-

Posts

13,391 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

Nice demonstration of the triumvirate of lines at the clue of the sail. Now no-one seeing your photos will be clueless!

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Nice explanation, Ron. BTW, rubbing alcohol is also an effective acrylic solvent and is cheaper than Brush Restorer!

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

The Battle of the Bitts! An epic combat indeed. Let's hope the result holds this time around. Neat repair job, Steven. For drilling small holes, do you not have a set of small drill bits, #61-80? Using them a pin chuck, you can drill holes in tight spots when necessary.

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

Looking very impressive with her wings spread!

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

William Elliott (active 1774–1810) was a lieutenant in the Royal Navy and marine painter. Elliott gained some repute from his paintings of the naval actions between 1780 and 1790. He first appears as an exhibitor in 1774 at the Free Society of Artists, with 'A Perspective View of the European Factory at Canton in China,' and 'A View of the Green, &c. at Calcutta in Bengal.' At the Royal Academy he first appears as an honorary exhibitor in 1784 with 'A Frigate and Cutter in Chase;' to the same exhibition he subsequently contributed 'The Fleet in Port Royal Harbour, Jamaica, after the Action of 12 June 1781' (1785), 'View of the City of Quebec' (1786), 'Breaking the French Line during Lord Rodney's Action on 12 April 1782' (1787), 'The Fire at Kingston, Jamaica, on 8 Feb. 1782' (1788), 'The Action between H.M.S. Quebec and Le Surveillant' and 'The Action between H.M.S. Serapis and Le Bonhomme'. More at: https://www.wikiwand.com/en/William_Elliott_(painter) If using that image, allow for the yellowed varnish having altered the actual coloration of the painting. It is likely much bluer under.

