-

Posts

4,126 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by glbarlow

-

A never ending source of good ideas and techniques. A really great job of detailed paintwork. I enjoy this work myself and appreciate others taking the time and having the skill to do it right. Nice work!

- 345 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

The curve of the bow is not the same top to bottom.

- 476 replies

-

- sphinx

- vanguard models

-

(and 1 more)

Tagged with:

-

I’m content with good lighting and a pair of 2.0 and 2.5x readers. I tried the head magnifiers, didn’t like my field of vision restricted and for me they just weren’t comfortable.

-

Most models don’t include sails. For me the reason is simple: this is a model, I don’t want cloth hiding and covering all the detailed work I did on the model and on the rigging. I included every line Pegasus would have, I added some lines to Lady Nelson per my reference book on cutters because the plans are sparse, so far as I know Cheerful includes all her rigging, etc.. I never considered attaching cloth to any of them, why conceal my work. In this case I do have contemporary models on my side, they don’t include sails, I imagine for the same reason.

-

Hard for me to see but looks like you need more angle on the first and or second bulkhead and or you’ve removed too much from the third. Either way it has to be a smooth run. James could advise you better or maybe check photos of BE’s model at that stage.

- 476 replies

-

- sphinx

- vanguard models

-

(and 1 more)

Tagged with:

-

The bow area can and should be faired for the smooth flow of a batten top than bottom stem to the fourth or even fifth bulkhead. There should be no reason to add a strip. Often in my experience it is the 2nd or 3rd bulkheads that have not been faired properly and considered as part of a unit, not individual or 1 to 2 or 2 to 3. It looks like 2 in your photo has insufficient angle faired but it’s hard to see what’s causing. It isn’t faired until a plank runs smooth Keep the back edge of bulkheads fore of midship and front edge of bulkheads aft of midship as long as you can not to lose the proper design of the hull and both sides equal

- 476 replies

-

- sphinx

- vanguard models

-

(and 1 more)

Tagged with:

-

Great work, such expert carpentry and painting.

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Welcome from another Texas Glenn, I’m an Army vet

-

Admiralty Paints. French Blue, Red Ochre, Dull Black, Ironworks Black, Matte White. Cornwall Boats in the UK is my source for Admiralty Paints.

- 55 replies

-

- lady nelson

- victory models

-

(and 2 more)

Tagged with:

