-

Posts

1,355 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Thukydides

-

That's the problem, if you could do it all over again you would be much more organized. Also you don't have the benefit of many ideas from other build logs (as you are leading the way here). I would say that almost every change I made to alert that the idea didn't come from another build log I did later than I should have and consequently it was more complicated than it needed to be.

- 152 replies

-

- Vanguard Models

- Cutter

-

(and 2 more)

Tagged with:

-

Welcome to MSW

-

I do have a tentative plan, but I don't want to say anything until I have the major parts of it figured out and I am sure what I am going to do. This was always planned to be my test run in the hobby and I have largely tried to stay pretty close to the kit arrangement. I want my next one to really push the limits of what I think I can do with a kit. I am doing some research in the background, but there are enough unanswered questions yet that I have not absolutely decided. Realistically even at my current pace I won't have alert finished until mid to late 2024 so lots of time yet to change my mind.

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

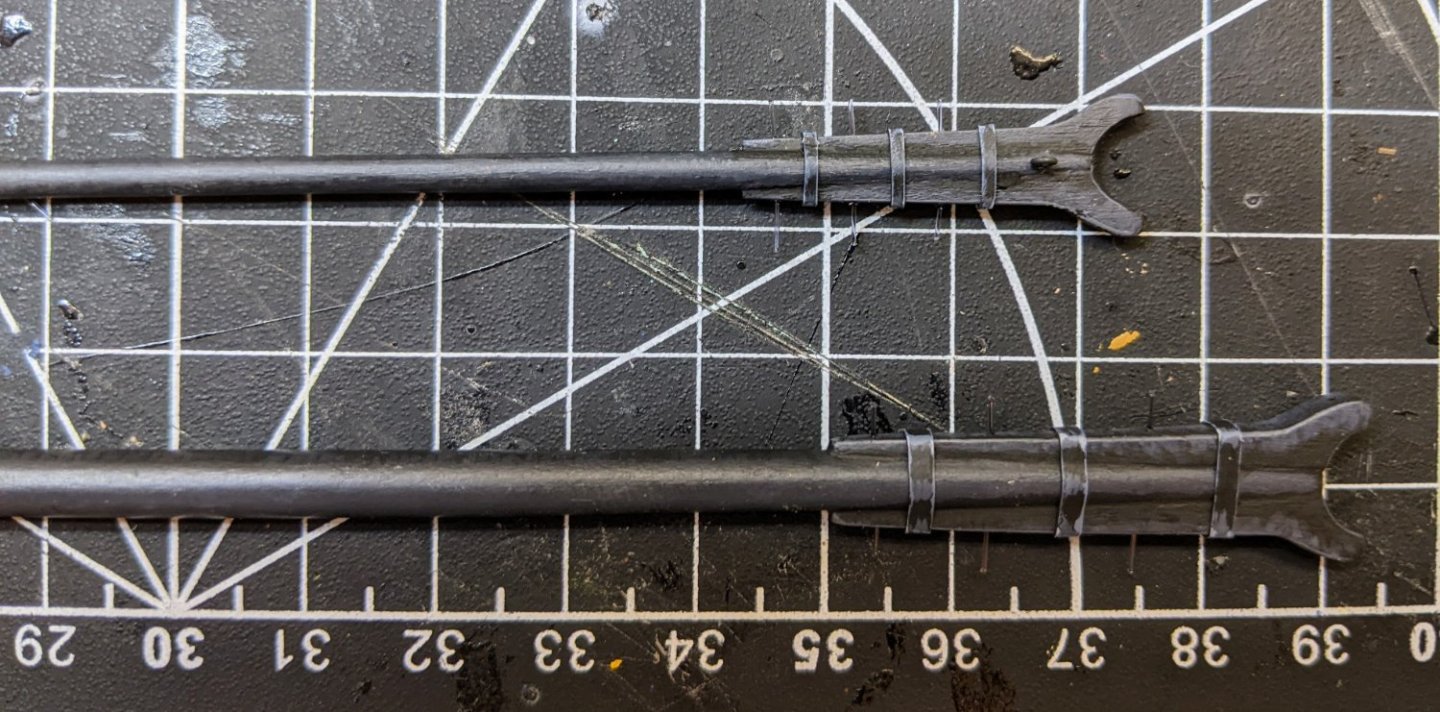

Minor update, I got the iron bands on the gaff and the boom as well as added the eyebolt to the gaff. Both Goodwin and the kit plans have the eyebolt further from the jaws, but Lees seems to suggest that this was only the practice after 1818 and so I went with him. I also painted the bands to try and help them stand out and give the illusion of metal. One of the challenges with close up photos is that the transitions for the colours look very abrupt when in real life they blend together much better.

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

It is looking really nice and smooth now. Great job on the painting.

- 122 replies

-

- Artesania Latina

- Pen Duick

-

(and 1 more)

Tagged with:

-

This is not as hard as you might think especially since you would mostly just be filling and smoothing the gaps between the wood pieces and the resin balls. You just need one of those silicone clay shapers so you can easily push it around into the cracks. Given the care and skill you have demonstrated I would think it well within your abilities. In any case the build is looking great and whatever you decide to do I suspect it will turn out well.

