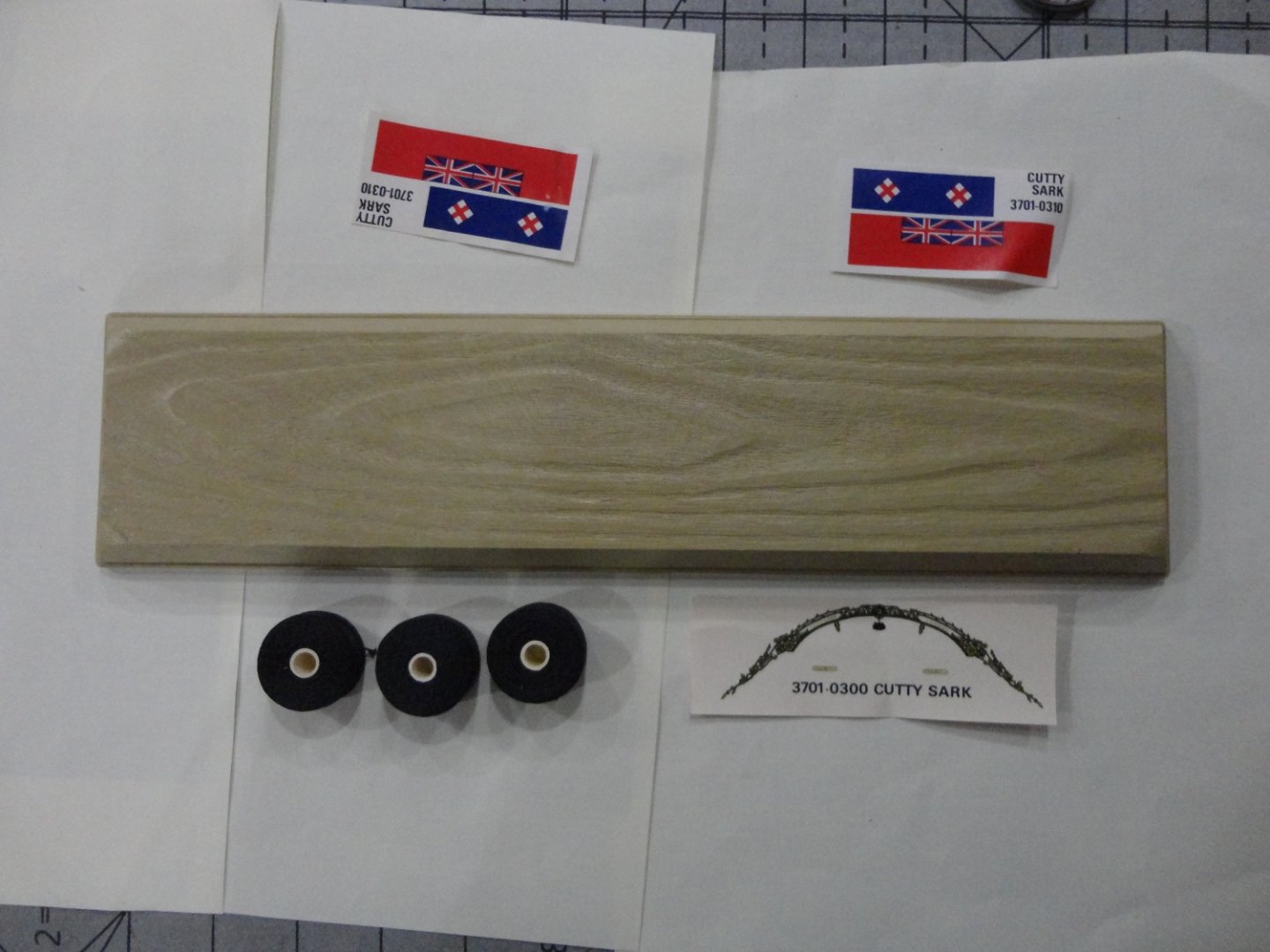

A plastic base is included with some 'average' rigging rope (I won't use), a decal and paper flags.

Below is the Imai mark molded on the underside of the base.

For hull comparison (to the Imai hulls show much further up in this post), I show the Revell 1:96 Thermopylae - another 'keeper' of mine that I really want to do 'justice' to by 'busting' where needed to get closer to the ship its supposed to be. Its a pretty big model as plastic models go, so starting with the 1:120 CS version (as I said - mainly to try out rigging ... also to become reacquainted with plastic modeling and painting) may be a good experience without loosing my eyesight (or patience) with anything smaller.