-

That all looks great Rusty.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

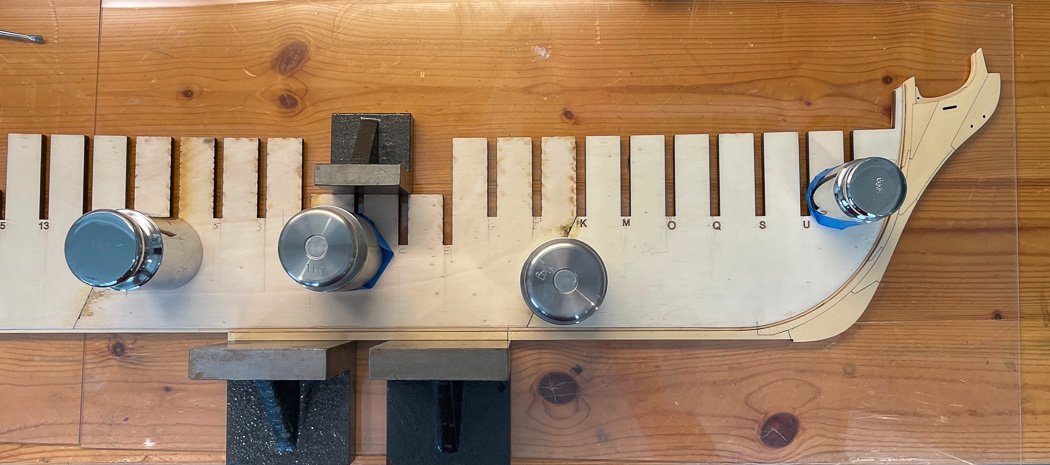

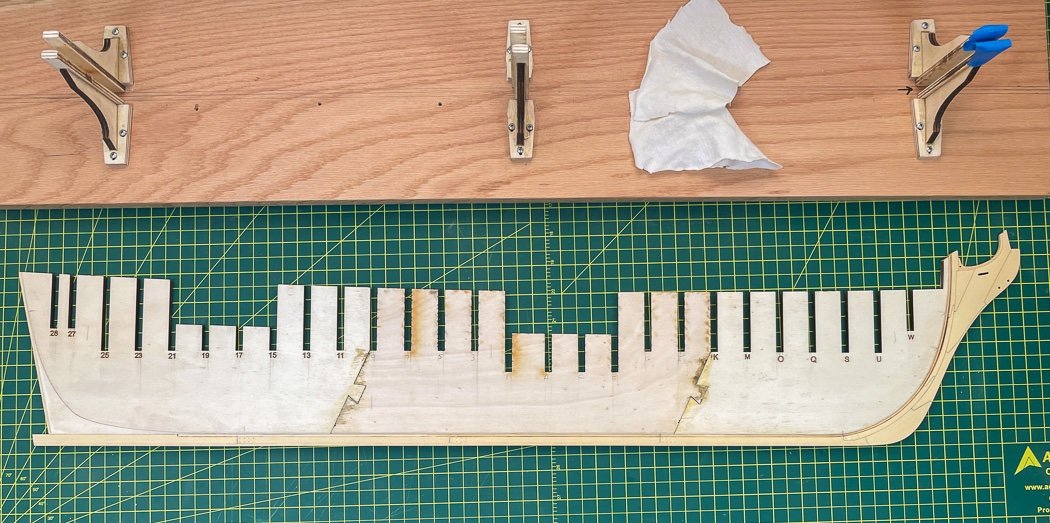

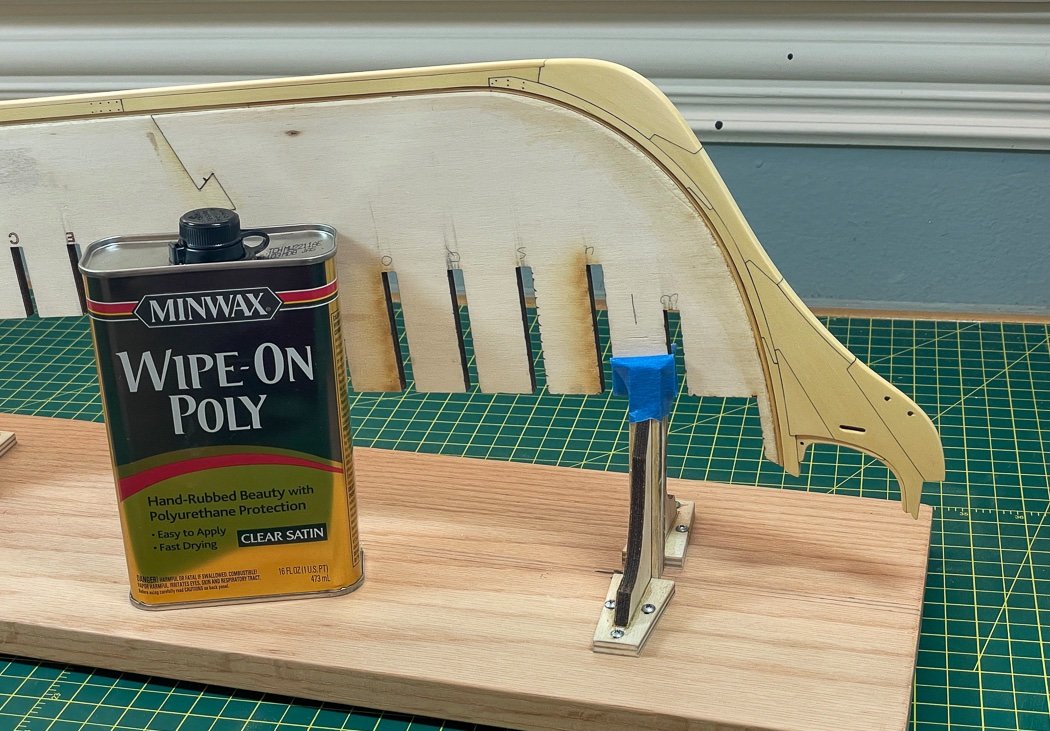

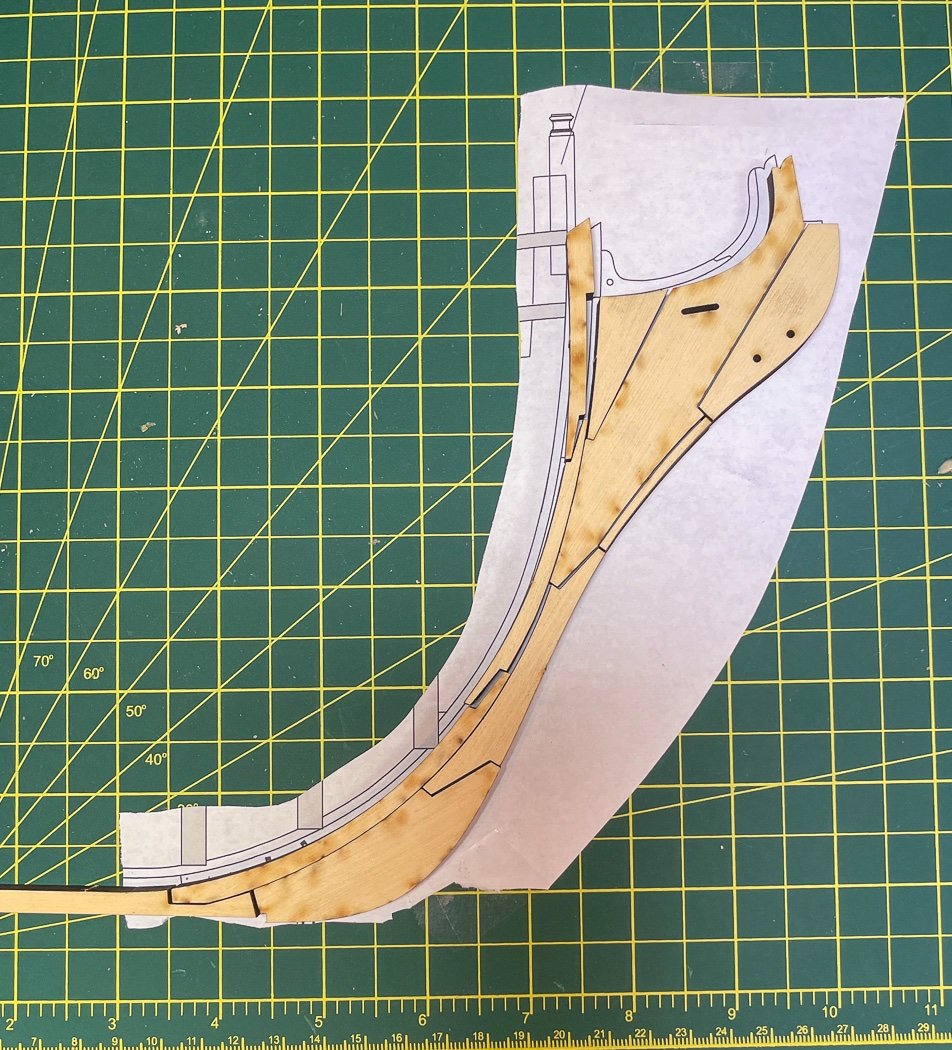

Stem & Keel One of the many signature items for our Winchelsea build is the stem and the multiple components that make it up. Constructing it is a project in and of itself and an enjoyable one at that. The necessary, maybe not so fun, part is removing a lot of laser char. Though it isn't cleared from the inside edges, simulating the tar used on the real thing. I did scrape off the “gummy” part of the char off to get a tighter fit. Chuck provided a nice tip to sand the sides while still in the billet, this protects the parts edges and frankly is just easier to do. As those that have built theirs know, assembling the steam not as simple as it might look. It takes some micro-sanding to get a tight fit on some of the pieces. I took my time with tapering, going from 1/4th at the aft to 1/8 on the upper fore, while fading that back to ¼ on the lower fore, fun. One of my challenges was interpreting the instruction's use maritime names for each piece, which I’d otherwise refer to as the triangle thingy, the sorta oval thingy, the skinny piece, etc. I needed a diagram, in fact I turned to my research books (yes I have them) and improved my naval education a bit (I’m an Army veteran, the squids were never much use to me back then). The gammon knee and extension pieces on the top took me most of a day to get the right fit. I had looked at the parts billet and wondered why Chuck provided three of each, by the end of the day I was wondering why he didn’t provide four. They are tricky little dudes (maritime term) to tuck tightly into that curve. The point of the tapering, aside from looking really cool, is to provide a seat for Rolo (I decided that’s his name), the mandolin playing dude, to sit on. Guided by the instructions I brushed on and wiped off Old Masters fruitwood gel stain, it really adds highlights. These resin castings from Syren are amazingly sharp in detail, I think I can make out fingernails. After spending a considerable amount of time micro-adjusting the stem and former to fit tightly it was time to glue the stem, keel, and false keel together with the former. Again more patience, taking it a section at time (there are three plus the stem). My acrylic sheets were an inexpensive and worthwhile purchase to provide a nice flat service for this task. Like clamps I’m