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

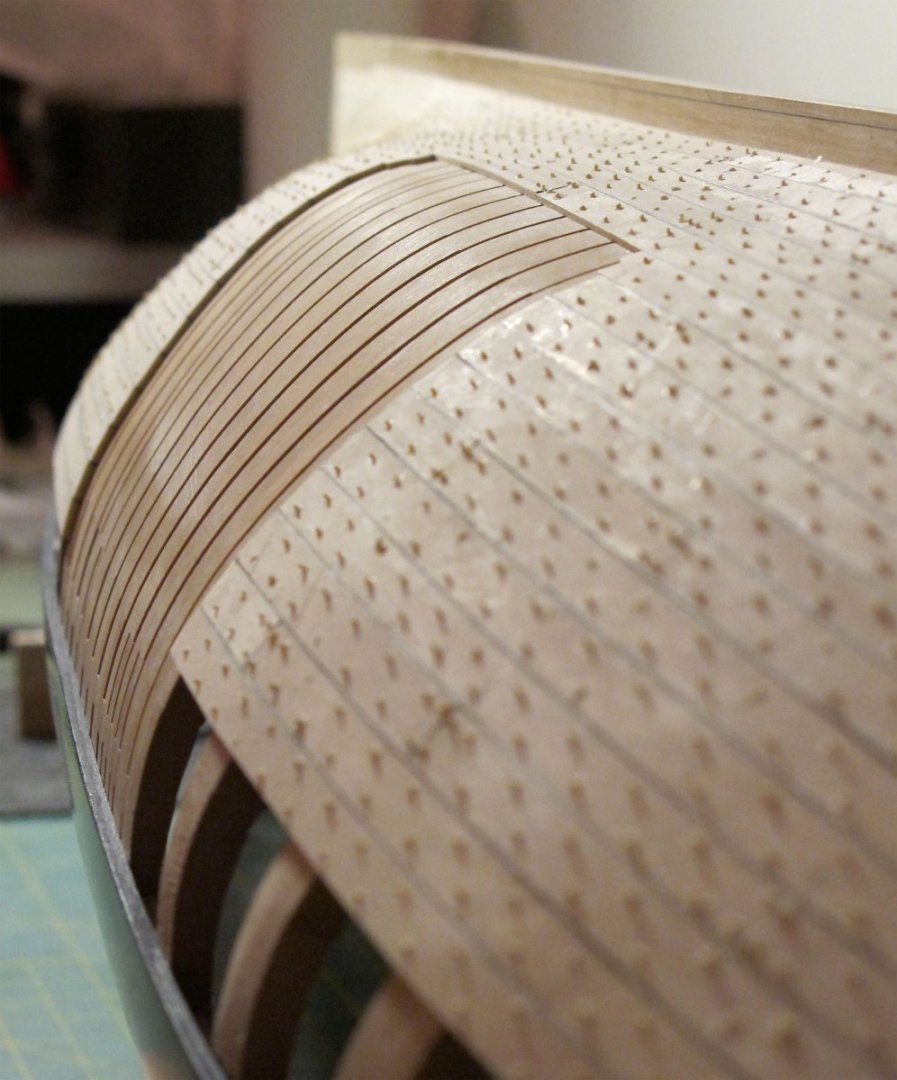

Approach with extreme patience, Kevin! It is a lengthy exercise. Make the treenails as small as practical; so often they are clunky and far out of scale. I mark out and prick each position first so that the drill doesn't wander and mess things up. Dip te ens of the treenail material in slightly diluted white glue, push it into a hole, snip short or flush using flush cutters. Repeat. Repeat.... When complete, the surface will look knobbly (see pic), but will look great after you've sanded it down.

- 1,134 replies

-

Mix a little white glue or acrylic matte medium with your water when forming coils. Your model is definitely looking good. Hope the cat's ears have recovered....

- 146 replies

-

- Harriet Lane

- Model Shipways

-

(and 1 more)

Tagged with:

-

Sharp paint scheme, Alex!

- 23 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

Even with scratch built models, I pin the yards to keep them in place while parrals, trusses or whatever appropriate gear is added. If the wire is blackened, it is not obvious.

- 146 replies

-

- Harriet Lane

- Model Shipways

-

(and 1 more)

Tagged with:

-

Screwed up

druxey replied to gregkthompson's topic in Building, Framing, Planking and plating a ships hull and deck

I would not recommend Gorilla glue for model-making purposes. But you know that already. PVA (white glue) or aliphatic (yellow) is more than adequate for wood to wood bonding. -

Glad to read that you have got going again. Hopefully the bitts hold now.

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

Trimming the yard using the lines - just like the full size ship - is fun, isn't it? Looking really fine, Bob.

- 146 replies

-

- Harriet Lane

- Model Shipways

-

(and 1 more)

Tagged with:

-

I feel your pain, Steven, but don't do that!

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

Nicely finished, Kevin. Well done! Termite treatment is something we northerners don't consider.

- 1,134 replies

-

Another point to consider is recycling of carved works from a ship being broken up and reused on another.

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Great digging, Marc! That damaged painting cries out for conservation and restoration.