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

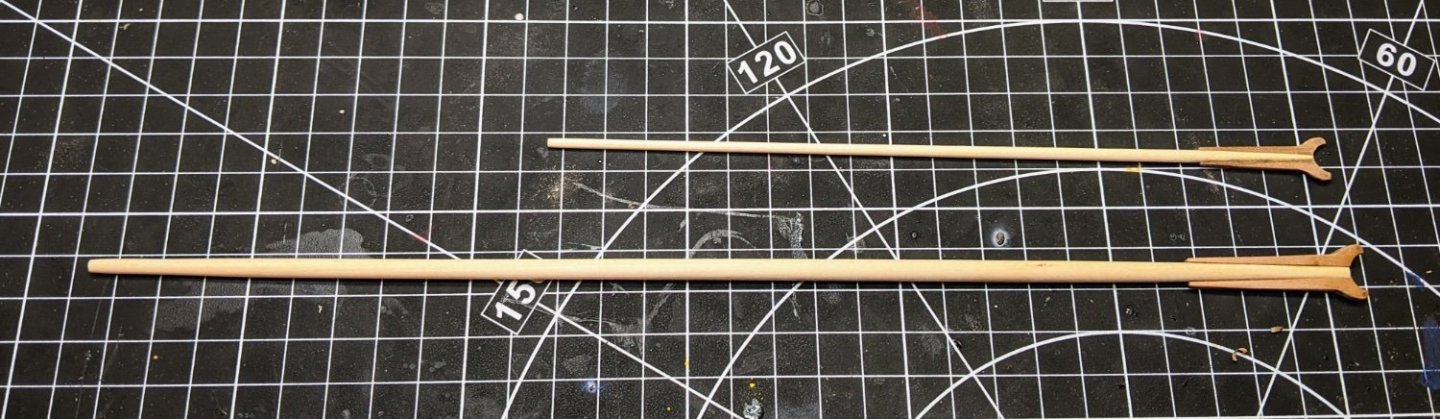

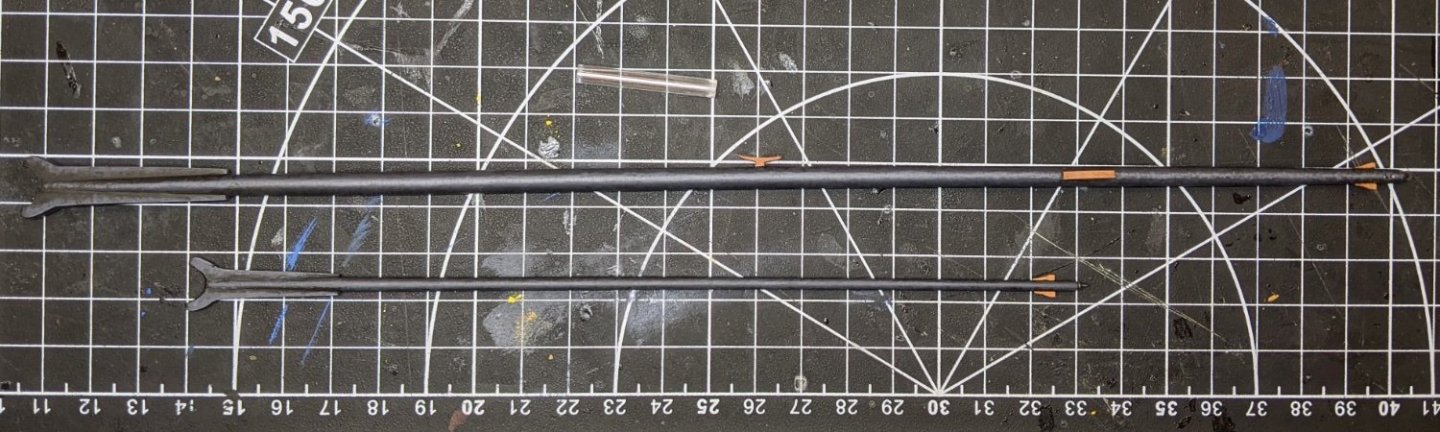

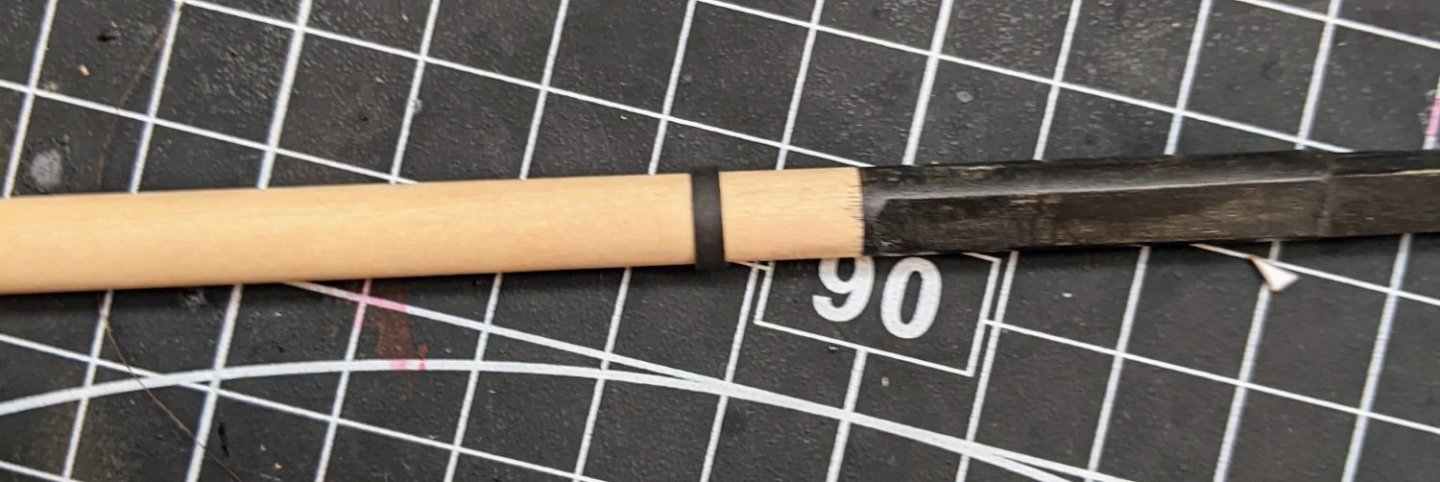

Log #56: The Boom and the Gaff Despite the lack of updates, I have been making progress on the model. I am currently in the process of trying to get everything associated with the mainmast that I can done off the model to make things easier. This however means that despite doing lots, I don’t have many things complete and ready to show. Much of what I will discuss in this log has been in progress for several weeks and I have many other things done, that I have not yet mentioned as they are not in a finished enough state to show. I say this mostly for the benefit of any other first time builders as the order I present stuff in my log is not necessarily the same as the order I worked on them. A significant amount of my time lately has been spent on the boom and the gaff. For the shape and length of them I followed the excellent directions in BE’s log. You can find them here. I achieved this by turning them on my drill much the same as with the mainmast. I also decided to adjust the kit arrangement for the jaws as I felt that with a little bit of effort they could be made more historically accurate. First I cut the two halves of the jaws in two and for the boom I doubled the thickness by gluing them to another piece of off cut and carefully shaping them. The gaff I left the same thickness. I then attached them to the boom and gaff and proceeded to give them a coat of black paint. I also took this opportunity to taper the edge of the gaff to let it sit more naturally. This taper is clearly marked in both Lees and Goodwin. After giving it a coat of black and sanding it back I decided to relocate the holes to more accurately reflect the diagrams in Lees. The old holes were filled with putty. Painting was a long slow process. I first coated them in black then sanded it smooth then coated then sanded and so on. Once I had a solid base I highlighted with one reflection point similar to how I have previously described. As a stylistic note I decided to leave all the cleats natural pear coloured with just a bit of WOP. I like the contrast this produces and also that it highlights the details. As a final touch I also made some changes to the end of the boom to simulate the pulley in it and also to make the end of the boom and gaff reflect what Lees said the practice at the time was (metal plate and eyebolt). For the gaff I used a leftover top of one of the extra stantion tops as the plate and one of my amati eyebolts. For the boom I used one of the leftover chain plates for the shrouds and one of the extra hoops that the running backstays attach to as the eyebolt. I still need to add the iron hoops that hold the jaws to the spars, but I needed to let everything dry completely before I start messing with that. And here are the two of them on Alert.

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

I really enjoy these posts where you talk through your thoughts process. I think these such posts on your alert log have been the most helpful to me as they allow me to see the why not just the what.

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Good job on the furniture, it has nice colour variation.