beginning to think I can never have enough weights. I have a slight bend in the former, I made sure I held it flat with the weights while applying the keel. Chuck tells me I’ll be ok once I add the bulkheads and fit it into the building board with its tight brackets. Plus now I can add wood strips along the bottom of the build board to further help keep it straight. Have I mentioned how big this thing is. I used 27.5 inches just for the false keel. Next up is adding the bolts along the keel. I pre-drilled the holes before attaching the keel sections, much easier to do that way. I’m using black monofilament (not braided) fishing line to simulate the bolts. After a bit of experimenting I elected to use 20 pound line with a #77 drill bit. Glue, snip, sand times 56 and we’re done. - The last step before adding the bulkheads is applying Satin Wipe On Poly. I’m always amazed at how fast the Alaskan Yellow Cedar absorbs the WOP after sanding with 400 grit. With a clean cotton cloth I wipe it on and wipe it off, it’s almost dry before I’m done wiping it off. The first coat barely shows up with the absorption factor. I’ll do a second coat once this first one has had time to dry thoroughly. I’ve said it other places, I’ll add it here, WOP is the way to go as a finish in my opinion. The AYC in particular loves it, turning the wood a nice golden color. My Cheerful has had a few months now to “age,” the WOP on it keeps looking better. The key is ‘Wipe On-Wipe Off,’ don’t let it sit. It’s just a great look. I’ve done Tung Oil and other finishes on earlier models, in my opinion WOP tops them all - especially on Boxwood and AYC. So with that, and later the second coat of WOP, I’lll move to attaching the bulkheads. I’m enjoying this, just need to keep myself in check and keep going slow. Thanks to Chuck for a great model, the Winnie builders group leading the way, and all your likes and comments.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I use only spotters and shaders (flat bristles like a full size paint brush) in those sizes plus 18/0, 10/0, and sizes up to 8. I’m not sure I still have any round brushes left, if I do I don’t use them. I only use the Masters cleaner after a project is complete, it does restore over worked brushes well. In addition to rinsing in a jar water I have a second jar at my work space for Winsor & Newton Brush Cleaner. A dip in water, a dip in W&N, back in water, wiped with paint towel, back in the brush jar. I buy high quality brushes and with care they last years. I’ve tried and quickly gave up on an angled brush. I am a bit of a fanatic about it admittedly. Glad you discovered this, appreciate your sharing it. I enjoy detailed paintwork as well.