My opinion is that the Imai/Mongram/Aoshima kits are reasonably well thought out (with only a couple of corrections needed), well molded with good detail, and can be made into a much better model than simply building 'out of the box'. Some scoff at the price examples have gone for ($125 - $165), but the supply is limited and shrinking all the time. You can't 'take it with you', mate. So if this floats your boat, go for it !

Fair weather ! Johnny

-

4 hours ago, shipman said:

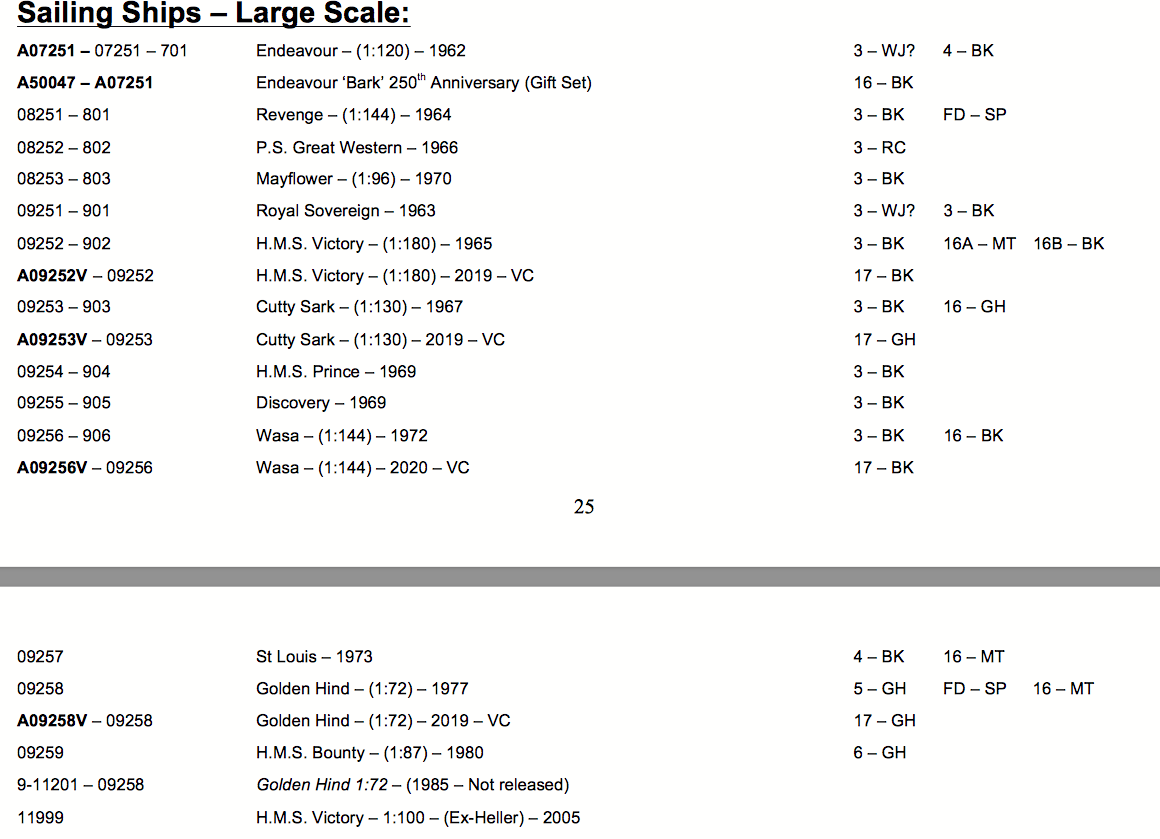

Found this info ..... gives brief details of when the sailing ship kits were originally issued.

https://www.vintage-airfix.com/kits-category/airfix-ships/large-scale-classic-ships/

Thanks, Shipman ! More news - today the Monogram issue of the 1:120 CS (first made by Imai) arrived. A few Imai and Aoshima issues were also seen on Ebay, but I went for the Monogram because I figured there would be English instructions - versus the Japanese only one the other issues ... and my hunch proved correct ! Also it was the lowest price - about $125 plus $15 UPS from New Jersey to my small town well West of Philadelphia (by no means a suburb, as farms are nearby ... but 'civilization' is slowly creeping as we are on the road to Reading PA). 'Seems a little steep for a plastic kit, (as much or more than one can come by a Revell 1:96 CS or Thermie) but ... my opinion (as expanded below) is that it it worthwhile.

With anticipation I examined the box with the original cellophane wrapping almost completely intact - the seller did picture a small slit on one side of the plastic, but it did not go to the corners - so the contents were as manufactured and sold. The cellophane was removed and the box opened, and I had to do a few double takes at the contents - some sprues were in their own thin but sealed plastic bags, and some not.