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

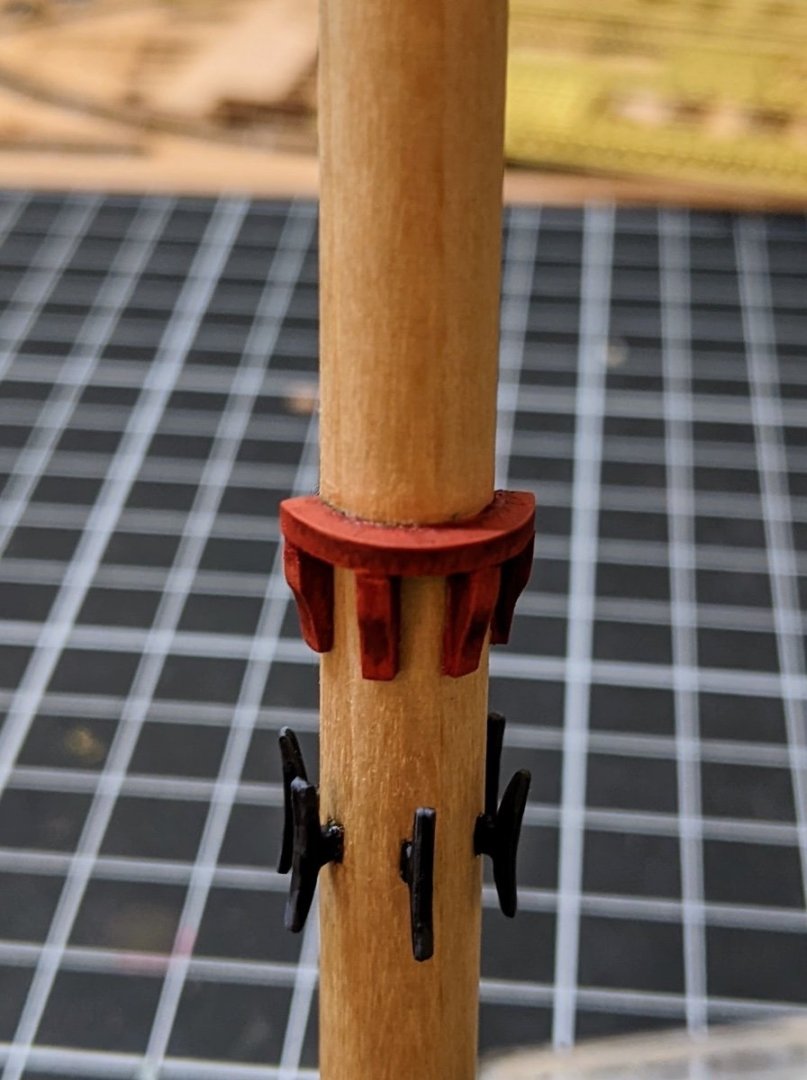

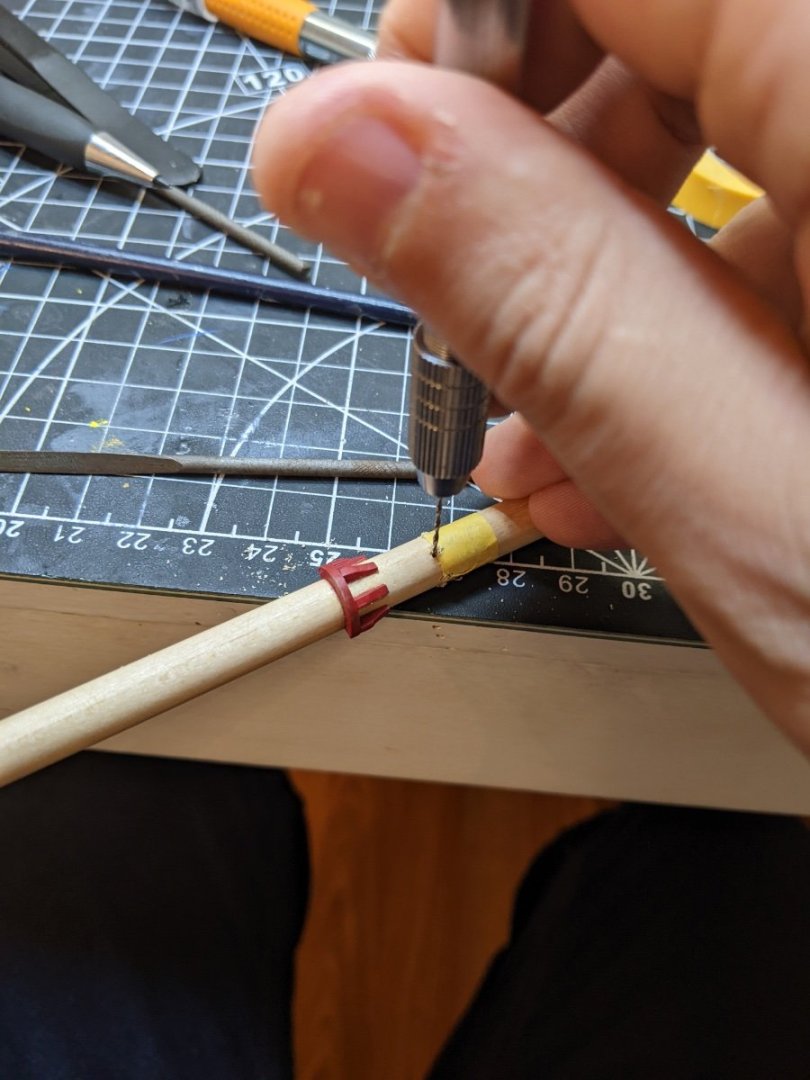

Log #55: Preparing the Mainmast While I am waiting on more rope arriving I have been doing the final preparations to the mainmast so it is ready to have the shrouds attached to it. First up was to create an iron hoop to serve as a stop for the shrouds. Based on the goodwin drawings I estimated this to be around 2mm thick. My previous tests had told me that tension alone mostly holds the shrouds in place so I decided to use the shrink tube held in place by epoxy. I placed the shrouds and stays on the mast to determine how much space I needed (leaving a bit of extra room for the 4 thinner ropes that still need to be served around the mast). I then marked the location and used epoxy to hold it in place and a hairdryer to shrink it. Note it looks closer to the top of the mast than it is as I had to paint my black line around 1.5 mm lower than desired due to an unfortunate accident with paint running. As this will all be covered with rope anyways it doesn’t really matter. I did not take a picture of this next step, but I coated it in a mix of flat black and metal colour dark aluminum as I did in the past on metal parts to give it a slight sheen. I then turned my attention to the bottom of the mast. I didn’t really like the PE ring provided in the kit to hold belaying pins (too thin), so I decided to follow BE’s method of using cleats instead. The problem is I had none so I decided to improvise. I had already decided to replace the PE shroud cleats provided by the kit with some pearwood ones and I discovered with a bit of modification these were just the right size for the base of the mainmast. However like many PE parts they were too thin so I glued them together in pairs to form thicker versions. I then filed them down to get them to look less like metal and more like shaped wood. I have discovered that PE in most cases need a lot of filing to make it look correct to scale. You can see the comparison of before and after below. I then prepared the mast by drilling two side by side holes to make a notch for the cleats. I determined the correct location by taking some masking tape, marking the place I wanted the first cleat to go and then spreading it out and marking the spacing for the remaining six. I then put the tape back on the mast and drilled just above it and just on the tape to make the notches. Meanwhile I primed and added several layers of paint and varnish to the cleated to try and make them look more rounded. I then attached them to the mast using epoxy resin. Then on to painting. I will not go into detail here as I have covered this in the past, but I used the same principles and colours I did for the red and black parts on the deck. Though some of this detail will likely be covered up, it is always safer to paint it all carefully and then any that is exposed will look right as it will be much harder to touch it up once it is on the model.

