-

Posts

1,398 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by DelF

-

-

Hi Messis

Treenails are very much a question of personal taste. In reality, they would be virtually invisible even at 1:48 scale. Some people like to show them, but they run the risk of the treenails looking far too prominent - like the ship has measles! If you paint Caroline as I did (here) then there are few bare planks on the exterior hull - I think treenails on these might look odd. I didn't show treenails on the deck planks either - if you want to show treenails I would just use a very light pencil mark rather than drilling holes and using real treenails.

But as I say, it really is a matter of personal taste - it's entirely up to you and what you want. My only advice is, if you are going to show treenails do it subtly - don't make them too obvious.

Best wishes

Derek

-

That's looking really good Mark - well done for persevering.

Derek

- NewbyMark and mort stoll

-

2

2

-

1 hour ago, glennard2523 said:

I have attached a couple of pictures.

Thanks Glenn - very helpful.

1 hour ago, Vane said:The stern is actually a section that i would like to see more photos in the manual.

I agree - it's the one area that's not covered as well as it might be in an otherwise excellent manual. Of course, the manual is light years better than most others - it's just that people like Chris and Chuck have spoilt us.

Derek

-

I wish I had friends like that!

A few bits of work on the hull yesterday and this morning. First, I scrounged some felt from my wife's craft stash to line the building cradle so I don't damage the copper.

Next, the hair brackets and bow cheeks were fitted both sides of the prow. These are laser cut pieces, requiring a minimal amount of sanding to fit in place:

Then I had my first breakage. The cap rail comes in four parts, laser cut in 1mm wood. Sanding the char I manage to snap the end off the starboard bow section. However it was easy to repair with a dab of glue.

You can just see the split across the first rectangular hole, but it won't show once painted. Here's the cap rails pinned and glued in place.

Just to prove that no kit is idiot proof, the next repair job was self inflicted. The outer edges of the cap rails have to extend 0.8mm from the hull to accommodate the swivel gun bases. In the bow area I got this wrong when I glued and pinned the cap rail, with a wider overhang. As a result there was no overhang inboard, and it just looked bad. I didn't want to risk pulling the cap rails off; I also think the hull is wider towards the bows, given the way I had to twist the gun port pattern to get it to fit. I decided to cheat by gluing thin strips of wood to the inside of the cap rails and filing them to shape.

I don't think the result is too horrendous, and there is now a more even overhang inboard. Here she is with the cap rail painted and hawse holes drilled.

The recommended 2mm diameter holes look a tad small to me, and I might widen them slightly.

I've now got a question to resolve regarding the stern counter side timbers. The instruction manual shows how these fit at the end of the wales, requiring the latter to be trimmed:

From the pictures in the manual it appears that Chris trimmed the wales at a much earlier stage, before painting. I'm finding it difficult to see how the side timbers are meant to fit, and I'm reluctant to trim the wales and risk damaging the hull if I'm not certain.

Reading ahead in the manual, I think the boom crutch needs to sit on top of the side timber so I can't leave it off all together. So I might just see if I can just fit the upper, curved part of the timber on top of the wale without cutting into the wale itself. Looking at the photo in the manual I think the net result would be the same. I'll check other people's logs who are further ahead than me before I commit to that.

Derek

- JpR62, Ryland Craze, GrandpaPhil and 4 others

-

7

7

-

John

The piece on Understanding Ships' Draughts was split into six articles in issues 46, 48, 50, 52, 54 & 58. David White also wrote a series of nine articles on Traditional Wooden Shipbuilding in issues 47, 49, 51, 53, 55, 57, 59, 61 & 63.

Plus lots of others on topics as diverse as load lines and boat davits.

Busy man!

Unfortunately I can't copy these articles. Leaving aside copyright issues, the magazines have stiff covers and I can't lay them flat without breaking the spines. However, as Thunder says Model Shipwright copies regularly appear on ebay. I didn't start subscribing until about 2000, but a few years ago I was able to get all the back copies in relatively short order without breaking the bank.

Derek

-

1 hour ago, glbarlow said:

IBEX 36mm FLAT FINGER PLANE

That looks like a beautiful tool.

Alaskan yellow cedar should be an excellent alternative to boxwood. I tried to get hold of some over here when I saw Chuck use it on the Winchelsea group project, but it only seems to be used by high-end boat builders and in large and expensive sizes. If I lived near a boat yard I'd be tempted to beg offcuts, but as I don't I'll have to make do with boxwood

.

