-

Posts

13,383 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

And I thought that the yard was seen from behind so that the stirrups were correctly hung! Well, what do I know? Nice anchor stocks. Are they the right way around? Now I doubt all that I see.

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Rob, I hate to cavil (groan), but the lay of your rope on the deckhouse looks very loose.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Certainly British Naval gun carriages were not iron shod: only land-based guns were. Whether the French did the same, I do not know.

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Ye gads! That looks like a medieval torture instrument, Kevin. It should simply scare the plank into shape! Ingenious.

- 1,132 replies

-

Nice photos and looks like a great trip, Marc. Hopefully you can move those pesky heads inboard a bit!

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

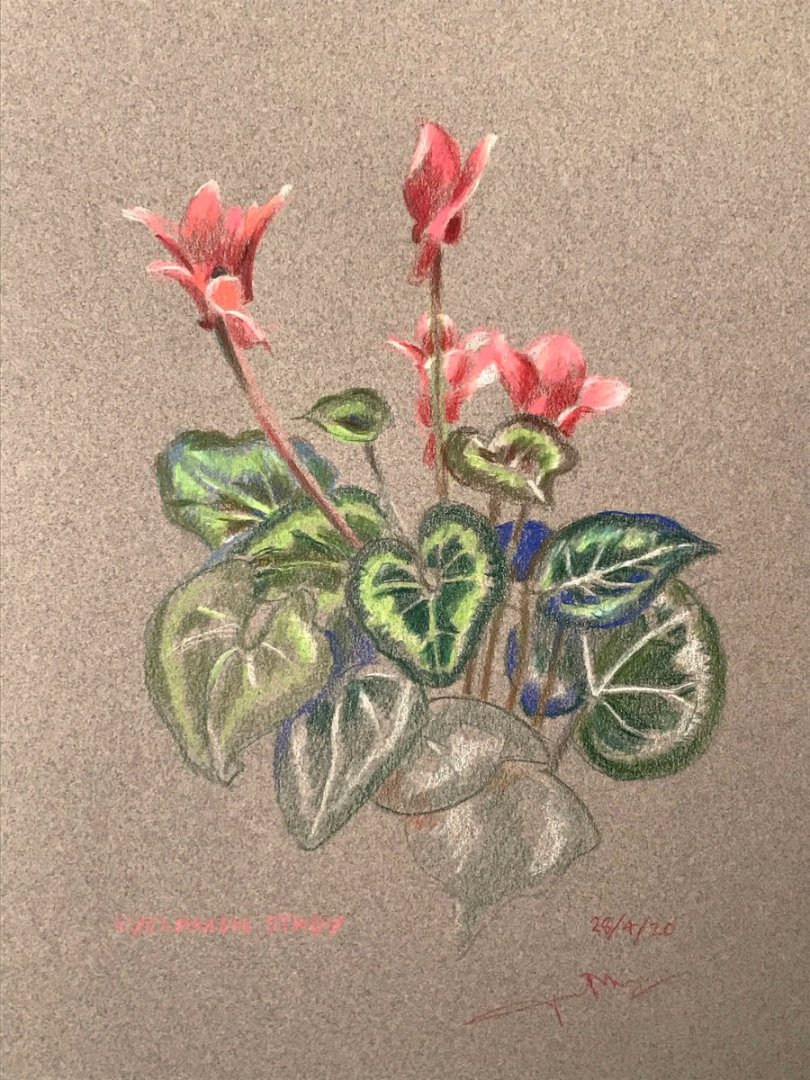

Thanks for your comments on Canson paper., Eberhard. I've never seen Iris/Vivaldi over here' only the much heavier, through-dyed paper which is excellent for colored pencil work. Hopefully you will stay healthy now....

-

Hmm. The dictionary definition of 'cavil' is....

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

One can build models with very few basic tools, it just takes longer! The magnificent models of 300 years ago were built entirely with hand tools. The main thing is to know how to sharpen edge tools properly and when to use which one. Yes, power tools are nice to own and speed up certain operations, but....

-

Hopr you are back up to speed now, Eberhard. That virus is no fun, even if you are fully vaccinated. That planking is something at that small scale. One question though: Canson paper (at least the kind that I know and use for art) has one side smooth but the other side is heavily textured. Isn't this an issue at micro scale size?

-

Just catching up with your work, Ron. Beautifully done spars at 1:96!

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Looking good. I'd suggest a round Swiss file to shape those inside curves to the standards.

-

Brilliant deductions and research. Seafood and steaks all round!

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Yes, it's the opposite of a line running foul - it runs fair. There is also a line from the weird sisters in MacBeth: "Fair is foul and foul is fair, Hover through fog and filthy air." They wish to turn things upside down.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Fairleads is usual: the lines run fair through them. They neither eat or pay, as in 'fare'!

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Hattery? Is there no arcane skill that you do not possess? I hope you stay away from mercuric compounds - wouldn't want you getting hatters' syndrome. Lovely work on the model as well, SHJ.

- 63 replies

-

- Finished

- Khufus Solar Boat

-

(and 1 more)

Tagged with:

-

Sweet! Good to see progress on your model, Ben.

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Welcome and accept the excellent advice from Keith and Chris.

-

Running Rigging _ Running in Circles....

druxey replied to USNCHief's topic in Masting, rigging and sails

Yes, rigging looks like a rat's nest or intricate maze and seems very intimidating. One needs to take each line soearately, one at a time, and it will become less daunting. -

To use Silkspan, it must first be wetted and stretched like watercolor paper. If you do not do this properly, wrinkles are inevitable!

-

HMS Euryalus 1803 by rlb - 1:48 scale

druxey replied to rlb's topic in - Build logs for subjects built 1801 - 1850

And druxey has a big scrap box!- 122 replies

-

- Euryalus

- Plank-on-frame

-

(and 4 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.