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

Just a note. Depending on how deep the indent is you may want to try more than one layer of varnish before moving on to sanding.

- 122 replies

-

- Artesania Latina

- Pen Duick

-

(and 1 more)

Tagged with:

-

Welcome back.

-

It's looking good. Keep an eye on the bow, I think it is just the angle of the photograph (not completely straight on), but, it appears that the strakes meeting the stem are starting to get a little bit out of line with each other.

- 152 replies

-

- Vanguard Models

- Cutter

-

(and 2 more)

Tagged with:

-

For what it's worth I don't think the mark will be that noticable. It is hard to tell from the picture of it is an indent or a bump. If it is a bump you could o as you said masking off the area. Note this doesn't have to be perfect as the line is already established. Just mask off the specific area you want to work on. If it is an indent what you could do is brush on some varnish on the area. This will level and fill the area. Then sand and mask and paint again. In either case give it a few days before trying anything. It is looking really good.

- 122 replies

-

- Artesania Latina

- Pen Duick

-

(and 1 more)

Tagged with:

-

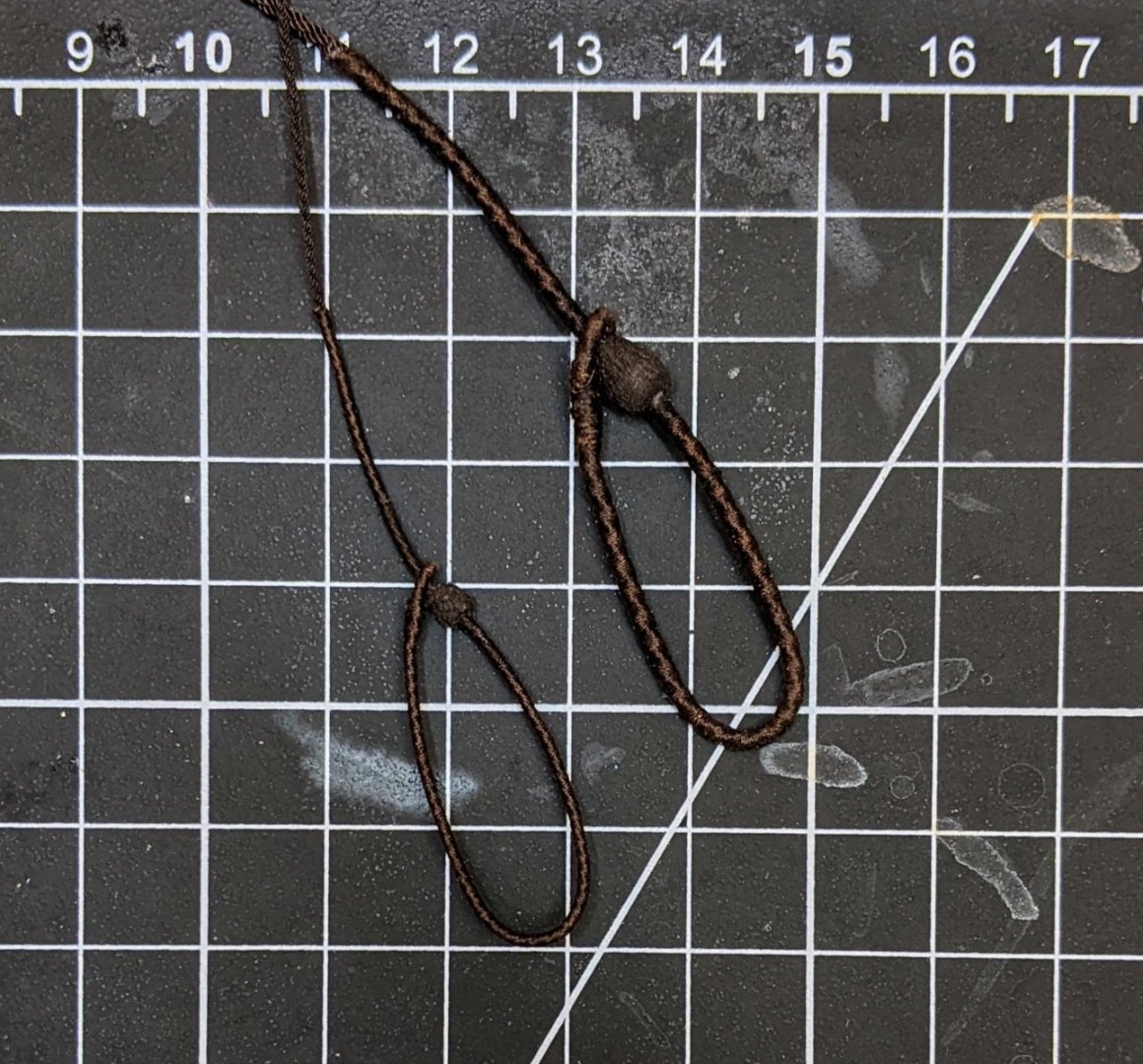

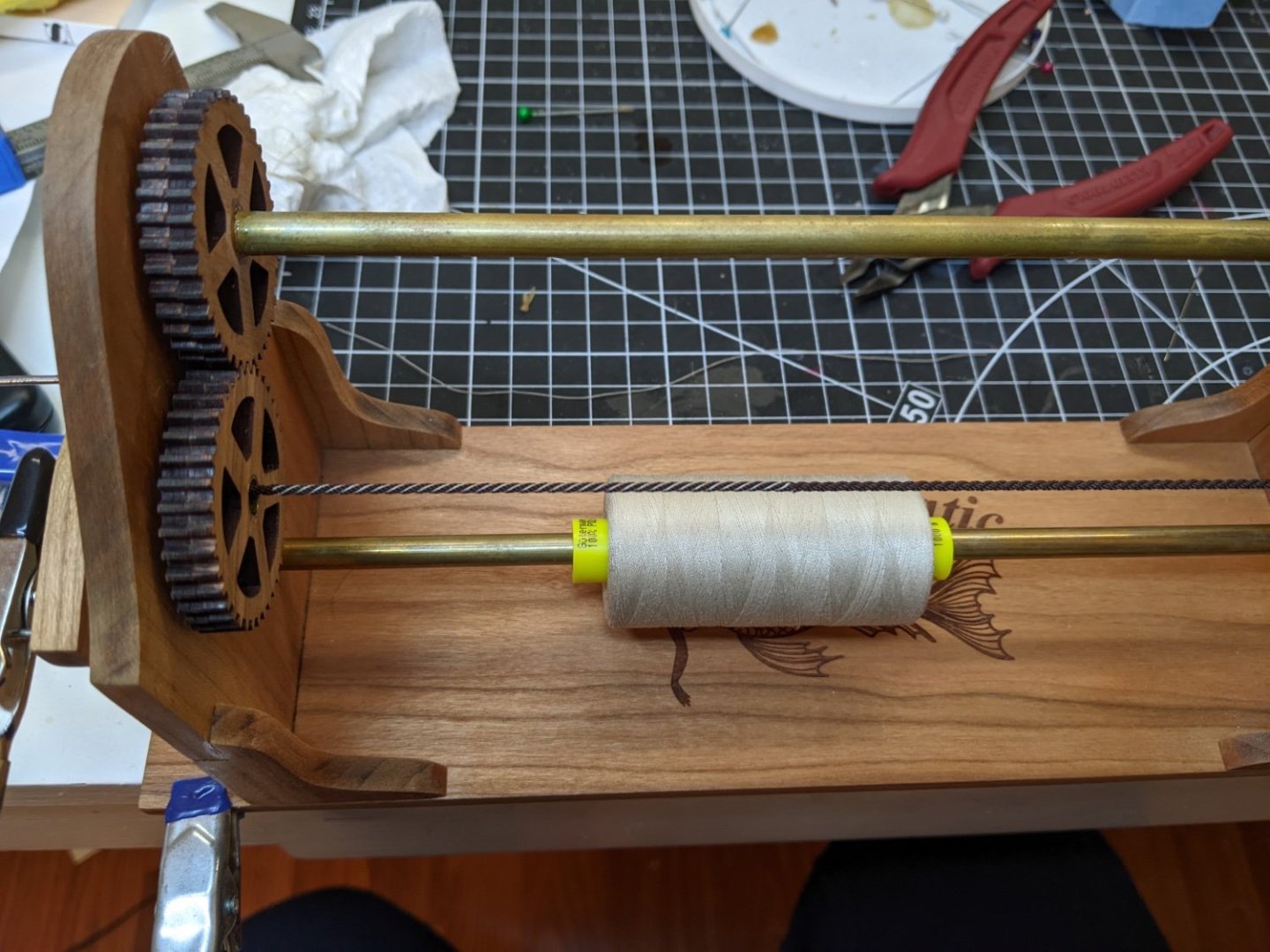