At last I figured it out by both counting masts and yards PLUS looking through the instruction booklet. BTW - the instructions are mostly line drawings with cursory text, and there is almost no advice on rigging. So if someone gets a version with Japanese text, they are not missing much - its easy to see whats going on from the pictures and the Japanese use arabic numerals anyway. The woody Joe Khufu barge kit I built had a LOT more text and other stuff, so I got a Google translate Ap for my 'somewhat smart' Tracphone used only occasionally - and I could translate almost all of the Japanese into English.

In light of the above, Noel Hackney's book on building the Airfix CS will be VERY useful for building this (or any reasonably sized CS kit). Noel did a fantastic job explaining certain details on modifying the kit before diving into construction, and this 1:120 kits can use many of them. Of course, one has to do a bit of cross referencing to get through the book - but in the process I've learned a great deal.

I note that in terms of hull length, this 1:120 kit is halfway between the 1:168 Airfix and the 1:96 Revell. The Monogram kit has about a 22" hull not counting all of the keel projecting forward of the hull. The quality of the tooling and molding is excellent. I note that the deck has negative space between the planks instead of positive caulking as some other kits have (no joggling, though). The masts and spars have some springiness to them - but not too much. That means that they are not too rigid either, so should not be subject to stress breakage.

Counting SIX masts threw me at first ... yes - 2 fore, 2 main and 2 mizzen masts (the three mast sections of each are molded together as a unit). Some of the yards had studding sail booms extended, and some did not. Then I saw the model built EITHER way in the instruction booklet - one version with extended booms and one where they are retracted. So I counted ALL the yards and realized that one sprue has the three masts PLUS seven yards with extended booms - and this sprue was not in a plastic bag. Other bagged sprues have the masts and all the spars with retracted booms (plus the yards with no booms that are common to both versions) !

The kit is molded in 4 colors (like the 1:150 Academy CS ... but THAT kit only has extended booms - which forces one to either have it in full sail with studding sails, or having to cut-off and remount the booms inboard on the yards). 'Haven't looked on all sprues, but one said "Made in Japan". Yet the booklet stares in BOLD type, "Plastic parts in this kit are molded in the United States from IMAI molds without any modifications". The deadeyes/ratlines are molded, but doing them properly with actual deadeyes and thread seems doable at 1:120 scale. The beads proposed for a possible build at 1:168 (oversized for the small scale, and I've given up on it anyway) are pretty close at 1:120.

Thin molded plastic sails are in the kit (typical for several kits) - I'd never use them, but they could be forms for much thinner material treated with thinned water-based glue. For 'harbor rig', they aren't needed at all.

A couple parts were off their sprue from whatever handling occurred in at least 40 years of existence - and this is not uncommon for plastic kits in general. A couple railing stanchions were not fully 'filled out', and one was broken off but in the box. One of the topgallant mast molded ratlines is a bit deformed, but bendable and likely re-formable ... that is, if one wanted to use the provided molded ratlines. No blocks were ever molded, but I saw one report of an early Imai kit that had some blocks bagged inside the kit. My guess is that they may have thrown some plastic blocks in the first release, but economized soon thereafter ... and they were probably out-of-scale.

What I'll have to do is take pictures and put a "kit review" together in the kit review section of the forum. It would likely apply to any version of this kit, since the same molds were used by all. I note that there are reports that late-issue Aoshima kits have more flexible yards due to softer plastic ... just saying.

Fair sailing ! Johnny

-

-

19 hours ago, shipman said:

Thanks SHJ, for the work put in there.

Can you please explain the two right hand columns?

Without digging even more, I think some of your info isn't quite correct, but not far off.

According to Hackney, the CS (originally marketed as 1:130) is actually 1:168. Victory (originally marketed as 1:180) is actually 1:171.

By Airfix standards, back in the day, their sailing ship kits were the largest they produced.

Even empty boxes have value to collectors.

Crazy World Enterprises LOL.

18 hours ago, 72Nova said:Likewise SHJ really appreciate your efforts, very informative info there.

Me personally I prefer the more pliable/ bendy plastics that lesson the break factor so to speak, up to this point I've had no issues with this reissued kit,( keeping fingers crossed) in regards to the masts not being up to the task.

Michael D.

Ahoy Shipman and 72Nova ...

The text from a much larger history of Airfix was 'quoted' as a 'review' (I didn't write any of it myself, and wanted to respect the originator by only reproducing a small portion in our forum in the spirit of 'fair use' - for informational purposes only), and a specific sub-list of 'large' Airfix ships (per our scope of interest) was also pasted 'as is' - warts and all. This info was found by repeated 'googling' (e.g. Airfix collectors, Airfix model shows, etc.) until stumbled upon - in that there seem to be Airfix collectors, and an EXTENSIVE list of every model ever produced by that manufacturer can be thus viewed by the public.