.

Derek

-

I loved building Caroline and will follow your log with interest. The kit allows lots of scope for improvement and adding extra detail - I'm sure you'll enjoy it.

Derek

-

Thanks Glenn - great that you're planning to have a go at making spars from square stock. I found it daunting at first and needed a couple of practice sessions, but if you mark your work carefully, use a nice stable planing jig and a sharp well-adjusted plane it becomes surprisingly easy and enjoyable. It's particularly gratifying to be able to make spars with combinations of square, octagonal and round sections. Just out of interest, what plane have you ordered?

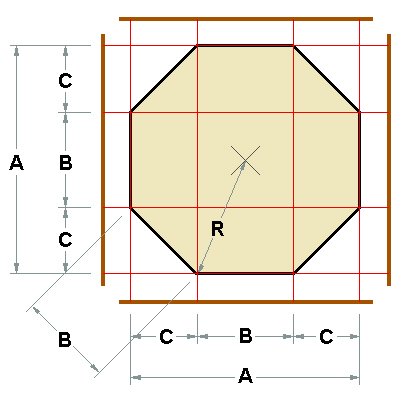

As for marking, in the absence of a jig it's just down to a sharp pencil and an accurate ruler. Or possibly a miniature version of a carpenter's marking gauge? Here's an example from Blue Ensign's Pegasus log, where he uses the 7:10:7 method to draw his lines prior to planing. I wouldn't worry about being hyper accurate - even the 7:10:7 ratio is just an approximation. You can work out the correct value from high school geometry, but for the lazy among us there's a neat online calculator at http://www.liljedahl.info/projects/octagon_calculator/. The calculator lets you input one any of the dimensions of an octagon in the diagram below and it will calculate the others.

So if your stock is 24 units wide (for ease of calculation), ie dimension A, then the calculator tells us that C:B:C is 7.03 : 9.94 : 7.03.

Close enough to 7:10:7 in wood, and at our scales. There's another calculator at https://rechneronline.de/pi/octagon.php which is even more comprehensive, and gives access to calculators for lots more geometric shapes.

So long as you don't plane too much off the corners, sanding your spar in a lathe/drill should even out any slight inaccuracies in your octagon as you reduce it to round.

To answer your question on boxwood, I get mine from a UK supplier here. Unfortunately they don't ship outside Europe. However their castello boxwood comes from South America so I should think you'd be able to get it in the States. It seems expensive - the 6mm sheet I picked for illustration in the link is £25.20 - about $31. However the 1060 X 140 mm sheet will produce a lot of spars and planks - if you mill your own it probably works out less expensive than cheap timber bought ready sized.

Let me know how you get on with your new plane.

Derek

- chris watton, ccoyle, Ryland Craze and 1 other

-

4

4

-

Thanks Eamonn!

1 hour ago, 6ohiocav said:Can you please send your measurements

Sure, glad you found it helpful. The brass pegs are 2.5mm. Not crucial, but thinner is better - too thick and I think it throws the ratio out. The centres of the pegs are 17mm apart, and the steel pin is 5mm from the centre of one pin. The pegs and pins are just fixed in holes I drilled in a piece of scrap aluminium. One word of caution - don't scribe too deep or it'll be difficult to sand the lines out without reducing the diameter of your stock too much.

I should add that I decided to do this how-to piece after Glenn Barlow started an interesting discussion on Chris Watton's thread about the possibility of boxwood spars. I made all the spars for my Royal Caroline build in a similar fashion, including yards with octagonal centres etc. Definitely my favourite technique.

Derek

-

I thought I'd have a break from the hull and cannon and show how I intend to make the spars for Speedy from castello boxwood sheet. I've gone for the bowsprit as it is a reasonable size to demonstrate the method.

The bowsprit is 6mm diameter, so the first step was to rip a square strip from 6mm sheet. I made it over-length to allow for trimming and to allow sufficient waste to grip in the lathe.

The next step is to reduce the square section to an octagon. Some years ago I made a little jig to mark square stock prior to planing:

The idea is to pull the stock between the two brass pegs, making sure that the wood keeps in contact with both pegs and the marking pin between them. When you've made one pass, you turn the wood round end to end and pull the wood through again. You repeat this for all four faces, ending up with two scribed lines in each face. So what, you say?