Log #54: The Mainstay and Preventer Stay Having settled on a plan of action (see previous post) I realized that I didn’t have the correct sizes of rope and so while I wait for another rope order to arrive, I started work on the stays. The mainstay is listed by steel at 13 inches circumference which works out to 1.6mm at our scale. As noted by BE in his log, this seems a bit on the chunky side, but after some thought I decided to stick with the steel tables. As the cable laid rope has larger gaps between the threads I decided in this case to worm it first. This helps the served portion to look rounder and particularly on this large rope I think it helped. I used beige thread as it is very hard to see what you are doing with the darker thread. For the mouses I decided to copy the example of @DelF in his speedy log where he turned them using a piece of dowel. Not having a lathe I had to use my drill. I marked off the length with tape and then used sandpaper and a file to get the right shape. The diameter of the mouse should be 3x the diameter of the rope so in this case this worked out to 4.8mm for the mainstay and 2.4mm for the preventer stay. I then drilled holes in them starting with a smaller bit size and then slowly increasing the size until it was correct. Then I covered them in watered down p a and stretched some tights over them holding them tight with clamps. The excess was then cut away and a spot of super glue was used to secure them in place on the stays. I then painted them with a very watered down (2 parts water to 1 part paint) 50-50 mix of citadel rhinox hide and VMC flat black.