You are quite right (my oversight) that Hackney specifies the issue scale of the CS as 1:168, and certainly the original effort at details such as 'pierced' fretwork at the bow, sub-miniature molding of CS scroll work at the bow (and a 3-piece sections inserted in the stern with 3D scrollwork, so no decals were needed), deadeye groups for the pin rail that have chainplate going through the rail and down at an angle to the water way - as well as separate mast segments, tops, caps & cross trees for assembly (permitting shroud loops at the option of the builder as the masts and yards are built in the order that a real ship was built per Hackney's book) was a masterful work of mold-making 'back in the day'.

The state of my eyes and less-than-nimble fingers made dealing with the shortcomings of the 'Vintage Classics' version overly daunting. I imagined that bonding spring wire to the tops of the yards (after replacing the top and topgallant mast sections with relatively firm wood) would limit selection of the yards - and would be completely disguised by having a little folded material grommeted on top of the yard to represent furled sails. Once I've learned more (and other obtain an original issue kit or get a good buy on a PAIR of latter-day kits - to assure the likelihood of 'one good kit' in terms of non-deformed, fully-molded components) I might be tempted to try it someday ...

I've no idea what the codes on the right hand side represent, and presumed them to be meaningful only to diehard kit collectors. As a former train collector (Marx 3/16 'scale' freight cars that ride on O-gauge track), I realize just how far 'into the weeds' as collector of anything can go. If it exists, there seem to be collectors of it. I sold-off my train stuff a while back - as well as a bunch of astronomy gear and also U.S. Civil War small arms used for live-fire in the N-SSA (North-South Skirmish Association) ... can't hang onto everything.

Airfix seems to have dabbled in a bunch of different "actual" scales (moldmakers' whims ?), as opposed to doing them all in, say, 1:144. I see the 'ladder' now with how English (and American) scales bear a relationship - twice 1:24 and you have 1:48. Twice that and you have 1:96. Add 24 more and you have 1:120. 24 more and you have 1:144. So 1:120 would (sizewise, as volume is a different calculation) would be right between a 1:96 CS and a 1:144 version (if that existed). Well, for the hell of of it, I found a 1:120 Monogram CS on Ebay (U.S. 'branding', so maybe there will be English instructions versus the Japanese found with Imai or Aoshima releases of the same components). The flat black beads for blocks will be just about right in that scale.

We'll see ... Fair sailing, mates ! Johnny

-

'Did some digging into Airfix history, and there are collectors of kits. Yup, just the unbuilt kits - and they go by the box numbers of the release. That goes for all sorts of kits - but we're interested in ships on this forum. An excerpt from a history indicates that many molds had to be remade at a certain point in the many sales of the Airfoil name:

By 1981, Airfix had released over 800 models ranging from aircraft to dinosaurs and claimed to have, “The Largest Range of Construction Kits in the World”! In January 1981, however, the Airfix Company called in the Receiver largely caused by problems at its Meccano subsidiary and most of the toy divisions were closed for good. The kit division along with Airfix Model Railways (GMR) and, ironically, Meccano and Dinky were purchased by General Mills a U.S. company, and placed under its U.K. subsidiary, Palitoy. Production of Airfix products was transferred to General Mills’ Miro-Meccano factory in Calais. It was owned by General Mills under the Palitoy label until 1985 when General Mills closed its U.K. operation when it withdrew from the European toy market and was put up for sale again. It was then purchased by Humbrol, the model paint manufacturer in 1986.

Humbrol was based at Marfleet in Hull but production was transferred to the Heller factory in Trun, France, because Humbrol had recently purchased Heller. In 2006, Humbrol got into difficulties, when the Heller subsidiary, which had been bought out by its management, closed and Humbrol was unable to access its Airfix moulds. Humbrol and Airfix were purchased by the present owner, Hornby Hobbies Ltd, based then in Margate, Kent. Since then there has been a renaissance at Airfix with new tools being produced at a rate not seen since the 1950s-1970s with kits like the magnificent 1:24 Mosquito being modelled, and in 2014 we had an incredibly detailed 1:24 kit of the Hawker Typhoon being moulded. Many ‘tired’ old kits, like the Defiant, have recently been replaced by new ‘state of the art’ models and many new subjects added to the range, such as the Whitley and Shackleton.