The idea is that these two lines divide each face in the ratio 7:10:7, which ensures that when you plane each corner down to the lines, all eight resulting faces will be equal. The beauty of the little jig is that it doesn't matter what size the stock is - provided it will fit between the pegs, the scribed lines will always be in the correct ratio. When I made the jig I had to work out the spacings and the diameter of the pegs from basic geometry but if anyone's interested I could post the measurements.

Here's the next stage, using a standard planing jig.

Starting with the green Stanley 100-type finger plane and finishing with the Veritas low-angle block plane it only took a few minutes to reduce all four corners.

On to the lathe - although a drill or Dremel-type rotary tool would do equally well:

Again, it only took a few minutes to sand the dowel down to a reasonable round section. I started with 120 grit and finished on 600. A quick coat of shellac which protects and imparts a nice warm sheen and the bowsprit's finished, bar trimming to final length.

I'll make the remaining spars in due course. Even if you can't get hold of boxwood, I'd certainly consider using a lighter coloured wood than walnut if you can.

Derek

-

-

Limited progress this week as I've been taking advantage of the fine weather to get jobs done in the garden (that's manspeak for trying to cross off a few of my chores from my wife's lengthy list).

First job was painting the wales and prow. I started by masking off the unpainted areas but made a mess of it. Paint seeped through in some places, and in other the tape pulled bits of paint off the top edge of the wales. I used good quality tamiya tape so I don't believe that was the problem. Rather, I think my mistake was applying several coats of matt polyurethane to the unpainted areas before painting the wales. Some of the varnish got onto the wales and prevented the acrylic adhering properly. So, after much sanding, cleaning and swearing I went back to basics and repainted the wales with as steady a hand as possible. The result is certainly better than my original attempt (which I was too disappointed to photograph ☹️).

Meanwhile I've made some progress with the cannon, starting with a little jig to shape the cap squares. It's just a drill bit the same diameter as the trunnions, half-sunk into a groove in a piece of wood. Once in place I just use a thumbnail either side to press the little piece of photo-etch into shape. Just makes it a bit easier to fit to the carriage. As for that, I started using CA but found I couldn't always get the cap square sitting properly before the glue set, so now I use PVA. Not ideal but it's not load bearing so it shouldn't matter.

The cannon are coming along, but you'll see that the blackening process didn't work too well on the cap squares. I think it was because I tried to do too many small pieces all together, and I couldn't agitate them enough to get them all evenly treated. I'll touch up with Admiralty metal black when I've finished them all.

Back to the chores!

Derek

-

Hi Mark

I share your pain - Speedy is also my first attempt at coppering and it's not easy. I got some good advice from Glenn - see the link here. I used Gorilla CA gel, applied with a toothpick. Rather than one blob in the middle, I applied five tiny blobs - four near the corners and one in the middle. Otherwise I found, like you, that the corners didn't stick well. With practice I found I could judge the size of the blobs so none squeezed out. If it did, I tried to wipe it away immediately. For that, I used acetone on a small pad made from a piece of an old cotton shirt. I found with some blobs of CA that I had to rub for quite a while to remove all traces, especially if I'd allowed the glue to dry. It will all come off eventually. I should also add that I wear rubber gloves when coppering - partly to protect my hands but mainly to prevent fingerprints tarnishing the copper.

I found Glenn's advice about how to line plates up with the leading edge of the preceding pate (I used tweezers) and adjust them with a metal pointer particularly helpful. It's worth getting this right, because if a plate is just a small fraction of a millimetre off line it catches the eye. Better to lift it and try again if you can't nudge it into place before the glue dries.

Hope this helps, and I hope you feel you can persevere with Speedy.

Derek

-

Hi James

I've checked all Keith Julier's books and unfortunately Clara May does not feature in any of them. I can only assume Google got it wrong. However the good news is you've found this forum, which has got to be the best source of information and advice on model ship building on the internet, with an incredibly knowledgeable and helpful community of modellers. On planking in particular, you will find lots of how-to guides and videos (look out especially for anything by Chuck Passaro of the Syren Ship Model Company, who is very active on the forum). Check out the Modelling Techniques tab near the top of the forum home page.

Come back if you have any specific questions, and I'll try my best to help, or point you in the right direction.