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

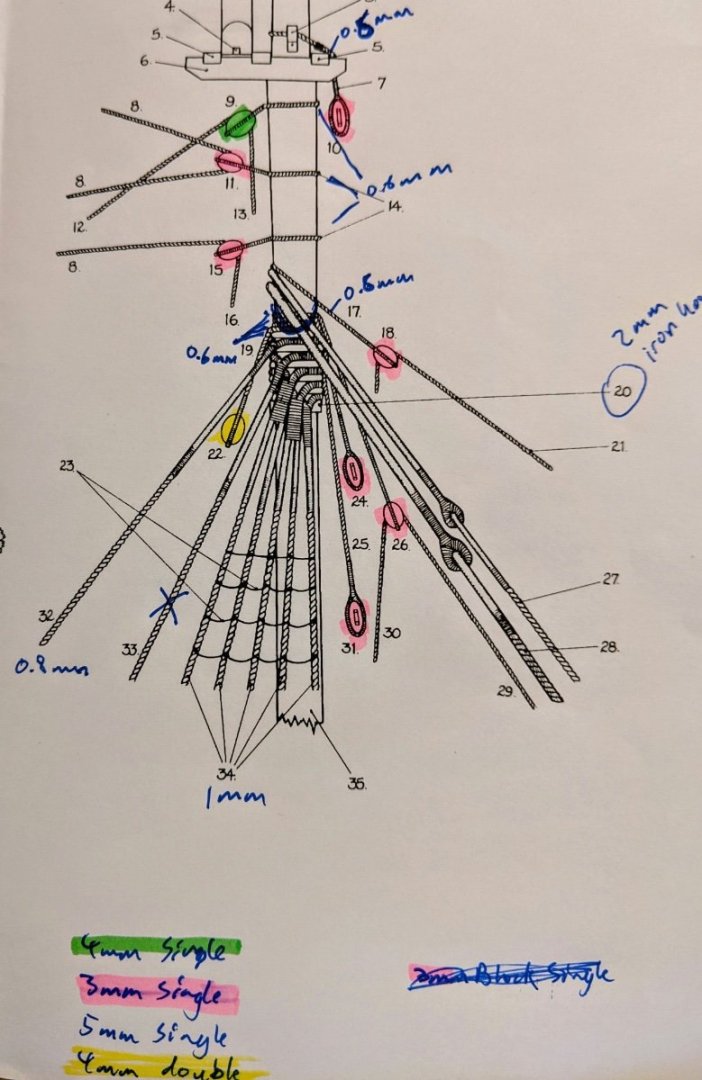

Thanks @Gregory for the suggestions to look at cheerful. I did find it helped clarify some things in my mind. @Blue Ensign I appreciate the encouragement. I do consider your log the gold standard when it comes to rigging alert and the care and detail you put into your explanations is fantastic. That is why whenever I am not sure I am arriving at the same conclusions as you or I can’t figure out why you decided to do things the way you did it gives me pause. I am hesitant to deviate from what is so clearly meticulously researched :). I think after much consideration I have a potential plan (see the picture below). Basically I have made a compromise between what the kit says (partially due to the blocks I have on hand), @Blue Ensign’s log and my own musings on Goodwin and the Steel tables. The running part of the rigging I still need to give more thought to, but I think this is a reasonable plan for the standing part of the rigging.

