-

Posts

4,015 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by glbarlow

-

-

I have a different way of doing this but yours is much better. I'm going to have to read it a couple of times more when I get to this point on Cheerful. I'm not exactly clear on how you finally closed "the circle" (right photo two up from bottom) on the bowsprit once you have the four deadeyes seized.

As usual, very nice work. I see the quad hands is working out well - glad I have one now. Beats the old beat up third hands thing I've had for years.

-

-

Amazing work, well beyond anything I’d ever try. My patience is tested enough as it is with my models. Nicely done!

- MEDDO, BobG and Ryland Craze

-

3

3

-

On 10/14/2020 at 12:02 AM, MEDDO said:

very symmetrical

Thanks, that I think is a tribute to the extra time spent on fairing at the very beginning

On 10/14/2020 at 8:07 AM, garthog said:how you work on such small pieces

I wish I had a good answer other than good tweezers, 2.0 yellow tinted (improves contrast) reading glasses, and two bright Daylight lights on the bench. I fiddled and fumbled about dropping and losing little wire hinges and 1mm brass tubing quite a bit. I like how it turned out, but glad it’s done.

-

The HMS Surprise prototype has been shown on their website as coming soon for over 5 years. They’ve not made a single update to that website in all that time. Years ago I sent an inquiry and got a similar response. I will be surprised if the Surprise is ever released, but we can all hope.

- Ryland Craze, mtaylor and rshousha

-

3

3

-

Thanks BE and Derek, I appreciate your comments!

I was only able to enjoy ship building in short increments over the last several weeks. Water is a tough thing to deal with when it doesn't go where it's supposed to go.

- Edwardkenway and mtaylor

-

2

2

-

The kitchen was a pain, but we did use the opportunity to update it so at least there is the one upside. I thought about adapting some of the Clear Alder used in our cabinets in the model, but its way to hard and too much grain for ship building, but it would have been funny to do.

- Ryland Craze, mtaylor and Edwardkenway

-

3

3

-

I elected to take what I thought was a short diversion, and at the same time had a larger diversion thrust upon me. The large one was a long undetected leak in our dishwasher drain resulted in a six week demolition and reconstruction of our kitchen. Not fun, lots of contractors, noise and dust to deal with every day and not much ship time at all. But enough of that.

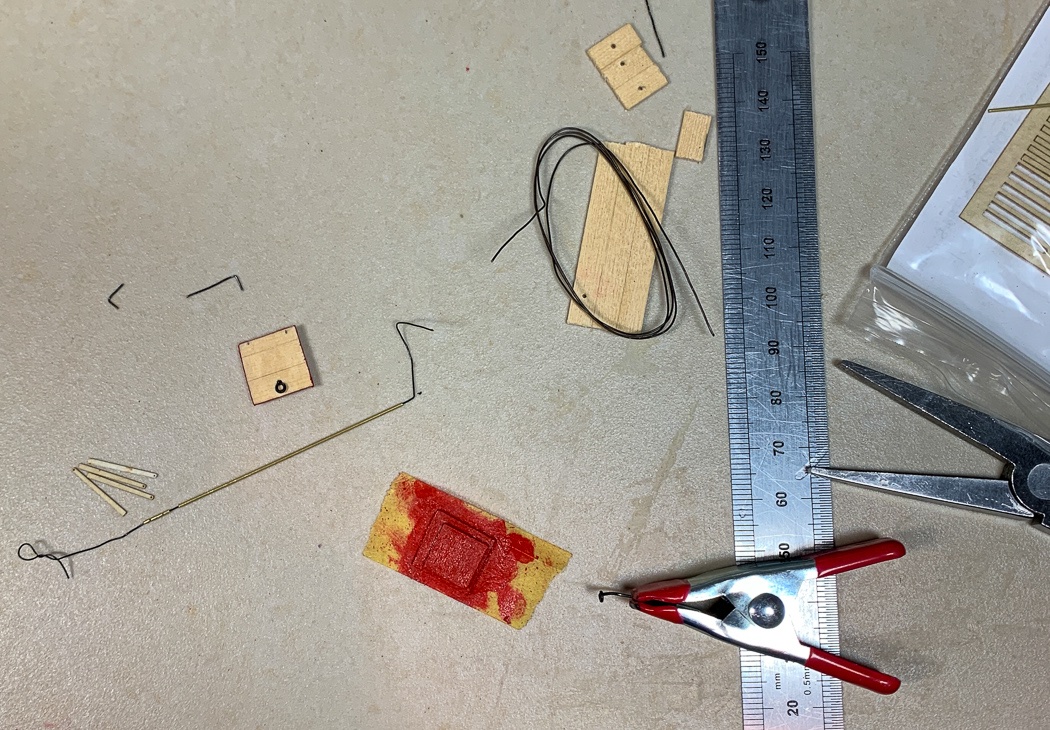

What I though was going to be a short diversion while all the above was going on, was completing the stern port lids. I used Chuck’s hinge mini-kit with the instructions printed from his website. It all seems pretty straight forward, but as our British friends say there is a lot of fiddling to get all the tiny pieces to come together.