Recently, Hornby sold the Margate site and moved to a new Headquarters at Sandwich, Kent, with stock being held at Hersden near Canterbury. Most production is carried out in India, but some models, including the Quick Build range are moulded in the U.K. Financial difficulties experienced by Hornby following the move resulted in a culling of the kit range. However, in May 2018, Airfix announced it is to bring back many of the older pre-Hornby models in a new range entitled “Vintage Classics”. The models will appear in the new Type 17 box top and will bear their old box illustrations with the year of original release being shown on the box, ensuring that modellers realise that it a ‘legacy’ kit. The company moved back into its old Margate site in early 2019, alongside the Hornby Visitor Centre which had remained there.

The original CS nominal (1:130) of 1967 had a box number 09253-903, and the Wasa of 1972 (1:144 - likely the actual scale of their CS as well) was kit# 09256-906 per the pasted section of the relevant kit list of Airfix sailing ships characterized as "large". If one wishes to hunt down any of the 'good' original issues, perhaps finding out where there might by a collectors' show of Airfix or similar items might be of some uses.

Lots of luck.

-

12 hours ago, shipman said:

Thanks Michael.

So what is the story re your blocks, especially the smallest?

These must be extremely tiny....if you made them yourself, how?

You're making an inspiring model, thank you for your time and trouble sharing your methods and excellent photographs.

One of the last ship models made by the London Science Museum craftsmen, (before they collectively retired and left a vacuum) was a piece of art, but made decades before the actual ship research revealed many details and secrets were later published.

No doubt it was that model which inspired the Airfix product.

Don't know the order in which Airfix released their line of sailing ship kits, but surely their Vasa and St Louis must have been the final ones, before the company effectively abandoned nautical stuff to concentrate on the more lucrative aeroplane/armor subjects.

I do have quite a stash of most of these kits. The earliest releases are the ones to get; the superior detail definition and lack of flash is very evident, as is the progressive lower quality of plastic used, especially while they were being produced by the French Heller factory.

Examples of this are the original black plastic used on the Victory and Cutty Sark kits. The later brown plastics are butter soft by comparison.

You are Soooo right on the poor plastic (pale tan) used on the so-called Airfix "Vintage Classic" 1:145-150 (claimed to be 1:130 on the box) Cutty Sark. The thin upper mast sections and the yards ben almost like rubber ! 'Can't see how they an be rigged without deformation. And I suspect that not all the molds are the original ones as well. Hackney's modification of the tops to make lubber holes and fairleads do not agree with the pieces in the example I acquired to 'see for myself' just 'what's in the box' being sold today.

The spindly top and topgallant masts are WAY smaller than the holes in the caps, making assembly problematic unless one fabricates time replacement caps - as well as make wood or metal upper mast sections to both fit properly AND avoid the deflection problem. The yards have to be re-made as well due to the bendy nature.

And a fair number of parts are deformed or not fully molded, with flash present as well in many areas - so the mold was run 'hot' and some of the sprues were therefore soft upon ejection and subject to deformation. Also, photos of the model in the Hackney book show the fore and aft guardrails - that are not in the latter-day reissue.

If one can find a genuine 'original issue' kit in much better black plastic, I suppose it might be worth building, but I simply 'binned' the above described re-issue as not being worth the time and effort to correct all the deficiencies.

-

'Just gave up on the "Vintage Classic" edition of the Airfix Cutty Sark 'nominally' 1:130 BUT the true scale is about 1:150 ... somewhere between 1:145 and 1:150 depending on how one figures it. First off - the plastic used is lousy and bends terribly. Just trying to get the foremast components together proved that the parts are just not made right. The topmast and topgallant mast sections are way smaller than the holes in the caps, trestle and top - just no way to get any semblance of fit without remaking all the parts above the first mast section from scratch. In frustration, it went out with the trash.

Many parts had flash, or were not filled and also misshapen by poor handling after molding OR the mold rate was too fast so the parts were too hot coming out. Way too many problems, so it makes me wonder if the latter day production was even made from the same molds ... In short, I consider it unbuildable without investing WAY too much time for a difficult scale to do with finesse - and not even suitable for a young builder. 'Makes me wonder how half the stuff in the Hackney book could even have been done on an 'original' Airfix English-made example. Yet I note that the same book can be a GREAT learning tool for the Revell 1:96 models (or many other clippers) as far as rigging goes.

This makes the second kit I've binned at 1:150 scale - the first being the Academy CS, supposedly a 'shrunk down' version of the Imai/Monogram/ Aoshima (all versions from the same molds) 1:120 CS, which is well-regarded by those who parted with the $130 - $160 (US) for what is considered to be a 'rare' kit (which it is). The Academy 1:150 is molded in 4 colors and is at least buildable, and might be suitable for a youngster wanting to give ship modeling a try. I note that all the studding sail booms were molded fully extended (just as with the 1:120 version), a very limiting choice on the part of the designers - and most builders cut them for moving to the retracted position (or discard for depicting her in the 'wool trade' years when the studding booms would have been stored below.