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

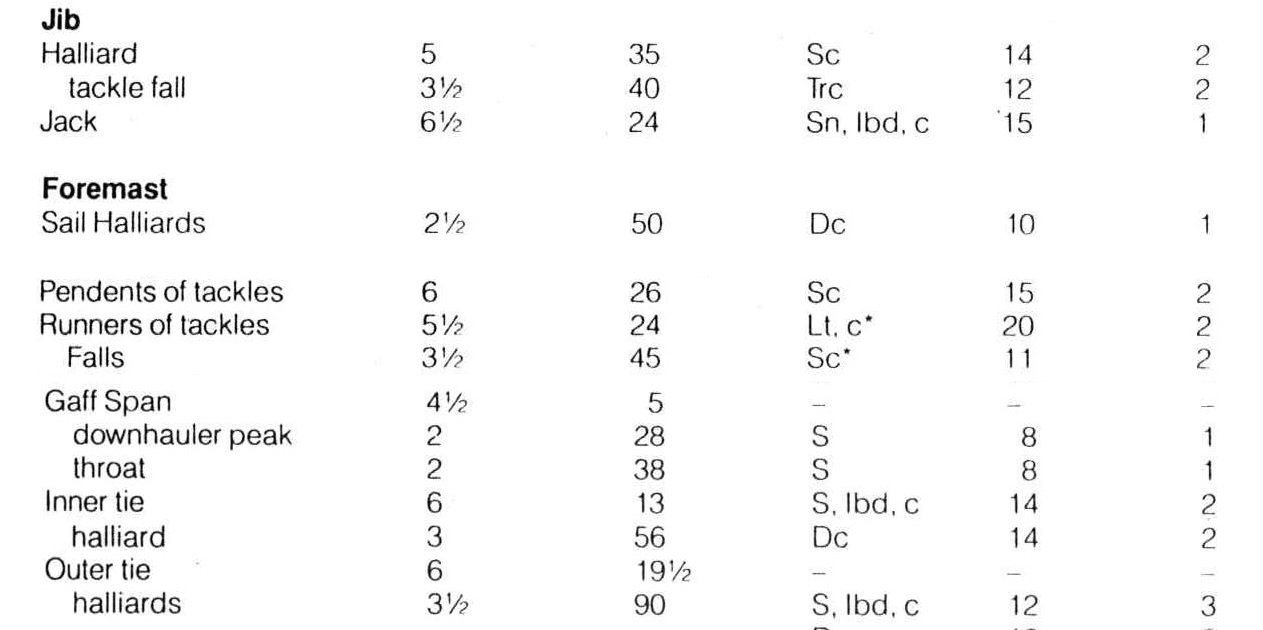

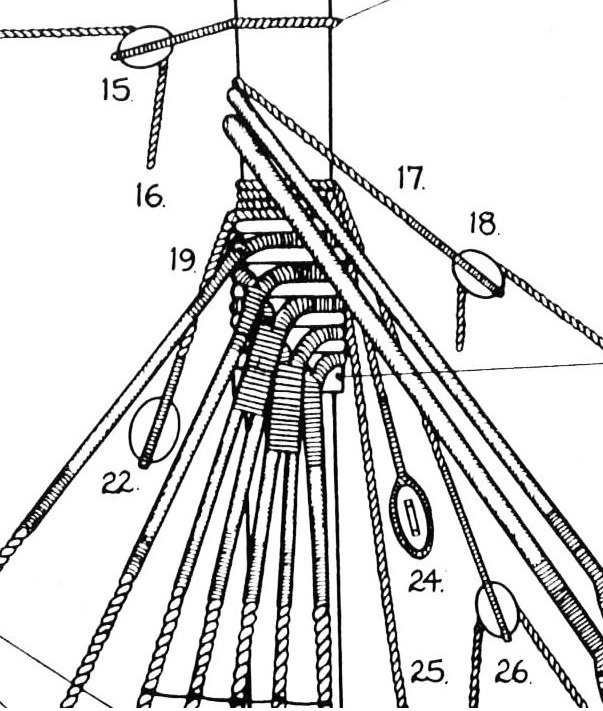

Log #53: Puzzling about the Mainmast Standing Rigging I have not gotten much done since my last update as I have spent most of my time trying to plan / understand what should be going on with the mainmast standing rigging. The problem is exacerbated by the fact that there are some inconsistencies in Goodwin and as far as I can tell, names for these sections are not always consistent. My main confusion comes from trying to figure out the sizes / seizing for the pendants just above the shrouds and backstays. My main reference has been this diagram from page 117 of Goodwin. You can see above the shrouds and backstays there are four smaller lines. These are labeled: 19) Standing gaff jeer tackle 25) Spreadyard standing tie pendant 24) Square sail yard standing tie pendant 26) Foresail halliard pendant Goodwin seems to use the term haliard and tie interchangeably (he explicitly says this earlier in the book). From this diagram we can also observe that these pendants are all drawn around the same size, but are smaller than the shrouds. As a note, the running backstay (the very top of the heavy lines falling away to the left) is slightly smaller than the shroud lines. This may not be on purpose, but is one of the reasons I decided to go with a slightly smaller line for it as articulated in my last post. Below I have copied sections of the steel table. This is where things get confusing. The names used do not always match and even when I think I have a good guess as to which is which, the line/block sizes don't really line up with either @Blue Ensign's very detailed rigging explanations or the kit plans. Since my default assumption is that I know less about rigging than either of these two, I am having trouble reconciling everything. So here are the questions I am mulling around in my head and am hoping anyone reading might have some insight on: I had assumed (see my last post) that the pendents of tackles referred to the ruining backstay. My reasoning for this was (a) there is no mention of backstays in the steel list (b) the fact that it had both runners and falls along with a fiddle block lined up very well with Goodwin's wording for the various parts of the running backstay (c) the size seemed about right as I imagine it would be slightly thinner than the shrouds. However, Blue ensign in his blog references them as a completely separate piece of rigging and googling the matter it seems that pendants of tackles might have been used to lift stuff. So are these not the running backstays and if not then where in the table are the running backstays referenced. Either the inner tie or the outer tie seems to me the best fit for the three ties, but a few issues with this come up: The size of this line is the same as the pendants of the tackles that I used to size the running backstay. From the diagram they are depicted as thinner than the backstay. Both Blue Ensign and the kit plans appear to depict this with a much thinner line and smaller blocks than indicated by the steel tables if I go with the assumption that the inner/outer ties are referring to these pendants. The foremast sail haliard appears to match the name for #26, but if true then the rope size for this one is much smaller than for the other ties. Maybe this is only referring to the ruining part of the rigging and not the standing part? The Gaff Span appears to me to be the best match for #19 and I assume that it is referring to the standing part of the rigging while the downhauler peak refers to the running parts that go to the end of the gaff and the throat refers to the running part of the rigging that goes to the base. However this brings up the question why the standing rigging for the gaff is thinner than that for the square sail spars. Any insight anyone is able to share on this would be appreciated as I really want to get this right even if it means I have to go back and redo some stuff.

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

New member with questions about first kit options

Thukydides replied to HeyIwanttolearn's topic in New member Introductions

Yes, he is located in UK. I believe he also has a German distributor, but the instructions for those ones I believe are in German. -

New member with questions about first kit options

Thukydides replied to HeyIwanttolearn's topic in New member Introductions

Yes the list is a bit dated. The hard thing with recommendations is it is impossible to do so without knowing more about the builder. What is your comfort level with modeling in general, do you have any experience with wood, what catches your imagination, how determined as a person are you (do you need to see results quickly to keep yourself motivated), how much does price matter to you. All of these factors impact what sort of project you should do for your first one. That all being said if you want to build a warship that covers all of the basic skills you will eventually need to build something bigger I would recommend starting with a cutter (speaking as someone who is working on his first model ship). If you are more unsure or have limited experience modeling then go with something smaller such as a fishing boat. Some options I would recommend are below: Non Warship: The beginner three boat series from Model Shipways Vanguard's Nisha Warships: Vanguard's Alert Vanguard's Trial Cutter Amati Lady Nelson - This is much cheaper in the short term, but you may find yourself spending money in the long term upgrading the parts. Vanguard's offerings let you make very nice models out of the box.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.