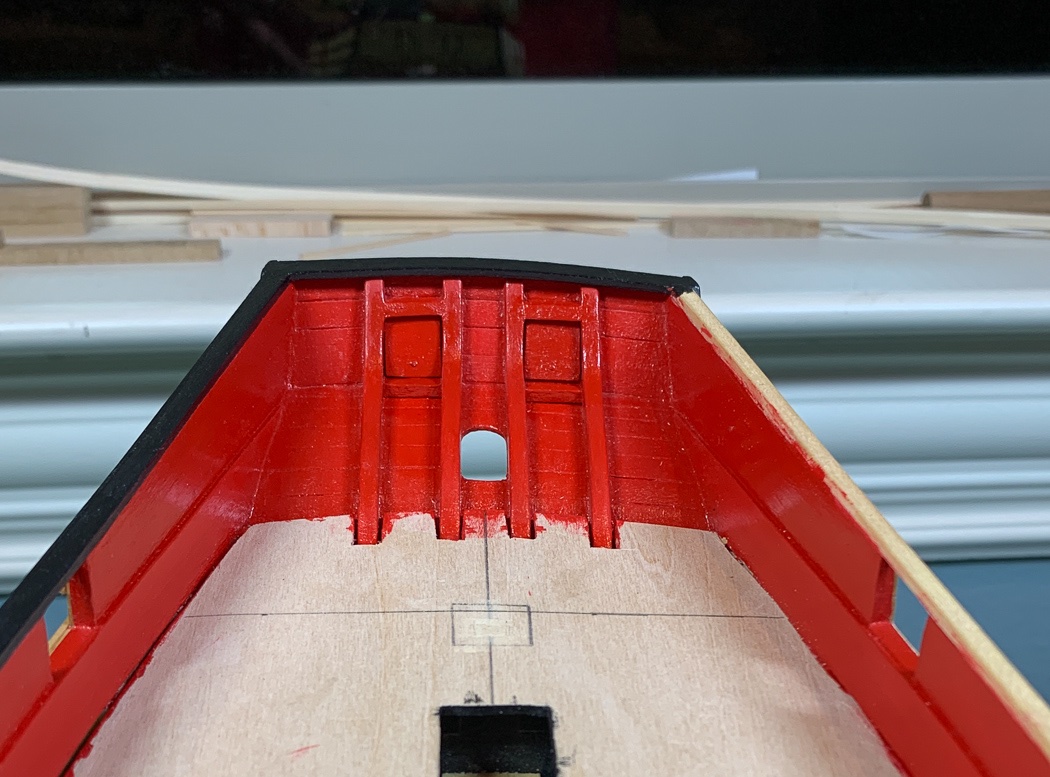

First I glued three strips of planking together, long enough to cut more than two lids. I measured, cut, and gently sanded to get those planks to fit flush to the opening (the WOP will bring out the seams as its done on the rest of the planking, they show up faint here).

Once that was done I measured, cut and glued and painted red a smaller set of planks to to fit within the interior of the port (the difference of the 1/64th rabbit), shown here inboard with a photo also designed to display the most possible dust particles (I cut the bowsprit hole earlier today, more on that later).

I created the lid lift ring by wrapping 24 gauge black anodized wire around the right size drill bit and with a little snipping, shaping, and bending, pulled it through the lid. So far, easy and fun.

The fiddling comes not in following the instructions to paint, mount and install the hinge plates or cutting 1mm lengths of tiny brass tubing for the hinges along with very short pieces of 28 gauge wire, it’s getting it all fitted together and mounted. Nothing difficult in concept, just working with tiny pieces and tiny holes. Between dealing with contractors in the kitchen I managed to get it done over a longer period than I had anticipated. Anyway…patience tested and passed.

Every stern on every model I’ve build has been an adventure. It seems on many kits it’s an afterthought, just that thing at the end of the ship. At least in my case it was always an adventure in adapting and overcoming little challenges to get everything to fit and call it a stern.

None of that’s true with @Chuck Cheerful. It is a well guided process from the initial base, to adding the counter, completing the planking as it rises up then finishing it off with a fun to make square tuck. Then there’s the fit of the transom to the counter and the addition of rail and moulding strips. There’s my choice to follow Chuck with a RED painted counter with me adding black to the fashion pieces either side meeting the transom rail and the contrast of my choice of a natural stern post, and of course those fiddlely port lids. It all works, it looks like a stern should look in my humble opinion. I’m kind of pleased with the final finished stern of my Cheerful (still one more coat of WOP to go). I hope you like it and decide to build one of your own.

