-

Posts

496 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Oldsalt1950

-

Air Compresser

Oldsalt1950 replied to Guyuti's topic in Painting, finishing and weathering products and techniques

I have this one and it is very quiet. Amazon.com: VIVOHOME 110-120V Professional Airbrushing Paint System with 1/5 HP Air Compressor and 3 Airbrush Kits for Tattoo Makeup Shoes Cake Decoration Black : Beauty & Personal Care -

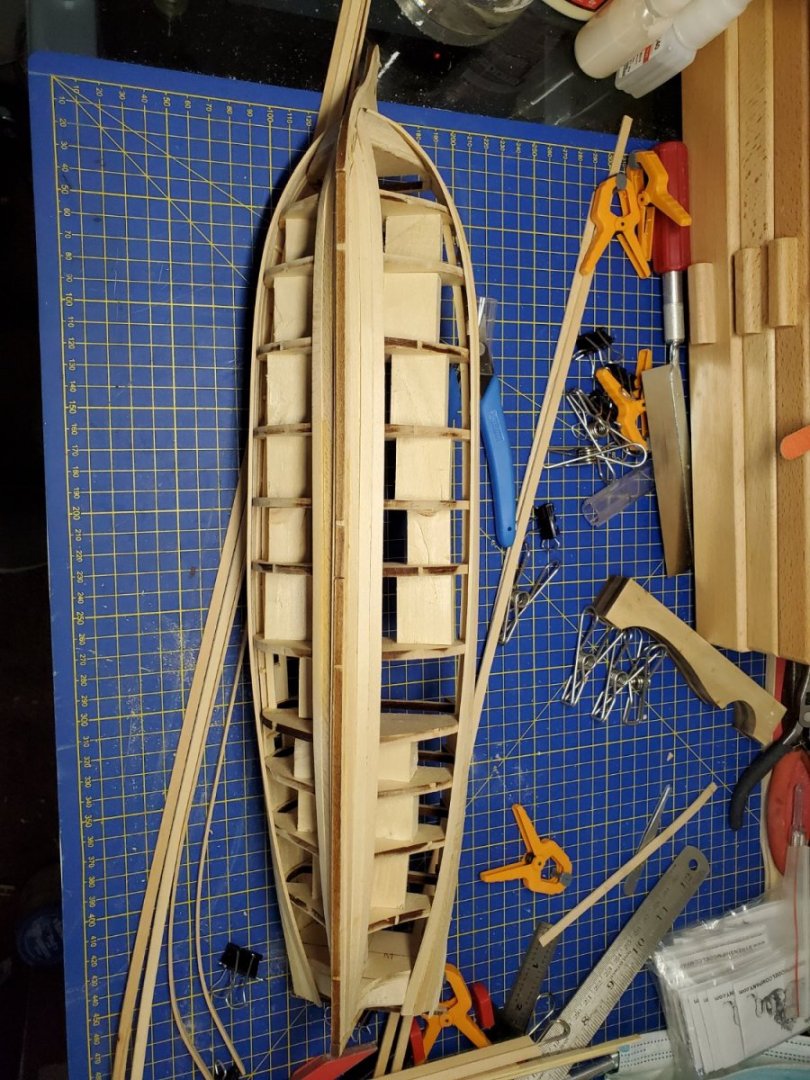

She is really starting to take shape.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Ken, you are correct in the assumption of the shrouds being directly seized to the mast. E Z also hit the nail on the head as small boats have much lighter loads on the mast due to less sail.

-

The question is, what is the kit worth to you? The kit is a paperweight to them at the moment regardless of what they paid for it 20 years ago. Jim

-

Mark, if it was me I'd sand by hand. Those beams are pretty delicate. How are you storing your kit wood once you open the box? Does in remain in the bag or is in left in the open. Vertical or horizontal storage and is there air circulation around it? All those factors come into play to affect what happens to the wood.

- 505 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Greeting from Pennsylvania

Oldsalt1950 replied to New England Captain's topic in New member Introductions

Welcome Andrew. Be sure and poke around the site a bit. You will find a trove of great info here in both the build logs and the articles database. I find if I'm stumped it is best to step back and do a search here for the info or technique. If it needs reinforcement, then YouTube. -

The kit bass wood will work fine for the cross arms of the anchors. Some form of building board or a good panning vise would come in handy for setting up the bulkheads on the frame. Once the bulkheads are squared up and glued in place you really only need something soft to place the assembled skeleton on.

-

Looking very smart and handsome. Very nice work.

- 476 replies

-

- sphinx

- vanguard models

-

(and 1 more)

Tagged with:

-

Glad you are feeling better James. That is a lot of progress for still not feeling up to par. Stashing money away in anticipation of Indies release to the public.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

The one step forward two steps back dance is in full swing. I wasn't happy with the way the hull planking was laying, so off came the strakes. A bit more sanding on the bow fillers, and a bit of sanding along the rabbet and bearding line. Because I use PVA glue, removal wasn't hard and I just have to clean up the residual glue on everything and it is back to planking the hull. I may take another look at plank layout and see if by shaving just a bit off each plank I can get away without adding any stealers into the hull. It is a good thing that wood is forgiving.

-

USF Essex by mtbediz - FINISHED - 1:50

Oldsalt1950 replied to mtbediz's topic in - Build logs for subjects built 1801 - 1850

Very nicely executed, but there is one thing missing. No name on the stern board/transom. -

Every build is a learning process. The Swift is a great project and has been around for more years than I wish to think about. This is a testament to not only its timelessness, but its popularity as a learning vessel and just plain fun build. It isn't over complicated but allows you to learn a little about everything concerning ship building and it can be detailed really well. Enjoy.

- 24 replies

-

- swift

- artensia latina

-

(and 1 more)

Tagged with:

-

For those that object to the base, in addition to either using pins or pegs to keep your figure upright, why not use a piece of acetate as a base it is clear and unobtrusive. Then you don't have to drill holes in the decking.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Go over every piece carefully and double check your replacement part list Dave. It will be a long one. Be sure and make templates for the bow and stern blocks and try to keep the knockouts in frames A-C and I-L you will be breaking off the cross pieces otherwise. You already know about the mainframe issue so make that shim piece and reenforce it when you glue it in to obtain the matching length. Also make sure the rabbet is at the depth specified in the plans (trust me on this). Before you start building determine if you are going to put cannons in all the ports it will affect how a lot of the build goes. Read and re-read the instructions and the build logs , depending on how you like to build you will find there are many steps you will take out of sequence. Plan carefully for the removeable bulkhead at frame L . Best of luck on your new build, the adventure begins. Jim

-

Follow your gut. Just make sure that you measure and set both the rake and plumb side to side. Use a slow setting wood glue so you have time to make adjustments. You have plenty of room to use a small machinists square(s) to set the mast square along the center line. You can make a small jig to set the rake out of scrap wood. If you were building a ship with more complicated rigging , that is when I would wait to fix the mast in place. Also make sure any holes that need to be drilled in the mast are done before you glue it in place.

- 24 replies

-

- swift

- artensia latina

-

(and 1 more)

Tagged with:

-

The issue started with the planks either side of the king plank. The two planks are not identical for where the butts are cut.

- 36 replies

-

- Harvey

- Artesania Latina

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.