'Don't know how you've managed, mate, with the Great Harry at 1:200. My hat's off on what you've done ... perhaps enough to attain Jedi mastery of the miniature !

-

Since its too late to have a filler block in that 'deadly' gap between the fist frame and the keel (you have too many first planks in place to go back), there is another approach you might try. It involves pushing so-called wood putty down into the void and pack it in good with a dowel so that the putty completely fills the void and even 'bloops' or oozes out of the gaps in the planking. You can also use a common product found in hardware stores known as 'plastic wood'.

To help limit the amount of oozing, you cam apply blue 'painters tape' to the exterior to hold back the product bing packed inside. Then allow plenty of time for a hard cure. Removing the painters tape part way during the cure (the outside hardens first) will allow you to scrape away some excess on the outside. Since there is some gapping in the planks between the first and second bulkhead, you might fill that void too.

Once cured, you can continue planking. Then when sanding down to fair the hull prior to the second planking - done with thinner wood that will conform more easily to the hull shape - even if you sand completely through one or more planks in places, there will be a substrate in place and not a void. Just a thought.

- The Gimps Chimp and Capella

-

1

1

-

1

1

-

I have the Billing 1:25 kit in stash, which has some very good aspects to it. Yet Pavel's version (also 1:25) has some really good aspects: like MUCH better shields - I love the little shield bosses that come in the kit, and making/decorating each shield is like its own 'little kit' within a kit. The same is true for the sea chests used as seats to down on. Seriously, the rowers didn't sit with their butts on the deck. The woods Pavel uses are nice, whereas the Billing kit is all plywood (I've considered bonding walnut veneer to the sides that will show). Pavel also has a flatter deck amidships in the vicinity of the mast fish. Having served aboard a reproduction Knarr a few times over 3 years (building a 12' Viking dinghy in the process), having a big bulge in the deck amidships would be very inconvenient - not just for movement fore and aft, but also for rowing.

I believe the deformation of the original grave ship due to settling under tons of earth exaggerated any 'bulge' (there may have been some close to the 'fish'). If money is no object, one can buy BOTH kits and incorporate the best aspects of each into a fine project indeed ! On a similar note, I came upon a Lindbergh plastic Robert E. Lee kit recently at a rock shop (of all places - must have been in a relative's stash) and snapped it up to compare with the Scientific wooden kit of the same riverboat that I already have. Son of a gun, both hulls turn out to be EACTLY the same length and width, ergo the models (despite some discussion elsewhere as to exactly WHAT that 'real' scale of either kit is) are the same scale.

There are positive aspects to BOTH kits, and since each was affordable at $60 each, the plan is to eventually combine both (perhaps with the aftermarket laser cut wood decking available for the Lindbergh -also sold under the PYRO brand) and get the best of both worlds by using whatever individual component is best.

-

Hmmmmm ... let's see, 0.25mm x 100 (I use 100 instead of 96 for scaling, since the math is easier and it seems 'close enough') = 25mm in diameter - which is about an inch. That seems fair for most lighter ropes. Now 2.0mm x 100 = 200mm - which is about 8" !

I didn't think that there would be 8" diameter ropes even used for shrouds or forestays - but correct me if I'm wrong. Then again, many (including myself) may tend to use 'slightly' out-of-scale ropes, blocks and deadeyes since that makes things easier to work with. So representing 6" diameter rope with 2.0mm cordage (whether purchased or home-made on a 'Rope Rocket' or other rope spinner) should be OK.

A small 6" block (e.g. bunt blocks) "in scale" at 1:96 would be a mere 1.5mm - (devilish to try and make, much less work with). The smallest blocks I've been able to purchase are 2.0mm (From HIS Model), and they are still quite small. I wouldn't blame anyone for going with 2.5mm blocks as the smallest. Thus 0.25mm thread (one can't 'spin' 3-strand rope that small) need not be sought, when 0.5mm can do just fine.

The above is why attempting a clipper in smaller scales gets more difficult, and the degree of over-sizing some of the components becomes greater due to necessity. The Sergal 1:124 Thermopylae being an example - yet photos of completed ones lend a 'cuteness' to the model when held in one hand. Now the 1:150 versions of the Cutty Sark (plastic kits by Airfix or Academy) - now there's a challenge! My thoughts there are to attempt to follow the Hackney book (just to see if it CAN be done), but use flat-black beads for blocks and deadeyes. If I fall on my face, there will be no attempt to post anything, but I likely can learn some lessons useful on larger scale modeling.