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

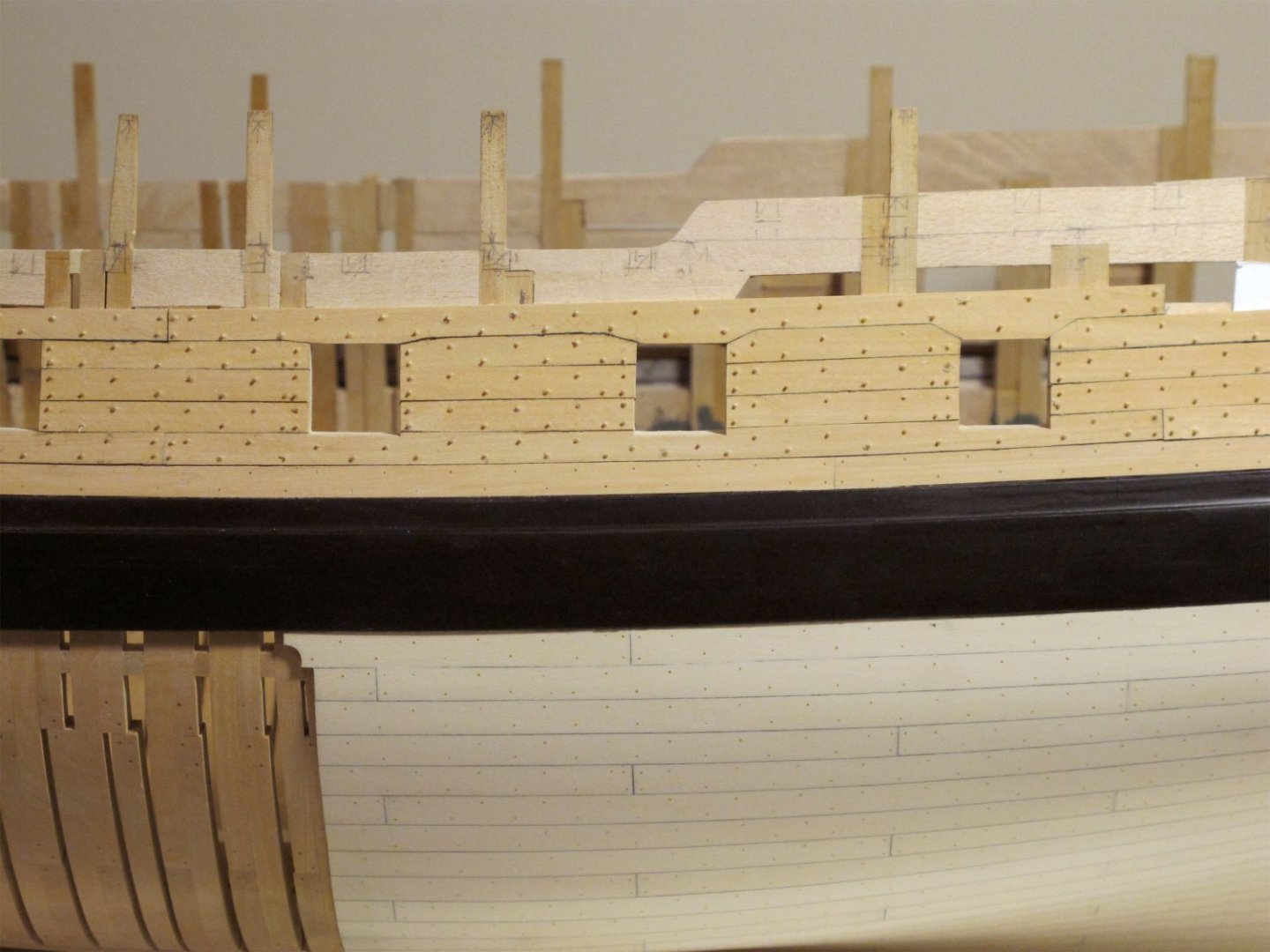

I don't know whether this would apply to your model, but I've found working the inside first enables one to make vertical measurements between frames of things like deck clamps more easily. If the outer plank is on, then one needs a gantry style set-up to make internal height measurements. Looking very nice so far!

-

I did not take you to mean that you were critical of the kit, Bob. I appreciate your wish to be more scale-accurate than the 'out of the box' version. Go for it! There are excellent commercial ropes available, or you can learn to spin your own with a suitable machine.

- 146 replies

-

- Harriet Lane

- Model Shipways

-

(and 1 more)

Tagged with:

-

Nice looking sail color, Ron. Trivia: 'Unbleached' titanium white does not exist! Originally a batch of regular titanium white paint (TiO2 ) was accidentally contaminated with a little yellow oxide. Rather than ditch the whole batch, the manufacturer decided to sell it as 'unbleached'. It took off, so it's been marketed ever since. True story.

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

My, but I lived a sheltered childhood. My chemistry experiments were merely growing crystals in super-saturated solutions. OK, there was that time we kids made potassium iodide, saturated small pieces of paper with it and let them dry on the dormitory floor (this was at a boarding school). Late that night when the dorm monitor, a senior student, cam to bed, he always took off his shoes so as not to wake us. He trod on the pieces of paper and, potassium iodide being unstable, created a series of tiny explosions and an involuntary dance.

-

Looking good, SHJ! I use Saran wrap stretched with masking tape around the edges rather than waxed paper for a non-adhesive surface.

- 63 replies

-

- Finished

- Khufus Solar Boat

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.