-

Hi Dave, welcome to MSW. You are on the right path. Start with a basic kit like Lady Nelson and reference the many build logs for support. As Chris said Vanguard’s Alert (which is in stock on the Vanguard site) is a better kit and Speedy or Flirt one up from that due to the detailed instructions, almost a primer on modeling by themselves. You can first download the instructions before buying the model to see for yourself. Frankly the Alert instructions would probably help as a reference for Lady Nelson given the similarities. A half hull,kit bashing, and scratch building are all advanced topics for another day, get a basic kit under your belt first. My one suggestion in that area might be to replace Lady Nelson’s walnut planking with pear or even yellow cedar. The simplest way to do that starting out is to order it precut from Modeler’s Sawmill, a MSW sponsor you can find a link there on the bottom right of the MSW home page. Stay simple to build confidence.

-

Don’t be gone too long, you’re doing great with your problem solving and building.

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

review build Small Building Slip

glbarlow replied to James H's topic in REVIEWS: Model Shipwrighting Tools, Parts and fittings

Take a look at the several Lady Nelson build logs on this site including mine. None that I’m aware of use this building slip, if it’s still available. You certainly need a build board or cradle from the very start, but if a cradle is not included with the kit it’s something you can easily make yourself. It doesn’t need to be elaborate, just a place to set the ship while you’re working on it. The build log of others are a great source for help and reference, especially for models like LN where instructions are sketchy, I encourage you to check them out and refer to them as you move along in your own build. Welcome to MSW and best of luck building Lady Nelson -

Always your call if you’re satisfied with the planking you should leave it unpainted. I would with Flirt if it weren’t for the problems I had with the stem. The boxwood is so nice. Your painting looks great, nice tight lines. As always, Derek clever with the filler to “line” the oval gun ports. What would be the point really if something didn’t break off for us to have to fix. The WOP job looks really nice as well.

- 345 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.