I was able to find a few flat black beads at Hobby Lobby in '6/0', 8/0 and 11/0 - corresponding to 4.0mm, 3.0mm and 1.6mm respectively. That would be 24" large deadeyes or hearts at 1:150 scale (about 240% of ideal, but no 7/0 beads are available), 11" small deadeyes (180% in that application) or large pulleys (only 110% for triple blocks or 140% for doubles) and 9" small blocks (about 150%). Such are the difficulties of small scale, but finding flat black beads (instead of the usual shiny ones) will not draw attention to them - and they'd be fine at around 1:125 scale.

-

-

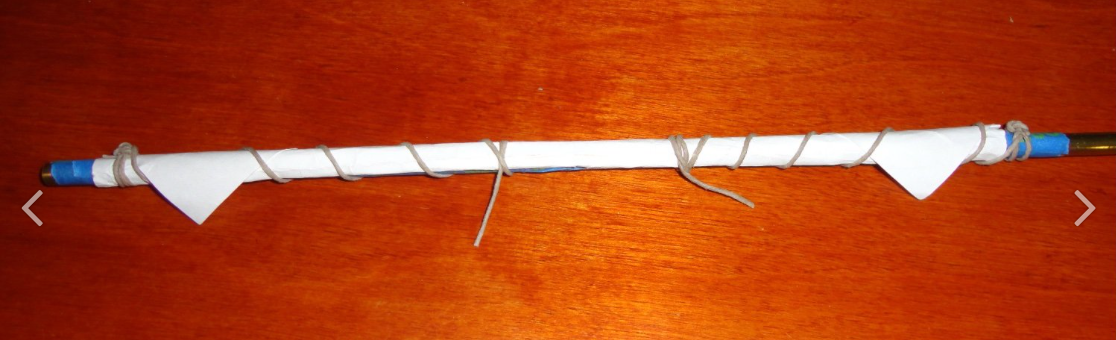

I wanted to do a test with a piece of paper in roughly the proportion of a clipper's upper top sail bent (taped) to a piece of brass tubing representing a yard. Yes, the clew lines pulls the corners of the sail up the back side - as the buntlines pull the lower edge of the sail up the front. In real life, a canvas sail is REALLY thin in proportion to the yards and overall clipper dimensions - so my paper test was still well 'out of scale', but suitable for an Origami test to see if a sail can be folded so the clews hang below a furled sail as 'mouse ears' (or dog ears).

There are photos of this test in Bruma's CS log on page 8 - so no need to re-post those pictures here. The concept is that sailors were standing on the foot ropes behind the yard (the bunt blocks flipped to the back of the yard as Rob noted) and after the above mentioned raising of the lower edge both behind and in front of the yard, there will be natural 'fold lines' that the canvas finds. The crew in unison bend over the yard to grab the front of the sail an arms length below the mast, then pull it up and just over the top of the yard (as they lean back - both hand have a purchase on the sail, so there is little danger of falling). Then they lean forward to 'pinch' that fold of sail to the yard with their bodies, so they can lean forward again to grab another bunch.

Photos of clippers with furled sails atop the yards show how compact real sails become. Canvas that is 1/32" thick (about .030) would only be .0003" (three ten-thousandth of an inch !) at 1:100 scale (which I use for 1:96 since the math is easier and it's 'close enough'). My sheet of paper was .005" - 16 times thicker than it were 'in scale' !

Anyway, I finally ended up with a compact folded 'sail' atop the yard - so to reduce the 'bunching', I cut out a piece (shown in the series of photos) and re-folded on the pre-existing fold lines, added grommeting rope, and - shazaam - I got exactly the look ... realizing that there are several ways this can look as different pictures of furled sails do show variation in application.

I wanted to do a test with a piece of paper in roughly the proportion of a clipper's upper top sail bent (taped) to a piece of brass tubing representing a yard. Yes, the clew lines pulls the corners of the sail up the back side - as the buntlines pull the lower edge of the sail up the front. In real life, a canvas sail is REALLY thin in proportion to the yards and overall clipper dimensions - so my paper test was still well 'out of scale', but suitable for an Origami test to see if a sail can be folded so the clews hang below a furled sail as 'mouse ears' (or dog ears).

There are photos of this test in Bruma's CS log on page 8 - so no need to re-post those pictures here. The concept is that sailors were standing on the foot ropes behind the yard (the bunt blocks flipped to the back of the yard as Rob noted) and after the above mentioned raising of the lower edge both behind and in front of the yard, there will be natural 'fold lines' that the canvas finds. The crew in unison bend over the yard to grab the front of the sail an arms length below the mast, then pull it up and just over the top of the yard (as they lean back - both hands have a purchase on the sail, so there is little danger of falling). Then they lean forward to 'pinch' that fold of sail to the yard with their bodies, so they can reach down again to grab another bunch (single thickness of canvas - not both).