Best wishes

Derek

-

2 hours ago, glbarlow said:2 hours ago, ASAT said:

You gotta make ‘em

I guess we could do that if there was any boxwood of the right dimensions to be found in the world. Although I’m sure it be a bit pricey. Chris’ thought of lime is a good one.

If you can get good castello boxwood it’s not too expensive. I made the spars for Royal Caroline from some 6mm and 10mm sheets, each about 100mm x 1000mm. They were about £30 for the two although the price has probably gone up since. I had plenty left over and used some to plank my recent pinnace.

I may do the same for Speedy, but don’t tell Chris.

Derek

-

Hi Ryland

I've just found your log and I'm seriously impressed! You were kind enough to comment on my recently completed English Pinnace, also by Chuck, but having seen your workmanship I know I've still got a way to go. I was particularly impressed with your carpentry - beautifully clean and precise. I also like the painting technique you learned from Chuck. I don't usually pay much attention to painting as I prefer the look of natural wood, and as a consequence when I do use paint I usually just slap on a couple of coats with mixed results. I will certainly try the many-coat method in future if it leads to the finish you have achieved.

Looking beyond my current project (HMS Speedy by Vanguard Models) I'd been edging towards the Queen Anne's Barge for my next build having seen Meddo's excellent log but now I'm seriously tempted by the Medway Longboat. Maybe I'll have to get both?

Derek

-

-

- Ryland Craze, yvesvidal, jwvolz and 12 others

-

15

15

-

Six kits? That should last us ‘til the end of lockdown (I hope!).

- BobG, chris watton, mtaylor and 1 other

-

4

4

-

-

-

Hi

I've used the Proxxon 240/E bandsaw for several years for small-scale work. Like all Proxxon tools it is well made and (for a bandsaw) reasonably accurate. I've fitted a fence on mine to make straight cuts in thick stock - for thinner material I use a table saw. It will cut reasonably tight curves - I often use it to cut out rough shapes before final finishing with files and sandpaper - see here for examples. Although it's a small saw, with the right blade you can cut reasonable thicknesses of metal as well as wood. Obviously if you want to re-saw really big planks then you'll need a bigger machine.

My scroll saw is also by Proxxon. See here for an example of its use by Blue Ensign when he built a 1:64 scale pinnace (I copy a lot from him!).

You could also look at any of Marsalv's logs on this forum for more examples of what can be achieved with Proxxon tools. They aren't cheap, but you can save money by buying direct from Germany (until the EU transition period ends, that is).

Hope that helps.

Derek

-

Slow but steady progress on the port coppering.

I'm taking it slow because as I mentioned before I'm having to wear a mask to avoid adverse reactions to the CA and It gets very uncomfortable after a while. As a break, I've started preparing all the components for the 14 cannon. Being more used to 1/48 scale I'm finding the pieces TINY, to the extent that I can't assemble the carriages without assistance. I'm going to have to make up a little jig to hold everything in place while it's being glued. I tried to dry-fit a carriage (as described by Glenn in his Speedy log) but the pieces were so small and light I just couldn't get them to behave.

Oh well, at least it keeps me away from the CA for a bit.

Derek

- egkb, GrandpaPhil, chris watton and 9 others

-

12

12

-

4 hours ago, glbarlow said:

I’ll be looking for some decent quality wood pins

Will you find any at 1/64 scale? They're usually far too fat and need sanding/turning down (I use a home made draw plate in combination with the Proxxon lathe - a drill or Dremel-type tool would do just as well). But at 1/64 the pin would need a handle of around 0.8mm diameter and a shaft 0.5mm to be in proportion. Once draped with rope would the PE pins stand out that much? I suppose you could always buy a few properly turned brass pins for locations where they will show more. For example 5mm pins from Cornwall Model Boats @ about 22p for 10 seem quite realistic. Either way you would have to paint them.

I think I'll reserve judgement until I get to that stage (by which time Glenn will have finished Speedy and probably another two models beside! 😁)

Derek

HMS Speedy by ErnieL - Vanguard Models - 1/64

in - Kit build logs for subjects built from 1751 - 1800

Posted

Welcome aboard Ernie. The quality of kit models has come a long way in the last 40 years and you've picked a particularly good one.

So do I, but I still make mistakes as you'll see from my Speedy log - must be an age thing!

Derek