The contractors are gone, now I’ll do the port side moulding.

- MEDDO, DelF, Blue Ensign and 13 others

-

16

16

-

Very sharp looking deck, very crisp work.

I don’t see any reason to leave the swivel guns free. You won’t move them once the model is complete and on the shelf. I don’t even install them on the mounts until almost done with the final rigging, they get in the way and become great at snagging lines. It’s usually one of my last steps.

- Old Collingwood and VTHokiEE

-

2

2

-

Shapeways.com. Lots of people in multiple scales. I have a mini-me.

- mtaylor and Larry Cowden

-

2

2

-

I have always been inspired by your work, all the way back to the Confederacy. Now I need to go back and improve the sills on my gunports after adding the spirketting

- FrankWouts and Elijah

-

2

2

-

Do you have the masts already installed on the hull? That would make adding block challenging, but seems like you’re solving the problems as you come to them. I also thing it’s always good practice to drill out the blocks before installing them, if nothing more to give the rope a smooth passage as it’s being run.

I’ve also been away from the bench due to having to reconstruct and renovate our kitchen due to a major water leak. Not fun.

-

Gluing on these long thin strips is such fun... You made nice work of it.

- Martin W and Blue Ensign

-

2

2

-

On 9/28/2020 at 6:36 AM, Blue Ensign said:

suits my eye

Sometimes this is the best judge regardless of specs. “In my mind’s eye” is a valid measurement in my book.

- VTHokiEE and Blue Ensign

-

2

2

-

As I have recently learned with Cheerful , moulding can be easily scraped from strip wood and a piece of filed brass. No need to increase kit costs. Even not scraped as a plain strip it can serve the purpose.

- Ryland Craze, VTHokiEE, TBlack and 4 others

-

7

7

-

7 hours ago, Blue Ensign said:

grateful to Chuck

Thanks BE, your Cheerful log is one I frequently visit for ‘how-to’ as I move to the next step. So much about Chuck’s design just works right, it’s made my dive into semi-scratch building so much more fun.

The mini-me is kinda fun, plus I like it for the sense of scale.

-

1 hour ago, bartley said:

be interested in your comments

I don’t really know yet, it isn’t something I’ll use often and it’s a moderately priced unit. It does have variable speed, does both pin and painless blades, has a light and a blower. Those are about all The features I was looking for. I have a jewelers saw which was quite handy reducing the stern frames as I described here in my log. The scroll saw was quite smooth cutting out the bow portion of the cap rail. I don’t think it will be a big part of my modeling, I’m fine with my hand tools, but it will be handy when I need it.

-

-

6 hours ago, DelF said:

you might not realise

The things I don’t know...thanks Derek. So what are the grits of your sandpaper row? So you put honing fluid on sandpaper?

That guy has a lot of chisels and planes on his shelves, now I feel like I’ve neglected my tools. For the record I have a number of high end knives, and they are all kept sharp. I’m not a complete poser.

- Ryland Craze, BobG and mtaylor

-

3

3

-

18 minutes ago, Rustyj said:

determination and perseverance

Thanks Rusty.

-

4 hours ago, DelF said:

set of Veritas miniature chisels

I love these tools, they are extremely well made. I use them a lot and for a lot more than a chisel’s typical use. I’m going to have to sort out how to sharpen them soon

-

53 minutes ago, DelF said:

low down on the starboard stern

Thanks Derek. I appreciate the kind words. I'm kinda happy with how its turning out. I like how the planks are a bit varying in color that stands out in that photo, it helps bring out the butt joints and that it isn't a single long run of planks.

-

For us Americans, I looked this up.

Fettle: to prepare or arrange (a thing, oneself, etc), esp to put a finishing touch to. b. to repair or mend (something). Not sure if BE is in Yorkshire, there it means to put in order.

It's a cool word, but one I'd never seen until reading BE's logs 🙂

Oh, and nice work as always BE. I enjoy your ever informative logs.

-

Just now, Edwardkenway said:

the effort you're putting in on

Thank you very much for saying so.

Yes, the Amati scrapers were a bust, at least for this model. There are step profiles that would have worked on the 3/32 square strip, but I just didn't like the look of them. I'd recommend not going to thick on the brass. I had several sizes on hand and determined 1/32nd thick brass was best for me.

Queen Anne Barge by MEDDO - FINISHED - Syren - scale 1:24

in - Kit build logs for subjects built from 1501 - 1750

Posted

Outstanding!