Photos of clippers with furled sails atop the yards show how compact real sails become. Canvas that is 1/32" thick (about .030) would only be .0003" (three ten-thousandth of an inch !) at 1:100 scale (which I use for 1:96 since the math is easier and it's 'close enough'). My sheet of paper was .005" - 16 times thicker than it were 'in scale' !

Anyway, I finally ended up with a compact folded 'sail' atop the yard - so to reduce the 'bunching', I cut out a piece (shown in the series of photos) and re-folded on the pre-existing fold lines, added grommeting rope, and - shazaam - I got exactly the look ... realizing that there are several ways this can look as different pictures of furled sails do show variation in application.

The last photo in the series is shown below:

Once grommets have been removed (and the clew lines un-belayed), crew on deck give a tug on the sheets and the sail will practically set itself as it 'falls off the yard' and unfolds by aid of gravity. As I always say, "Work smarter, not harder."

- 3DShipWright and mtaylor

-

2

2

-

In nearby Wilmington Delaware, there is a full sized reconstruction of the Kalmar Nyckel (trans: Key to Kalmar). I was present for the cermonial laying of the keel, re-enacting the role of a soldier with a matchlock musket (there's a picture of me in that garb somewhere). Below are pictures of her stern decoration, under sail and at dock. At dock, I note that the topsails are furled in period manner with the central part of the sail 'bunched' around the mast.

Wasa 1628 by Snug Harbor Johnny - Billing Boats - 1:100 - old kit c. 1970

in - Kit build logs for subjects built from 1501 - 1750

Posted · Edited by Snug Harbor Johnny

'Just messing around the man cave (aka shop) and thought I'd try an idea I had for making tiny eye bolts from hypodermic syringe needles. I thought they could be useful with the end ground flat to use as tiny gun barrels for the small guns on a Metal Earth U.S.S. Missouri in my stash. But then I was thinking (the Admiral thought she smelled wood burning !) ... what if some material was ground away behind the flattened end, then the 'eye' of the needle lumen of an 18 gauge 'blunt fill' could be bent over to form an eye bolt. A 22 gauge needle fits inside the blunt fill to help keep the eye round when bending.

I've got to be careful as I've 'cored' a finger a few times before when working in an I.V. hood doing admixtures - an occupational hazard of a Hospital Pharmacy Technician. The first picture shows the 18 ga. needle.

Step 2 is to grind the end flat ... nice for a secondary gun barrel on a warship.

Step 3 is to grind behind the end as shown. BTW, the brass 'gall' on the stone wheel is from trimming other stuff.

Bending with fine needle nose tended to distort the eye, so the insertion of a smaller needle proved helpful.

Clip with flush cutters to separate. This is very tedious and the results are not perfect eyes. There are PE eyes available that will save lots of time and trouble. Also, the needle was not the biggest risk, as iImanaged to grind a bit on one finger. A great thing to put over an open wound is Dura Bond - sort of an artificial epidermis. Dura Bond is waterproof, stays on for days and allows the skin to heal in by 'secondary intention'.

Below is a picture with the covered boo-boo. After a while the wound site may appear to 'bubble up' below the Dura Bond - but this is normal and allows healing. Oh, the plastic box lid contains a bunch of really tiny steel mini brads that came with the 1:100 Billing kit. They were supposed to be used for the single planking (yeah, how much did I know about fairing or adding extra bulkheads years ago), but I didn't want to used them.

Now I see that the original ship had a lot of iron nails (spikes) used in construction and visible on the outside. Maybe Billings had the right idea with these brads ... but they would be best applied AFTER planking (pre-bending & shaping with glue as the bonding agent like I did it). The 'instructions' could have been a lot better, but what better instruction than to study builds on MSW?

OK, so I counted them and found 556 ... plus a few extra that slipped by the tweezers I used to count them all - so the number is more like 560+. So the plan is now to allocate about 250 per side to apply and get an appearance similar to the ship on display in Stockholm (they are replacing the old iron with stainless steel to better preserver the ship). Holes will be drilled so the brads will not split the thin single planked mahogany. My smallest drill (.030) is the same size as the brad shanks, so testing proves that a slightly smaller hole is needed to provide a little interference to retain the brads.

A set of 'wire drills' was ordered on Amazon using a gift card left over from Christmas - Fair dinkum ! Johnny